Unlocking the Potential: The Ultimate Guide to 5-Axis CNC Router for Woodworking

By:Admin

[date]

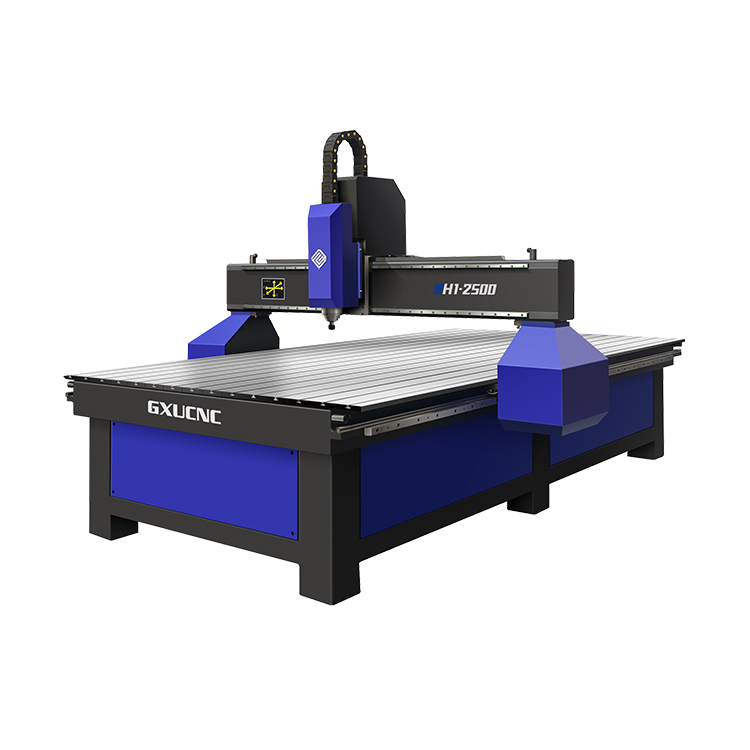

[Location] - [Company Name], a leader in innovative manufacturing solutions, has unveiled its latest breakthrough in woodworking technology with the launch of the next-generation 5-axis CNC router. Engineered to deliver unparalleled precision and efficiency, this cutting-edge solution is set to revolutionize the woodworking industry.

Woodworking has been a traditional craft for centuries, and technology has played a significant role in advancing the field. The introduction of computer numerical control (CNC) routers has automated and streamlined the woodworking process, allowing for greater accuracy, speed, and versatility. [Company Name], renowned for its commitment to excellence and advancement, has taken this to the next level with its latest offering.

The 5-axis CNC router woodworking solution brings forth a host of new features and enhancements that leverage the power of modern technology. Its advanced design and construction enable craftsmen to tackle the most intricate woodworking projects with ease and precision. By integrating cutting-edge software and hardware, the machine empowers users to unleash their creativity without compromising on quality.

One of the key highlights of this new CNC router is its revolutionary 5-axis capability. Unlike traditional routers that only operate on three axes (X, Y, and Z), this latest offering introduces two additional axes (A and B). This added flexibility allows for more complex and dynamic woodworking operations, enabling craftsmen to create intricate designs and shapes that were previously deemed impossible.

Furthermore, the CNC router's state-of-the-art software ensures seamless integration with CAD/CAM applications, providing users with a seamless workflow. The intuitive interface simplifies the design process and allows craftsmen to visualize their creations in a digital environment before initiating production. This feature not only saves time and resources but also minimizes the risk of errors, resulting in higher-quality finished products.

In addition to its impressive technical capabilities, the 5-axis CNC router boasts robust construction and durability. The machine utilizes high-quality materials and components, ensuring optimal performance and longevity. Its stability and precision are further enhanced by the incorporation of advanced servo motors and ball screws, guaranteeing accurate movements and consistent results.

[Company Name]'s commitment to customer satisfaction extends beyond product excellence. The company has established a comprehensive customer support network to assist users at every stage of their woodworking journey. From initial setup and training to ongoing technical assistance, [Company Name] aims to provide a hassle-free experience to its valued customers.

