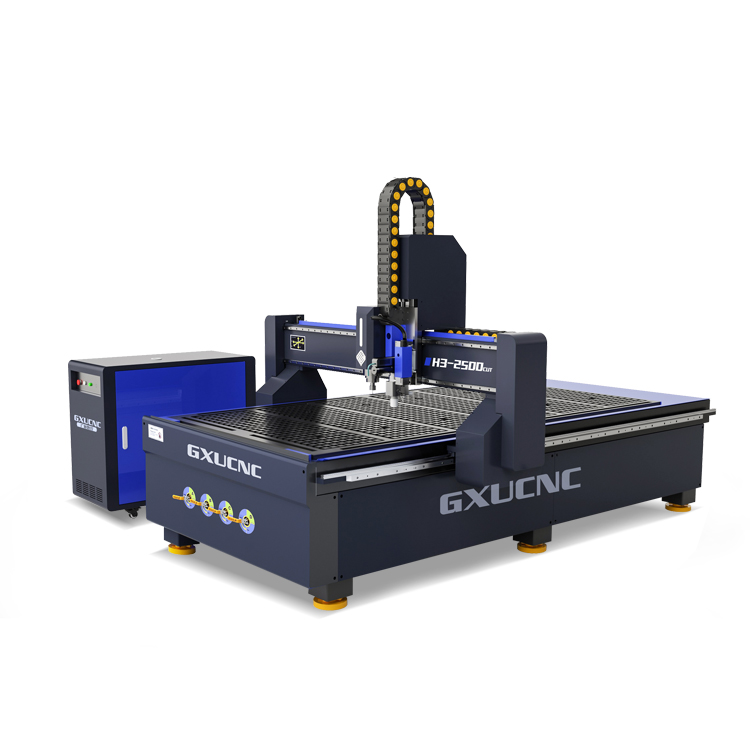

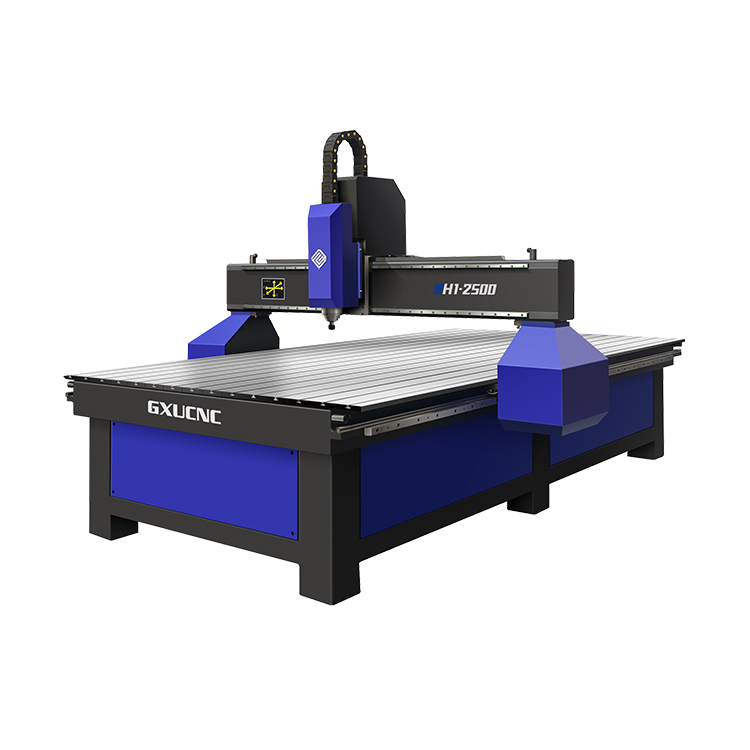

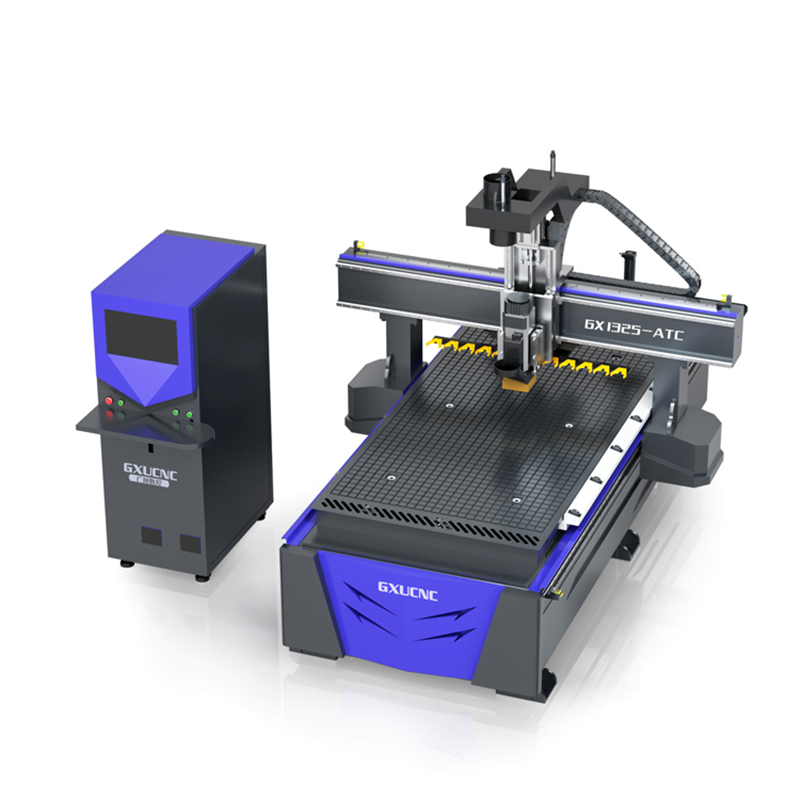

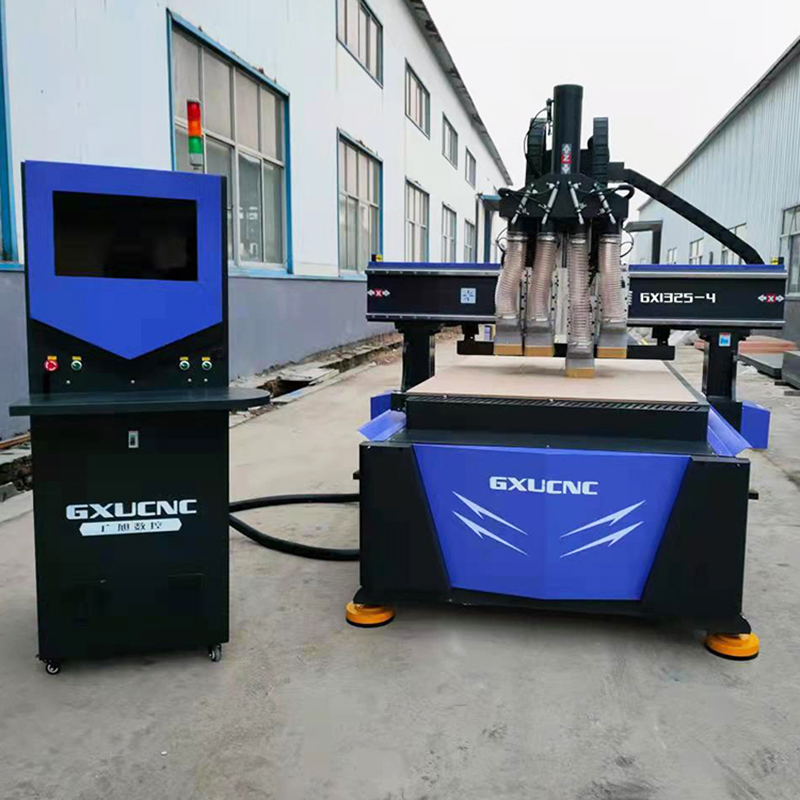

| Table size | 1300x2500x350mm |

| X-axis travel | 1300mm |

| Y-axis travel | 2500mm |

| Z-axis travel | 350mm |

| Spindle power | 9KW |

| Running speed | 60m/min |

| Tool change mode | automatic tool change |

| Work table | vacuum suction table |

| Cooling method | water cooling |

| Spindle speed | 24000r/m |

| Machining accuracy | ±0.03mm |

| Repeat positioning accuracy | ±0.01mm |

| Oil supply method | automatic oil supply |

| Control method | Taiwan Baoyuan Industrial Control System |

| Working voltage | AC380/50HZ |

| Machine weight | 4000KG |

1. 24/7 online service . 2. 2 years warranty for machine. 3. After sale office in differ country 4. Life time maintenance 5. Free online technical support and install train. 6. We have a professional and experienced after-sales team. 7. We support door-to-door after-sales service. 8. In order to effectivelysolve customer problems and help customers use the machine better, we will conduct skill assessments on our after-sales team every year.Lubrication system:Supply lubricating oil to increase the service life of linear slides and ball screws. Unique oil circuit design ensures the supply of lubricating oil at each oil filling point. Automatic tool calibration:Precisely detect the position of the tool calibration point, and automatically input the tool length data, which can quickly solve the correction and automatic calibration of the tool length for complex processing products, ensuring work efficiency. Industrial electric