High-Precision Fiber Laser Cutting Table for Industrial Use

By:Admin

Fiber Laser Cutting Table is a cutting-edge technology that has been developed by our company to meet the growing demands of precision cutting and high efficiency in various industries. This cutting table is designed to provide a high level of accuracy and speed in cutting a wide range of materials including metal, plastic, and composites.

The Fiber Laser Cutting Table is equipped with a powerful fiber laser that can deliver a superior cutting performance, with the ability to cut through materials with high precision and at a much faster rate than traditional cutting methods. The technology used in the cutting table allows for a clean and smooth cut, with minimal heat affected zone and superior edge quality.

One of the key features of the Fiber Laser Cutting Table is its versatility. It can handle a wide range of materials, from thin sheets to thick plates, and can accommodate various shapes and sizes with ease. This makes it an ideal solution for industries such as automotive, aerospace, furniture, and general manufacturing.

The cutting table is also equipped with advanced automation features, such as a laser beam guidance system and a material handling system, which allows for seamless integration with other manufacturing processes. This ensures a high level of productivity and efficiency, while reducing the need for manual intervention.

In addition to its cutting capabilities, the Fiber Laser Cutting Table also offers a range of other features, such as advanced nesting software for optimized material utilization, and a user-friendly interface for easy operation and monitoring. This makes it an ideal solution for businesses looking to improve their production processes and reduce operational costs.

Our company has been at the forefront of developing and integrating advanced manufacturing technologies for over 20 years. We have a strong track record of providing cutting-edge solutions to our customers, and the Fiber Laser Cutting Table is a testament to our commitment to innovation and excellence.

We believe that the Fiber Laser Cutting Table has the potential to revolutionize the industry by offering a solution that combines precision, speed, and efficiency in a single package. It has already been well-received by our customers, who have reported significant improvements in their production processes and overall quality of their products.

As we continue to develop and enhance the capabilities of the Fiber Laser Cutting Table, we are confident that it will become an essential tool for businesses looking to stay ahead of the competition and meet the increasing demands of the market.

In conclusion, the Fiber Laser Cutting Table is a cutting-edge technology that offers a new level of precision, speed, and efficiency in cutting a wide range of materials. Our company is proud to be at the forefront of this innovation, and we are committed to providing our customers with the best solutions to help them stay competitive in today's fast-paced manufacturing environment.

Company News & Blog

High-Precision Fiber Laser Cutting Machine for Efficient Metal Processing

CNC Fiber Laser Cutting Machine: The Innovation in Metal Cutting TechnologyOver the years, different advancements in technology have been made for different industries. One of the biggest beneficiaries of technological advancements is the manufacturing industry, and specifically the metal cutting industry. With the introduction of CNC Fiber Laser Cutting machines, manufacturers can cut different kinds of metal materials with a high precision and speed like never before.CNC Fiber Laser Cutting machines have gained immense popularity in the manufacturing industry. Companies like Shandong Pengwo Laser Technology Co., Ltd. have been at the forefront of designing and manufacturing CNC Fiber Laser Cutting machines that are efficient, precise, and reliable. The machine uses a fiber laser generator and ball screw moving system that enable it to cut and punch different types of metal materials without compromising on quality.Features of CNC Fiber Laser Cutting Machines1. High Cutting Precision:CNC Fiber Laser Cutting Machines have a high cutting precision that enables them to deliver top-notch end products. The laser is transmitted through a fiber, which ensures that there is no loss of energy, and hence precision cutting is achieved. Whether you need to cut intricate designs or thick metals, CNC Fiber Laser Cutting Machines will deliver.2. High Speeds:The use of advanced fiber laser technology with ball screw moving systems enables CNC Fiber Laser Cutting machines to achieve high speeds while cutting, without compromising the precision. By increasing the production speed, your manufacturing process will become more efficient, and your business will be more profitable.3. Low Maintenance:One of the biggest advantages of installing CNC Fiber Laser Cutting Machines is its low maintenance. Since the laser is transmitted through a fiber, there is no need to adjust or maintain the laser optical path. In contrast, traditional laser cutting machines require frequent maintenance, which can be costly and time-consuming.4. Energy Efficiency:CNC Fiber Laser Cutting Machines have excellent energy efficiency compared to other traditional metal cutting methods. The advanced fiber laser technology used in these machines significantly reduces the amount of energy consumed, which in turn helps to lower your operating costs. It is an environmentally friendly cutting option with no emissions of harmful substances.5. Versatile:CNC Fiber Laser Cutting Machines can cut different types of metals, including steel, stainless steel, aluminum, copper, and brass. This versatility makes them indispensable in the manufacturing process as they offer a wide variety of options to cut different shapes and sizes of metal materials.Conclusion:CNC Fiber Laser Cutting Machines are the latest innovation in the metal cutting industry. They offer a plethora of features that make them indispensable to the manufacturing process. High precision, high speed, low maintenance, energy efficiency, and versatility are some of the unique selling points of CNC Fiber Laser Cutting Machines. By incorporating them into your manufacturing process, you will increase efficiency, profitability, and precision cutting. So, if you are looking for an efficient and reliable way to cut metals, CNC Fiber Laser Cutting Machines are definitely worth considering.

