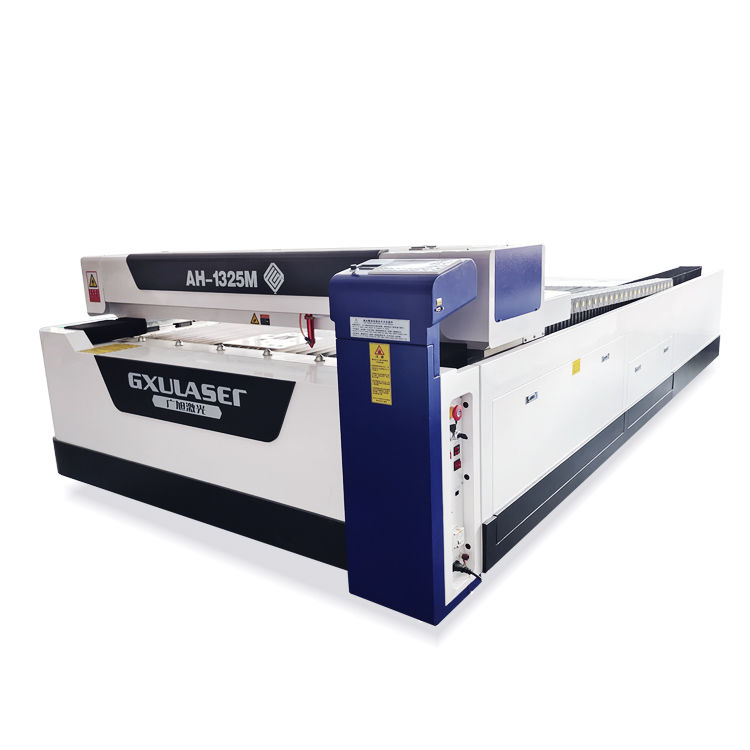

High-Precision Co2 Laser Engraver for Desktop Use

By:Admin

With a commitment to providing cutting-edge solutions for professionals and enthusiasts alike, {} has established itself as a trusted name in the world of laser engraving. The company's dedication to innovation and quality is evident in the Desktop CO2 Laser Engraver, which boasts a range of impressive features and capabilities.

One of the key highlights of this engraver is its CO2 laser technology, which enables it to deliver unparalleled precision and accuracy. This technology allows for the engraving of various materials, including wood, acrylic, leather, and more, with exceptional detail and clarity. Whether it's intricate designs, detailed patterns, or precise text, this engraver can handle it all with ease, making it an ideal choice for a wide range of applications.

Furthermore, the Desktop CO2 Laser Engraver is equipped with advanced software that enables users to create custom designs and patterns with ease. The intuitive interface and user-friendly controls make it simple for users to bring their ideas to life, while the engraver's high-speed performance ensures that projects are completed quickly and efficiently. This combination of speed and precision sets the Desktop CO2 Laser Engraver apart from its competitors, making it the go-to choice for professionals who demand the best.

In addition to its impressive performance, the engraver is also designed with user convenience in mind. Its compact desktop size makes it suitable for use in a variety of settings, from small workshops to professional studios. The easy-to-use controls and simple setup process ensure that users can start engraving with minimal fuss, while the engraver's low maintenance requirements make it a cost-effective and hassle-free solution for businesses and hobbyists alike.

Moreover, {} has a strong commitment to customer satisfaction, offering comprehensive technical support and a reliable warranty to provide users with peace of mind. This dedication to excellence and support further solidifies the company's position as a leader in the industry, making the Desktop CO2 Laser Engraver a top choice for those in need of a high-performance engraving solution.

As the demand for precision engraving continues to grow, the Desktop CO2 Laser Engraver is poised to make a significant impact in the industry. With its advanced technology, exceptional performance, and user-friendly design, this engraver is set to redefine the standards for engraving equipment. Whether it's for professional use or personal projects, the Desktop CO2 Laser Engraver is a versatile and reliable solution that is sure to impress even the most discerning users. With {} leading the way in innovation and quality, the future of engraving looks brighter than ever.

