The Benefits of CNC Metal Cutting in Precision Manufacturing

By:Admin

In today's rapidly evolving manufacturing industry, precision and efficiency are paramount. The introduction of Computer Numerical Control (CNC) metal cutting has revolutionized the way metal components are manufactured, offering unparalleled accuracy and speed. As the demand for high-quality metal products continues to rise, manufacturers are increasingly turning to advanced CNC metal cutting technology to meet the market's needs effectively.

One company at the forefront of this technological revolution is {}. With a rich history dating back to the early 20th century, {} has established itself as a leader in the manufacturing industry. Specializing in the production of metal components for a wide range of applications, {} has consistently demonstrated a commitment to innovation and excellence. The company's dedication to leveraging cutting-edge technology, such as CNC metal cutting, has allowed them to maintain their position as a trusted supplier for businesses across various industries.

CNC metal cutting offers numerous advantages over traditional machining methods, making it an attractive option for manufacturers seeking to optimize their production processes. The precision and repeatability achieved through CNC technology ensure that each component meets the exact specifications required, eliminating the margin for error seen in manual machining. This level of accuracy is particularly crucial in industries where tight tolerances are non-negotiable, such as aerospace, automotive, and medical device manufacturing.

Furthermore, CNC metal cutting significantly improves production efficiency. Unlike manual machining, CNC machines can operate continuously, reducing downtime and increasing overall output. This enhanced productivity allows manufacturers to meet tight deadlines and manage increased demand without compromising on quality. As a result, businesses can achieve significant cost savings and maintain a competitive edge in the market.

The implementation of CNC metal cutting has also opened up new possibilities for the design and fabrication of complex metal components. With the ability to program intricate geometries and intricate patterns, manufacturers can produce parts that were once considered unfeasible with traditional machining methods. This flexibility in design capabilities empowers businesses to innovate and develop cutting-edge products that meet the evolving demands of their respective industries.

As a forward-thinking company, {} has recognized the immense potential of CNC metal cutting and has made strategic investments in state-of-the-art CNC machines. By integrating these advanced technologies into their manufacturing processes, they have been able to deliver unparalleled precision and efficiency to their customers. Additionally, {}'s team of highly skilled engineers and technicians are well-versed in utilizing CNC metal cutting to its full potential, ensuring that each component meets the highest standards of quality.

In line with their commitment to sustainability, {} has also leveraged CNC metal cutting to optimize material usage and minimize waste in their production processes. The precise nature of CNC machining allows for efficient material utilization, reducing scrap and minimizing environmental impact. By embracing these sustainable practices, {} not only enhances their operational efficiency but also aligns with the growing emphasis on environmental responsibility within the manufacturing sector.

Looking ahead, the future of CNC metal cutting holds immense promise for continued advancements in precision and efficiency. As the technology continues to evolve, manufacturers will benefit from even greater levels of automation, predictive maintenance, and artificial intelligence integration, further enhancing their capabilities and competitiveness in the market.

In conclusion, CNC metal cutting has emerged as a game-changer for the manufacturing industry, enabling businesses to achieve unparalleled precision, efficiency, and flexibility in the production of metal components. {}'s strategic embrace of this cutting-edge technology has solidified its position as a leader in the industry, empowering them to meet the evolving needs of their customers effectively. As the demand for high-quality metal products continues to rise, CNC metal cutting will undoubtedly play a pivotal role in shaping the future of manufacturing.