The introduction of the 5-axis CNC router woodworking solution marks a significant milestone for [Company Name] and the woodworking industry as a whole. By pushing the boundaries of innovation and engineering, [Company Name] is empowering craftsmen to unleash their full potential, revolutionizing the way woodworking is approached.

In conclusion, the next-generation 5-axis CNC router woodworking solution offered by [Company Name] promises to be a game-changer in the industry. With its advanced features, intuitive software, and robust construction, this machine offers craftsmen unlimited creativity and precision, elevating their woodworking projects to new heights. As technology continues to evolve, [Company Name] remains at the forefront, dedicated to delivering cutting-edge solutions that shape the future of manufacturing.

Company News & Blog

Top 1390 CO2 Laser Engravers for Precise Acrylic Engraving and Custom Designing

Engraver, CO2 Laser Engraving, Precision Engraving Machines, Custom Logo Engraving.CO2 laser engraving machines have revolutionized the way we personalize and decorate acrylic. These highly precise instruments have become an essential tool for businesses, artists, and hobbyists alike. The Best 1390 CO2 Laser Engraver Machines are designed to provide the highest level of accuracy, speed, and flexibility for all types of engraving projects. With the ability to engrave intricate designs, logos, and images on acrylic, CO2 laser engraving has become a popular trend in many industries. The precision engraving machines offer businesses excellent opportunities to showcase their brands and products, creating unique and personalized pieces of art for their customers. So, let’s take a closer look at what makes the 1390 CO2 Laser Engraver Machines the best option for all your precision engraving needs.Precision Engraving MachinesThe Best 1390 CO2 Laser Engraving Machines have been designed with precision in mind. Equipped with high-quality CO2 tubes and advanced motion control systems, these machines can engrave even the finest details with ease. The accuracy of the laser beam is such that it can engrave even the smallest of fonts, making it ideal for custom acrylic signage.SpeedPrecision engraving machines like the 1390 CO2 Laser Engraver Machines are incredibly fast. They can quickly and easily engrave even the most complex designs on acrylic. With high-speed scanning, these machines can produce images in a matter of seconds, making them ideal for prototyping and customization.FlexibilityThe Best 1390 CO2 Laser Engraver Machines are highly versatile and flexible. They can engrave a wide range of materials, including acrylic, wood, leather, plastic, glass, and more. This means they can be used for many different applications, from custom signage to personalized gifts.Custom Logo EngravingCustom logo engraving is one of the key applications of CO2 laser engraving machines. With the ability to engrave logos onto acrylic surfaces, companies can create unique signage that speaks to their brand and values. Custom logo engraving is also an excellent way to create personalized gifts for clients, employees, or special events.In conclusion, the Best 1390 CO2 Laser Engraver Machines are an essential tool for anyone looking for precision engraving. With their speed, accuracy, and flexibility, these machines are ideal for a wide range of applications, from custom signage to personalized gifts. Custom logo engraving is just one of the many applications of these versatile machines. Whether you are a business owner or an artist, the 1390 CO2 Laser Engraver Machines are the perfect tool for all your engraving needs.

Polyurethane Belt Welding Machine for Seamless Connectors - 220V, Temperature Range of 180-200 Degrees, Achieves Perfect Belt Forming