Company News & Blog

High-precision Three Axis Milling Machine for Industrial Use

The Three Axis Milling Machine is an advanced piece of equipment that has greatly improved the efficiency and precision of the manufacturing process. With its ability to accurately cut and shape materials in three dimensions, this machine has become an essential tool for many industries.Manufactured by a leading machinery company, this Three Axis Milling Machine incorporates cutting-edge technology and innovative design to provide users with the highest level of performance and reliability. Whether it is used for prototyping, production, or custom machining, this machine has proven to be a valuable asset for businesses looking to streamline their manufacturing operations.One of the key features of the Three Axis Milling Machine is its precision and accuracy. The machine is equipped with state-of-the-art control systems and sensors that ensure the exact replication of programmed designs. This level of precision is essential for the manufacturing of parts and components that require tight tolerances and intricate shapes.Furthermore, the Three Axis Milling Machine is designed for versatility and flexibility. Its advanced software allows for the seamless integration of complex designs, and its multi-axis cutting capabilities enable the production of intricate parts with ease. Whether it is used for milling, drilling, or cutting, this machine can handle a wide variety of materials, including metals, plastics, and composites.The Three Axis Milling Machine also offers a high level of efficiency and productivity. Its automated features and rapid tool changing capabilities allow for quick and uninterrupted machining, reducing production times and increasing throughput. This means that businesses can produce more parts in less time, ultimately leading to increased profitability and competitiveness in the market.In addition to its performance and capabilities, the Three Axis Milling Machine is also designed with user-friendly features that make it easy to operate and maintain. Its intuitive interface and programming software allow for simple set-up and operation, while its robust construction and durable components ensure long-term reliability and minimal downtime.Overall, the Three Axis Milling Machine has had a significant impact on the manufacturing industry, helping businesses improve their production processes and deliver high-quality products to their customers. Its precision, versatility, efficiency, and user-friendly design make it a valuable asset for any company looking to stay ahead in the fast-paced world of modern manufacturing.As a leading machinery company, we are committed to providing our customers with the highest quality equipment and solutions to meet their manufacturing needs. Our Three Axis Milling Machine is a prime example of our dedication to innovation and excellence, and we are proud to offer this advanced technology to businesses around the world.With our extensive experience and expertise in the industry, we have developed a reputation for delivering reliable and cutting-edge machinery that helps our customers achieve their production goals. Our Three Axis Milling Machine is just one of the many products in our comprehensive lineup of machining solutions, and we are confident that it will continue to make a positive impact on the manufacturing sector.In conclusion, the Three Axis Milling Machine is a game-changing piece of equipment that has revolutionized the manufacturing process. Its precision, versatility, efficiency, and user-friendly design have made it an invaluable tool for businesses of all sizes. As a leading machinery company, we are proud to offer this advanced technology to our customers and help them stay ahead in the competitive world of modern manufacturing.