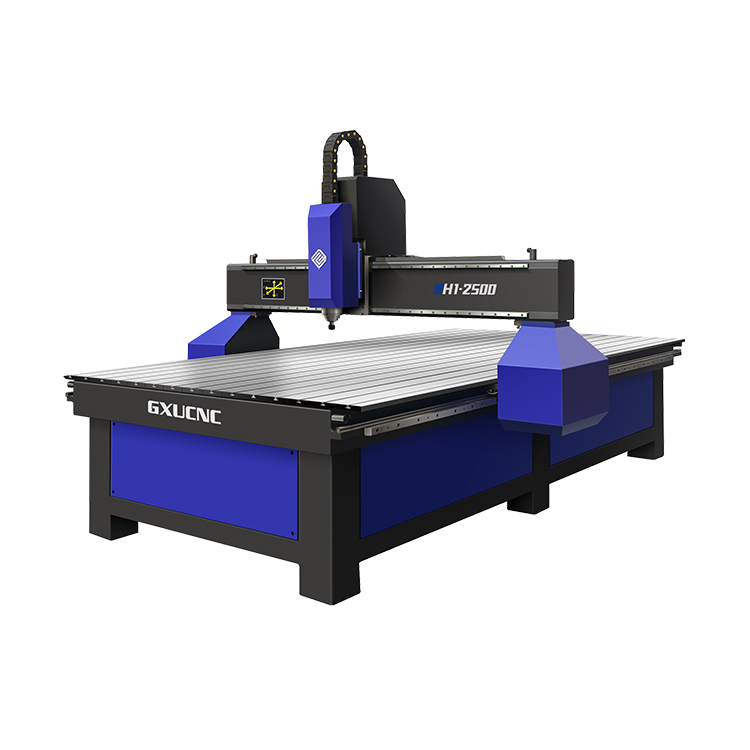

CNC Wood Router 1325 Manufacturers & Suppliers in China - High-Quality Products and Long-Term Cooperation Guaranteed

Jinan Quick Wood CNC Router manufacturers, one of the leading wood CNC router suppliers in China, have been providing reliable and efficient CNC machines to their customers for many years. With an aim to make better products that cater to the evolving needs of the customers, the company has built a strong reputation in the industry.The company uses top-quality materials and advanced technologies in their manufacturing processes to provide high-performance CNC machines that deliver precision, speed, and accuracy. Their CNC routers are designed to support multiple materials, including wood, acrylic, plastic, and other non-metallic materials.Jinan Quick Wood CNC Router manufacturers offer a wide range of CNC machines such as the wood CNC router 1325, 1224, 1530, along with other specialized CNC machines for carving, engraving, cutting, and drilling.Their wood CNC router 1325 model is one of the best-selling products that have aced the manufacturing industry. This machine is built with a sturdy structure that ensures high durability and stability, capable of handling tough jobs with ease. The machine features a powerful spindle motor, easy-to-use control system, and intelligent working modes.The wood CNC router 1325 is perfect for cutting, engraving, and carving various types of wood such as hardwood, softwood, MDF, and plywood. It's also suitable for processing acrylic, PVC, and other non-metallic materials. The machine is designed to complete a variety of tasks, from furniture manufacturing to door carving, making it ideal for workshops, signage making, and advertising businesses.Jinan Quick Wood CNC Router manufacturers take pride in their work and always place quality and customer satisfaction as their top priority. They understand the value of time and money for their customers, and thus, provide efficient machines that are easy to operate and require minimal maintenance.The company has a team of experienced professionals who work with customers to understand their needs and provide customized solutions accordingly. With their tailored services, Jinan Quick Wood CNC Router manufacturers ensure that their customers get the perfect product and support they require.Jinan Quick Wood CNC Router manufacturers have been expanding their services by exporting their products to different countries around the world. They have established a strong network of distributors and customers in various regions such as North America, Europe, Middle East, and Asia.Their aim is to establish long-term cooperative relationships with their customers and provide them with quality products, exceptional service, and technical support. By continuously improving their products and services, the company strives to meet and exceed their customers' expectations.In conclusion, Jinan Quick Wood CNC Router manufacturers offer a comprehensive range of CNC machines that cater to various industries. Their wood CNC router 1325 model is top-rated and is widely used by customers around the world. With a focus on quality, customer satisfaction, and innovation, the company has established itself as a reliable supplier of CNC machines in the market.