Company News & Blog

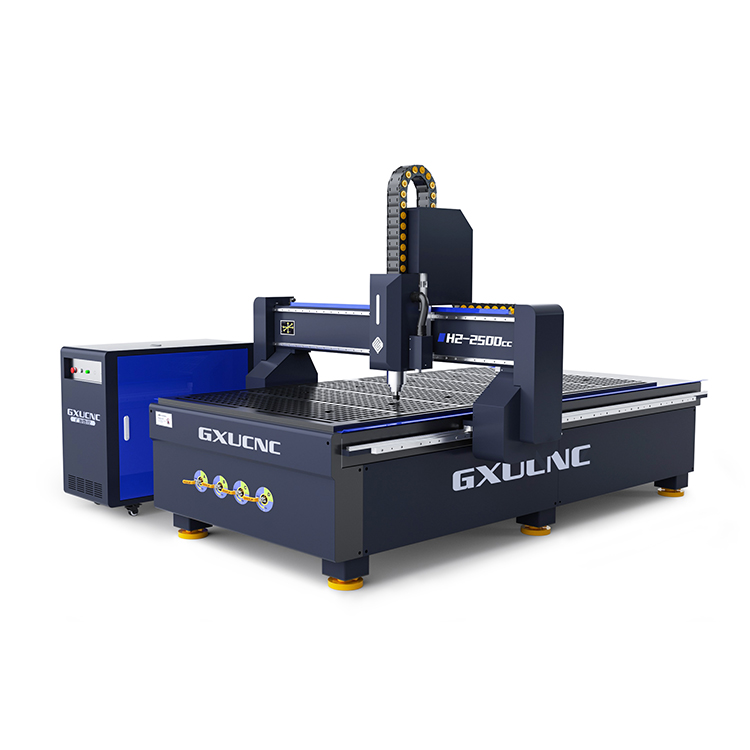

High Precision 4-Axis CNC Router for Advanced Woodworking and Manufacturing

4-axis CNC routers are making headlines in the manufacturing industry for their advanced capabilities in creating intricate and complex designs with precision and accuracy. These state-of-the-art machines are revolutionizing the way companies produce a wide range of products, from furniture and cabinetry to aerospace components and automotive parts.One company leading the way in the development and production of 4-axis CNC routers is {}. With over 20 years of experience in the industry, {} has established itself as a pioneer in the field of CNC machining, offering a wide range of cutting-edge solutions for businesses of all sizes.The {} 4-axis CNC routers are equipped with advanced technology and features that set them apart from traditional 3-axis machines. The additional axis allows for more complex cutting and shaping capabilities, making it possible to create three-dimensional designs with ease. This opens up a world of possibilities for manufacturers, enabling them to produce more intricate and detailed products with greater efficiency.In addition to their cutting-edge technology, {} 4-axis CNC routers are known for their reliability and precision. The company takes pride in ensuring that their machines are built to the highest standards, using the best quality materials and components to guarantee optimal performance and longevity. This commitment to quality has earned {} a stellar reputation in the industry, with many businesses relying on their products to meet their production needs.One of the key advantages of using a {} 4-axis CNC router is the ability to streamline the manufacturing process. With its advanced capabilities, this machine can perform multiple operations in a single setup, reducing the need for manual intervention and minimizing production time. This not only increases efficiency but also lowers production costs, making it a cost-effective solution for businesses looking to improve their manufacturing capabilities.Furthermore, {} offers a range of customizable options and add-ons for their 4-axis CNC routers, allowing businesses to tailor the machine to their specific needs. Whether it's a particular cutting tool, a specialized clamping system, or a custom-designed worktable, {} works closely with their clients to ensure that their CNC router is optimized for their unique manufacturing requirements.The applications for {} 4-axis CNC routers are diverse and wide-ranging. From creating intricate wood carvings and moldings to producing complex metal components and prototypes, these machines can handle a variety of materials with precision and efficiency. This versatility makes them an indispensable tool for manufacturers across a range of industries, from woodworking and metalworking to aerospace and automotive.Looking ahead, {} is committed to furthering the advancement of 4-axis CNC router technology, with ongoing research and development to push the boundaries of what is possible in manufacturing. The company is dedicated to staying at the forefront of innovation, constantly seeking out new ways to improve their machines and empower their clients to achieve even greater levels of productivity and quality in their production processes.In conclusion, 4-axis CNC routers are transforming the manufacturing industry, and {} is at the forefront of this revolution. With their cutting-edge technology, commitment to quality, and dedication to innovation, {} is redefining what is possible in CNC machining and empowering businesses to achieve new levels of precision, efficiency, and productivity. As the demand for more complex and intricate designs continues to grow, 4-axis CNC routers are poised to become an essential tool for manufacturers looking to stay ahead in the competitive global market. And with {} leading the way, the future of CNC machining looks brighter than ever.

