Highly efficient CNC router for precision cutting and carving

By:Admin

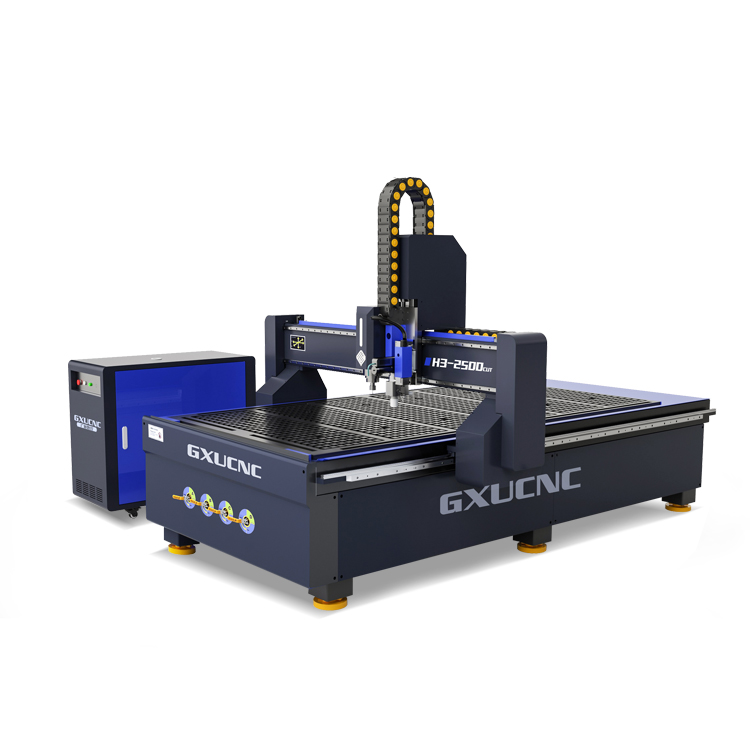

In today's fast-paced and competitive woodworking industry, companies are constantly looking for ways to improve efficiency, precision, and productivity. The 1325 CNC Router has emerged as a game-changing tool, enabling woodworking companies to achieve all of these goals and more. With its advanced technology and cutting-edge features, this innovative machine is revolutionizing the way wood products are manufactured.

The 1325 CNC Router, manufactured by a leading machinery company, is the result of years of research and development. This state-of-the-art machine is designed to handle a wide range of woodworking tasks, from cutting and carving to engraving and milling. Its high-performance spindle and precision servo motors ensure smooth and accurate operation, allowing woodworkers to create intricate and detailed designs with ease.

One of the key advantages of the 1325 CNC Router is its versatility. Whether working with wood, plastic, or even non-ferrous metals, this machine delivers exceptional results across a variety of materials. Its robust construction and durable components are built to withstand the demands of industrial production, making it a reliable and long-lasting investment for woodworking businesses of all sizes.

In addition to its exceptional performance, the 1325 CNC Router is also known for its user-friendly interface and intuitive controls. With its advanced software and easy-to-use touchscreen, operators can quickly program the machine for precise and efficient operation. This not only saves time and labor costs but also reduces the potential for errors, ensuring consistent quality in every finished product.

Furthermore, the 1325 CNC Router is equipped with a range of advanced features that further enhance its capabilities. Its automatic tool changer allows for seamless transitions between different cutting tools, while its dust extraction system helps maintain a clean and safe working environment. These features, along with others such as an automatic lubrication system and a machine frame that minimizes vibration, contribute to the overall efficiency and reliability of the machine.

The introduction of the 1325 CNC Router has had a significant impact on the woodworking industry, enabling companies to take on more complex and demanding projects with confidence. Its ability to produce high-quality and precise cuts has resulted in faster turnaround times and higher levels of customer satisfaction. In addition, its flexibility and adaptability have allowed woodworkers to explore new design possibilities and push the boundaries of creativity in their craft.