3D Carving Machine for Customized Creations

CNC 3D Carving Machine Revolutionizes Manufacturing ProcessThe manufacturing industry is constantly evolving, with new technologies and innovations driving efficiency and enhancing product quality. One such innovation that is making waves in the industry is the CNC 3D carving machine. This cutting-edge technology is revolutionizing the way products are designed and created, offering unprecedented precision and flexibility in the manufacturing process.The CNC 3D carving machine, developed by [company name], is a state-of-the-art machine that is capable of transforming raw materials into intricate and complex designs with incredible accuracy and speed. The machine utilizes advanced computer numerical control (CNC) technology to precisely carve and shape a wide range of materials, including wood, plastic, and metal. This level of precision and versatility makes the CNC 3D carving machine an invaluable tool for manufacturers across various industries.At the heart of the CNC 3D carving machine is its high-speed spindle, which is capable of rotating at speeds of up to 24,000 revolutions per minute. This allows for rapid and precise cutting, carving, and shaping of materials, enabling manufacturers to produce high-quality and detailed products with ease. Additionally, the machine is equipped with advanced software that allows for seamless integration with CAD/CAM programs, enabling manufacturers to effortlessly translate digital designs into physical objects.One of the key features of the CNC 3D carving machine is its ability to produce complex and intricate designs with unparalleled precision. The machine's multi-axis cutting capabilities allow for the creation of elaborate 3D shapes and patterns that were previously difficult or impossible to achieve with traditional manufacturing methods. This level of precision opens up a world of possibilities for product design and innovation, enabling manufacturers to bring their creative visions to life with unprecedented accuracy.In addition to its precision and speed, the CNC 3D carving machine also offers a high level of efficiency and cost-effectiveness. By automating the manufacturing process, the machine can significantly reduce production time and labor costs, while also minimizing material waste. This not only allows manufacturers to increase their productivity and output but also helps them to remain competitive in the market by delivering high-quality products at a lower cost.Furthermore, the CNC 3D carving machine is highly adaptable, capable of producing a wide range of products across various industries. From intricate furniture and decorative items to complex industrial components and prototypes, the machine's versatility makes it an ideal solution for manufacturers with diverse production needs. This adaptability also ensures that the machine remains relevant and valuable as new design trends and product requirements emerge in the market.[Company name], the company behind the innovative CNC 3D carving machine, has a strong track record of delivering cutting-edge manufacturing solutions to its clients. With a focus on innovation, quality, and customer satisfaction, the company has established itself as a leader in the industry, providing state-of-the-art machinery and equipment to manufacturers worldwide.By harnessing the power of advanced technology and engineering expertise, [company name] has developed the CNC 3D carving machine as a solution to address the evolving needs of the manufacturing industry. The machine's ability to deliver unparalleled precision, speed, and flexibility is a testament to the company's commitment to driving innovation and excellence in manufacturing.In conclusion, the CNC 3D carving machine represents a significant advancement in the manufacturing industry, offering manufacturers a powerful tool to streamline their production processes, increase efficiency, and deliver high-quality products. With its precision, speed, adaptability, and cost-effectiveness, the machine is poised to transform the way products are designed and created, driving innovation and competitiveness in the manufacturing sector. As manufacturers continue to embrace new technologies and advancements, the CNC 3D carving machine is set to play a pivotal role in shaping the future of manufacturing.