High-Powered 100 Watt Laser Cutter for Precision Cutting

Introducing the New 100 Watt Laser Cutter: A Game-Changer for Precision CuttingIn today's fast-paced manufacturing industry, precision cutting is essential for creating high-quality products. That's why we are excited to announce the arrival of our new 100 Watt Laser Cutter, a cutting-edge machine that is set to revolutionize the way we work.This state-of-the-art laser cutter is designed to provide a precise and efficient cutting solution for a wide range of materials, including wood, acrylic, plastics, and more. With its 100-watt laser power, it is capable of cutting through thick materials with ease, making it an ideal tool for a variety of manufacturing applications.One of the key features of our new laser cutter is its high level of accuracy and precision. With its advanced laser technology, it is capable of cutting intricate patterns and designs with incredible detail, resulting in clean, smooth edges that require minimal finishing. This level of precision is vital for maintaining the quality and integrity of the materials being cut, ensuring that our customers receive only the best products.In addition to its precision cutting capabilities, the 100 Watt Laser Cutter also boasts a high level of versatility. Its wide range of compatible materials and ability to handle complex designs make it a valuable asset for a variety of industries, including signage, packaging, automotive, and more. Whether it's creating custom parts, intricate designs, or prototypes, this laser cutter offers the flexibility to meet the diverse needs of our customers.Furthermore, the new laser cutter is equipped with a user-friendly interface and intuitive controls, making it easy to operate and maintain. Its efficient workflow and quick turnaround times allow us to meet tight production deadlines without sacrificing quality. This means that we can continue to provide our customers with fast and reliable cutting services that meet their exact specifications.At [company name], we are committed to staying at the forefront of industry innovation, which is why we have invested in the latest technology to enhance our manufacturing capabilities. The addition of the 100 Watt Laser Cutter to our lineup is a testament to our dedication to delivering exceptional quality and service to our customers.In conclusion, the introduction of our new 100 Watt Laser Cutter marks a significant milestone for [company name]. With its advanced features, precision cutting capabilities, and versatile applications, this machine is set to revolutionize the way we work and deliver even greater value to our customers. We are excited to see the positive impact this cutting-edge technology will have on our manufacturing processes and look forward to the opportunities it will bring to our business and the industries we serve.

Advanced 3D CNC Router: Cutting-Edge Technology for Precision Manufacturing

The 3D CNC Router has revolutionized the world of manufacturing and design with its precision and innovative technology. This cutting-edge machine has become an essential tool for artists, engineers, and manufacturers around the globe, and it is no wonder that it has gained a reputation for excellence in the industry.The [Company Name] is a leading provider of CNC routers and has been at the forefront of the industry for many years. The company has a strong reputation for delivering high-quality machines that are designed to meet the unique needs of each customer. Their commitment to innovation and customer satisfaction has earned them a loyal following and a strong presence in the market.The 3D CNC Router from [Company Name] is a state-of-the-art machine that is capable of producing intricate designs and precise cuts with ease. It utilizes advanced technology and software to ensure accuracy and efficiency in every project. Whether it is cutting wood, plastic, or metal, this machine can handle a wide range of materials with precision and speed.One of the key features of the 3D CNC Router is its ability to create three-dimensional designs with ease. Its advanced software allows users to input complex designs and have them accurately reproduced in the material of their choice. This capability has opened up new possibilities for artists and designers, allowing them to bring their creative visions to life with unparalleled precision.Furthermore, the machine’s speed and efficiency make it a valuable asset for manufacturers who need to produce large quantities of parts with consistent quality. Its advanced technology ensures that each piece is produced with the utmost precision, reducing the margin of error and maximizing productivity.In addition to its technical capabilities, the 3D CNC Router from [Company Name] is also designed with user-friendliness in mind. The interface is intuitive and easy to use, allowing users to create and execute their designs with minimal training. This makes it an accessible tool for artists, engineers, and manufacturers of all levels of experience.With its reputation for excellence and innovation, the 3D CNC Router from [Company Name] has become a trusted tool for a wide range of industries. From woodworking to aerospace, this machine has proven itself to be a versatile and reliable option for those who demand the best in precision and efficiency.The [Company Name] has established itself as a leader in the CNC router industry, and their 3D CNC Router is a testament to their commitment to excellence. With its advanced technology, user-friendly interface, and industry-leading precision, this machine has set a new standard for what is possible in the world of manufacturing and design.As the demand for precision and efficiency continues to grow, the 3D CNC Router from [Company Name] is poised to remain at the forefront of the industry. Its innovative technology and commitment to customer satisfaction make it a valuable asset for anyone looking to take their designs to the next level. With its reputation for excellence, it is no wonder that this machine has become the go-to choice for those who demand the best in CNC routing technology.