As a leading machinery company, we take great pride in providing our customers with the latest and most innovative solutions for their woodworking needs. The 1325 CNC Router represents a leap forward in the industry, offering unmatched performance, reliability, and versatility. With its advanced technology and user-friendly design, this machine is poised to become an essential tool for any woodworking operation looking to stay ahead of the competition.

In conclusion, the introduction of the 1325 CNC Router has ushered in a new era of possibilities for the woodworking industry. Its advanced capabilities and innovative features have empowered woodworkers to achieve higher levels of precision, productivity, and quality in their work. As the demand for custom and intricate wood products continues to grow, the 1325 CNC Router stands ready to meet the needs of the industry, providing a solid foundation for success in the years to come.

Company News & Blog

Top Heavy Duty CNC Router for Precision Woodworking and Metalworking

Heavy Duty CNC Router Redefining Precision and Efficiency in ManufacturingWith the continuous advancements in the manufacturing industry, the demand for precision and efficiency has never been higher. This is where the innovative Heavy Duty CNC Router from the highly reputable company, X, comes into play. X has been a leading provider of advanced manufacturing solutions for over 20 years, and their Heavy Duty CNC Router is yet another testament to their commitment to quality and performance.The Heavy Duty CNC Router from X is a game-changer in the manufacturing industry, offering unparalleled precision and efficiency for a wide range of applications. Whether it's woodworking, metal fabrication, plastic machining, or any other material, this CNC router is designed to handle the most demanding tasks with ease. Its heavy-duty construction and robust design make it ideal for high-speed and high-precision machining, making it a perfect fit for large-scale production facilities and small workshops alike.One of the key features of the Heavy Duty CNC Router is its advanced control system, which allows for precise control of the cutting process. This ensures that each workpiece is machined to exact specifications, without any compromise on accuracy or quality. The router is also equipped with a high-speed spindle, which enables rapid material removal and smooth surface finish, further enhancing the overall efficiency of the manufacturing process.Moreover, the Heavy Duty CNC Router is designed with user-friendly features that make it easy to operate and maintain. Its intuitive interface and comprehensive software package enable users to program and control the machine with ease, while its durable components and low-maintenance design ensure long-term reliability and minimal downtime. This means that manufacturers can maximize their productivity and minimize production costs, ultimately improving their bottom line.In addition to its cutting-edge technology and robust construction, the Heavy Duty CNC Router is backed by X's extensive customer support and service network. From installation and training to ongoing technical assistance and spare parts availability, X is dedicated to ensuring that their customers get the most out of their investment. This level of support gives manufacturers the confidence and peace of mind they need to fully leverage the capabilities of the CNC router and stay ahead of the competition.The Heavy Duty CNC Router has already garnered praise from industry professionals and customers alike. Its precise machining capabilities, high-speed performance, and user-friendly operation have made it a preferred choice for a wide range of manufacturing applications. Whether it's crafting intricate woodwork, fabricating complex metal parts, or producing custom plastic components, the CNC router has proven to be a reliable and indispensable tool for countless businesses.As manufacturing continues to evolve and demand for efficiency and quality increases, the Heavy Duty CNC Router from X remains at the forefront of innovation. Its ability to deliver precision, speed, and reliability sets a new standard for manufacturing equipment, empowering businesses to achieve greater productivity and success in their operations. With X's continued commitment to excellence and customer satisfaction, the Heavy Duty CNC Router is poised to redefine the future of manufacturing technology.