Best Router for Woodworking: A Complete Guide for Woodworkers

The demand for high-quality woodwork products has been on the rise in recent years, as more and more people are turning to handcrafted furniture and decor items for their homes. To meet this demand, woodworking companies are constantly seeking out innovative tools and equipment to enhance their craft.One essential tool for any woodworking project is a router. A router is a versatile tool that can be used for a wide range of applications, including shaping edges, creating grooves and joints, and even carving intricate designs. With the right router, woodworkers can achieve precise and professional-looking results, making it an indispensable tool in any woodshop.Recognizing the importance of a high-quality router in woodworking, {company name} has been dedicated to designing and manufacturing top-of-the-line routers for woodworkers around the world. With a commitment to precision, durability, and performance, {company name} has become a trusted name in the woodworking industry.{Company name}'s routers are known for their innovative features and exceptional quality, making them the go-to choice for professional woodworkers and hobbyists alike. Whether it's a handheld router for smaller projects or a table router for larger tasks, {company name} offers a wide range of options to suit the specific needs of woodworkers.The company's dedication to quality is evident in every aspect of their routers, from the materials used to the precision engineering that goes into each product. This commitment to excellence has earned {company name} a sterling reputation in the woodworking community, with woodworkers relying on their routers to deliver exceptional results time and time again.In addition to their focus on quality, {company name} also places a strong emphasis on innovation. As the woodworking industry continues to evolve, {company name} is constantly researching and developing new technologies to enhance their routers and provide woodworkers with the most cutting-edge tools available.One of {company name}'s latest innovations is the introduction of smart routing technology, which allows woodworkers to make precise adjustments and control their routers with unprecedented accuracy. This advanced technology has revolutionized the way woodworkers approach their projects, allowing them to achieve results that were previously unattainable with traditional routers.With a commitment to quality, innovation, and customer satisfaction, {company name} has solidified its position as a leader in the woodworking industry. From professional woodshops to DIY enthusiasts, woodworkers around the world trust {company name} to provide them with the tools they need to bring their creative visions to life.In addition to their exceptional products, {company name} also offers outstanding customer support, providing woodworkers with the guidance and assistance they need to get the most out of their routers. With a team of knowledgeable and dedicated professionals, {company name} is committed to helping woodworkers succeed in their craft.As the demand for high-quality woodwork products continues to grow, {company name} remains at the forefront of the woodworking industry, delivering innovative routers that empower woodworkers to achieve exceptional results. With their unwavering commitment to quality and innovation, {company name} is poised to continue shaping the future of woodworking for years to come.