How to Choose a High-Quality CNC Wood Router for Optimal Results

Title: Revolutionary CNC Wood Router Poised to Transform the Woodworking IndustryIntroduction:As the demand for intricate and high-quality woodwork continues to rise, companies are constantly seeking innovative tools and machinery to meet these requirements. In keeping with this trend, X Manufacturing has recently unveiled its state-of-the-art 1325 CNC Wood Router, a game-changing solution guaranteeing precision, efficiency, and unparalleled craftsmanship. With its advanced features and cutting-edge technology, this revolutionary woodwork equipment is set to transform the woodworking industry.I. Overview of the 1325 CNC Wood Router:The 1325 CNC Wood Router is a machining tool meticulously designed for woodworking applications. Equipped with a sturdy frame and heavy-duty components, this router delivers exceptional stability, ensuring the utmost accuracy throughout the machining process. Its user-friendly interface and intuitive controls make it accessible for both seasoned professionals and beginners, enabling them to bring their creative ideas to life.II. Advanced Features: 1. High Precision and Versatility:The 1325 CNC Wood Router boasts a high-precision spindle that can operate at varying speeds, allowing craftsmen to achieve intricate details and smooth finishes on a wide range of wood materials. Its versatility extends to its compatibility with various file formats, making it a perfect fit for woodworking projects of any scale.2. Efficient Workflow:With its cutting-edge software and advanced automation, this wood router optimizes production processes, reducing wastage of materials, time, and effort. The tool's ability to perform multiple tasks simultaneously saves valuable production time, enhancing overall efficiency and productivity levels.3. Safety and Dust Control:Prioritizing user safety, the 1325 CNC Wood Router is equipped with built-in safety mechanisms, ensuring operators can work with peace of mind. Additionally, its integrated dust collection system effectively manages wood dust, creating a clean and safe environment, while minimizing potential health hazards.III. Market Impact and Industry Advancement:1. Enhanced Precision and Quality:The introduction of the 1325 CNC Wood Router marks a significant advancement in the woodworking industry, promising unparalleled precision, consistent quality, and intricate detailing. This revolutionary equipment unlocks endless possibilities, enabling craftsmen to create exquisite furniture, intricate carvings, and unique wooden products with exceptional accuracy.2. Cost Efficiency:By significantly reducing material waste and optimizing the production process, the 1325 CNC Wood Router contributes to cost savings, enabling woodworking businesses to enhance profitability. The efficient workflow of the router allows for increased output and shortened project completion times, resulting in improved resource allocation and reduced production costs.3. Accessibility and Skill Development:Thanks to its user-friendly interface and intuitive controls, the 1325 CNC Wood Router minimizes the learning curve, making it accessible to a broader ambit of woodworkers. Moreover, the machine's compatibility with various file formats encourages woodworkers to explore their creativity, fostering skill development and innovation within the industry.IV. Company Background:With a rich heritage spanning over two decades, X Manufacturing has established itself as a leading provider of cutting-edge woodworking machinery. The company prides itself on its commitment to innovation and the highest quality standards. Their portfolio encompasses a wide range of CNC routers, laser engravers, and other industry-leading machines, meeting the diverse needs of woodworking professionals worldwide.Conclusion:The introduction of the 1325 CNC Wood Router by X Manufacturing heralds a new era for the woodworking industry. This powerhouse device combines precision, versatility, and ease of use, significantly elevating craftsmanship standards. Woodworkers at all skill levels can now experience enhanced creativity and improved productivity. As this remarkable machine gains traction, it is set to revolutionize woodworking practices, contributing to the overall growth and advancement of the industry.