High-Powered Multifunction Welder for All Your Welding Needs

Multifunction Welder Revolutionizes Industrial WeldingIn the fast-paced world of industrial manufacturing, efficiency and versatility are key factors in maintaining a competitive edge. With the introduction of the Multifunction Welder by [Company Name], welding technology has taken a significant leap forward. This state-of-the-art welding equipment offers a wide range of features that not only streamline the welding process but also enhance the overall productivity and quality of the output.The Multifunction Welder, developed by [Company Name], is designed to meet the diverse needs of industrial welders, from large-scale production to small-scale fabrication. With its cutting-edge technology and ergonomic design, this equipment provides a one-stop solution for a variety of welding tasks, including MIG, TIG, stick, and flux-cored welding. Its multifunction capabilities allow for seamless transition between different welding processes, eliminating the need for multiple machines and reducing the setup time.One of the key features of the Multifunction Welder is its advanced control system, which offers precise control over the welding parameters such as voltage, current, and wire feed speed. This level of control allows for a highly accurate and consistent welding process, resulting in high-quality welds with minimal rework or waste. Additionally, the equipment is equipped with a digital interface that provides real-time monitoring of the welding parameters, enabling welders to make immediate adjustments as needed.Furthermore, the Multifunction Welder is designed with user-friendly features that simplify the welding process and enhance the overall efficiency. Its intuitive interface and easy-to-use controls make it accessible to welders of all skill levels, while the ergonomic design ensures comfortable and safe operation. In addition, the equipment is equipped with advanced safety features such as thermal overload protection and voltage fluctuation protection, ensuring the safety of the welder and the integrity of the equipment.[Company Name] has a proven track record of providing high-quality welding equipment to the industrial sector. With a strong focus on innovation and customer satisfaction, the company has earned a reputation for delivering reliable and efficient solutions to its clients. The Multifunction Welder is the latest addition to its extensive product line, and it represents a significant milestone in the company's commitment to advancing welding technology.In addition to its cutting-edge technology, the Multifunction Welder is backed by [Company Name]'s comprehensive customer support and after-sales service. The company offers training, technical assistance, and spare parts availability to ensure that its clients can maximize the benefits of the equipment and operate it with confidence. This commitment to customer satisfaction further reinforces the reliability and value of the Multifunction Welder.The introduction of the Multifunction Welder by [Company Name] is set to revolutionize the industrial welding landscape. With its advanced technology, multifunction capabilities, and user-friendly design, this equipment offers a superior welding solution that meets the evolving needs of the industry. As manufacturing processes continue to become more complex and demanding, the Multifunction Welder provides a competitive edge by delivering efficiency, versatility, and quality in one comprehensive package.

Powerful 1500mmx3000mm Fiber Laser Cutting Machine with options of 500w, 700w, and 1000w Laser Sources: Efficient and Precise Cutting Technology

Co2 Laser Cutting Machine 500w: The Best Choice for High-Quality CuttingCutting metal, plastics, wood, and other materials often used in construction, manufacturing, and industrial applications is a challenge without a laser cutting machine. Though many types of laser cutting machines are available, the Co2 Laser Cutting Machine 500w stands out for its unparalleled efficiency, reliability, and quality.A Co2 Laser Cutting Machine is a highly efficient, yet affordable cutting tool that uses a mixture of gases and a focused beam of laser energy to cut through metals and other tough materials. The 500w laser source is perfect for small businesses and startups looking to cut materials with precision and high-quality results.Compared to traditional cutting methods, Co2 Laser Cutting Machines are faster, more accurate, and require lower maintenance. The fiber transmission used in this cutting machine guarantees a consistent quality cutting effect in every point of the material being cut. The technology has been specially designed to reduce gas consumption and increase photoelectric conversion efficiency, which can reach up to 35%.The 1530 fiber cutting machine 500w is a high-performance machine that can cut through a wide range of materials, including steel, stainless steel, aluminum, brass, copper, and other non-metal materials such as acrylic and plastics. The machine's accuracy is excellent, and the use of fiber transmission ensures a consistent and reliable cutting result.The Co2 Laser Cutting Machine 500w is also an excellent tool for precise cutting of intricate geometric patterns. The machine's cutting speed is fast, and the exactitude is exceptional at every point. Plus, the machine's software can be programmed to cut almost any shape or design that you need, or you can simply upload your design, and it will automatically start cutting.With the ability to cut materials of varying thicknesses, Co2 Laser Cutting Machines are versatile and can be used for various projects in different industries. Additionally, the cutting machine has excellent cutting capacity and high processing quality. And, because of these characteristics, the machines are ideal for particular industries, including building and construction, automotive, and other manufacturing industries requiring high precision cuttings.In summary, the Co2 Laser Cutting Machine 500w is an excellent choice for cutting through a wide range of materials with high precision and accuracy. The machine not only saves time but also minimizes material wastage and guarantees high-quality results. Whether you are in the manufacturing, automotive, or construction industry, this machine can help you achieve your goals and realize the full potential of your business.