BAOSHISHAN PU Round Belt Welding Machine: The New Revolution in Polyurethane Belt Hot Melt TechnologyBAOSHISHAN, a leading technology company that specializes in the development of advanced welding machines, has recently released a new product on the market - the PU Round Belt Welding Machine. This machine is designed to weld polyurethane round belts using a hot melt process, thus providing a much stronger and more efficient connection between the belts.The machine is made from the highest quality materials and is available in several different models, each with its own unique features and capabilities. Regardless of which model you choose, you can be sure that your welding projects will be completed quickly and efficiently, with minimal downtime and high-quality results.One of the most significant advantages of the BAOSHISHAN PU Round Belt Welding Machine is its temperature range. The welding machine usually ranges from 180 to 200 degrees Celsius, which is perfect for welding polyurethane belts without damaging them. This ensures that your belts will remain strong and durable, even after years of continuous use.Another feature that sets the PU Round Belt Welding Machine apart from its competitors is its belt forming effect. With this machine, you can easily form belts into a perfect circle, which gives them a cleaner and more professional look. Plus, this feature guarantees a much tighter connection between the belts, ensuring that they stay in place even under heavy loads.The machine is also very versatile, making it suitable for use in a wide range of industries, including automotive, packaging, construction, and many more. Whether you need to weld belts for conveyor systems, packaging machines, or industrial equipment, the BAOSHISHAN PU Round Belt Welding Machine can handle it all.Furthermore, the machine is incredibly easy to use, thanks to its simple design and intuitive controls. Even if you're not familiar with welding machines, you'll be able to operate this machine with ease, thanks to its user-friendly interface and detailed instructions.In conclusion, the BAOSHISHAN PU Round Belt Welding Machine is an excellent choice for anyone looking to improve the quality and durability of their polyurethane belts. With its advanced features, high-quality materials, and ease of use, this machine is sure to exceed your expectations and provide you with the best possible results. So why wait? Order your BAOSHISHAN PU Round Belt Welding Machine today and experience the new revolution in polyurethane belt hot melt technology!

CNC Programming Book: Tips and Techniques for Metal and Woodworking Machines

CNC Machines for Metal and Wood: Tips and Techniques for ProgrammersCNC machines have become increasingly popular in recent years, especially in the field of metalworking and woodworking. These machines offer precise cutting and engraving capabilities, making them a favorite among manufacturers and artisans alike. However, the intricacies of CNC programming can be overwhelming, especially for those new to the technology. That's where Peter Smid's CNC Tips and Techniques: A Reader for Programmers comes in.This book is the perfect guide for those who want to learn more about CNC programming. Smid's expertise in the field is evident in the way he breaks down complex topics into easy-to-understand sections. Whether you're looking to improve your existing skills or just getting started, this book has something for everyone.One of the standout features of this book is the inclusion of tips and techniques specific to metalworking and woodworking. Smid's extensive experience in both fields makes him uniquely qualified to provide insights and strategies that are tailored to each industry. Whether you're working with hard metals or fragile woods, you'll find tips and tricks to help you achieve precise and accurate results every time.Another great feature of this book is the emphasis on practical applications. Smid doesn't just provide theoretical knowledge - he also includes real-world examples of how CNC programming can be used in manufacturing and artistic contexts. This makes the content more engaging and relevant for readers who are looking to apply their newfound knowledge in practical ways.Of course, one of the biggest benefits of CNC machines is their efficiency. They allow manufacturers to produce large quantities of products quickly and accurately. Smid's book takes this into account, with chapters dedicated to optimizing speed and reducing cycle time. These tips can help manufacturers save time and money, while maintaining high levels of quality and precision.In summary, CNC Tips and Techniques: A Reader for Programmers is an excellent resource for anyone looking to improve their CNC programming skills, particularly in metalworking and woodworking. It offers practical strategies, real-world examples, and expert guidance from an industry veteran. Whether you're an experienced programmer or just starting out, this book is sure to help you achieve better results with your CNC machines. So what are you waiting for? Start reading today!

