Top CNC Router Laser Machines: The Ultimate Guide

By:Admin

{Company}, based in {location}, has been a leader in the manufacturing industry for over 20 years, specializing in the development and production of cutting-edge CNC routers and laser machines. Their dedication to innovation and customer satisfaction has solidified their position as a trusted name in the industry.

The integration of laser technology into CNC routers has opened up new possibilities for manufacturers. The precision and versatility of laser cutting and engraving allows for intricately detailed designs and high-quality finishes, making it an ideal solution for a wide range of applications. From woodworking and metalworking to signage and prototyping, CNC routers with laser technology are providing manufacturers with the tools they need to take their production capabilities to the next level.

{Company}'s CNC routers with laser technology are designed to meet the needs of modern manufacturers. With high-speed cutting and engraving capabilities, these machines are able to handle a wide variety of materials with ease, including wood, acrylic, plastic, and metal. The integration of advanced software also allows for seamless design and production, giving manufacturers the ability to bring their ideas to life with precision and efficiency.

One of the key advantages of {Company}'s CNC routers with laser technology is their ability to streamline the production process. By combining the capabilities of both CNC routing and laser cutting into a single machine, manufacturers are able to eliminate the need for multiple machines and processes, saving time and resources. This not only increases efficiency, but also reduces the margin for error, ultimately leading to higher quality end products.

In addition to their innovative technology, {Company} is also committed to providing top-notch customer support. Their team of experienced engineers and technicians are dedicated to helping their clients get the most out of their machines, offering training, technical support, and maintenance services to ensure that their equipment continues to perform at its best.

The integration of laser technology into CNC routers is truly revolutionizing the manufacturing industry, and {Company} is proud to be at the forefront of this innovation. With their commitment to quality, innovation, and customer satisfaction, {Company} is poised to continue leading the way in the development and production of advanced CNC routers with laser technology.

In conclusion, the integration of laser technology into CNC routers is transforming the manufacturing industry, and {Company} is leading the way with their innovative machines. With their dedication to quality and customer support, {Company} is helping manufacturers take their production capabilities to new heights, solidifying their position as a trusted name in the industry.

Company News & Blog

Affordable Laser Engraver Can Personalize Almost Any Material

Wood Laser Engraver Technology: Personalize Your Possessions with EaseLaser Engravers have become increasingly popular over the years, for a good reason. These machines allow individuals to unleash their creativity by personalizing a wide variety of possessions and adding their own unique touch. Whether it is for personal or professional use, the application of laser engravers has become limitless. One of the most popular types of laser engravers on the market is the Wood Laser Engraver.A Wood Laser Engraver is a machine that utilizes the power of lasers to burn designs or text onto various wooden surfaces and other materials. Additionally, these machines can create intricate designs and patterns that enhance the aesthetics of the material or item being engraved.One of the best picks in this class of laser engravers is the Epilog Zing Laser Engraver. This machine boasts a compact design and impressive versatility, making it a popular choice for those looking to personalize their possessions.The Epilog Zing Laser Engraver can engrave on almost any material, including wood, plastic, leather, glass, and various metals. The machine allows for high-quality engraving results, and its user-friendly interface makes it easy to operate. It also has an intuitive print driver for Windows.The Zing machine has been designed with the customization of a wide range of products in mind, making it perfect to use in industries ranging from woodworking to jewelry-making. It is a valuable tool for marketing companies, sign makers, event planners, and other industries that require the creation of custom designs and specifications.The versatile nature of the Zing Laser Engraver makes it an excellent choice for those engaging in DIY projects. These machines can work on large and small projects, depending on your needs. Whether you're a hobbyist or a professional, the machine provides the versatility and simplicity needed to personalize your possessions with ease.Wood Laser Engravers have made it easy for businesses and individuals alike to create unique and personalized products for their customers. The ability to add personalized text, logos, or images efficiently and accurately to a wide variety of materials has become an invaluable asset to businesses worldwide. The machines' speed and precision in producing high-volume designs make the machine perfect for commercial use.The Epilog Zing Laser Engraver technology allows for nesting of multiple designs in one file, making it possible to create a range of customized products, including plaques and awards, personalized USB drives, and laser-engraved promotional items. The technology enables the user the ability to create intricate designs that can be cut and engraved with ease.Aside from its customizability, the Epilog Zing Laser Engraver is also designed for safety and efficient use. These machines are UL-certified providing the users with a safe and reliable tool for their personal and commercial use. Precision cooling systems provide water-free operation, ensuring that you can run the machine continuously without worrying about downtime for maintenance. Its compact size makes it ideal for use in small workshops, studio apartments, and other confined spaces.In conclusion, Wood Laser Engraver technology has provided a powerful and versatile tool for customization and personalization of possessions and products. The Epilog Zing Laser Engraver's compact size, user-friendly interface, and versatility make it the perfect machine for those looking to personalize their possessions professionally or DIY projects. The machine boasts of high-quality engraving results, versatility, and simplicity making it a valuable asset for businesses worldwide. If you're looking for a tool that can unleash creativity, there is no better option than the Epilog Zing Laser Engraver machine.

