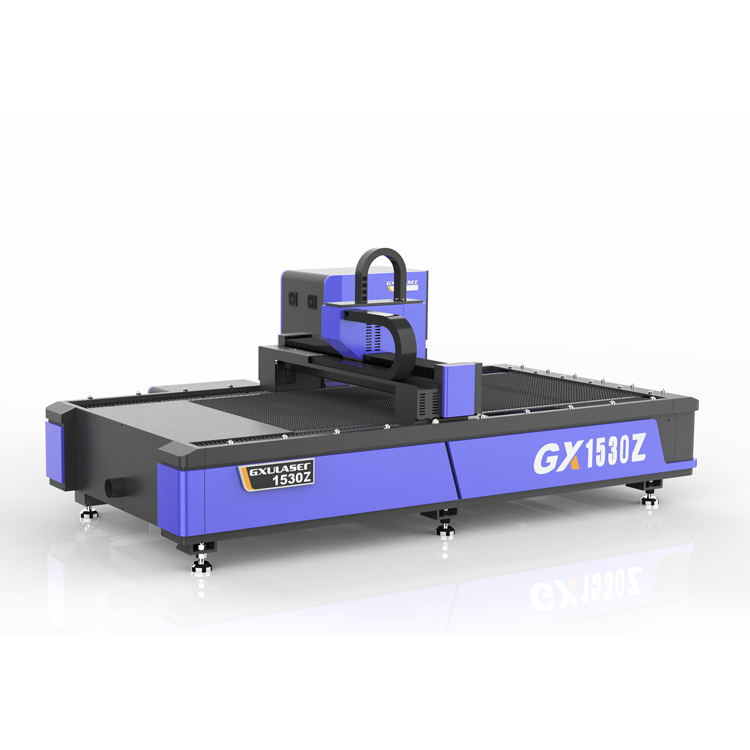

| Laser Power | 3000W~6000W | Cutting thickness | 6~25mm |

| The laser wavelength | 1070±10nm | Aimed and positioning | Red light |

| Min. Line Width | 0.1mm | Power supply | 380V/50HZ |

| Repeat position accuracy | ±0.02mm | Cooling mode | Water cooled |

| Cutting range | 1500×3000mm | N.W. | ≥4000Kg |

- Packaging Details:

- Port:

