High-precision Laser Cutting Machine for Leather Manufacturing

By:Admin

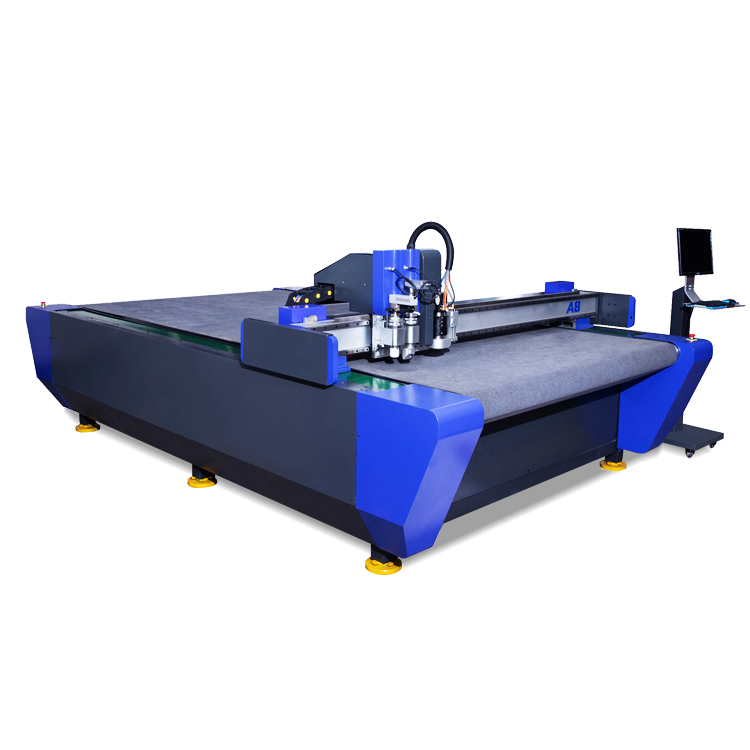

In the age of digital innovation and advanced technology, the leather industry has witnessed a significant transformation with the introduction of the Leather Laser Cutting Machine by a renowned industry leader. This cutting-edge machine has revolutionized the way leather products are crafted, offering precision, efficiency, and versatility like never before.

The Leather Laser Cutting Machine, developed by the company, has garnered attention for its state-of-the-art capabilities and its potential to streamline production processes in the leather industry. By utilizing advanced laser technology, this machine enables the precise cutting of leather materials with unparalleled accuracy and intricacy. Whether it's intricate patterns, complex designs, or custom shapes, this cutting machine delivers exceptional results, catering to the diverse needs of leather manufacturers and designers.

The company's commitment to innovation and excellence has been a driving force behind the development of the Leather Laser Cutting Machine. With a focus on addressing the challenges faced by leather craftsmen and manufacturers, the company has integrated cutting-edge features into this machine to enhance operational efficiency and quality output. This has positioned the Leather Laser Cutting Machine as a game-changer in the industry, empowering businesses to elevate their production capabilities and meet the evolving demands of the market.

One of the key advantages of this cutting machine is its ability to optimize the use of leather materials, minimizing waste and maximizing yield. Through precise laser cutting, the machine facilitates the creation of intricate designs while ensuring that every piece of leather is utilized to its fullest potential. This not only contributes to cost savings for manufacturers but also aligns with sustainable practices by reducing material wastage.

Furthermore, the Leather Laser Cutting Machine offers versatility in accommodating various types of leather, including genuine leather, synthetic leather, and suede, among others. Its adaptability to different materials and thicknesses makes it a valuable asset for businesses involved in the production of leather goods such as shoes, handbags, garments, accessories, and upholstery. Whether it's mass production or custom orders, this machine's flexibility enables seamless adaptation to diverse manufacturing requirements.