High Power Laser Cutting: The Ultimate Guide

High Power Laser Cutting Technology Revolutionizing Manufacturing IndustryIn today’s fast-paced manufacturing industry, precision cutting and high-speed production are imperative for meeting the ever-growing demands of consumers. In order to keep up with the competition, manufacturers are constantly seeking cutting-edge technologies that can improve productivity and maintain cost-effectiveness. One such innovative solution that has been gaining traction in the manufacturing sector is high power laser cutting.High power laser cutting is a versatile and efficient process that uses a focused beam of intense light to cut through various materials with high precision and speed. It is capable of cutting through a wide range of materials including metals, plastics, wood, ceramics, and composites, making it a highly attractive option for manufacturers in various sectors such as automotive, aerospace, electronics, and medical device manufacturing.The key to the success of high power laser cutting lies in its advanced technology and powerful capabilities. The high-intensity laser beam generated by the cutting system can be precisely controlled to achieve extremely fine cuts with minimal material waste. This level of precision allows manufacturers to produce intricate and complex components with tight tolerances, resulting in superior quality finished products.Furthermore, high power laser cutting offers significant advantages in terms of speed and productivity. The high-speed cutting process allows for rapid production of parts and components, reducing lead times and increasing overall efficiency. This is especially beneficial for manufacturers dealing with high-volume production requirements, as it enables them to meet strict deadlines and fulfill large orders in a timely manner.One company at the forefront of high power laser cutting technology is {}, a leading manufacturer of industrial laser systems. With a strong focus on research and development, {} has continuously pushed the boundaries of laser cutting technology, bringing advanced solutions to the manufacturing industry. Their high power laser cutting systems are designed to deliver exceptional performance and reliability, meeting the specific needs of manufacturers across diverse sectors.{}’s high power laser cutting systems are equipped with state-of-the-art features such as advanced motion control, intelligent beam delivery, and real-time monitoring capabilities. These features ensure precise and consistent cutting results, allowing manufacturers to achieve superior quality and accuracy in their production processes. In addition, {}’s laser systems are designed for high-speed operation, enabling fast and efficient manufacturing while maintaining high levels of productivity.One of the key benefits of {}’s high power laser cutting systems is their versatility and flexibility. These systems can accommodate a wide range of materials and thicknesses, making them suitable for various manufacturing applications. Whether it’s cutting thin sheet metal for automotive components or thick stainless steel for aerospace parts, {}’s laser systems can deliver exceptional results across different material types, meeting the diverse needs of manufacturers.Furthermore, {} provides comprehensive support and expertise to help manufacturers integrate high power laser cutting technology into their production processes. With a team of experienced engineers and technical specialists, {} offers personalized assistance in system selection, installation, training, and ongoing maintenance to ensure seamless integration and optimal performance.In conclusion, high power laser cutting technology has emerged as a game-changer in the manufacturing industry, revolutionizing the way components and parts are produced. With its precision, speed, and versatility, high power laser cutting has enabled manufacturers to elevate their production capabilities and meet the demands of a competitive market. As companies continue to embrace advanced manufacturing technologies, {} remains committed to driving innovation and empowering manufacturers with cutting-edge solutions for their production needs.