control box:The use of fan cooling cycle can effectively control the heat energy generated by the electric control box and prolong the service life of electrical parts. Adopt green environmental protection cable, anti-interference and long service life. Precision linear slides:The precision slide block is equipped with manual pressure centralized lubrication function, which can increase the service life of the linear slide rail. Bed frame:The whole bed adopts industrial seamless welding technology, and the bed is all quenched and stress-relieved to ensure that the long-term use accuracy of the equipment will not be lost. All the installation holes of the equipment are processed by a five-axis machining center at one time, which ensures the final assembly accuracy of the equipment. System (NK280):Support a variety of codes and carving processing formats, based on WINDOWS operating system, standard user interface, easy to operate. Support log function to help users view detailed processing information and system diagnosis High-precision rack and rail:Large bearing capacity, high transmission precision and low noise. The overall operation is stable and the actual effect is guaranteed.

1. 24/7 online service . 2. 2 years warranty for machine. 3. After sale office in differ country 4. Life time maintenance 5. Free online technical support and install train. 6. We have a professional and experienced after-sales team. 7. We support door-to-door after-sales service. 8. In order to effectivelysolve customer problems and help customers use the machine better, we will conduct skill assessments on our after-sales team every year.Lubrication system:Supply lubricating oil to increase the service life of linear slides and ball screws. Unique oil circuit design ensures the supply of lubricating oil at each oil filling point. Automatic tool calibration:Precisely detect the position of the tool calibration point, and automatically input the tool length data, which can quickly solve the correction and automatic calibration of the tool length for complex processing products, ensuring work efficiency. Industrial electric control box:The use of fan cooling cycle can effectively control the heat energy generated by the electric control box and prolong the service life of electrical parts. Adopt green environmental protection cable, anti-interference and long service life. Precision linear slides:The precision slide block is equipped with manual pressure centralized lubrication function, which can increase the service life of the linear slide rail. Bed frame:The whole bed adopts industrial seamless welding technology, and the bed is all quenched and stress-relieved to ensure that the long-term use accuracy of the equipment will not be lost. All the installation holes of the equipment are processed by a five-axis machining center at one time, which ensures the final assembly accuracy of the equipment. System (NK280):Support a variety of codes and carving processing formats, based on WINDOWS operating system, standard user interface, easy to operate. Support log function to help users view detailed processing information and system diagnosis High-precision rack and rail:Large bearing capacity, high transmission precision and low noise. The overall operation is stable and the actual effect is guaranteed.