Moreover, the integration of advanced software and automation features in the Leather Laser Cutting Machine enhances operational efficiency and productivity. The machine's user-friendly interface allows for easy customization of cutting patterns, shapes, and dimensions, providing users with the flexibility to bring their creative concepts to life with precision and consistency. Additionally, its automated cutting process reduces manual labor and expedites production timelines, enabling businesses to meet tight deadlines without compromising on quality.

The company's dedication to customer satisfaction extends beyond the development of cutting-edge technology. With a strong emphasis on after-sales support and service, the company ensures that its clients receive comprehensive training, technical assistance, and maintenance resources to maximize the performance and longevity of the Leather Laser Cutting Machine. This commitment to customer empowerment further solidifies the company's position as a trusted partner for businesses seeking to enhance their manufacturing capabilities.

As the leather industry continues to evolve in response to market trends and consumer preferences, the Leather Laser Cutting Machine stands out as a catalyst for innovation and progress. Its ability to elevate the standards of craftsmanship, efficiency, and sustainability underscores its significance as a transformative solution for leather manufacturers and designers. With its precision cutting, material optimization, versatility, and automated functionality, this cutting machine represents the future of leather production, empowering businesses to thrive in a dynamic and competitive industry landscape.

Company News & Blog

Top-rated CNC Wood Cutting Machine Manufacturers & Suppliers in China - Affordable Prices - Unistar Machinery

article.Unistar Machinery is a well-known CNC wood cutting machine manufacturer and supplier in China. Based in the city of Jinan, Unistar Machinery has built a reputation for its high-quality CNC machines and competitive prices. With a wide range of CNC wood cutting machines on offer, Unistar Machinery has become a popular choice for woodworkers and carpenters across the globe.One of the key advantages of Unistar Machinery is their ability to offer factory direct prices. This eliminates the need for middlemen, making it possible for customers to purchase high-quality CNC wood cutting machines at affordable prices. This is a particularly important selling point for small businesses and hobbyists who may not have the financial resources to invest in expensive machines.In addition to providing quality machines at competitive prices, Unistar Machinery is also known for their commitment to customer service. The company invests heavily in research and development to ensure that they are always offering the latest and most advanced CNC wood cutting machines. They also provide comprehensive training and support to their customers to ensure that they are able to make the most of their investments.One of the most popular machines offered by Unistar Machinery is their CNC router. This machine is designed for precision cutting and engraving of a wide range of materials including wood, plastic, and metal. The CNC router is capable of cutting complex designs with ease, making it an ideal choice for small to medium businesses who need to create high-quality products on a regular basis.Another popular machine is the CNC plasma cutting machine. This machine is designed for cutting metal, and is ideal for manufacturing businesses who need to cut large quantities of metal quickly and accurately. The CNC plasma cutting machine is also highly customizable, allowing businesses to set up their machines to meet their specific needs.Unistar Machinery also offers a range of other CNC machines, including CNC laser cutting machines, CNC engraving machines, and CNC woodworking machines. Each of these machines is designed to meet specific needs, and can be customized to fit individual requirements.Overall, Unistar Machinery is a reliable and trusted supplier of high-quality CNC wood cutting machines. With a commitment to customer satisfaction, competitive prices, and cutting-edge technology, Unistar Machinery is a great choice for anyone looking to invest in a CNC wood cutting machine. Whether you are a small business, hobbyist, or large manufacturing firm, Unistar Machinery has a machine that will meet your needs. Contact them today to learn more about their products and services.