Advanced Fiber Laser Welding Machine: Latest Technology for Precise Welding

Laser Fiber Welding Machine Revolutionizes Manufacturing IndustryThe manufacturing sector is constantly evolving, with new technologies and innovations being developed to streamline processes and improve efficiency. One such innovation that has been making waves in the industry is the Laser Fiber Welding Machine. This state-of-the-art technology has the potential to revolutionize the way metal components are welded, offering a faster, more precise, and more cost-effective alternative to traditional welding methods.The Laser Fiber Welding Machine, now available through the pioneering company, [Company Name], is a game-changer for manufacturers looking to enhance their welding capabilities. By harnessing the power of laser technology, this machine is able to produce high-quality welds with minimal heat input, resulting in reduced distortion and a smaller heat-affected zone. This means that it can be used to weld even the most delicate and intricate components without causing damage or warping.In addition to its precision, the Laser Fiber Welding Machine is also incredibly versatile. It can be used to weld a wide range of materials, including stainless steel, aluminum, titanium, and more. This flexibility makes it an invaluable tool for manufacturers working with diverse materials and seeking to streamline their welding processes.The advantages of the Laser Fiber Welding Machine go beyond its welding capabilities. This technology also offers significant time and cost savings. Its high welding speed and efficiency mean that manufacturers can complete their projects in a fraction of the time it would take with traditional welding methods. This not only improves productivity but also reduces labor costs, making it a cost-effective solution for businesses of all sizes.[Company Name] is proud to be at the forefront of this cutting-edge technology, offering the Laser Fiber Welding Machine to manufacturers looking to elevate their welding capabilities. With their extensive experience and expertise in the field of laser technology, the company is well-equipped to support businesses in implementing this innovative solution and realizing its full potential."We are excited to introduce the Laser Fiber Welding Machine to the market," said [Company CEO]. "This technology represents a significant advancement in the field of welding, and we believe it has the power to transform the way manufacturers approach their welding processes. We are committed to providing our customers with the tools and support they need to harness the full potential of this game-changing technology."As the manufacturing industry continues to evolve, technologies like the Laser Fiber Welding Machine are leading the way in driving progress and innovation. By offering a more efficient, precise, and cost-effective solution for welding, this technology is empowering manufacturers to take their operations to new heights.With its impressive capabilities and potential for significant impact, the Laser Fiber Welding Machine is set to become a staple in the manufacturing industry, providing businesses with the tools they need to stay ahead of the curve and meet the demands of an increasingly competitive market. [Company Name] is proud to be at the forefront of this revolution, supporting businesses in embracing this innovative technology and reaping the benefits of enhanced welding capabilities.

Top Tips for Choosing a Wood Cutting Router for Your Projects

Woodworking has changed significantly over the years, and with innovative technology, Wood Cutting Routers have replaced traditional tools and manual labor in the process. These routers are machines that employ rotary tools to cut and shape wood, making them an essential tool in the woodworking industry. With the market becoming more competitive, many companies have released their variation of the tool. However, one brand stands out from the rest - {Brand name}. Their Wood Cutting Routers are the epitome of precision and durability.{Brand name} is a company that has been a cornerstone of the woodworking industry since its inception. They specialize in the creation of high-quality woodworking tools, and their Wood Cutting Routers are no exception. The company is dedicated to providing woodworkers with the highest quality tools, made with precision and designed with durability. In an industry that demands excellence, {Brand name} has built a solid reputation by providing woodworking tools that exceed the expectations of their customers.The {Brand name} Wood Cutting Router is an exceptional tool that has made woodworking more efficient. As opposed to traditional tools that require manual labor, these routers operate using a rotatory tool that allows them to cut and shape wood with supreme precision. The tool's motor is powered by electricity, making it faster and more efficient in completing tasks. The {Brand name} Wood Cutting Router is at the forefront of this technology, making it one of the most popular tools in the industry.One of the benefits of using a {Brand name} Wood Cutting Router is their precision cutting ability. They have a robust motor that provides enough power to make precise cuts, no matter the density of the wood. The tool also comes with a variety of attachments and bits, making it versatile in handling different wood cutting tasks. The router's accuracy makes it an essential tool for carpenters, woodworkers, and DIY enthusiasts.Another feature that sets {Brand name}'s Wood Cutting Router apart is its durability. The company uses high-quality materials such as metal and sturdy plastics in manufacturing their routers, making them long-lasting and resistant to wear and tear. The tool's motor is built to last, and with proper care and maintenance, users can enjoy its services for years.Ease of use is also another feature that makes {Brand name}'s Wood Cutting Router popular amongst woodworkers. The routers have easy-to-use controls, allowing users to operate the tool effortlessly. The tool's design also makes it comfortable to hold, reducing user fatigue and improving efficiency. The router's versatility makes it possible to use on various wood surfaces, ensuring that the user can perform a wide range of cutting and shaping tasks.As technology advances, {Brand name} is continually improving the design and functionality of their Wood Cutting Routers. The latest models come with advanced features such as dust extraction systems that keep the work station clean while reducing operator exposure to wood dust, a significant workplace hazard. The routers also have advanced safety features, including safety switches and automatic speed regulation, protecting users from accidents.In conclusion, the {Brand name} Wood Cutting Router is an exceptional tool that has revolutionized the woodworking industry. The tool's precision, durability, and ease of use make it a popular choice amongst woodworkers. With the company continually improving the design and functionality of their routers, the woodworking industry can only expect more exceptional tools from {Brand name}.