Top High Power Laser Cutting Techniques for Precision Cutting

High Power Laser Cutting Technology Revolutionizing Industrial ManufacturingIn recent years, the industrial manufacturing sector has witnessed a significant transformation with the emergence of high power laser cutting technology. This innovative process allows for the precise and efficient cutting of a wide range of materials, including metals, plastics, and composites. The introduction of this advanced technology has not only revolutionized the manufacturing process but has also opened up new possibilities for the production of complex and intricate components.One company at the forefront of this technology revolution is [Company Name], a leading provider of cutting-edge laser cutting solutions. With a strong focus on innovation and continuous improvement, [Company Name] has been instrumental in driving the adoption of high power laser cutting across various industries. Their advanced laser cutting systems have set new standards for accuracy, speed, and reliability, making them a preferred choice for manufacturers looking to stay ahead in a competitive market.The key to the success of [Company Name]'s high power laser cutting technology lies in its state-of-the-art laser systems, which are designed to deliver exceptional performance and precision. These systems utilize advanced fiber laser technology, allowing for increased power output and beam quality, resulting in superior cutting capabilities. Additionally, the integration of advanced motion control and automation features ensures maximum efficiency and productivity, making [Company Name]'s laser cutting systems the ideal choice for high-volume production environments.One of the primary advantages of high power laser cutting is its ability to produce high-quality cuts with minimal material waste. Traditional cutting methods often result in significant material loss due to the imprecise nature of the process. However, high power laser cutting technology offers a more sustainable solution, allowing manufacturers to minimize material waste and optimize their production processes. This not only leads to cost savings but also contributes to the overall sustainability of the manufacturing industry.Another significant benefit of high power laser cutting is its versatility in handling a wide range of materials. Whether it's stainless steel, aluminum, carbon steel, or even non-metallic materials such as ceramics and plastics, [Company Name]'s laser cutting systems are capable of delivering clean, precise cuts with exceptional edge quality. This versatility has opened up new opportunities for manufacturers to explore innovative designs and material combinations, enabling them to meet the evolving demands of their customers.Furthermore, high power laser cutting has proven to be a game-changer in the production of complex and intricate components. The fine beam width and high cutting speeds of [Company Name]'s laser systems enable the accurate shaping and profiling of intricate designs, regardless of the material's thickness. This level of precision and flexibility has empowered manufacturers to take on challenging projects while maintaining the highest standards of quality and performance.In addition to its cutting-edge technology, [Company Name] has established itself as a trusted partner for its customers through its comprehensive service and support offerings. From initial consultation and system installation to ongoing maintenance and training, [Company Name] is dedicated to ensuring the success of its customers at every stage of the process. Their team of experienced engineers and technical experts are committed to providing tailored solutions that align with the unique needs and requirements of each customer, resulting in a seamless integration of high power laser cutting technology into their manufacturing operations.As the demand for high precision and efficient manufacturing continues to grow, the role of high power laser cutting technology is only set to become more prominent. With [Company Name] leading the way in driving innovation and excellence in laser cutting, the future of industrial manufacturing looks brighter than ever. By harnessing the power of high power laser cutting, manufacturers can expect to achieve unmatched levels of productivity, quality, and operational efficiency, positioning themselves at the forefront of their respective industries.In conclusion, high power laser cutting technology is redefining the manufacturing landscape, and [Company Name] is at the forefront of this revolution. With its cutting-edge laser systems and unwavering commitment to customer success, [Company Name] is empowering manufacturers to push the boundaries of what's possible, setting new standards for quality and performance in industrial manufacturing. As the world embraces the era of advanced manufacturing, high power laser cutting is undoubtedly a game-changer, and [Company Name] is leading the charge towards a future of limitless possibilities.

Affordable Laser Engraver Can Personalize Almost Any Material

Wood Laser Engraver Technology: Personalize Your Possessions with EaseLaser Engravers have become increasingly popular over the years, for a good reason. These machines allow individuals to unleash their creativity by personalizing a wide variety of possessions and adding their own unique touch. Whether it is for personal or professional use, the application of laser engravers has become limitless. One of the most popular types of laser engravers on the market is the Wood Laser Engraver.A Wood Laser Engraver is a machine that utilizes the power of lasers to burn designs or text onto various wooden surfaces and other materials. Additionally, these machines can create intricate designs and patterns that enhance the aesthetics of the material or item being engraved.One of the best picks in this class of laser engravers is the Epilog Zing Laser Engraver. This machine boasts a compact design and impressive versatility, making it a popular choice for those looking to personalize their possessions.The Epilog Zing Laser Engraver can engrave on almost any material, including wood, plastic, leather, glass, and various metals. The machine allows for high-quality engraving results, and its user-friendly interface makes it easy to operate. It also has an intuitive print driver for Windows.The Zing machine has been designed with the customization of a wide range of products in mind, making it perfect to use in industries ranging from woodworking to jewelry-making. It is a valuable tool for marketing companies, sign makers, event planners, and other industries that require the creation of custom designs and specifications.The versatile nature of the Zing Laser Engraver makes it an excellent choice for those engaging in DIY projects. These machines can work on large and small projects, depending on your needs. Whether you're a hobbyist or a professional, the machine provides the versatility and simplicity needed to personalize your possessions with ease.Wood Laser Engravers have made it easy for businesses and individuals alike to create unique and personalized products for their customers. The ability to add personalized text, logos, or images efficiently and accurately to a wide variety of materials has become an invaluable asset to businesses worldwide. The machines' speed and precision in producing high-volume designs make the machine perfect for commercial use.The Epilog Zing Laser Engraver technology allows for nesting of multiple designs in one file, making it possible to create a range of customized products, including plaques and awards, personalized USB drives, and laser-engraved promotional items. The technology enables the user the ability to create intricate designs that can be cut and engraved with ease.Aside from its customizability, the Epilog Zing Laser Engraver is also designed for safety and efficient use. These machines are UL-certified providing the users with a safe and reliable tool for their personal and commercial use. Precision cooling systems provide water-free operation, ensuring that you can run the machine continuously without worrying about downtime for maintenance. Its compact size makes it ideal for use in small workshops, studio apartments, and other confined spaces.In conclusion, Wood Laser Engraver technology has provided a powerful and versatile tool for customization and personalization of possessions and products. The Epilog Zing Laser Engraver's compact size, user-friendly interface, and versatility make it the perfect machine for those looking to personalize their possessions professionally or DIY projects. The machine boasts of high-quality engraving results, versatility, and simplicity making it a valuable asset for businesses worldwide. If you're looking for a tool that can unleash creativity, there is no better option than the Epilog Zing Laser Engraver machine.