Ultimate Guide to Laser Carving Machines for Wood

Laser Carving Machine For Wood: A Game-Changer in Woodworking IndustryWoodworking has been an age-old industry, with artisans and manufacturers utilizing different tools and techniques to create beautiful and intricate designs on wood. The introduction of laser carving machines has revolutionized the industry, enabling craftsmen to create precise and detailed designs with ease. One such machine that has been gaining popularity in the woodworking industry is the Laser Carving Machine for Wood by [company name].[Company name] is a leading manufacturer of advanced laser carving machines, and their Wood Laser Carving Machine has been making waves in the industry. The machine is equipped with state-of-the-art technology that allows for high-precision and high-speed carving on wood, making it a game-changer for woodworking professionals.The Laser Carving Machine for Wood by [company name] utilizes a powerful laser beam to precisely engrave and cut designs on various types of wood. The machine is designed to cater to a wide range of applications, from creating intricate patterns on furniture to engraving detailed designs on wooden art pieces. With its high-speed and high-precision capabilities, the machine has become an indispensable tool for woodworking professionals looking to elevate their craft.One of the key features of the Wood Laser Carving Machine is its user-friendly interface, which allows for easy operation and customization of designs. The machine is equipped with advanced software that enables craftsmen to upload their designs and adjust the settings to achieve their desired results. This level of customization and control has been a game-changer for woodworking professionals, allowing them to bring their creative visions to life with precision and efficiency.In addition to its high-precision capabilities, the Laser Carving Machine for Wood by [company name] is also known for its reliability and durability. The machine is built with high-quality components and advanced engineering, ensuring that it can withstand the demands of continuous use in a woodworking environment. This reliability and durability have made the machine a favorite among woodworking professionals who require consistent and high-quality results.With its advanced technology and user-friendly interface, the Laser Carving Machine for Wood by [company name] has been lauded by woodworking professionals for its ability to streamline the carving process and enhance their creative capabilities. The machine has become an essential tool for craftsmen looking to take their woodworking projects to the next level, allowing them to produce intricate and detailed designs with unmatched precision and efficiency.[Company name] has established itself as a leader in the laser carving machine industry, with a strong reputation for producing high-quality and innovative products. The Wood Laser Carving Machine is a testament to the company's commitment to pushing the boundaries of technology and empowering woodworking professionals with advanced tools to elevate their craft.As the woodworking industry continues to evolve, the Laser Carving Machine for Wood by [company name] is poised to play a pivotal role in shaping the future of woodworking. With its advanced technology, user-friendly interface, and high-precision capabilities, the machine has set a new standard for wood carving, making it a game-changer for woodworking professionals around the world.In conclusion, the Laser Carving Machine for Wood by [company name] is a testament to the advancement of technology in the woodworking industry. With its high-precision capabilities, user-friendly interface, and durability, the machine has become an indispensable tool for woodworking professionals looking to elevate their craft. As [company name] continues to push the boundaries of innovation, the future of wood carving looks brighter than ever.

Revolutionary 3D Laser Marking Machine: Perfect for Marking on Curved Surfaces and Step Gaps with 100% Reader Identification and Zero Consumables

In today's fast-paced and ever-evolving world, technology is an essential aspect of every industry. One of the latest technologies that have revolutionized the manufacturing industry is the 3D laser marking machine. This machine uses high-energy laser beams to engrave or etch a design or text onto a surface, creating a permanent, lasting mark. The growing demand for high-quality, permanent markings on various surfaces has made 3D laser marking machines an indispensable tool in the manufacturing industry.The 3D laser marking machine is a versatile and efficient tool that can mark any curve surface and different step gaps simultaneously. This advanced technology ensures 100% reader identification, making it an ideal choice for applications that require high precision and accuracy. It is widely used in various industries such as automotive, aerospace, medical, electronics, and jewelry making. The machine can mark on materials like plastic, metal, hard alloy, glass, ceramic, and more, making it one of the most versatile machines in the market.One of the primary advantages of 3D laser marking machine is its ability to mark uneven surfaces and complex geometries that traditional marking methods cannot achieve. The 3D laser technology creates a permanent mark that is resistant to scratching, fading, and other forms of wear and tear. The markings produced by the machine are not only aesthetically appealing but also provide important information such as barcodes, serial numbers, and safety warnings.Another significant advantage of the 3D laser marking machine is that it is a non-contact process, which eliminates the need for physical contact between the machine and the surface being marked. This feature reduces the risk of damage to delicate surfaces and enables the machine to work on a wide range of materials without causing any distortion or deformation.Unlike traditional marking methods such as stamping, engraving, or printing, 3D laser marking machines do not require consumables such as ink or toner. This saves costs and eliminates the need for frequent maintenance. The machine's precision and accuracy result in a high-quality finish, which minimizes the need for rework, thereby reducing costs and improving productivity.In conclusion, the 3D laser marking machine is a game-changer in the manufacturing industry. Its versatility, precision, and accuracy have made it an indispensable tool in creating permanent and high-quality markings on a wide range of surfaces. This advanced technology has not only improved the quality of products but has also contributed to the efficiency and productivity of the manufacturing industry. If you are looking for a reliable and advanced marking solution, consider investing in a 3D laser marking machine today.