Fastest 5000 Watt Laser Cutters for Sheet Metal Prototyping Equipment

The utilization of laser cutters has revolutionized the field of manufacturing, particularly in the realm of sheet metal prototyping. With this technology, intricate designs can be achieved with precision and accuracy, creating a high-quality end product that meets customer requirements. At Incodema, we are proud to offer our customers the latest in laser cutting technology- the 5000 Watt Laser Cutter.The 5000 Watt Laser Cutter is the fastest laser cutting machine available on the market. Our machine is equipped with two flying optic Mitsubishi lasers, renowned for their speed and accuracy. This state-of-the-art technology allows us to deliver high-quality laser cutting services with quick turnaround times.The 5000 Watt Laser Cutter is powered by a high wattage laser beam that is used to vaporize the material being cut. The material is then removed by a jet of gas, leaving a clean, precise cut that meets the exact specifications of the customer. This process is highly efficient and accurate, making it ideal for prototyping and production runs.As an industry leader, we understand the importance of delivering exceptional quality to our customers. Our laser cutters are designed to handle a wide range of materials, including stainless steel, aluminum, brass, and copper. We are constantly innovating to improve our processes, ensuring that our customers receive the best possible product.At Incodema, we have a team of skilled professionals who operate our 5000 Watt Laser Cutters. We take pride in their expertise and knowledge, and we work hard to create a culture of continuous improvement. We regularly invest in the latest equipment and technology, providing our team with the tools they need to deliver the highest quality products.In addition to our 5000 Watt Laser Cutter, we offer a comprehensive range of services, including laser welding, CNC machining, and prototyping. We pride ourselves on our ability to deliver exceptional products to our customers while providing them with excellent customer service.In conclusion, the 5000 Watt Laser Cutter is a game-changer in the field of sheet metal prototyping. At Incodema, we understand the importance of cutting-edge technology in delivering a superior end product, and our 5000 Watt Laser Cutter is just one example of our commitment to excellence. Contact us today to learn how we can help bring your project to life.

Tens of Thousands Left Without Internet as Fiber Cables Severed – Stay Connected and Informed!

Fiber Cutting: Paving the Way for Advanced ConnectivityIn today's fast-paced world, connectivity is crucial for individuals and businesses alike. Whether it's for communication, education, entertainment, or commerce, a reliable and high-speed internet connection has become a necessity. That's where Fiber Cutting, a leading provider of cutting-edge fiber optic solutions, comes into play. With their commitment to innovation and technical expertise, Fiber Cutting has revolutionized the way we connect, communicate, and collaborate.Headquartered in [], Fiber Cutting has established itself as a global leader in the field of fiber optic technology. With a strong focus on research and development, the company has consistently pushed the boundaries of what is possible in terms of internet connectivity. By leveraging the power of fiber optics, Fiber Cutting enables faster data transmission rates, lower latency, and improved reliability compared to traditional copper-based networks.One of Fiber Cutting's most noteworthy achievements is the development of their proprietary fiber optic cables, which are designed to meet the ever-increasing demands of today's digital landscape. These cables are constructed using the finest quality materials and advanced techniques, ensuring maximum performance and durability. The company's commitment to quality and attention to detail have earned them a stellar reputation in the industry.What sets Fiber Cutting apart from its competitors is their end-to-end approach to connectivity solutions. From initial design and installation to ongoing maintenance and support, the company provides a comprehensive suite of services tailored to meet the specific needs of their clients. This holistic approach ensures a seamless integration of their fiber optic solutions into existing infrastructure, resulting in a hassle-free and future-proof network.Furthermore, Fiber Cutting's solutions are not limited to a particular sector or industry. The company caters to a wide range of clients, including telecommunications providers, data centers, educational institutions, hospitals, and government agencies. By offering scalable and customizable solutions, Fiber Cutting ensures that their clients can adapt to the ever-changing technological landscape and stay ahead of the competition.One of the key advantages of Fiber Cutting's fiber optic solutions is the ability to support the growing demand for bandwidth. As the world becomes increasingly interconnected, the need for faster and more reliable internet connections continues to rise. Fiber Cutting's solutions address this need by providing ultra-high-speed connectivity, allowing businesses and individuals to transfer large amounts of data seamlessly.Moreover, Fiber Cutting's fiber optic solutions offer exceptional security features, protecting sensitive data from unauthorized access. With the increasing threat of cyberattacks and data breaches, this aspect has become paramount for individuals and organizations alike. Fiber Cutting's commitment to data security ensures peace of mind for their clients, knowing that their information is safeguarded.In addition to their technological prowess, Fiber Cutting is also dedicated to environmentally friendly practices. The company understands the importance of sustainability and has implemented various initiatives to reduce their carbon footprint. By using energy-efficient components, recycling materials, and implementing environmentally conscious manufacturing processes, Fiber Cutting ensures that their solutions contribute to a greener future.Looking ahead, Fiber Cutting has ambitious plans to further expand its market presence and continue driving innovation in the field of fiber optic technology. The company aims to develop even faster and more reliable solutions, capitalizing on emerging technologies such as 5G and the Internet of Things (IoT). By staying at the forefront of technological advancements, Fiber Cutting aims to empower individuals and businesses with the connectivity they need to thrive in a digital world.In conclusion, Fiber Cutting's focus on innovation, technical expertise, and commitment to customer satisfaction have positioned them as a global leader in the fiber optic industry. With their state-of-the-art solutions, the company has transformed the way we connect and communicate. As the world becomes increasingly reliant on fast and reliable connectivity, Fiber Cutting remains at the forefront, paving the way for a more connected and efficient future.