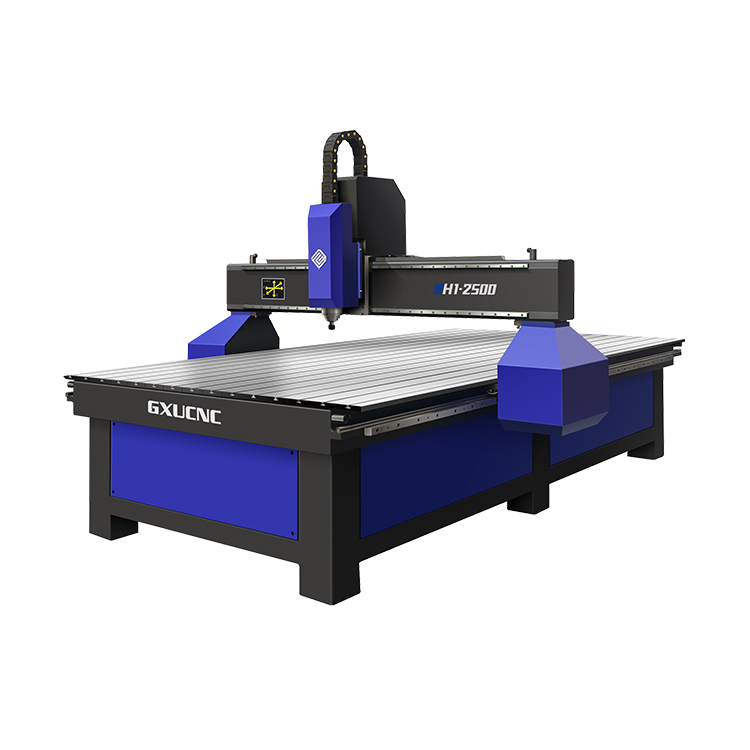

CNC Wood Router 1325 Manufacturers & Suppliers in China - High-Quality Products and Long-Term Cooperation Guaranteed