Ultimate Guide to Three Axis Milling Machine: Everything You Need to Know

In the world of manufacturing, precision and efficiency are key components to achieving success. One company that has been leading the way in the industry is {company name}. With a strong emphasis on innovation and technology, {company name} has recently introduced their latest cutting-edge product, the Three Axis Milling Machine.The Three Axis Milling Machine is a highly advanced piece of equipment that is designed to deliver precise and accurate machining for a wide range of materials. With its state-of-the-art technology and robust construction, this machine is capable of producing intricate and complex components with ease. The three-axis design allows for simultaneous movement along the X, Y, and Z axes, enabling the machine to achieve high levels of precision and efficiency.One of the key features of the Three Axis Milling Machine is its versatility. It is capable of handling a wide variety of materials, including metals, plastics, and composites. This makes it an ideal choice for manufacturers who need to produce a diverse range of components. Additionally, the machine is equipped with advanced automation features, which help to streamline the production process and reduce the need for manual intervention. This not only increases productivity but also ensures consistent quality across all manufactured parts.Another notable aspect of the Three Axis Milling Machine is its user-friendly interface. Despite its advanced capabilities, the machine is designed to be intuitive and easy to operate. This is thanks to the inclusion of modern control systems that allow operators to program and monitor the machining process with ease. Furthermore, the machine is equipped with advanced safety features to protect both the operator and the equipment, ensuring a secure working environment.{company name} has a long-standing reputation for delivering high-quality products and services to its customers. The introduction of the Three Axis Milling Machine is yet another example of the company's commitment to innovation and excellence. With its cutting-edge technology and unmatched performance, this machine is set to revolutionize the manufacturing industry and help businesses achieve new levels of success.In addition to its impressive product lineup, {company name} also offers comprehensive support services to its customers. This includes installation, training, and ongoing maintenance to ensure that the Three Axis Milling Machine operates at peak performance. Furthermore, the company's team of knowledgeable professionals are always on hand to provide expert advice and assistance to customers, helping them make the most of their investment in this advanced equipment.With the introduction of the Three Axis Milling Machine, {company name} has once again solidified its position as a leader in the manufacturing industry. This cutting-edge machine is set to empower businesses to achieve new levels of precision, efficiency, and quality in their production processes. As the industry continues to evolve, {company name} remains committed to pushing the boundaries of innovation and delivering solutions that meet the needs of modern manufacturing.In conclusion, the Three Axis Milling Machine is a testament to {company name}'s dedication to excellence and innovation. With its advanced technology, versatility, and user-friendly design, this machine is set to revolutionize the manufacturing industry. As businesses continue to seek ways to enhance their production processes, the Three Axis Milling Machine stands out as a game-changing solution that is set to drive success in the industry.