Discover the Portability and Efficiency of Laser Welding Machines

[Headline]: Revolutionary Portable Laser Welding Machine Redefines Industrial Manufacturing[Subheading]: Cutting-Edge Innovation Leverages Technology and Portability for Superior Welding Capabilities[date]In a major breakthrough, [Company Name] has unveiled its latest technological innovation – a Portable Laser Welding Machine that is set to transform the manufacturing industry. This cutting-edge device combines the power of laser technology with unparalleled portability, revolutionizing the way industries approach welding. Experts predict that this state-of-the-art invention will catapult manufacturing productivity to new heights, making it an indispensable tool across various sectors.[Company Name], a recognized industry leader in laser-based solutions, has always been at the forefront of technological advancement. The newly launched Portable Laser Welding Machine truly signifies their commitment to innovation and their vision of providing seamless solutions to complex manufacturing challenges.The brilliance of this Portable Laser Welding Machine lies in its ability to bring laser welding capabilities to previously inaccessible areas. Unlike traditional bulky and stationary welding machines, this revolutionary device offers unmatched portability. Weighing a mere [weight], it can be effortlessly transported to different locations, making it ideal for both large-scale manufacturing plants and small-scale operations.What sets this Portable Laser Welding Machine apart from its competitors is its exceptional precision and control. With advanced laser technology, this cutting-edge device ensures high-quality and flawless welds, consistently maintaining superior workmanship. The machine is equipped with ultra-high-speed cameras and sophisticated sensors that enable real-time monitoring and adjustment, guaranteeing precise weld positioning and impeccable results.[Company Name]'s Portable Laser Welding Machine has been crafted with meticulous attention to detail. Its ergonomic design ensures maximum efficiency by providing the operator with exceptional ease of use. The device is fitted with an intuitive touchscreen interface, making it easy to navigate and operate. This user-friendly interface, combined with the machine's swift response time, ensures increased productivity and reduced downtime.Moreover, this state-of-the-art machine boasts remarkable versatility. It can be utilized across a wide range of industries, catering to various welding requirements. From automotive and aerospace industries to construction and electronics, this Portable Laser Welding Machine offers an all-encompassing solution. Its adaptability and ease of integration into existing production systems make it an attractive prospect for numerous manufacturers.In addition to its unprecedented capabilities, [Company Name] emphasizes sustainability in their product design. The Portable Laser Welding Machine has been engineered to minimize energy consumption, resulting in significant cost savings for industrial manufacturers. This commitment to eco-friendly technology further solidifies [Company Name]'s reputation as a responsible corporate citizen."We are extremely proud to present this ground-breaking Portable Laser Welding Machine to the world," says [Name], the CEO of [Company Name]. "Our aim has always been to push the boundaries of innovation and redefine manufacturing practices. With this new invention, we are confident that we have achieved just that."Industry experts and professionals have eagerly awaited a portable laser welding machine that combines cutting-edge technology with user-friendly design. This revolutionary invention by [Company Name] has surpassed expectations, marking a paradigm shift in the welding industry. It is expected to enhance manufacturing processes, improve output quality, and boost overall operational efficiency.The Portable Laser Welding Machine will undoubtedly establish [Company Name] as an industry leader in laser-based technologies. Its ability to redefine manufacturing practices and its commitment to sustainable solutions will undeniably shape the future of industrial manufacturing.In conclusion, [Company Name] has introduced a game-changing Portable Laser Welding Machine that has the potential to revolutionize the manufacturing industry. With unparalleled portability, precision, and versatility, this cutting-edge innovation optimizes welding processes and takes productivity to unprecedented heights. As manufacturers embrace this remarkable technology, the production landscape is set to undergo significant transformation, propelling industries towards a more efficient and sustainable future.