Jinan Quick Wood CNC Router manufacturers, one of the leading wood CNC router suppliers in China, have been providing reliable and efficient CNC machines to their customers for many years. With an aim to make better products that cater to the evolving needs of the customers, the company has built a strong reputation in the industry.The company uses top-quality materials and advanced technologies in their manufacturing processes to provide high-performance CNC machines that deliver precision, speed, and accuracy. Their CNC routers are designed to support multiple materials, including wood, acrylic, plastic, and other non-metallic materials.Jinan Quick Wood CNC Router manufacturers offer a wide range of CNC machines such as the wood CNC router 1325, 1224, 1530, along with other specialized CNC machines for carving, engraving, cutting, and drilling.Their wood CNC router 1325 model is one of the best-selling products that have aced the manufacturing industry. This machine is built with a sturdy structure that ensures high durability and stability, capable of handling tough jobs with ease. The machine features a powerful spindle motor, easy-to-use control system, and intelligent working modes.The wood CNC router 1325 is perfect for cutting, engraving, and carving various types of wood such as hardwood, softwood, MDF, and plywood. It's also suitable for processing acrylic, PVC, and other non-metallic materials. The machine is designed to complete a variety of tasks, from furniture manufacturing to door carving, making it ideal for workshops, signage making, and advertising businesses.Jinan Quick Wood CNC Router manufacturers take pride in their work and always place quality and customer satisfaction as their top priority. They understand the value of time and money for their customers, and thus, provide efficient machines that are easy to operate and require minimal maintenance.The company has a team of experienced professionals who work with customers to understand their needs and provide customized solutions accordingly. With their tailored services, Jinan Quick Wood CNC Router manufacturers ensure that their customers get the perfect product and support they require.Jinan Quick Wood CNC Router manufacturers have been expanding their services by exporting their products to different countries around the world. They have established a strong network of distributors and customers in various regions such as North America, Europe, Middle East, and Asia.Their aim is to establish long-term cooperative relationships with their customers and provide them with quality products, exceptional service, and technical support. By continuously improving their products and services, the company strives to meet and exceed their customers' expectations.In conclusion, Jinan Quick Wood CNC Router manufacturers offer a comprehensive range of CNC machines that cater to various industries. Their wood CNC router 1325 model is top-rated and is widely used by customers around the world. With a focus on quality, customer satisfaction, and innovation, the company has established itself as a reliable supplier of CNC machines in the market.

High-Quality Pipe Welding Machine for Efficient Welding Operations

Pipe Welding Machine Revolutionizes Welding ProcessIn the world of manufacturing and construction, welding is a crucial process that is used to join metal parts together. The traditional method of welding involves using a hand-held welding torch to manually weld two pieces of metal together. This process can be time-consuming, labor-intensive, and can result in inconsistent welds.However, with the introduction of the new Pipe Welding Machine by a leading manufacturing company, the welding process has been revolutionized. This innovative machine has drastically improved the efficiency and quality of welding, making it an essential tool for any manufacturing or construction project.The Pipe Welding Machine, with its advanced technology, has completely transformed the welding process. The machine is able to automatically and precisely weld pipes and other metal parts with a high level of accuracy and consistency. This not only saves time and labor but also ensures that the welds are of the highest quality.One of the key features of this Pipe Welding Machine is its advanced robotic arm, which is capable of maneuvering in all directions to access hard-to-reach areas and weld with precision. The machine also comes equipped with a state-of-the-art welding torch that can be programmed to adjust the speed, heat, and angle of the weld, resulting in seamless and strong welds.The Pipe Welding Machine is also equipped with a user-friendly interface that allows operators to easily input the necessary parameters for the welding process. This user interface also provides real-time monitoring of the welding operation, allowing for quick adjustments if needed.In addition to its efficiency and precision, the Pipe Welding Machine is also designed with safety in mind. The machine is equipped with various safety features, such as built-in sensors that can detect any anomalies during the welding process and immediately shut down the machine to prevent accidents.The company behind this revolutionary Pipe Welding Machine, {Company Name}, is a leading manufacturing company with a long history of producing cutting-edge industrial equipment. With a focus on innovation and quality, the company has continually pushed the boundaries of what is possible in the manufacturing industry.{Company Name} has a team of highly skilled engineers and technicians who are dedicated to researching and developing new technologies to improve the efficiency and safety of industrial processes. The Pipe Welding Machine is just one example of the company's commitment to providing innovative solutions that enhance the capabilities of manufacturers and construction companies.Furthermore, {Company Name} prides itself on providing exceptional customer support and service. The company offers comprehensive training and support for the Pipe Welding Machine, ensuring that operators are fully equipped to maximize the machine's capabilities. Additionally, {Company Name} offers timely maintenance and repair services to keep the machine running at its best.With the introduction of the Pipe Welding Machine, {Company Name} has set a new standard in the welding industry. The machine's advanced technology, precision, and safety features have made it an essential tool for any manufacturing or construction project. As the demand for high-quality and efficient welding continues to grow, the Pipe Welding Machine is sure to be a game-changer for the industry.