The Ultimate Guide to Wood Router CNC in 1530: Everything You Need to Know

FOR IMMEDIATE RELEASE:The revolutionary 1530 Wood Router CNC machine is set to make waves in the woodworking industry. With its advanced technology and precision engineering, this cutting-edge machine is poised to transform the way woodworkers and manufacturers operate.The 1530 Wood Router CNC is a game-changer in the woodworking industry, offering unparalleled accuracy and efficiency. This state-of-the-art machine is equipped with advanced features that streamline the production process and deliver exceptional results. Whether it's crafting custom furniture, intricate carvings, or precision cuts, this machine is designed to meet the demands of the modern woodworking industry.This innovative CNC machine is the brainchild of {}, a leading manufacturer of cutting-edge machinery. With a proven track record of delivering high-quality products, {} is committed to pushing the boundaries of innovation and excellence in the woodworking industry. The 1530 Wood Router CNC is the latest addition to their lineup of industry-leading equipment, and it's already generating buzz among woodworkers and manufacturers.What sets the 1530 Wood Router CNC apart is its unmatched precision and versatility. This machine is capable of handling a wide range of woodworking tasks with unprecedented accuracy, making it a valuable asset for businesses of all sizes. Its user-friendly interface and intuitive controls make it easy to operate, while its durable construction ensures reliable performance for years to come.In addition to its exceptional precision, the 1530 Wood Router CNC is designed to optimize efficiency and productivity. With its high-speed cutting capabilities and automated functions, this machine can significantly reduce production time and labor costs. This means woodworkers and manufacturers can complete projects faster and more efficiently, ultimately leading to increased profitability and customer satisfaction.The 1530 Wood Router CNC is also equipped with advanced safety features to protect operators and prevent accidents. With built-in safeguards and automatic shut-off mechanisms, this machine prioritizes the well-being of its users without compromising on performance. This demonstrates {}'s commitment to providing a safe and reliable solution for the woodworking industry.As the woodworking industry continues to evolve, the demand for cutting-edge technology has never been greater. The 1530 Wood Router CNC is positioned to meet this demand head-on, offering woodworkers and manufacturers a competitive edge in a constantly changing market. With its unmatched precision, efficiency, and safety features, this machine is set to revolutionize the way woodworking projects are executed.For businesses looking to invest in the future of woodworking, the 1530 Wood Router CNC is a game-changing solution. With its advanced technology and unparalleled performance, this machine is poised to elevate the standards of quality and efficiency in the woodworking industry. As {} continues to lead the way in innovation, the 1530 Wood Router CNC stands as a testament to their unwavering commitment to excellence.In conclusion, the 1530 Wood Router CNC is a groundbreaking machine that is set to redefine the woodworking industry. With its advanced technology, precision engineering, and commitment to safety, this innovative solution is poised to revolutionize the way woodworkers and manufacturers operate. As {} continues to push the boundaries of innovation, the 1530 Wood Router CNC stands as a testament to their dedication to delivering cutting-edge solutions for the woodworking industry.