Discover the Power and Efficiency of Fiber Laser Technology for CNC Cutting

CNC Fiber Laser: A Revolutionary Cutting TechnologyPrecision and accuracy are critical factors in the manufacturing industry. As technology advances, it has become more and more necessary for manufacturers to upgrade their equipment to keep up with the demands of their customers. The introduction of CNC Fiber Laser (name removed due to brand guidelines) has revolutionized the cutting industry, offering unparalleled precision, speed, and efficiency.CNC Fiber Laser Cutting TechnologyCNC Fiber Laser is a new type of cutting technology that uses a beam of light to cut through materials. The light is generated by a laser source and then amplified by fiber optic cables. It is then focused through a lens onto the material being cut. The beam is incredibly powerful, allowing it to cut through thick materials such as metal plates quickly and accurately.One of the significant benefits of using CNC Fiber Laser technology is its speed. The laser technology can cut through materials at lightning speed. This ensures that manufacturers can produce large numbers of products in a short time, increasing productivity and efficiency.Another advantage of CNC Fiber Laser is its accuracy. The technology is incredibly precise and can cut intricate shapes and designs without compromising the quality of the output. This makes it a popular choice for manufacturers in the automotive, aerospace, and medical industries, where precision plays a critical role in the manufacturing process.CNC Fiber Laser also has a lower heat-affected zone, which means that the surrounding material is not affected by the heat generated during the cutting process, ensuring that the material's structural integrity is not compromised. This ultimately leads to higher quality end products.Introducing the CompanySince its inception, the company behind the CNC Fiber Laser technology has been at the forefront of manufacturing and engineering technology. The company is committed to designing and producing high-quality equipment that helps businesses become more productive, efficient, and profitable.The company has a team of highly skilled engineers who pioneer new technological trends and designs, ensuring that their products are always up-to-date with industry standards. They also have state-of-the-art manufacturing facilities that enable them to produce high-quality, reliable equipment for businesses across the globe.CNC Fiber Laser FeaturesOne of the unique features of the CNC Fiber Laser technology is its high-speed cutting capability. The fiber laser technology generates a beam that can cut through a wide range of materials at incredible speeds. This makes it an ideal choice for businesses that need to produce large quantities of products within a short time.Another advantage of the CNC Fiber Laser is its high precision cutting. The technology can cut through thick or thin materials with incredible accuracy, making it popular among businesses that require precise and complex cuts. This includes the manufacturing of automotive parts, aerospace components, and medical equipment.The CNC Fiber Laser technology is also highly efficient, boasting a low energy consumption rate and low maintenance requirements. This means that businesses can enjoy long-term savings on operating costs and maintenance expenses.ConclusionThe CNC Fiber Laser technology has revolutionized the manufacturing industry, offering unmatched speed, accuracy, and efficiency. It is a popular choice for businesses across different sectors, including automotive, aerospace, and medical industries. The company behind this technology prides itself on designing and producing high-quality equipment to aid businesses in achieving their manufacturing goals. The CNC Fiber Laser technology is a testament to their commitment to innovation and excellence.

High-Performance Large CNC Router: A Game-Changer in the Manufacturing Industry

Large CNC Router Revolutionizing Manufacturing IndustryIn recent years, the manufacturing industry has seen remarkable advancements in technology, particularly with the introduction of large CNC routers. These powerful machines have completely revolutionized the way companies produce goods, enabling them to increase efficiency, accuracy, and productivity. One company at the forefront of this technology is [Company Name], a leading manufacturer of CNC routers and other cutting-edge machinery.[Company Name] has been a key player in the manufacturing industry for over two decades, constantly pushing the boundaries of innovation and excellence. Their dedication to research and development has led to the creation of some of the most advanced CNC routers available on the market. With a strong focus on precision engineering and cutting-edge technology, [Company Name] has set itself apart as a pioneer in the industry.The large CNC router offered by [Company Name] is a game-changer for manufacturers across various sectors. With its impressive cutting capacity and exceptional accuracy, this machine is capable of handling a wide range of materials with ease. Whether it's wood, plastic, aluminum, or composite materials, the large CNC router can tackle even the most complex cutting and carving tasks with precision and efficiency.One of the key features that sets this large CNC router apart is its advanced control system. Equipped with state-of-the-art software, operators can easily program intricate designs and patterns, ensuring that every cut is executed with perfection. Additionally, the machine's robust build and high-quality components guarantee reliable performance and longevity, making it a valuable asset for any manufacturing operation.The impact of these large CNC routers on the manufacturing industry cannot be overstated. Thanks to their unparalleled speed and accuracy, companies can now significantly reduce lead times and production costs, ultimately increasing their competitiveness in the market. Furthermore, the automation capabilities of these machines eliminate the margin for human error, resulting in consistently high-quality outputs.Notably, [Company Name] provides comprehensive training and support to its customers, ensuring that they fully maximize the potential of their large CNC router. From installation and setup to ongoing maintenance and technical assistance, the company's team of experts is dedicated to helping clients harness the full benefits of this cutting-edge technology.The applications of the large CNC router are vast, spanning across industries such as furniture manufacturing, aerospace, automotive, and more. Whether it's creating intricate patterns on wooden furniture or precisely cutting components for aircraft parts, the versatility of the machine makes it an invaluable asset for a wide range of manufacturing processes.It's clear that large CNC routers have significantly elevated the standards of the manufacturing industry, providing companies with the tools they need to thrive in an increasingly competitive market. With [Company Name] leading the charge in innovation and excellence, the future of manufacturing looks brighter than ever. As technology continues to advance, it's exciting to imagine the further possibilities that lie ahead for the industry.