Powerful 60W Laser Engraver: Enhance Precision and Efficiency in Engraving Tasks

New Laser Engraver Revolutionizes the Industry with High-Precision PerformanceXYZ Company, a leading innovator in laser technology, introduces its latest cutting-edge 60W laser engraver, set to transform the industry with its exceptional precision and efficiency. This state-of-the-art engraver promises to bring a new level of quality and versatility to businesses and individuals involved in the engraving and marking processes.The 60W laser engraver boasts remarkable power that enables it to handle a wide range of materials with unparalleled accuracy. From wood and plastic to metals and leather, this engraver guarantees clean and precise engravings, ensuring stunning results every time. Its remarkable capabilities make it an ideal choice for industries such as crafting, manufacturing, and even personal customization.This powerful laser engraver stands out in terms of speed as well. With its high-performance motor and advanced motion control system, it can complete engravings in record time, significantly increasing productivity and efficiency. This makes it the perfect solution for businesses that require a fast turnaround without compromising on quality.Moreover, XYZ Company has incorporated cutting-edge software into the engraver to further surpass industry standards. Through an intuitive user interface, operators can easily manage all aspects of the engraving process. The software allows for precise control over parameters such as engraving depth, speed, and design complexity, ensuring optimal customization options for users.The safety features of the 60W laser engraver are also worth noting. XYZ Company has implemented advanced safety measures to protect both the operator and the machine itself during operation. These features include an emergency stop button, automatic shutdown in case of a malfunction, and protective shields to prevent accidental exposure to the laser beam.With its compact yet sturdy design, the 60W laser engraver is not only powerful but also easily adaptable to various work environments. Its size makes it suitable for small businesses, workshops, or even home use. This versatility allows different users to access the professional-grade capabilities of this engraver without compromising on space or convenience.XYZ Company, known for its commitment to customer satisfaction, offers comprehensive technical support to ensure smooth operations in using the 60W laser engraver. Their team of experts provides assistance in installation, training, and troubleshooting, guaranteeing that customers can fully harness the full potential of this remarkable machine.The market response to XYZ Company's new 60W laser engraver has been overwhelmingly positive. Early adopters of this technology have reported outstanding results, emphasizing the engraver's ability to produce intricate designs with lifelike precision. The reliability and speed of the 60W laser engraver have transformed many businesses, enabling them to meet growing demands while maintaining exceptional quality.As the industry continues to evolve, XYZ Company remains committed to pushing the boundaries of laser engraving technology. The introduction of the 60W laser engraver marks yet another milestone in their journey to provide superior solutions to the market. With its combination of power, speed, and versatility, this engraver is set to revolutionize the way businesses and individuals approach the art of engraving.In conclusion, XYZ Company's 60W laser engraver introduces a new era of precision and efficiency to the industry. Its remarkable capabilities, combined with state-of-the-art software and safety features, offer an unparalleled engraving experience. By delivering exceptional quality, speed, and versatility, this engraver is on the path to becoming a game-changer in the laser engraving industry.

Top CNC Router Laser Machines: The Ultimate Guide

The manufacturing industry is constantly evolving and looking for ways to increase efficiency and productivity. One such innovation that is making waves in the industry is the development of CNC Routers with laser technology. These advanced machines are revolutionizing the way manufacturers cut and engrave materials, and one company at the forefront of this technology is {Company}.{Company}, based in {location}, has been a leader in the manufacturing industry for over 20 years, specializing in the development and production of cutting-edge CNC routers and laser machines. Their dedication to innovation and customer satisfaction has solidified their position as a trusted name in the industry.The integration of laser technology into CNC routers has opened up new possibilities for manufacturers. The precision and versatility of laser cutting and engraving allows for intricately detailed designs and high-quality finishes, making it an ideal solution for a wide range of applications. From woodworking and metalworking to signage and prototyping, CNC routers with laser technology are providing manufacturers with the tools they need to take their production capabilities to the next level.{Company}'s CNC routers with laser technology are designed to meet the needs of modern manufacturers. With high-speed cutting and engraving capabilities, these machines are able to handle a wide variety of materials with ease, including wood, acrylic, plastic, and metal. The integration of advanced software also allows for seamless design and production, giving manufacturers the ability to bring their ideas to life with precision and efficiency.One of the key advantages of {Company}'s CNC routers with laser technology is their ability to streamline the production process. By combining the capabilities of both CNC routing and laser cutting into a single machine, manufacturers are able to eliminate the need for multiple machines and processes, saving time and resources. This not only increases efficiency, but also reduces the margin for error, ultimately leading to higher quality end products.In addition to their innovative technology, {Company} is also committed to providing top-notch customer support. Their team of experienced engineers and technicians are dedicated to helping their clients get the most out of their machines, offering training, technical support, and maintenance services to ensure that their equipment continues to perform at its best.The integration of laser technology into CNC routers is truly revolutionizing the manufacturing industry, and {Company} is proud to be at the forefront of this innovation. With their commitment to quality, innovation, and customer satisfaction, {Company} is poised to continue leading the way in the development and production of advanced CNC routers with laser technology.In conclusion, the integration of laser technology into CNC routers is transforming the manufacturing industry, and {Company} is leading the way with their innovative machines. With their dedication to quality and customer support, {Company} is helping manufacturers take their production capabilities to new heights, solidifying their position as a trusted name in the industry.