Top High Power Laser Cutting Techniques for Precision Cutting

High Power Laser Cutting Technology Revolutionizing Industrial ManufacturingIn recent years, the industrial manufacturing sector has witnessed a significant transformation with the emergence of high power laser cutting technology. This innovative process allows for the precise and efficient cutting of a wide range of materials, including metals, plastics, and composites. The introduction of this advanced technology has not only revolutionized the manufacturing process but has also opened up new possibilities for the production of complex and intricate components.One company at the forefront of this technology revolution is [Company Name], a leading provider of cutting-edge laser cutting solutions. With a strong focus on innovation and continuous improvement, [Company Name] has been instrumental in driving the adoption of high power laser cutting across various industries. Their advanced laser cutting systems have set new standards for accuracy, speed, and reliability, making them a preferred choice for manufacturers looking to stay ahead in a competitive market.The key to the success of [Company Name]'s high power laser cutting technology lies in its state-of-the-art laser systems, which are designed to deliver exceptional performance and precision. These systems utilize advanced fiber laser technology, allowing for increased power output and beam quality, resulting in superior cutting capabilities. Additionally, the integration of advanced motion control and automation features ensures maximum efficiency and productivity, making [Company Name]'s laser cutting systems the ideal choice for high-volume production environments.One of the primary advantages of high power laser cutting is its ability to produce high-quality cuts with minimal material waste. Traditional cutting methods often result in significant material loss due to the imprecise nature of the process. However, high power laser cutting technology offers a more sustainable solution, allowing manufacturers to minimize material waste and optimize their production processes. This not only leads to cost savings but also contributes to the overall sustainability of the manufacturing industry.Another significant benefit of high power laser cutting is its versatility in handling a wide range of materials. Whether it's stainless steel, aluminum, carbon steel, or even non-metallic materials such as ceramics and plastics, [Company Name]'s laser cutting systems are capable of delivering clean, precise cuts with exceptional edge quality. This versatility has opened up new opportunities for manufacturers to explore innovative designs and material combinations, enabling them to meet the evolving demands of their customers.Furthermore, high power laser cutting has proven to be a game-changer in the production of complex and intricate components. The fine beam width and high cutting speeds of [Company Name]'s laser systems enable the accurate shaping and profiling of intricate designs, regardless of the material's thickness. This level of precision and flexibility has empowered manufacturers to take on challenging projects while maintaining the highest standards of quality and performance.In addition to its cutting-edge technology, [Company Name] has established itself as a trusted partner for its customers through its comprehensive service and support offerings. From initial consultation and system installation to ongoing maintenance and training, [Company Name] is dedicated to ensuring the success of its customers at every stage of the process. Their team of experienced engineers and technical experts are committed to providing tailored solutions that align with the unique needs and requirements of each customer, resulting in a seamless integration of high power laser cutting technology into their manufacturing operations.As the demand for high precision and efficient manufacturing continues to grow, the role of high power laser cutting technology is only set to become more prominent. With [Company Name] leading the way in driving innovation and excellence in laser cutting, the future of industrial manufacturing looks brighter than ever. By harnessing the power of high power laser cutting, manufacturers can expect to achieve unmatched levels of productivity, quality, and operational efficiency, positioning themselves at the forefront of their respective industries.In conclusion, high power laser cutting technology is redefining the manufacturing landscape, and [Company Name] is at the forefront of this revolution. With its cutting-edge laser systems and unwavering commitment to customer success, [Company Name] is empowering manufacturers to push the boundaries of what's possible, setting new standards for quality and performance in industrial manufacturing. As the world embraces the era of advanced manufacturing, high power laser cutting is undoubtedly a game-changer, and [Company Name] is leading the charge towards a future of limitless possibilities.

Top 10 Wood Routers to Consider for Your Carpentry Projects

[Company] Unveils Innovative Wood Router for DIY Enthusiasts[City, State – Date] – Woodworking enthusiasts can now enjoy the benefits of [Company]'s latest innovation – the powerful and versatile wood router. With decades of experience in the industry, [Company] has a reputation for delivering high-quality and reliable tools for both professionals and hobbyists. The new wood router is set to revolutionize the woodworking experience with its advanced features and user-friendly design.The wood router is designed to meet the needs of both beginner and experienced woodworkers, offering a range of features that make it easy to use and highly efficient. Its powerful motor and precision cutting capabilities make it perfect for a wide range of woodworking projects, from simple household repairs to intricate furniture making. The variable speed control allows users to adjust the router's performance to suit the demands of different materials and tasks, ensuring clean and precise cuts every time.In addition to its performance, the wood router is also designed with user comfort and safety in mind. The ergonomic handle and smooth operation reduce fatigue during extended use, while the built-in safety features provide added peace of mind for users. With [Company]'s commitment to quality and durability, users can rely on the router to deliver outstanding performance for years to come.“Our goal is to empower woodworking enthusiasts with the tools they need to bring their creative ideas to life,” said [Spokesperson], [Company]'s spokesperson. “With our new wood router, we are providing a versatile and reliable tool that will enhance the woodworking experience for both professionals and hobbyists. We are confident that this innovation will set a new standard for wood routers in the industry.”Aside from its technical specifications, the wood router also features a sleek and modern design, reflecting [Company]'s dedication to both functionality and aesthetics. The router's compact and lightweight build makes it easy to handle and store, while its high-quality construction ensures long-term performance.The launch of the wood router marks another milestone for [Company], as it continues to expand its range of innovative and high-performance tools. With a strong focus on research and development, [Company] is committed to pushing the boundaries of what is possible in the industry, striving to create tools that meet the evolving needs of its customers.The wood router is now available for purchase through [Company]'s authorized retailers and online stores, offering woodworking enthusiasts easy access to this game-changing tool. As a leading provider of woodworking tools, [Company] aims to support its customers with excellent customer service and reliable after-sales support, ensuring that they can make the most of their new wood router.For woodworking enthusiasts looking to elevate their craft, the new wood router from [Company] offers a compelling solution that combines performance, user-friendliness, and value. With its innovative features and stylish design, this wood router is set to become an essential tool for DIY enthusiasts and professional woodworkers alike.For more information about the wood router and other products from [Company], visit [Company]'s website or contact their customer service team at [contact information].[Company] is a leading manufacturer of high-quality and innovative woodworking tools, serving a diverse range of customers around the world. With a commitment to excellence and customer satisfaction, [Company] continues to push the boundaries of what is possible in the industry, delivering reliable tools that empower woodworking enthusiasts to bring their creative ideas to life.