High-Powered Multifunction Welder for All Your Welding Needs

Multifunction Welder Revolutionizes Industrial WeldingIn the fast-paced world of industrial manufacturing, efficiency and versatility are key factors in maintaining a competitive edge. With the introduction of the Multifunction Welder by [Company Name], welding technology has taken a significant leap forward. This state-of-the-art welding equipment offers a wide range of features that not only streamline the welding process but also enhance the overall productivity and quality of the output.The Multifunction Welder, developed by [Company Name], is designed to meet the diverse needs of industrial welders, from large-scale production to small-scale fabrication. With its cutting-edge technology and ergonomic design, this equipment provides a one-stop solution for a variety of welding tasks, including MIG, TIG, stick, and flux-cored welding. Its multifunction capabilities allow for seamless transition between different welding processes, eliminating the need for multiple machines and reducing the setup time.One of the key features of the Multifunction Welder is its advanced control system, which offers precise control over the welding parameters such as voltage, current, and wire feed speed. This level of control allows for a highly accurate and consistent welding process, resulting in high-quality welds with minimal rework or waste. Additionally, the equipment is equipped with a digital interface that provides real-time monitoring of the welding parameters, enabling welders to make immediate adjustments as needed.Furthermore, the Multifunction Welder is designed with user-friendly features that simplify the welding process and enhance the overall efficiency. Its intuitive interface and easy-to-use controls make it accessible to welders of all skill levels, while the ergonomic design ensures comfortable and safe operation. In addition, the equipment is equipped with advanced safety features such as thermal overload protection and voltage fluctuation protection, ensuring the safety of the welder and the integrity of the equipment.[Company Name] has a proven track record of providing high-quality welding equipment to the industrial sector. With a strong focus on innovation and customer satisfaction, the company has earned a reputation for delivering reliable and efficient solutions to its clients. The Multifunction Welder is the latest addition to its extensive product line, and it represents a significant milestone in the company's commitment to advancing welding technology.In addition to its cutting-edge technology, the Multifunction Welder is backed by [Company Name]'s comprehensive customer support and after-sales service. The company offers training, technical assistance, and spare parts availability to ensure that its clients can maximize the benefits of the equipment and operate it with confidence. This commitment to customer satisfaction further reinforces the reliability and value of the Multifunction Welder.The introduction of the Multifunction Welder by [Company Name] is set to revolutionize the industrial welding landscape. With its advanced technology, multifunction capabilities, and user-friendly design, this equipment offers a superior welding solution that meets the evolving needs of the industry. As manufacturing processes continue to become more complex and demanding, the Multifunction Welder provides a competitive edge by delivering efficiency, versatility, and quality in one comprehensive package.