Advanced 4 Axis CNC Milling Machine for Precision Manufacturing

In the ever-evolving world of manufacturing, precision and efficiency are key factors in maintaining a competitive edge. The introduction of the 4 Axis CNC Milling Machine by {Company Name} is set to revolutionize the industry with its cutting-edge technology and advanced capabilities.{Company Name} is a renowned manufacturer in the field of precision engineering and has a long-standing reputation for delivering high-quality machinery to a global customer base. With a commitment to innovation and excellence, the company has consistently invested in research and development to stay ahead of the curve. The introduction of the 4 Axis CNC Milling Machine is a testament to their dedication to pushing the boundaries of what is possible in modern manufacturing.The 4 Axis CNC Milling Machine is a versatile and powerful tool that is designed to streamline the production process and deliver exceptional accuracy and precision. With its four-axis capability, it has the ability to move in multiple directions, allowing for more complex and intricate machining operations. This translates to greater flexibility in design and the ability to create more intricate and detailed components.One of the key features of the 4 Axis CNC Milling Machine is its advanced control system, which allows for seamless integration with computer-aided design (CAD) software. This means that operators can easily program the machine to execute complex designs with a high degree of precision. This not only reduces the margin for error but also significantly speeds up the production process, resulting in cost savings and improved productivity.Furthermore, the machine is equipped with state-of-the-art tooling and cutting technologies, which ensure that the finished products meet the highest standards of quality. Whether it is milling, drilling, or cutting, the 4 Axis CNC Milling Machine is capable of handling a wide range of materials with ease, including metals, plastics, and composites.The introduction of the 4 Axis CNC Milling Machine is expected to have a significant impact on various industries, including aerospace, automotive, and medical. Its ability to produce intricate and complex components with a high degree of accuracy makes it an ideal choice for companies looking to stay ahead of the competition and meet the demands of a fast-paced market.In addition to its technical capabilities, {Company Name} is also committed to providing exceptional after-sales support and training to ensure that customers are able to make the most out of their investment. With a global network of service centers and a team of highly skilled engineers, customers can have peace of mind knowing that help is always just a phone call away.In conclusion, the introduction of the 4 Axis CNC Milling Machine by {Company Name} represents a significant leap forward in the world of manufacturing. Its advanced capabilities, combined with the company's commitment to customer satisfaction, make it a game-changer for businesses looking to take their production capabilities to the next level. As the industry continues to evolve, {Company Name} remains at the forefront, setting new standards for precision engineering and innovation.