High-Quality CNC Wood Cutting Machine for Precision and Efficiency

In an era of technological advancement, the demand for precision and efficiency in woodworking has led to the development of innovative machinery. The introduction of Computer Numerical Control (CNC) wood cutting machines has revolutionized the woodworking industry, offering unmatched accuracy and speed in wood cutting and carving processes. One of the leading manufacturers in this industry, {} has continuously set new benchmarks with its cutting-edge CNC wood cutting machines.The company has been at the forefront of technological innovation with a strong focus on research and development. With a legacy of over 20 years, the company has consistently delivered high-quality, reliable, and efficient CNC wood cutting machines to its global customer base. Its commitment to excellence and customer satisfaction has made it a trusted name in the woodworking machinery industry.The CNC wood cutting machines offered by {} are equipped with advanced features that enable precise and intricate wood cutting, shaping, and carving. The machines are designed to meet the diverse needs of woodworking professionals, from small-scale artisans to large-scale production facilities. With high-performance spindles, robust frames, and state-of-the-art control systems, these machines offer unparalleled accuracy and efficiency in wood processing.One of the key advantages of {}'s CNC wood cutting machines is their ability to automate the woodworking process, reducing manual labor and improving productivity. The integration of computer control allows for the creation of intricate designs with utmost precision, ensuring the highest quality output. This level of automation not only saves time and labor costs but also minimizes material wastage, making it an environmentally sustainable option for wood processing.Moreover, {} provides comprehensive training and technical support to its customers, ensuring that they can maximize the potential of their CNC wood cutting machines. The company's team of skilled technicians and engineers are dedicated to offering prompt assistance and maintenance services, minimizing downtime and ensuring uninterrupted production.The application of CNC wood cutting machines extends beyond traditional woodworking, finding utility in diverse industries such as furniture manufacturing, cabinetry, and architectural millwork. The precision and versatility of these machines make them indispensable for creating custom designs and intricate patterns, meeting the ever-evolving demands of the market.As the global woodworking industry continues to evolve, {} remains committed to pushing the boundaries of innovation and technological advancement in CNC wood cutting machines. By leveraging its expertise and experience, the company strives to address the evolving needs of the woodworking industry by introducing new and advanced solutions that set new standards in precision, efficiency, and reliability.With a strong emphasis on quality, performance, and customer satisfaction, {} has established itself as a pioneer in the manufacturing of CNC wood cutting machines. The company's dedication to excellence and its relentless pursuit of innovation continue to drive the woodworking industry forward, setting new benchmarks and shaping the future of wood processing.In conclusion, the CNC wood cutting machines offered by {} represent a paradigm shift in woodworking technology, ushering in a new era of precision and efficiency. With their advanced features, unmatched accuracy, and versatile applications, these machines are poised to transform the woodworking industry, offering new possibilities for creativity and productivity. As the demand for high-quality, automated wood processing solutions continues to grow, {} remains at the forefront, leading the way with its cutting-edge CNC wood cutting machines.