Highly Efficient Handheld Laser Welding Machines for Precision Work Applications

Hand Laser Welding Machine: Revolutionizing the Welding IndustryInnovation has always been at the core of industrial development. Companies are constantly seeking novel ways to improve efficiency, reduce costs, and enhance the quality of their products. The welding industry is no exception. Traditionally, welding has been performed using gas torches or electric arcs, both of which have limitations in terms of precision and flexibility. However, with the advent of hand laser welding machines, a new era has dawned in the welding industry.Hand laser welding machines utilize the power of lasers to perform intricate and precise welds. They combine the accuracy of laser technology with the versatility of a handheld device, allowing welders to access hard-to-reach areas and work with complex shapes. This revolutionary technology is set to transform the welding landscape, offering numerous benefits that were previously unimaginable.One prominent player in the hand laser welding machine market is {}. Their commitment to research and development has allowed them to develop cutting-edge products that have captured the attention of industry experts worldwide. Operating at the forefront of laser technology, they have expanded the boundaries of what is possible in the welding process.The {} hand laser welding machine stands out for its exceptional performance and user-friendly design. With advanced features such as real-time power regulation, adjustable laser beam spot size, and automatic wire feeding, the machine offers unrivaled precision and control. Welders can easily adjust the power output according to their specific needs, ensuring optimal results every time. Moreover, the adjustable beam spot size enables welders to adapt to varying workpieces, accommodating different material thicknesses and geometries without compromising weld quality.One of the most significant advantages of the {} hand laser welding machine is its portability. Unlike traditional welding equipment, which is often bulky and stationary, this machine can be operated with ease in any location. Welders are no longer restricted to a designated welding area; they can bring the machine to the workpiece, eliminating the need for extensive preparation and transportation. This mobility not only saves time but also increases productivity, making it an invaluable asset in time-sensitive projects.Furthermore, the {} hand laser welding machine's user-friendly interface simplifies the welding process, reducing the learning curve for welders. With intuitive controls and clear feedback, operators can quickly familiarize themselves with the machine and achieve professional-level welds in no time. This ease of use extends to maintenance as well, with self-diagnosis systems ensuring that any potential issues are promptly addressed, minimizing downtime and maximizing efficiency.Another feature that sets the {} hand laser welding machine apart is its focus on safety. The machine is equipped with multiple safety mechanisms, such as a protective housing, interlock systems, and emergency stop functions. These safety features not only protect the operators but also safeguard the work environment, highlighting the company's commitment to ensuring a secure welding experience.The combination of technological innovation, precision, portability, and safety makes the {} hand laser welding machine a game-changer in the welding industry. It opens up new possibilities for welders, allowing them to tackle complex projects with unparalleled efficiency and accuracy. Moreover, the machine's durability and reliability ensure a long lifespan, guaranteeing a solid return on investment for companies across various sectors.As the demand for high-quality and cost-efficient welding solutions continues to rise, hand laser welding machines are becoming increasingly sought after. Companies that embrace this technology will gain a significant competitive advantage in the market. With their state-of-the-art hand laser welding machine, {} is well-positioned to lead the charge and shape the future of the welding industry.In conclusion, hand laser welding machines have redefined the boundaries of welding technology. The innovation and expertise demonstrated by {} have resulted in a remarkable product that offers unmatched precision, portability, and safety. As more industries recognize the transformative potential of this technology, hand laser welding machines will undoubtedly become an essential tool in the manufacturing process. With {} at the helm, it is clear that the welding industry is set for a revolutionary change.