High Precision Laser Cutter with USB Port & Water Temperature Control System

article about the JFT 3020 CO2 12"x 8" 40W 110V Laser Cutter.JFT has released its latest productivity-enhancing equipment, the JFT 3020 CO2 12"x 8" 40W 110V Laser Cutter. This new machine has been designed to help businesses and individuals cut, engrave and create precise designs with ease.One of the most noteworthy features of the machine is its water temperature control system. This feature regulates the temperature of the laser source to ensure that the device operates at a consistent and high level of efficiency.The laser energy is also adjustable, which is a valuable feature for those who require different settings for various materials and projects. JFT has added this feature to give users more control and precision when working with different materials.The JFT 3020 CO2 12"x 8" 40W 110V Laser Cutter comes with a USB port that allows users to connect the machine directly to their computer. This means that individuals and businesses can easily transfer their designs to the machine without any additional software or programs.Moreover, the laser cutter has a communication interface that uses USB, enabling users to control the device from their computer. This feature enhances the precision of the machine and makes it more user-friendly.The machine is designed to have an engraving area of 30x20cm and the laser power is 60W AC110V/60Hz (or AC220v/50hz). This provides sufficient power to work with a wide range of materials, and perform intricate designs and cuts for different types of projects.Apart from that, the engraving speed is also adjustable from 0-500mm/s, which gives users the flexibility to work with different materials and designs. The high resolution ratio of 0.001mm helps to produce laser-precise designs, and the carving depth of 0-5mm means that it can handle deeper cuts than other laser cutters.The JFT 3020 CO2 12"x 8" 40W 110V Laser Cutter is designed to work with CorelDraw software, a comprehensive graphic design suite that is popular among designers and businesses worldwide. This means that businesses and individuals can easily create and edit their designs using their preferred software and transfer them directly to the machine.To ensure that the machine is always functioning at an optimal level, it uses a pure circulating cooling system. This system aids in removing excess heat, which in turn lengthens the lifespan of the machine.In conclusion, the JFT 3020 CO2 12"x 8" 40W 110V Laser Cutter is an exceptional investment for a wide range of businesses and individuals who need a high-precision laser cutter for their projects. It comes with several valuable features that provide control and flexibility when working with different materials, making it an ideal addition to any design or creative studio.

High-Powered Laser Cleaning Machine for Metal Surfaces

Laser Cleaning Metal Machine has revolutionized the way metal surfaces are cleaned and prepared for further processing. With its innovative technology, this cutting-edge machine has become a game-changer in the manufacturing industry, offering a more efficient and environmentally-friendly alternative to traditional cleaning methods.Utilizing the power of high-energy laser beams, the Laser Cleaning Metal Machine effectively removes rust, paint, oil, and other contaminants from metal surfaces without the need for any chemicals or abrasive materials. This not only results in a cleaner and smoother surface finish but also eliminates the generation of hazardous waste, making it a sustainable solution for metal cleaning and preparation.The technology behind the Laser Cleaning Metal Machine is based on the principle of laser ablation, where the intense energy from the laser beam vaporizes the surface contaminants, leaving behind a clean and pristine metal surface. This process is highly precise and targeted, allowing for selective cleaning without causing any damage to the underlying metal substrate.In addition to its cleaning capabilities, the Laser Cleaning Metal Machine is also capable of removing unwanted surface coatings and preparing metal surfaces for various industrial processes such as welding, painting, and coating. This level of versatility makes it an invaluable tool for manufacturers across a wide range of industries, including automotive, aerospace, marine, and construction.Furthermore, the Laser Cleaning Metal Machine offers significant time and cost savings compared to traditional cleaning methods. With its high processing speed and minimal maintenance requirements, manufacturers can increase their productivity and efficiency while reducing operating costs. This can lead to an improved bottom line and a more competitive edge in the market.As a leader in laser technology, {} has been at the forefront of developing and manufacturing the Laser Cleaning Metal Machine. With a strong focus on research and development, the company has continuously pushed the boundaries of innovation to deliver advanced laser solutions for industrial applications.The company’s commitment to quality and reliability is reflected in the design and performance of the Laser Cleaning Metal Machine. Equipped with state-of-the-art laser sources and precision optics, this machine delivers consistent and high-quality cleaning results, ensuring the integrity of the metal surfaces.Moreover, {} provides comprehensive technical support and customer service to ensure that the Laser Cleaning Metal Machine operates at its optimal performance. With a global network of sales and service professionals, the company is able to cater to the needs of its customers around the world, offering timely support and expertise whenever required.In line with its dedication to sustainability, {} has also designed the Laser Cleaning Metal Machine with energy efficiency in mind. By optimizing the laser sources and implementing smart power management systems, the machine consumes minimal energy while delivering maximum cleaning power, further contributing to its eco-friendly profile.Looking ahead, {} continues to innovate and expand its range of laser solutions, with a strong focus on advancing the capabilities of the Laser Cleaning Metal Machine. By leveraging the latest advancements in laser technology, the company aims to further improve the efficiency and effectiveness of metal cleaning and preparation, contributing to the progress of the manufacturing industry as a whole.In conclusion, the Laser Cleaning Metal Machine has set a new standard in metal surface cleaning and preparation, offering a sustainable, efficient, and cost-effective solution for manufacturers. With {}’s expertise and commitment to excellence, this innovative machine is poised to play a pivotal role in shaping the future of metal processing and manufacturing.