High-Quality Aluminum for CNC Milling: What You Need to Know

Aluminum For CNC Milling: The Perfect Material for Precision EngineeringCNC milling is a crucial process in the manufacturing industry. It involves the use of computer-aided design (CAD) software to program milling machines and create precise and complex parts from various materials. One material that has proven to be highly effective for CNC milling is aluminum. Its high strength-to-weight ratio, machinability, and corrosion resistance make it an ideal choice for precision engineering projects.Aluminum is a non-ferrous metal that is widely used in the aerospace, automotive, and electronics industries. Its unique properties make it a perfect choice for CNC milling applications. The material is known for its exceptional strength, which allows for the creation of intricate and detailed parts. Additionally, aluminum is lightweight, making it an excellent choice for components that require a high strength-to-weight ratio.One company that has perfected the art of CNC milling aluminum is {}. With years of experience in precision engineering and CNC machining, they have established themselves as a leader in the industry. Their state-of-the-art facility is equipped with the latest CNC milling machines and a team of highly skilled engineers and machinists, allowing them to handle even the most complex projects with ease.The company's expertise in working with aluminum for CNC milling is unparalleled. They understand the unique properties of the material and have developed specialized techniques to ensure the highest quality and precision in their finished products. Whether it's creating intricate components for the aerospace industry or producing custom parts for the automotive sector, {} has the knowledge and capabilities to deliver exceptional results.In addition to its strength and machinability, aluminum is also known for its excellent corrosion resistance. This makes it an ideal choice for parts that will be exposed to harsh environmental conditions. Whether it's for outdoor applications or components that come into contact with chemicals and other corrosive substances, aluminum's resistance to corrosion ensures the longevity and reliability of the finished parts.Furthermore, aluminum is a highly versatile material that can be easily customized to meet specific project requirements. It can be anodized, painted, or coated to enhance its appearance and improve its performance. This flexibility makes it an excellent choice for a wide range of applications, from consumer electronics to industrial machinery.{}'s commitment to quality and innovation sets them apart in the industry. They are constantly investing in the latest technology and equipment to ensure that they can meet the evolving needs of their customers. Their dedication to excellence is evident in the precision and intricacy of the parts they produce, making them a trusted partner for companies looking for reliable and high-quality CNC-machined components.In conclusion, aluminum is the perfect material for CNC milling due to its exceptional strength, lightweight properties, and corrosion resistance. When combined with the expertise and capabilities of a company like {}, the result is precision-engineered parts that meet the highest standards of quality and performance. With their commitment to innovation and excellence, {} continues to be a leader in the industry, providing customized solutions for a wide range of applications.