| Quantity(sets) | 1 - 1 | >1 |

| Lead time (days) | 7 | To be negotiated |

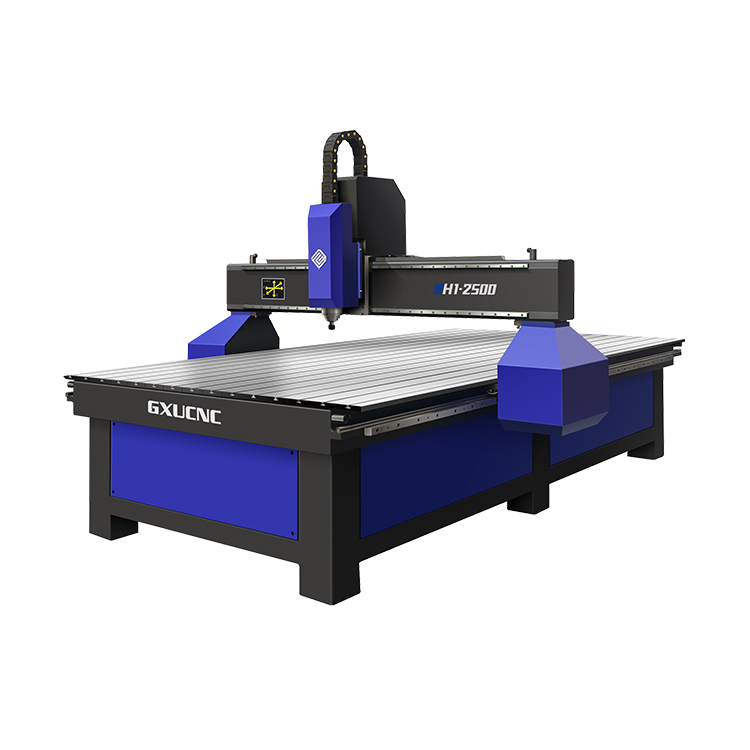

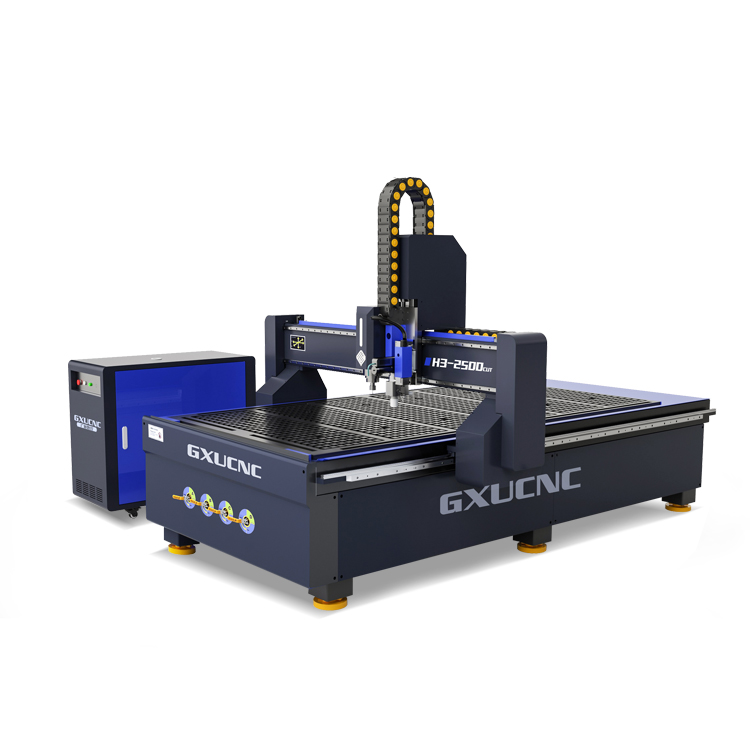

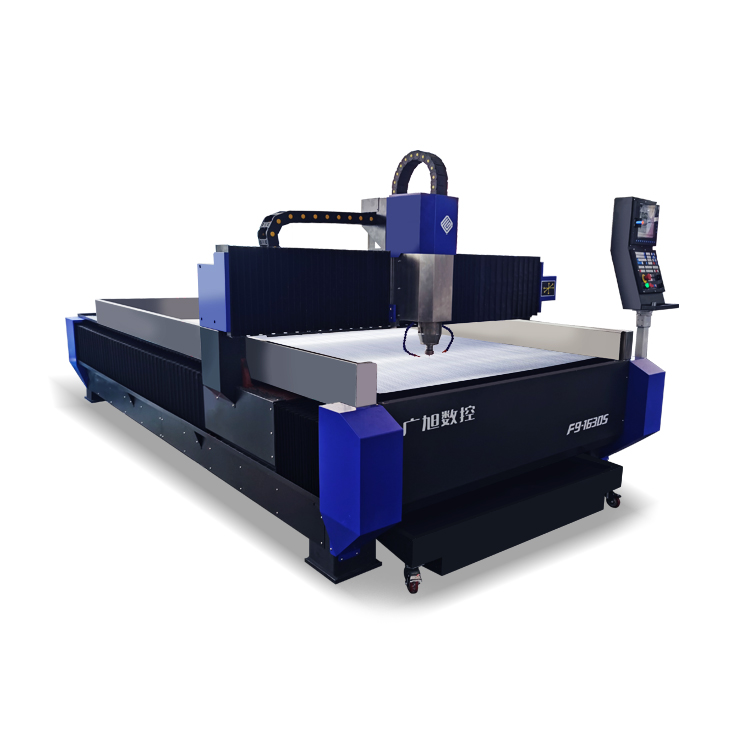

Please feel free to send us an inquiry or message to know more about the machine.We specialize in CNC routers and laser machines for 16 years.You haven't found the machine you need, don't hesitate to contact us too. We will do best to give you the best suggestion.

Please feel free to send us an inquiry or message to know more about the machine.We specialize in CNC routers and laser machines for 16 years.You haven't found the machine you need, don't hesitate to contact us too. We will do best to give you the best suggestion. Welcome to Visit Our Factory

Welcome to Visit Our Factory Welcome to Visit Our Factory If you have plan to visit our factory, just contact us is ok, we willarrange everything well according to your schedule. no matter what trantport way that you want to choose, We will have pick you up, if you need us to arrange your hotel, please contact us.