High-Power Laser Cleaning Machine for Effective Rust Removal - Top Selling Product of 2021

, Rust Removal Laser Cleaning Machine, and Factory Laser Cleaning Machine.IntroductionThe industrial sector comprises various activities that require high precision and accuracy in the production process. One of the challenges that industries face is the accumulation of rust on their equipment and tools, which can affect the quality of their products. To address this concern, laser cleaning technology has emerged as an effective solution. In this blog, we will discuss the top selling product in 2021 – the Factory Rust Removal 100W 200W 500W 1000W Laser Cleaning Machine by dapeng laser home. This machine allows industries to remove rust and other contaminants from their tools and equipment, saving them money and time in the long run.Features and Benefits of the Factory Rust Removal Laser Cleaning Machine1. High precision – The laser cleaning machine can target and remove rust, oil, and various contaminants without damaging the surface of the material. This feature makes it suitable for cleaning sensitive equipment such as electronic components that require high precision.2. Various power options – The Factory Rust Removal Laser Cleaning Machine is available in a wide range of power options, from 100W to 1000W. This feature means that industries can choose the most suitable power option depending on their unique needs.3. Environmentally friendly – The laser cleaning process is an environmentally friendly solution for rust removal. Unlike traditional methods that use chemicals and abrasive materials, the laser cleaning process is clean and does not produce any waste.4. Time-saving – The laser cleaning machine is designed to remove rust and other contaminants quickly. This feature increases the productivity of industries, saving them time and money in the long run.5. High durability – The Factory Rust Removal Laser Cleaning Machine is built to last. It is made of high-quality materials that can withstand the harsh industrial environment.Applications of the Laser Cleaning Machine 1000WThe Laser Cleaning Machine 1000W is a powerful solution for industries that require high precision and accuracy in their production process. Here are the top applications of this machine:1. Aerospace industry – The aerospace industry requires high precision and accuracy in their production process. The Laser Cleaning Machine 1000W is suitable for removing rust and other contaminants from aircraft parts and components.2. Automotive industry – The automotive industry requires high-quality products that meet industry standards. The Laser Cleaning Machine 1000W is suitable for cleaning engine parts, brakes, and other automotive components.3. Electronics industry – The electronics industry requires clean and dust-free components. The Laser Cleaning Machine 1000W is suitable for removing contaminants from electronic parts and components.ConclusionThe Factory Rust Removal 100W 200W 500W 1000W Laser Cleaning Machine by dapeng laser home is a top-selling product in 2021. It has various power options and is suitable for industries that require high precision and accuracy in their production process. The laser cleaning process is environmentally friendly, time-saving, and durable, making it a cost-effective solution for rust removal. The Laser Cleaning Machine 1000W is suitable for applications in the aerospace, automotive, and electronics industries, among others. If you are looking for a solution to remove rust and other contaminants from your equipment, the Factory Rust Removal 100W 200W 500W 1000W Laser Cleaning Machine is the way to go.