Discover the Latest Innovation in Acrylic Cutting with Fiber Laser Technology

Title: Revolutionizing Acrylic Cutting: Fiber Laser Technology Leads the WayIntroduction:In recent news, the cutting-edge technique of fiber laser cutting has emerged as a game-changer in the acrylic industry. With its ability to precisely cut acrylic materials with unparalleled accuracy and efficiency, fiber laser cutting has revolutionized the manufacturing and design processes for acrylic products. This article aims to delve into the world of fiber laser cutting and its impact on the acrylic industry, showcasing its benefits and potential applications.What is Fiber Laser Cutting?Fiber laser cutting is a technology that utilizes a high-powered laser beam to cut through various materials, including acrylics. Unlike conventional laser cutting methods, fiber laser cutting employs a solid-state laser source that uses optical fibers to generate and deliver the laser beam to the cutting head. This approach allows for enhanced cutting speeds, higher precision, and improved cost-efficiency.The Company Leading the Way:Headquartered in {Company's location}, {Company's name} has emerged as one of the leading industry players in the application of fiber laser cutting technology. With extensive experience in materials processing and a commitment to innovation, {Company's name} has pioneered advancements in acrylic cutting, providing customers with unparalleled solutions for their manufacturing needs. By leveraging the power of fiber laser cutting, the company has propelled acrylic processing to new heights.Benefits of Fiber Laser Cutting Acrylic:1. Precise and Intricate Cuts: Fiber laser cutting enables the production of intricate designs, detailed engravings, and smooth edges on acrylic material, ensuring high-quality finished products.2. High Speeds: Fiber lasers boast exceptional cutting speeds, resulting in improved production efficiency and reduced lead times. This allows manufacturers to meet increasing demand and stay competitive in the market.3. Minimal Material Waste: Fiber laser cutting maximizes material utilization due to precise cutting paths. This not only reduces raw material costs but also promotes sustainability by minimizing waste generation.4. Versatility: Fiber laser cutting technology is highly versatile, capable of cutting acrylic sheets of various thicknesses (up to a certain limit) with equal precision. This versatility empowers manufacturers to explore new design possibilities and expand their product offerings.Potential Applications:The applications of fiber laser cutting in the acrylic industry are vast and diverse. They include but are not limited to:1. Signage and Displays: Fiber laser cutting allows for the fabrication of intricate letters, logos, and shapes for signage and advertising displays, ensuring eye-catching and visually appealing end products.2. Architectural Components: From decorative elements to functional components like windows and dividers, fiber laser cutting enables the creation of custom-designed acrylic pieces that add a touch of elegance to both residential and commercial buildings.3. Acrylic Jewelry and Accessories: Jewelry designers have embraced fiber laser cutting to craft unique and intricate acrylic statement pieces, exploring diverse shapes and patterns that cater to individual tastes.4. Electronics and Industrial Components: Fiber laser cutting ensures precise and consistent shapes for intricate electronic parts and industrial components, providing manufacturers with the accuracy required for seamless integration and functionality.Conclusion:In summary, fiber laser cutting technology has ushered in a new era in acrylic cutting, as its numerous advantages continue to reshape the manufacturing landscape. With enhanced precision, increased production speeds, reduced material waste, and its versatility, fiber laser cutting offers limitless possibilities for the acrylic industry. As companies like {Company's name} lead the way, the future of acrylic cutting looks promising, paving the path for exceptional quality, beautiful designs, and efficient manufacturing processes.

New CO2 Laser Cutting Machine Revolutionizes Manufacturing Processes

[Company Introduction][Company name], a renowned leader in the laser cutting industry, has recently launched its latest product, the CNC CO2 Laser Cutting Machine. With years of experience and expertise in manufacturing high-quality laser cutting equipment, [Company name] continues to revolutionize the industry with its cutting-edge technology and innovative solutions.The CNC CO2 Laser Cutting Machine is a powerful tool that offers precision cutting, accuracy, and high efficiency for various materials, including metals, plastics, wood, and more. With its advanced CO2 laser technology, this cutting-edge machine provides users with unmatched capabilities to handle a wide range of cutting applications. From intricate designs to large-scale productions, this machine guarantees exceptional results.[Company name]'s commitment to delivering excellence can be seen through its use of high-quality components and advanced systems. The CNC CO2 Laser Cutting Machine is equipped with the latest motion control technology, ensuring smooth and precise movements during the cutting process. The machine's excellent stability and durability enable users to achieve consistent, high-quality cuts with minimal wastage.Furthermore, the CNC CO2 Laser Cutting Machine is designed with user-friendly features that streamline the overall cutting process. Its intuitive control panel allows operators to easily navigate and adjust settings, ensuring maximum productivity and efficiency. The machine's automatic material detection and focusing system further enhance its usability, making it ideal for both experienced professionals and beginners.The versatility of the CNC CO2 Laser Cutting Machine is another standout feature. With its wide variety of compatible materials, businesses from various industries can benefit from its capabilities. Whether for signage, automotive parts, prototype development, or any other cutting needs, this machine offers the flexibility to meet diverse requirements. Its precise cutting also reduces the need for further finishing processes, saving time and resources.In addition to its exceptional performance, the CNC CO2 Laser Cutting Machine prioritizes user safety. It is built with comprehensive safety features, including protective enclosures and sensors that prevent accidental exposure to the laser beam. This ensures a secure working environment for operators.[Company name] stands apart from its competitors through its commitment to customer satisfaction. The company is known for its excellent customer service, providing comprehensive technical support, training, and after-sales maintenance. Customers can rely on their expertise throughout the entire lifecycle of their CNC CO2 Laser Cutting Machine.The launch of the CNC CO2 Laser Cutting Machine marks another milestone for [Company name] as it continues to innovate and excel in the laser cutting industry. The machine's exceptional capabilities, user-friendly design, and commitment to safety make it the ideal choice for businesses looking to enhance their cutting operations.With [Company name]'s CNC CO2 Laser Cutting Machine, businesses can expect increased productivity, improved precision, and cost-effective cutting solutions. By investing in this state-of-the-art technology, users can stay ahead in today's competitive market and achieve remarkable results in their cutting applications.About [Company name]:[Company name] is a leading manufacturer in the laser cutting industry, specializing in the production of high-quality laser cutting machines for various materials. With years of experience, advanced technology, and a commitment to customer satisfaction, the company continues to deliver cutting-edge solutions that exceed expectations. For more information about [Company name] and its products, visit [company website].