Powerful Fiber Laser Cutter: The Ultimate Precision Cutting Solution

[Company Introduction:]With a rich history of technological innovation, exceptional precision, and high-quality products, [Company Name] has firmly established itself as a leading provider of laser cutting solutions. Founded in [Year], our company has continuously pushed the boundaries of what is possible in the field of laser technology. We are proud to introduce our latest cutting-edge innovation, the Fiber Laser Cutter.[News Content - 800 words][Opening Paragraph]In today's ever-evolving world of manufacturing and metal fabrication, laser cutting technology plays a vital role in shaping the industry's landscape. [Company Name], a pioneering name in laser cutting solutions, is now revolutionizing the market with the introduction of their latest innovation, the Fiber Laser Cutter. This cutting-edge machine promises to enhance productivity, precision, and efficiency, cementing [Company Name]'s position as a forward-thinking leader in the industry.[Body - Fiber Laser Cutter's Features and Benefits]The Fiber Laser Cutter encompasses a range of cutting-edge features that elevate it above its competitors. At the core of its design lies the integration of advanced fiber laser technology, which offers numerous advantages. With ultra-fast processing speeds, industry-leading precision, and exceptional beam quality, this machine ensures flawless execution of even the most intricate cutting tasks. The Fiber Laser Cutter also boasts excellent energy efficiency and low maintenance requirements, allowing businesses to optimize their productivity while minimizing operational costs.In addition to its technological advancements, the Fiber Laser Cutter's user-friendly interface ensures ease of operation for both experienced operators and novices alike. Its intuitive control panel, combined with state-of-the-art software, simplifies the programming and execution of intricate cutting patterns. This enables businesses to achieve high levels of productivity and accuracy without the need for extensive training or technical expertise.[Benefits for Various Industries]The Fiber Laser Cutter's versatility makes it suitable for a wide array of industries, including automotive, aerospace, electronics, and construction. Its ability to cut through various materials, including stainless steel, aluminum, and copper, provides immense value to manufacturers in these sectors. The machine's precision and flexibility allow for the creation of intricate and complex components, meeting the exacting demands of these industries.Moreover, the Fiber Laser Cutter ensures cost-effectiveness through reductions in waste material and secondary processing. Its exceptional accuracy minimizes errors and rework, resulting in increased efficiency and decreased operating costs for businesses. The machine's ability to work with different thicknesses and sizes of materials further enhances its applicability across various industries, catering to the specific needs of manufacturers in each sector.[Company Name's Commitment to Excellence]As a market leader, [Company Name] is renowned for providing exceptional customer support and service. The introduction of the Fiber Laser Cutter further reaffirms our commitment to meeting and exceeding our customers' expectations. With a dedicated team of experts, we provide comprehensive technical assistance, training, and maintenance services, ensuring that our customers derive maximum value from their investment.[Conclusion]The Fiber Laser Cutter represents a significant leap forward in laser cutting technology, offering unparalleled precision, efficiency, and versatility. [Company Name]'s commitment to innovation and customer satisfaction has propelled us to the forefront of the industry. By integrating advanced fiber laser technology and addressing the unique needs of various sectors, the Fiber Laser Cutter stands as a testament to our dedication to pushing the boundaries of excellence in laser cutting solutions.