>>> Click here, Your 24x7 helper ^ ^

Support Door to Door

1. 24/7 online service . 2. 2 years warranty for machine. 3. After sale office in differ country 4. Life time maintenance 5. Free online technical support and install train.

6. We have a professional and experienced after-sales team.

7. We support door-to-door after-sales service.

8. In order to effectivelysolve customer problems and help customers use the machine better, we will conduct skill assessments on our after-sales team every year.

Q: How about after-sales service? A: 1. We can provide free training in our company. 2. If u need, our engineers are available to service machinery overseas. But u need pay the tickets and hotel fees for our engineers. Q: How about the warranty?

Q: How about after-sales service? A: 1. We can provide free training in our company. 2. If u need, our engineers are available to service machinery overseas. But u need pay the tickets and hotel fees for our engineers. Q: How about the warranty? A: 2-year warranty for engraving machine,3-year warranty for laser machine.Life time maintenance. Q: What should I do when I have some problems or questions? A: Pls don’t hesitate to contact us, we will reply u ASAP. Q: How about the quality? A: Before we pack each machine, we will test it first. If machine has problem in your place, our worker will take responsible for his mistake. And we will solve your problem. Q: Which is the most suitable model machine for me? A: Pls tell us your materials, thickness, size and business industries.We will select the machine model that is right for you.

Picture Example: 1. 18mm thick sheet welded body, rough machining after high temperature annealing, and finishing after secondary vibration aging treatment; cast aluminum beam. 2. The use of heavy-duty steel die pressure casting ensures the strength, precision and service life of the machine tool; 3. Adopt imported planetary helical gear reducer, high-precision rack and pinion and linear guide rail to ensure stable operation at high speed, low noise and reliable performance. 4. Using servo drive control, stronger torque, faster and more stable operation; 5. Follow-up smoking system, good smoking effect and energy saving; 6. Using laser cutting head and laser lens, the focusing spot is smaller, the cutting line is finer, the work efficiency is higher, and the processing quality is better; the L light of the whole machine is transmitted by optical fiber, no complicated light guide system such as a mirror is needed, and the light path is simple , the structure is stable, and the external optical path is maintenance-free; 7. Adopt fiber laser with high electro-optical conversion efficiency, which can greatly save power consumption during work and save operating costs; the cutting edge is less affected by heat, the cutting seam is flat, and generally does not require secondary processing. Professional laser cutting CNC control system, with intelligent typesetting function, easier operation and higher efficiency.

1. 18mm thick sheet welded body, rough machining after high temperature annealing, and finishing after secondary vibration aging treatment; cast aluminum beam. 2. The use of heavy-duty steel die pressure casting ensures the strength, precision and service life of the machine tool; 3. Adopt imported planetary helical gear reducer, high-precision rack and pinion and linear guide rail to ensure stable operation at high speed, low noise and reliable performance. 4. Using servo drive control, stronger torque, faster and more stable operation; 5. Follow-up smoking system, good smoking effect and energy saving; 6. Using laser cutting head and laser lens, the focusing spot is smaller, the cutting line is finer, the work efficiency is higher, and the processing quality is better; the L light of the whole machine is transmitted by optical fiber, no complicated light guide system such as a mirror is needed, and the light path is simple , the structure is stable, and the external optical path is maintenance-free; 7. Adopt fiber laser with high electro-optical conversion efficiency, which can greatly save power consumption during work and save operating costs; the cutting edge is less affected by heat, the cutting seam is flat, and generally does not require secondary processing. Professional laser cutting CNC control system, with intelligent typesetting function, easier operation and higher efficiency. We are certified by many parties, has multiple patent certificates.professionalism is guaranteed, the quality is worthy of your choice.

We are certified by many parties, has multiple patent certificates.professionalism is guaranteed, the quality is worthy of your choice.

in sheet metal processing, kitchenware and bathroom, advertising signs, lighting hardware, electrical cabinets, auto parts, mechanical equipment, electrical equipment, aerospace, shipbuilding, elevator manufacturing, rail transit, textile machinery, precision parts, and other metals processing industry.

in sheet metal processing, kitchenware and bathroom, advertising signs, lighting hardware, electrical cabinets, auto parts, mechanical equipment, electrical equipment, aerospace, shipbuilding, elevator manufacturing, rail transit, textile machinery, precision parts, and other metals processing industry.