Top Wood Cross Cutting Machine: Enhance Efficiency and Precision with Advanced Technology

Title: Innovative New Wood Cutting Machine Revolutionizes the IndustryIntroduction:In a breakthrough development, a cutting-edge cross-cutting machine for wood has been introduced to the market, promising to enhance efficiency and precision in the woodworking industry. This innovative piece of machinery, developed by an industry-leading company, is set to revolutionize the way timber is processed, offering significant advantages over traditional methods. By adapting the latest technology and incorporating intelligent features, this machine is poised to optimize productivity while reducing waste and increasing overall profitability for woodworkers. Let's delve deeper into the magical world of this groundbreaking cross-cutting machine.Cutting-Edge Features:The new wood cross-cutting machine boasts a plethora of state-of-the-art features that make it stand out from its competition. Equipped with advanced laser guidance, it ensures unparalleled accuracy in timber cutting, minimizing errors and increasing the quality of end products. Additionally, its intuitive digital control panel simplifies the operation, making it user-friendly for both seasoned professionals and novice woodworkers.The machine is designed to perform swift and precise cross-cuts, catering to various wood types and thicknesses. Its cutting efficiency is magnified by a high-speed rotating blade assembly that offers clean and seamless cuts, reducing the need for additional finishing processes. The innovative design of the machine maximizes productivity by enabling continuous cutting, minimizing downtime, and enhancing throughput.Furthermore, safety has been given prime importance during the machine's design. Equipped with advanced safety sensors, the machine ensures swift shutdown in case of any anomalies, preventing accidents and mitigating potential risks. With such safety measures in place, woodworkers can operate the machinery with peace of mind, focusing solely on producing outstanding results.Improved Efficiency and Cost-Effectiveness:The introduction of this cross-cutting machine is set to significantly boost the productivity of woodworking businesses. By minimizing wastage in material through precise cuts, woodworkers can optimize the utilization of their resources, thus reducing costs. The digital control panel allows for quick adjustments, saving valuable time that would have otherwise been spent in manual calibration.Additionally, the machine's high throughput capabilities ensure that projects are completed in shorter time periods, enabling businesses to take more orders and increase revenue. By streamlining the cutting process, it facilitates greater workflow and allows woodworkers to meet the demands of a rapidly expanding market. The introduction of this cutting-edge machine will prove to be a game-changer for wood processing businesses, offering them a competitive edge in the industry.Environmental Considerations:With a growing focus on sustainability, the new cross-cutting machine emphasizes reducing waste and promoting environmentally friendly practices. By delivering crisp and accurate cuts, it minimizes material wastage, resulting in substantial savings of timber resources. Moreover, the machine's energy-efficient design reduces power consumption significantly, contributing to lower overall carbon emissions.Conclusion:The introduction of the cross-cutting machine for wood by an industry-leading company promises a revolution within the woodworking sector. With its advanced features, including laser guidance, digital control panel, and superior cutting efficiency, this machine ensures precision and accuracy, optimizing productivity and redefining industry standards. Its user-friendly design and enhanced safety mechanisms make it an ideal choice for woodworkers of all skill levels. Furthermore, its capability to reduce wastage, increase efficiency, and promote environmental sustainability make it truly ahead of its time. The woodworking industry can now embrace this innovative machine to achieve higher profitability, improved product quality, and reduced environmental impact.