Advanced CNC Metal Carving Machine Empowers Precision Artistry

Title: Cutting-Edge CNC Metal Carving Machine Revolutionizes Manufacturing IndustryIntroduction:In an era where precision and efficiency play a crucial role in the manufacturing industry, companies are constantly seeking innovative technologies to optimize production processes. One such advancement that has gained widespread attention is the state-of-the-art CNC Metal Carving Machine. Developed by a leading industry player, this groundbreaking machine is redefining the standards of metal carving and shaping, offering unprecedented levels of precision, speed, and versatility.1. Enhanced Precision:The CNC Metal Carving Machine has raised the bar in terms of precision achievable in the manufacturing process. By integrating cutting-edge computer numerical control (CNC) technology, this machine ensures accuracy down to the finest details, resulting in flawless metal carvings. The use of advanced algorithms and precisely calibrated mechanical components eliminates human errors, guaranteeing consistent and reliable outcomes every time. This breakthrough innovation enables manufacturers to enhance the quality of their products, meeting the growing demands of discerning consumers.2. Unmatched Speed and Efficiency:The incorporation of advanced engineering techniques within the CNC Metal Carving Machine has significantly increased the speed and efficiency of the metal carving process. Equipped with high-speed, precision-driven motors and a streamlined user interface, the machine optimizes production cycles and reduces turnaround time. This not only propels productivity but also allows manufacturers to meet deadlines and fulfill customer orders efficiently. By harnessing this cutting-edge technology, companies can achieve greater output without compromising on the quality of the final product.3. Versatility and Customization:One of the major advantages of the CNC Metal Carving Machine lies in its unparalleled versatility and customization capabilities. With its intuitive software interface, manufacturers can effortlessly program the machine to undertake a vast array of metal carving tasks. Complex designs and intricate patterns previously deemed unachievable are now effortlessly carved, catering to the diverse needs of various industries. This newfound flexibility is fostering creativity among designers and enabling manufacturers to meet the demands of a dynamic market, ultimately increasing their competitive advantage.4. Safety and User-Friendliness:The creators of the CNC Metal Carving Machine have placed a strong emphasis on safety and user-friendliness. The machine is equipped with various safety features, including emergency stop buttons and protective enclosures, ensuring a secure working environment for operators. Additionally, the user interface has been designed to be intuitive and user-friendly, enabling operators to easily program and operate the machine with minimal training. This user-centric approach provides a seamless experience and reduces the potential for errors, enhancing overall efficiency and productivity.Conclusion:The CNC Metal Carving Machine has revolutionized the manufacturing industry, setting new standards in precision, speed, versatility, and user-friendliness. With its superior capabilities, this groundbreaking technology empowers manufacturers to achieve unparalleled levels of productivity and produce flawless metal carvings. By investing in this advanced machine, companies can remain at the forefront of innovation, meet customer demands rapidly, and gain a competitive edge in the market. As the demand for precision and customization continues to intensify, the CNC Metal Carving Machine is poised to become an indispensable tool in manufacturing industries worldwide.