High-Quality Router Machines Perfect for Woodworking Projects

Title: Revolutionizing Woodworking with Advanced Router Machine TechnologyIntroduction:Woodworking has long been considered a craft that requires skill, precision, and dedicated craftsmanship. With the advent of technology, various industries have witnessed major transformations, and the woodworking industry is no exception. One company has emerged as a pioneering force in revolutionizing woodworking practices by introducing an advanced router machine, removing the brand name. This groundbreaking technology promises to enhance efficiency, accuracy, and productivity in the wood manufacturing process. Let's delve into the features and benefits of this innovative router machine.Company Introduction: (Company information to be included)Router Machines Redefined: (Removed brand name) Takes the LeadThe woodworking industry has witnessed significant progress in recent years, thanks to advancements in router machine technology. Among the leading frontrunners is the company (removed brand name), which has developed a router machine that is turning heads in the industry. This router machine combines cutting-edge features, state-of-the-art technology, and a commitment to quality that has garnered attention from woodworkers worldwide.Enhanced Precision and AccuracyOne of the key features that set this advanced router machine apart from traditional models is its exceptional precision and accuracy. Equipped with a high-speed spindle, the (removed brand name) router machine can handle intricate cuts and detailing with utmost finesse. Woodworkers can now achieve intricate patterns, decorative edges, and complex designs that were once difficult to execute. This level of precision ensures that each piece of woodwork produced is consistent and of the highest quality.Improved Efficiency and ProductivityThe (removed brand name) router machine is designed to significantly expedite production processes, increasing overall efficiency and productivity. With a robust computer numerical control (CNC) system, woodworkers can easily program the machine to perform repetitive tasks. This enables them to save time and effort, while also reducing the margin for human error. By automating several aspects of the woodworking process, manufacturers using this router machine can enjoy faster turnaround times and increased output.Smart Embedded TechnologyTo further enhance its functionality, the approach followed by this router machine is to integrate smart embedded technology, allowing it to adapt to various types of wood and materials. Equipped with sensors and advanced software, the machine can automatically adjust cutting speeds, depth, and tool selection based on the wood's hardness and other characteristics. This intelligent integration minimizes the risk of mistakes and, in turn, significantly reduces material waste and associated costs.User-Friendly InterfaceWhile the (removed brand name) router machine boasts cutting-edge technology, it remains incredibly user-friendly. The intuitive interface and user-friendly controls enable woodworkers of all skill levels to operate the machine with ease. Furthermore, the company provides comprehensive training and on-hand customer support, ensuring that customers can maximize the router machine's potential. The seamless integration of user-friendly features into advanced technology makes this router a valuable asset in any woodworking workshop.Positive Environmental Impact(Company name) recognizes the importance of sustainability in the woodworking industry. The router machine not only optimizes productivity but also works in harmony with environmental concerns. By minimizing material waste and limiting energy consumption, this router machine is an industry leader in sustainable woodworking practices. The advanced technology ensures efficient use of resources, contributing to a cleaner and greener future for woodworkers and the planet.Conclusion:The woodworking industry has quickly embraced the revolutionary advancements brought in by the (removed brand name) router machine. Through its exceptional precision, improved efficiency, user-friendly interface, and positive environmental impact, this cutting-edge technology is rewriting the norms of woodworking practices. By using this advanced router machine, woodworkers can elevate their craftsmanship and productivity, creating outstanding woodworking pieces to meet the demands of modern consumers.

The ultimate guide to choosing a professional CNC router

CNC Router Professional is a leading provider of high-quality CNC routers for a wide range of industries and applications. With a strong focus on innovation and customer satisfaction, the company has established itself as a trusted partner for businesses looking to enhance their manufacturing capabilities.The CNC Router Professional team is comprised of highly skilled professionals with extensive experience in the design, development, and production of CNC routers. Their commitment to excellence is evident in the precision and reliability of their machines, which are widely used in the woodworking, signage, metalworking, and plastics industries, among others.One of the key factors that sets CNC Router Professional apart from its competitors is its dedication to continuous improvement. The company invests heavily in research and development to ensure that its products are at the cutting edge of technological advancement. This commitment to innovation has enabled CNC Router Professional to introduce a range of advanced features and capabilities that provide users with greater flexibility, efficiency, and productivity.In addition to its technical expertise, CNC Router Professional also places a strong emphasis on customer service. The company works closely with its clients to understand their specific requirements and provide tailored solutions that meet their needs. Whether it's a small-scale woodworking operation or a large-scale industrial facility, CNC Router Professional has the knowledge and resources to deliver the right CNC router for the job.Recently, CNC Router Professional unveiled its latest product line, which includes several new models designed to address the evolving needs of modern manufacturing. These cutting-edge machines incorporate state-of-the-art technology to deliver superior performance and versatility, making them an ideal choice for businesses looking to stay ahead of the curve.One of the standout features of CNC Router Professional's new product line is its advanced control system, which provides users with a user-friendly interface and seamless integration with industry-leading software. This enables operators to program complex cutting and carving tasks with ease, resulting in greater precision and faster production times.The new CNC routers also boast enhanced durability and reliability, thanks to their robust construction and high-quality components. This means that businesses can rely on these machines to deliver consistent performance and withstand the demands of heavy-duty use, day in and day out.Furthermore, CNC Router Professional has made significant improvements to the efficiency and energy consumption of its new product line. By implementing advanced engineering techniques and cutting-edge components, the company has been able to reduce the environmental impact of its machines while still delivering exceptional results.As a result of these advancements, CNC Router Professional's latest product line has garnered widespread attention and acclaim within the manufacturing community. Businesses that have adopted these new CNC routers have reported significant improvements in their productivity, quality, and overall operational efficiency.Looking ahead, CNC Router Professional remains committed to pushing the boundaries of possibility in the field of CNC machining. By staying at the forefront of technological advancement and maintaining a strong focus on customer satisfaction, the company is well-positioned to continue its success and provide industry-leading solutions for years to come. Businesses in search of a reliable and innovative partner for their CNC router needs can look to CNC Router Professional with confidence. With its track record of excellence and dedication to improvement, the company is poised to remain a driving force in the industry for the foreseeable future.