Discover Advanced Laser Cutting Machines and CNC Tools for Customized System Solutions

, Fiber Laser Machine, YAG Laser Cutting Machine, CNC Turret Punch, Electro-Hydraulic Servo Bending Machine, CNC Shearing Machine.In today's industry, precision and speed are essential elements. To achieve this, companies have started relying heavily on advanced technology. One such piece of technology that has proven its worth is CNC (Computer Numerical Control) machines. CNC machines have revolutionized the manufacturing industry and allow companies to produce products with high precision, accuracy, and speed.Among the different types of CNC machines, laser cutting machines have become increasingly popular. They use a high-powered laser beam to cut through various materials, such as metal, wood, plastic, and others. Laser cutting machines come in different types, each with its specific application and technology to produce a specific result.Fiber Laser Cutting MachineFiber laser cutting machines use a fiber optic laser beam to cut through metal, including aluminum, stainless steel, brass, and copper. They are known for their high cutting speed, ability to cut through thick metal, and low maintenance costs. The laser beam is small and precise, which allows for intricate designs and smooth cutting edges.YAG Medium Power Laser Cutting EquipmentYAG laser cutting machines use a crystal as the lasing medium and have a lower power than Fiber machines. They are commonly used in industries that require precise cutting in small volumes, such as the jewelry, electronics, and medical industries. YAG laser cutting machines have high beam quality, which allows for sharp cuts with little need for further processing.CO2 Power Laser Cutting MachineCO2 power laser cutting machines are used to cut through non-metal materials like plastic, wood, rubber, and acrylic. The technology uses a CO2 laser beam that vaporizes the material, creating a smooth and precise cut. CO2 power laser cutting machines are popular in the industrial sector for producing customized products, signs, and displays.CNC Turret PunchCNC turret punches are machines that punch holes and shapes in sheet metals with high precision. They come with a range of tooling options and can create intricate designs and shapes with minimal waste. They are ideal for high-precision metal manufacturing processes such as electrical enclosures, automotive components, and HVAC components.Electro-Hydraulic Servo Bending MachineThe electro-hydraulic servo bending machine is used for precision bending of sheet metals, steel tubes, and other materials. It is designed to provide high precision, uniformity, and repeatability. This machine is commonly used to produce parts and components for the automotive, aerospace, and construction industries.CNC Shearing MachineCNC shearing machines are mostly used for the cutting of metal sheets. They use hydraulic or electric mechanisms to maintain a constant gap between blades ensuring a smooth cut. These machines come in various sizes and can cut through different sheet thicknesses. CNC Shearing machines are commonly used for manufacturing metal cabinets, boxes, and trays.In conclusion, CNC machines have transformed the manufacturing industry and have proven to be highly efficient and precise. Laser cutting machines play a significant role in this transformation and offer a wide range of applications and precision cutting capabilities. Fiber laser cutting machines, CO2 power laser cutting machines, and YAG medium power laser cutting machines are just a few examples of the types of laser cutters available.In addition to lasers, CNC turret punch, electro-hydraulic servo bending machine, and CNC shearing machines are also essential in the efficient manufacturing of various materials. With the ever-increasing demand for high-quality products and precision, CNC machines have become an investment for companies to meet those demands.Keywords: Cnc Co2 Laser Cutting Machine, Fiber Laser Machine, YAG Laser Cutting Machine, CNC Turret Punch, Electro-Hydraulic Servo Bending Machine, CNC Shearing Machine.