Unlocking the Potential: The Ultimate Guide to 5-Axis CNC Router for Woodworking

[Company Name] Introduces Next-Generation 5-Axis CNC Router Woodworking Solution[date][Location] - [Company Name], a leader in innovative manufacturing solutions, has unveiled its latest breakthrough in woodworking technology with the launch of the next-generation 5-axis CNC router. Engineered to deliver unparalleled precision and efficiency, this cutting-edge solution is set to revolutionize the woodworking industry.Woodworking has been a traditional craft for centuries, and technology has played a significant role in advancing the field. The introduction of computer numerical control (CNC) routers has automated and streamlined the woodworking process, allowing for greater accuracy, speed, and versatility. [Company Name], renowned for its commitment to excellence and advancement, has taken this to the next level with its latest offering.The 5-axis CNC router woodworking solution brings forth a host of new features and enhancements that leverage the power of modern technology. Its advanced design and construction enable craftsmen to tackle the most intricate woodworking projects with ease and precision. By integrating cutting-edge software and hardware, the machine empowers users to unleash their creativity without compromising on quality.One of the key highlights of this new CNC router is its revolutionary 5-axis capability. Unlike traditional routers that only operate on three axes (X, Y, and Z), this latest offering introduces two additional axes (A and B). This added flexibility allows for more complex and dynamic woodworking operations, enabling craftsmen to create intricate designs and shapes that were previously deemed impossible.Furthermore, the CNC router's state-of-the-art software ensures seamless integration with CAD/CAM applications, providing users with a seamless workflow. The intuitive interface simplifies the design process and allows craftsmen to visualize their creations in a digital environment before initiating production. This feature not only saves time and resources but also minimizes the risk of errors, resulting in higher-quality finished products.In addition to its impressive technical capabilities, the 5-axis CNC router boasts robust construction and durability. The machine utilizes high-quality materials and components, ensuring optimal performance and longevity. Its stability and precision are further enhanced by the incorporation of advanced servo motors and ball screws, guaranteeing accurate movements and consistent results.[Company Name]'s commitment to customer satisfaction extends beyond product excellence. The company has established a comprehensive customer support network to assist users at every stage of their woodworking journey. From initial setup and training to ongoing technical assistance, [Company Name] aims to provide a hassle-free experience to its valued customers.The introduction of the 5-axis CNC router woodworking solution marks a significant milestone for [Company Name] and the woodworking industry as a whole. By pushing the boundaries of innovation and engineering, [Company Name] is empowering craftsmen to unleash their full potential, revolutionizing the way woodworking is approached.In conclusion, the next-generation 5-axis CNC router woodworking solution offered by [Company Name] promises to be a game-changer in the industry. With its advanced features, intuitive software, and robust construction, this machine offers craftsmen unlimited creativity and precision, elevating their woodworking projects to new heights. As technology continues to evolve, [Company Name] remains at the forefront, dedicated to delivering cutting-edge solutions that shape the future of manufacturing.

Limitations of Mini Desktop CNC Mills for Machining Parts at Home

The rise of the mini desktop CNC mill has revolutionized the way we approach machining tasks. These machines may not have the size and power of full-size milling centers, but they have proven to be reliable and versatile tools that can produce high-quality parts in a variety of materials.One of the biggest advantages of a desktop CNC mill is its size. These machines are compact and easy to set up, making them perfect for small workshops or home-based businesses. They also tend to be more affordable than their larger counterparts, which is great news for hobbyists and small-business owners on a tight budget.However, there are some drawbacks to consider before investing in a mini desktop CNC mill. The primary issue is its limited capability when it comes to machining hard materials like stainless steel. The lack of rigidity in these machines can lead to poor finishes and even tool breakage, which can be frustrating and costly.For this reason, it's important to choose a desktop CNC mill that is specifically designed for the materials you plan to work with. If you're interested in machining aluminum, for example, be sure to look for a machine that is capable of handling the specific demands of this material.Another factor to consider is the machine's spindle speed. Lower-end desktop CNC mills may not have the power necessary to achieve high-speed machining, which can limit your ability to work with tougher materials. Look for a machine with a high-quality spindle that can be dialed in for optimum performance.In summary, a mini desktop CNC mill can be a great investment for hobbyists and small-business owners who need a reliable and versatile machining tool. Just be sure to choose a machine that is suited to your specific needs and materials, and understand its limitations when it comes to machining harder materials. With the right machine and proper setup, you'll be able to produce high-quality parts with ease and efficiency.