Metal Sheet Cleaning Made Easy with Fiber Laser Technology

Metal Sheet With Fiber Laser Cleaner - Benefice of Bransgore and Hinton AdmiralThe world is changing and industries are fast adopting modern technologies to improve their efficiency and productivity. The metal sheet cleaning industry is no exception. In fact, the industry has been one of the early adopters of fiber laser cleaning technology. Fiber laser cleaning has revolutionized the metal sheet cleaning industry, and Bransgore and Hinton Admiral are now beneficiaries of this technology.Fiber lasers are highly efficient and reliable sources of laser beams. The cavity converts the low-quality diode light into single-mode laser light. One of the fiber Bragg gratings acts as a total reflector, while the other serves as a partial reflector or output coupler. The solid-state architecture of fiber lasers makes them insusceptible to environmental factors such as dust, moisture, and free-space air perturbations.The technology is not only efficient but also eco-friendly. It replaces traditional cleaning methods that use chemicals, which are not only harmful to the environment but also have the potential to cause long-term harm to humans. Fiber laser cleaning completely eliminates the need for chemicals and produces no toxic waste that could find its way into the environment.Lockdown across the globe has, undoubtedly, had a negative impact on the economy. Many businesses have had to shut down or work at limited capacity, and the metal sheet cleaning industry has not been spared. However, some businesses have managed to find ways to thrive, and one such company is Bransgore and Hinton Admiral. They have been able to leverage the benefits of fiber laser cleaning to offer their clients a safe and affordable cleaning service.Unlike traditional cleaning methods, fiber laser cleaning does not damage the substrate material. The laser beam selectively removes contaminants on the surface of the metal sheet while leaving the substrate material intact. This has been a major selling point for Bransgore and Hinton Admiral, as damage to the substrate material could result in additional costs for their clients.The cleaning system offered by Bransgore and Hinton Admiral is fast, efficient, and reliable. The system uses state-of-the-art scanners that are capable of removing contaminants quickly and accurately. The system allows their clients to clean large surface areas in a short amount of time thus improving their productivity. This has been particularly helpful for clients who have had to work under limited capacity during the lockdown.The technology is not only efficient but also safe for the operators. Fiber laser cleaning does not produce harmful fumes that could put the operators at risk. The system is also easy to operate, and Bransgore and Hinton Admiral have invested in the training of their operators to ensure that they can offer their clients a seamless service.The fiber laser cleaning technology has been a game-changer in the metal sheet cleaning industry. It has not only improved the efficiency and productivity of businesses but also has had a positive impact on the environment. Bransgore and Hinton Admiral have been able to leverage the technology to offer their clients a safe and affordable cleaning service. The lockdown may have had a negative impact on the economy, but businesses like Bransgore and Hinton Admiral have shown that it is possible to thrive in difficult times with the right technology and mindset.In conclusion, the technology offers numerous benefits to the metal sheet cleaning industry. It is fast, efficient, and reliable, and has a positive impact on the environment. With more businesses adopting the technology, the industry can look forward to a more productive and eco-friendly future.