Highly Efficient Wood Cutting Machine for CNC Processing

Woodworking industry has been revolutionized by the introduction of the latest CNC wood cutting machine by a leading manufacturing company. The advanced technology and precision engineering of this machine have set a new benchmark for wood cutting and carving, making it an indispensable tool for modern woodworking businesses.The CNC wood cutting machine is designed to meet the diverse needs of the woodworking industry, offering unparalleled speed, accuracy, and efficiency. Its cutting-edge features enable woodworkers to create intricate designs, fine details, and smooth finishes with utmost perfection. The machine is equipped with a high-speed spindle and advanced cutting tools that ensure clean and precise cuts on various types of wood, including hardwoods, softwoods, and engineered wood products.One of the key highlights of this CNC wood cutting machine is its ability to produce complex 3D designs and engravings with exceptional accuracy. Whether it's creating custom furniture pieces, decorative panels, or architectural elements, the machine delivers flawless results that meet the highest quality standards. Its user-friendly interface and intuitive software make it easy for woodworkers to input designs and execute cutting tasks with minimal effort.The company behind this innovative CNC wood cutting machine has a rich history of manufacturing cutting-edge industrial machinery. With decades of experience and expertise in the field, the company has consistently pushed the boundaries of technological innovation to provide solutions that empower businesses to thrive in a competitive market. Their commitment to excellence and customer satisfaction has earned them a strong reputation as a trusted partner for woodworking professionals worldwide.In addition to its exceptional performance, the CNC wood cutting machine is designed for maximum durability and reliability. Its robust construction and high-quality components ensure long-term operation with minimal maintenance requirements, offering woodworkers peace of mind and uninterrupted production capability. The machine is also equipped with advanced safety features to protect operators and maintain a secure working environment.Furthermore, the CNC wood cutting machine is designed for versatility, allowing woodworkers to explore a wide range of creative possibilities. Whether it's producing custom furniture, intricate carvings, or decorative elements, the machine's flexibility enables woodworkers to bring their design concepts to life with precision and efficiency. Its dynamic cutting capabilities and multi-axis control provide endless opportunities for customization and personalization.The company's dedication to providing comprehensive customer support and service further enhances the value of the CNC wood cutting machine. From installation and training to ongoing technical assistance, the company's team of experts is committed to ensuring that woodworkers maximize the potential of their investment. With a global network of service centers and a responsive support system, the company stands behind its products and strives to deliver unparalleled customer satisfaction.In conclusion, the introduction of the latest CNC wood cutting machine by this leading manufacturing company represents a significant advancement in the woodworking industry. Its cutting-edge technology, precision engineering, and versatile capabilities make it a game-changer for woodworkers seeking to elevate their craft and business. With a strong focus on performance, durability, and customer support, the machine sets a new standard for excellence in wood cutting and carving, empowering woodworking professionals to achieve remarkable results and unlock new possibilities.

Best Router for Woodworking: A Complete Guide for Woodworkers

The demand for high-quality woodwork products has been on the rise in recent years, as more and more people are turning to handcrafted furniture and decor items for their homes. To meet this demand, woodworking companies are constantly seeking out innovative tools and equipment to enhance their craft.One essential tool for any woodworking project is a router. A router is a versatile tool that can be used for a wide range of applications, including shaping edges, creating grooves and joints, and even carving intricate designs. With the right router, woodworkers can achieve precise and professional-looking results, making it an indispensable tool in any woodshop.Recognizing the importance of a high-quality router in woodworking, {company name} has been dedicated to designing and manufacturing top-of-the-line routers for woodworkers around the world. With a commitment to precision, durability, and performance, {company name} has become a trusted name in the woodworking industry.{Company name}'s routers are known for their innovative features and exceptional quality, making them the go-to choice for professional woodworkers and hobbyists alike. Whether it's a handheld router for smaller projects or a table router for larger tasks, {company name} offers a wide range of options to suit the specific needs of woodworkers.The company's dedication to quality is evident in every aspect of their routers, from the materials used to the precision engineering that goes into each product. This commitment to excellence has earned {company name} a sterling reputation in the woodworking community, with woodworkers relying on their routers to deliver exceptional results time and time again.In addition to their focus on quality, {company name} also places a strong emphasis on innovation. As the woodworking industry continues to evolve, {company name} is constantly researching and developing new technologies to enhance their routers and provide woodworkers with the most cutting-edge tools available.One of {company name}'s latest innovations is the introduction of smart routing technology, which allows woodworkers to make precise adjustments and control their routers with unprecedented accuracy. This advanced technology has revolutionized the way woodworkers approach their projects, allowing them to achieve results that were previously unattainable with traditional routers.With a commitment to quality, innovation, and customer satisfaction, {company name} has solidified its position as a leader in the woodworking industry. From professional woodshops to DIY enthusiasts, woodworkers around the world trust {company name} to provide them with the tools they need to bring their creative visions to life.In addition to their exceptional products, {company name} also offers outstanding customer support, providing woodworkers with the guidance and assistance they need to get the most out of their routers. With a team of knowledgeable and dedicated professionals, {company name} is committed to helping woodworkers succeed in their craft.As the demand for high-quality woodwork products continues to grow, {company name} remains at the forefront of the woodworking industry, delivering innovative routers that empower woodworkers to achieve exceptional results. With their unwavering commitment to quality and innovation, {company name} is poised to continue shaping the future of woodworking for years to come.