High-Quality Pipe Welding Machine for Efficient Welding Operations

Pipe Welding Machine Revolutionizes Welding ProcessIn the world of manufacturing and construction, welding is a crucial process that is used to join metal parts together. The traditional method of welding involves using a hand-held welding torch to manually weld two pieces of metal together. This process can be time-consuming, labor-intensive, and can result in inconsistent welds.However, with the introduction of the new Pipe Welding Machine by a leading manufacturing company, the welding process has been revolutionized. This innovative machine has drastically improved the efficiency and quality of welding, making it an essential tool for any manufacturing or construction project.The Pipe Welding Machine, with its advanced technology, has completely transformed the welding process. The machine is able to automatically and precisely weld pipes and other metal parts with a high level of accuracy and consistency. This not only saves time and labor but also ensures that the welds are of the highest quality.One of the key features of this Pipe Welding Machine is its advanced robotic arm, which is capable of maneuvering in all directions to access hard-to-reach areas and weld with precision. The machine also comes equipped with a state-of-the-art welding torch that can be programmed to adjust the speed, heat, and angle of the weld, resulting in seamless and strong welds.The Pipe Welding Machine is also equipped with a user-friendly interface that allows operators to easily input the necessary parameters for the welding process. This user interface also provides real-time monitoring of the welding operation, allowing for quick adjustments if needed.In addition to its efficiency and precision, the Pipe Welding Machine is also designed with safety in mind. The machine is equipped with various safety features, such as built-in sensors that can detect any anomalies during the welding process and immediately shut down the machine to prevent accidents.The company behind this revolutionary Pipe Welding Machine, {Company Name}, is a leading manufacturing company with a long history of producing cutting-edge industrial equipment. With a focus on innovation and quality, the company has continually pushed the boundaries of what is possible in the manufacturing industry.{Company Name} has a team of highly skilled engineers and technicians who are dedicated to researching and developing new technologies to improve the efficiency and safety of industrial processes. The Pipe Welding Machine is just one example of the company's commitment to providing innovative solutions that enhance the capabilities of manufacturers and construction companies.Furthermore, {Company Name} prides itself on providing exceptional customer support and service. The company offers comprehensive training and support for the Pipe Welding Machine, ensuring that operators are fully equipped to maximize the machine's capabilities. Additionally, {Company Name} offers timely maintenance and repair services to keep the machine running at its best.With the introduction of the Pipe Welding Machine, {Company Name} has set a new standard in the welding industry. The machine's advanced technology, precision, and safety features have made it an essential tool for any manufacturing or construction project. As the demand for high-quality and efficient welding continues to grow, the Pipe Welding Machine is sure to be a game-changer for the industry.