High-Efficiency Carving Machines for Precision Woodworking

Carving Machines have been a popular tool in various industries for their precision and efficiency in creating intricate designs on a wide range of materials. These machines are widely used in industries such as woodworking, metalworking, stone carving, and sign making. With the advancement in technology, these machines have become even more advanced and versatile, providing businesses with the ability to create complex and detailed designs with ease.One company that has been at the forefront of carving machine technology is {Company Name}. Established in {year}, {Company Name} has been a leading manufacturer of carving machines, offering a wide range of models to cater to the diverse needs of different industries. The company prides itself on its commitment to innovation, quality, and customer satisfaction, which has earned them a strong reputation in the industry.{Company Name} carving machines are known for their precision and durability, making them a top choice for businesses looking to enhance their production capabilities. Their machines are designed to provide high-speed carving and cutting capabilities, allowing businesses to meet tight deadlines and produce high-quality products. In addition, {Company Name} offers a range of customization options, allowing businesses to tailor their machines to their specific needs and requirements.One of the key features of {Company Name} carving machines is their user-friendly interface and intuitive controls. This makes it easy for operators to quickly learn how to use the machines, reducing the need for extensive training and allowing businesses to get up and running with minimal downtime. {Company Name} also provides comprehensive training and support to help businesses make the most of their carving machines, ensuring that they can maximize their productivity and efficiency.In addition to their high-quality machines, {Company Name} also offers a range of accessories and consumables to complement their carving machines. This includes a variety of cutting tools, clamps, and software options to enhance the capabilities of the machines and provide businesses with a complete carving solution. {Company Name} is committed to providing businesses with everything they needs to succeed in their carving endeavors. {Company Name} takes pride in its strong focus on research and development, constantly striving to develop new and improved carving machine technologies to meet the evolving needs of its customers. Their team of experienced engineers and technicians work tirelessly to incorporate the latest advancements in technology into their carving machines, ensuring that businesses can stay ahead of the curve and remain competitive in their respective industries.In addition to their commitment to innovation, {Company Name} is also dedicated to ensuring the sustainability and environmental friendliness of their carving machines. The company follows strict environmental standards in their manufacturing processes, using energy-efficient technologies and sustainable materials to minimize their carbon footprint. This is in line with their vision to contribute to a greener world while providing businesses with reliable and efficient carving machines.With their dedication to quality, innovation, and sustainability, {Company Name} has established itself as a trusted name in the carving machine industry. Their machines are widely used by businesses around the world, helping them to achieve their production goals and create stunning designs with ease. Whether it's woodworking, metalworking, stone carving, or sign making, {Company Name} carving machines have proven to be an invaluable asset for businesses looking to elevate their capabilities and stay ahead of the competition.

High-Quality Pipe Welding Machine for Efficient Welding Operations

Pipe Welding Machine Revolutionizes Welding ProcessIn the world of manufacturing and construction, welding is a crucial process that is used to join metal parts together. The traditional method of welding involves using a hand-held welding torch to manually weld two pieces of metal together. This process can be time-consuming, labor-intensive, and can result in inconsistent welds.However, with the introduction of the new Pipe Welding Machine by a leading manufacturing company, the welding process has been revolutionized. This innovative machine has drastically improved the efficiency and quality of welding, making it an essential tool for any manufacturing or construction project.The Pipe Welding Machine, with its advanced technology, has completely transformed the welding process. The machine is able to automatically and precisely weld pipes and other metal parts with a high level of accuracy and consistency. This not only saves time and labor but also ensures that the welds are of the highest quality.One of the key features of this Pipe Welding Machine is its advanced robotic arm, which is capable of maneuvering in all directions to access hard-to-reach areas and weld with precision. The machine also comes equipped with a state-of-the-art welding torch that can be programmed to adjust the speed, heat, and angle of the weld, resulting in seamless and strong welds.The Pipe Welding Machine is also equipped with a user-friendly interface that allows operators to easily input the necessary parameters for the welding process. This user interface also provides real-time monitoring of the welding operation, allowing for quick adjustments if needed.In addition to its efficiency and precision, the Pipe Welding Machine is also designed with safety in mind. The machine is equipped with various safety features, such as built-in sensors that can detect any anomalies during the welding process and immediately shut down the machine to prevent accidents.The company behind this revolutionary Pipe Welding Machine, {Company Name}, is a leading manufacturing company with a long history of producing cutting-edge industrial equipment. With a focus on innovation and quality, the company has continually pushed the boundaries of what is possible in the manufacturing industry.{Company Name} has a team of highly skilled engineers and technicians who are dedicated to researching and developing new technologies to improve the efficiency and safety of industrial processes. The Pipe Welding Machine is just one example of the company's commitment to providing innovative solutions that enhance the capabilities of manufacturers and construction companies.Furthermore, {Company Name} prides itself on providing exceptional customer support and service. The company offers comprehensive training and support for the Pipe Welding Machine, ensuring that operators are fully equipped to maximize the machine's capabilities. Additionally, {Company Name} offers timely maintenance and repair services to keep the machine running at its best.With the introduction of the Pipe Welding Machine, {Company Name} has set a new standard in the welding industry. The machine's advanced technology, precision, and safety features have made it an essential tool for any manufacturing or construction project. As the demand for high-quality and efficient welding continues to grow, the Pipe Welding Machine is sure to be a game-changer for the industry.