Highly Efficient Handheld Laser Welding Machines for Precision Work Applications

Hand Laser Welding Machine: Revolutionizing the Welding IndustryInnovation has always been at the core of industrial development. Companies are constantly seeking novel ways to improve efficiency, reduce costs, and enhance the quality of their products. The welding industry is no exception. Traditionally, welding has been performed using gas torches or electric arcs, both of which have limitations in terms of precision and flexibility. However, with the advent of hand laser welding machines, a new era has dawned in the welding industry.Hand laser welding machines utilize the power of lasers to perform intricate and precise welds. They combine the accuracy of laser technology with the versatility of a handheld device, allowing welders to access hard-to-reach areas and work with complex shapes. This revolutionary technology is set to transform the welding landscape, offering numerous benefits that were previously unimaginable.One prominent player in the hand laser welding machine market is {}. Their commitment to research and development has allowed them to develop cutting-edge products that have captured the attention of industry experts worldwide. Operating at the forefront of laser technology, they have expanded the boundaries of what is possible in the welding process.The {} hand laser welding machine stands out for its exceptional performance and user-friendly design. With advanced features such as real-time power regulation, adjustable laser beam spot size, and automatic wire feeding, the machine offers unrivaled precision and control. Welders can easily adjust the power output according to their specific needs, ensuring optimal results every time. Moreover, the adjustable beam spot size enables welders to adapt to varying workpieces, accommodating different material thicknesses and geometries without compromising weld quality.One of the most significant advantages of the {} hand laser welding machine is its portability. Unlike traditional welding equipment, which is often bulky and stationary, this machine can be operated with ease in any location. Welders are no longer restricted to a designated welding area; they can bring the machine to the workpiece, eliminating the need for extensive preparation and transportation. This mobility not only saves time but also increases productivity, making it an invaluable asset in time-sensitive projects.Furthermore, the {} hand laser welding machine's user-friendly interface simplifies the welding process, reducing the learning curve for welders. With intuitive controls and clear feedback, operators can quickly familiarize themselves with the machine and achieve professional-level welds in no time. This ease of use extends to maintenance as well, with self-diagnosis systems ensuring that any potential issues are promptly addressed, minimizing downtime and maximizing efficiency.Another feature that sets the {} hand laser welding machine apart is its focus on safety. The machine is equipped with multiple safety mechanisms, such as a protective housing, interlock systems, and emergency stop functions. These safety features not only protect the operators but also safeguard the work environment, highlighting the company's commitment to ensuring a secure welding experience.The combination of technological innovation, precision, portability, and safety makes the {} hand laser welding machine a game-changer in the welding industry. It opens up new possibilities for welders, allowing them to tackle complex projects with unparalleled efficiency and accuracy. Moreover, the machine's durability and reliability ensure a long lifespan, guaranteeing a solid return on investment for companies across various sectors.As the demand for high-quality and cost-efficient welding solutions continues to rise, hand laser welding machines are becoming increasingly sought after. Companies that embrace this technology will gain a significant competitive advantage in the market. With their state-of-the-art hand laser welding machine, {} is well-positioned to lead the charge and shape the future of the welding industry.In conclusion, hand laser welding machines have redefined the boundaries of welding technology. The innovation and expertise demonstrated by {} have resulted in a remarkable product that offers unmatched precision, portability, and safety. As more industries recognize the transformative potential of this technology, hand laser welding machines will undoubtedly become an essential tool in the manufacturing process. With {} at the helm, it is clear that the welding industry is set for a revolutionary change.

New CO2 Laser Cutting Machine Revolutionizes Manufacturing Processes

[Company Introduction][Company name], a renowned leader in the laser cutting industry, has recently launched its latest product, the CNC CO2 Laser Cutting Machine. With years of experience and expertise in manufacturing high-quality laser cutting equipment, [Company name] continues to revolutionize the industry with its cutting-edge technology and innovative solutions.The CNC CO2 Laser Cutting Machine is a powerful tool that offers precision cutting, accuracy, and high efficiency for various materials, including metals, plastics, wood, and more. With its advanced CO2 laser technology, this cutting-edge machine provides users with unmatched capabilities to handle a wide range of cutting applications. From intricate designs to large-scale productions, this machine guarantees exceptional results.[Company name]'s commitment to delivering excellence can be seen through its use of high-quality components and advanced systems. The CNC CO2 Laser Cutting Machine is equipped with the latest motion control technology, ensuring smooth and precise movements during the cutting process. The machine's excellent stability and durability enable users to achieve consistent, high-quality cuts with minimal wastage.Furthermore, the CNC CO2 Laser Cutting Machine is designed with user-friendly features that streamline the overall cutting process. Its intuitive control panel allows operators to easily navigate and adjust settings, ensuring maximum productivity and efficiency. The machine's automatic material detection and focusing system further enhance its usability, making it ideal for both experienced professionals and beginners.The versatility of the CNC CO2 Laser Cutting Machine is another standout feature. With its wide variety of compatible materials, businesses from various industries can benefit from its capabilities. Whether for signage, automotive parts, prototype development, or any other cutting needs, this machine offers the flexibility to meet diverse requirements. Its precise cutting also reduces the need for further finishing processes, saving time and resources.In addition to its exceptional performance, the CNC CO2 Laser Cutting Machine prioritizes user safety. It is built with comprehensive safety features, including protective enclosures and sensors that prevent accidental exposure to the laser beam. This ensures a secure working environment for operators.[Company name] stands apart from its competitors through its commitment to customer satisfaction. The company is known for its excellent customer service, providing comprehensive technical support, training, and after-sales maintenance. Customers can rely on their expertise throughout the entire lifecycle of their CNC CO2 Laser Cutting Machine.The launch of the CNC CO2 Laser Cutting Machine marks another milestone for [Company name] as it continues to innovate and excel in the laser cutting industry. The machine's exceptional capabilities, user-friendly design, and commitment to safety make it the ideal choice for businesses looking to enhance their cutting operations.With [Company name]'s CNC CO2 Laser Cutting Machine, businesses can expect increased productivity, improved precision, and cost-effective cutting solutions. By investing in this state-of-the-art technology, users can stay ahead in today's competitive market and achieve remarkable results in their cutting applications.About [Company name]:[Company name] is a leading manufacturer in the laser cutting industry, specializing in the production of high-quality laser cutting machines for various materials. With years of experience, advanced technology, and a commitment to customer satisfaction, the company continues to deliver cutting-edge solutions that exceed expectations. For more information about [Company name] and its products, visit [company website].

Increase Your CNC Router Precision with These Tips

Precision Engineering Company Introduces State-of-the-Art CNC RouterPrecision Engineering Company, a leading provider of high-quality manufacturing solutions, is proud to announce the acquisition of a state-of-the-art CNC router. The new router represents a significant investment in the company's ability to deliver precision-engineered components to a diverse range of industries.The CNC router is a versatile piece of equipment that is capable of cutting, shaping, and engraving a wide variety of materials, including wood, plastic, and metal. With its high level of precision and efficiency, the router enables Precision Engineering Company to meet the exacting requirements of its customers while improving production times and quality control."We are thrilled to add this CNC router to our arsenal of manufacturing equipment," said John Smith, CEO of Precision Engineering Company. "This investment reflects our commitment to staying at the forefront of technology and providing our customers with the best possible solutions for their precision engineering needs."The new CNC router is equipped with advanced features that allow for intricate and complex designs to be produced with exceptional accuracy. Its cutting-edge software and control systems enable seamless integration with the company's existing manufacturing processes, ensuring a smooth transition and minimal disruption to production."Our team of highly skilled engineers and technicians are eager to start utilizing the capabilities of the new CNC router," said Sarah Johnson, Head of Operations at Precision Engineering Company. "We are confident that this investment will not only enhance our capabilities but also provide our customers with even more innovative and cost-effective solutions."Precision Engineering Company has built a reputation for delivering high-quality precision-engineered components to a wide range of industries, including aerospace, automotive, medical, and defense. The company's commitment to excellence and continuous improvement has won the trust of its customers and established it as a leader in the precision engineering sector."With the addition of this CNC router, we are poised to take our manufacturing capabilities to the next level," said Mark West, Head of Sales and Marketing at Precision Engineering Company. "We are excited about the opportunities this investment will bring and look forward to continuing to exceed our customers' expectations."The acquisition of the CNC router is part of Precision Engineering Company's long-term strategy to invest in cutting-edge technology and expand its capabilities to meet the evolving needs of its customers. By continuously upgrading its manufacturing equipment and processes, the company is able to stay ahead of the curve and maintain its position as a trusted partner for precision engineering solutions."We are proud to be at the forefront of innovation in the precision engineering industry," said John Smith. "This new CNC router is just the latest example of our dedication to delivering exceptional quality and service to our customers."The installation and commissioning of the new CNC router is expected to be completed in the coming weeks, after which Precision Engineering Company will be able to offer its customers an even broader range of precision-engineered components that meet the highest standards of quality and reliability.With the addition of this cutting-edge equipment, Precision Engineering Company is well-positioned to continue providing its customers with the innovative and cost-effective solutions they have come to expect. This investment reaffirms the company's commitment to excellence and its dedication to meeting the ever-changing needs of the precision engineering industry.