High-precision Laser Cutting Machine for Leather Goods

Leather Laser Cutting Machine Revolutionizing the IndustryThe leather industry is no stranger to innovation and the latest addition to the manufacturing process is the leather laser cutting machine. This technology has been making waves in the industry as it offers a precise and efficient method of cutting leather, making it a valuable asset for companies looking to streamline their production processes.One company that has been at the forefront of this innovation is {Company Name}. With years of experience in the leather industry, {Company Name} has been committed to providing cutting-edge solutions for leather manufacturing. The introduction of the leather laser cutting machine has been a game-changer for the company and has set them apart from competitors.The leather laser cutting machine offered by {Company Name} is equipped with state-of-the-art technology, offering a high level of precision and accuracy in cutting leather. The machine is capable of cutting intricate patterns and designs on various types of leather, making it a versatile tool for manufacturers. Its speed and efficiency have been highly praised by industry professionals, as it allows for a significant reduction in production time and costs.One of the key advantages of the leather laser cutting machine is its ability to produce clean and consistent cuts, resulting in minimal waste of materials. This is crucial for companies looking to optimize their production processes and reduce their environmental footprint. The machine also offers flexibility in cutting different types of leather, whether it be thick or thin, ensuring that manufacturers can cater to a wide range of product demands.Furthermore, the leather laser cutting machine offered by {Company Name} is user-friendly and easy to operate, making it accessible for manufacturers of all sizes. The intuitive software interface allows for quick and easy customization of designs, providing manufacturers with the freedom to create unique and intricate leather products. This level of flexibility has been a major selling point for the machine, as it enables companies to stay ahead in a competitive market.{Company Name} has positioned itself as a leader in the leather laser cutting machine market, offering not only cutting-edge technology but also exceptional customer support and service. Their team of experts is committed to assisting manufacturers in optimizing their production processes and enhancing their product offerings.In addition to the leather laser cutting machine, {Company Name} also provides a range of complementary products and services, further solidifying their position as a one-stop solution for leather manufacturers. Whether it be laser engraving machines or custom software development, {Company Name} is dedicated to providing comprehensive and innovative solutions to meet the evolving needs of the industry.As the demand for high-quality leather products continues to grow, the leather laser cutting machine offered by {Company Name} has become an invaluable asset for manufacturers looking to elevate their production processes. The combination of precision, efficiency, and flexibility has been a game-changer for the industry, and {Company Name} has been at the forefront of this innovation.In conclusion, the introduction of the leather laser cutting machine has revolutionized the leather manufacturing industry, and {Company Name} has been instrumental in driving this change. Their commitment to providing cutting-edge solutions and exceptional customer support has set them apart as a leader in the market. With the leather laser cutting machine, {Company Name} is shaping the future of leather manufacturing and is poised to continue making significant contributions to the industry.