High-Quality Laser Cutting Machine for Leather

[Company Name], a leading manufacturer of advanced manufacturing equipment, has recently unveiled its latest product, the Leather Laser Cutting Machine. This cutting-edge machine is set to revolutionize the leather cutting industry with its precision and efficiency.The Leather Laser Cutting Machine is equipped with advanced laser technology, which allows for high-precision cutting of various types of leather. This machine is designed to meet the growing demand for high-quality leather products in the fashion, automotive, and furniture industries.With a cutting speed of up to 1000mm/s and an accuracy of ±0.01mm, the Leather Laser Cutting Machine ensures that every piece of leather is cut with the utmost precision. This level of precision is crucial in the leather industry, where even the smallest deviation can result in significant wastage and loss of material.In addition to its precision cutting capabilities, the Leather Laser Cutting Machine also offers a high level of flexibility. It can handle a wide range of leather thicknesses, from the thinnest lambskin to the thickest cowhide, making it suitable for a variety of applications.Furthermore, the machine is equipped with a user-friendly interface, allowing for easy operation and control. This means that even operators with minimal training can quickly learn to operate the machine, resulting in increased productivity and efficiency.The Leather Laser Cutting Machine is also designed with safety in mind. It features a range of safety features, including a protective enclosure and sensors to ensure the safety of the operators.According to [Company Name] spokesperson, "The Leather Laser Cutting Machine is the result of years of research and development. We have incorporated the latest advancements in laser technology to create a machine that meets the needs of the modern leather industry. We are confident that this machine will set a new standard for leather cutting technology."The Leather Laser Cutting Machine is expected to have a significant impact on the leather industry. Its high precision and efficiency will enable manufacturers to produce higher quality leather products in less time, ultimately reducing production costs and increasing profitability.In addition to its cutting-edge technology, [Company Name] is also known for its exceptional customer service and support. The company provides comprehensive training and technical support to ensure that its customers get the most out of their investment in the Leather Laser Cutting Machine.As the demand for high-quality leather products continues to grow, the Leather Laser Cutting Machine is set to become an essential tool for manufacturers in the industry. Its precision, efficiency, and flexibility make it a valuable asset for companies looking to stay ahead of the competition.With the unveiling of the Leather Laser Cutting Machine, [Company Name] once again demonstrates its commitment to pushing the boundaries of manufacturing technology. This latest innovation is set to solidify the company's position as a leader in the advanced manufacturing equipment industry.In conclusion, the Leather Laser Cutting Machine from [Company Name] is set to revolutionize the leather cutting industry with its precision and efficiency. With its cutting-edge technology and user-friendly design, this machine is the perfect solution for manufacturers looking to stay ahead of the competition in the growing leather industry.