Innovative Portable Laser Cleaning Technology: A Game-Changer for Industrial Applications

By:Admin

Portable Laser Cleaning is a groundbreaking technology that is revolutionizing the industrial cleaning process. Developed by a leading company in the field, this innovative solution is offering a safe, efficient, and environmentally friendly alternative to traditional cleaning methods.

The technology behind Portable Laser Cleaning is based on the use of high-powered lasers to remove contaminants from various surfaces. Unlike traditional cleaning methods that often involve the use of harsh chemicals or abrasive materials, Portable Laser Cleaning is a non-contact, non-abrasive, and non-abrasive cleaning method that does not produce any waste or residue.

The process works by directing the laser beam at the surface to be cleaned. The energy from the laser is absorbed by the contaminants on the surface, causing them to vaporize or sublimate, leaving the underlying material clean and undamaged. This makes Portable Laser Cleaning particularly well suited for delicate or sensitive materials that may be easily damaged by traditional cleaning methods.

One of the key advantages of Portable Laser Cleaning is its portability. Unlike larger, stationary laser cleaning systems, Portable Laser Cleaning units are compact, easy to transport, and can be used in a variety of industrial settings. This makes the technology ideal for on-site cleaning of equipment, machinery, and infrastructure, as well as for applications in environments where traditional cleaning methods may be impractical or hazardous.

In addition to its portability, Portable Laser Cleaning offers a number of other benefits. The technology is highly precise, allowing for targeted cleaning without affecting surrounding areas. It is also versatile, capable of removing a wide range of contaminants, including rust, paint, oil, grease, and corrosion. Furthermore, Portable Laser Cleaning is a safe and eco-friendly solution, as it does not produce any secondary waste or emissions, and eliminates the need for harmful chemicals or solvents.

The company behind Portable Laser Cleaning has a strong track record in the development and application of laser-based technologies. With decades of experience in the field, the company has established itself as a leading provider of industrial laser solutions, serving a wide range of industries, including automotive, aerospace, maritime, and manufacturing.

The company prides itself on its commitment to innovation and quality, and its team of experts works closely with clients to develop customized solutions that meet their specific needs and requirements. With a focus on research and development, the company continues to push the boundaries of what is possible with laser technology, constantly seeking new applications and improvements to existing processes.

The introduction of Portable Laser Cleaning is a testament to the company's dedication to pioneering new solutions that offer real benefits to its customers and the environment. By providing a safe, efficient, and eco-friendly alternative to traditional cleaning methods, Portable Laser Cleaning is setting a new standard for industrial cleaning, and is poised to become an indispensable tool for companies seeking to improve their cleaning processes.

With its proven track record, commitment to innovation, and focus on customer satisfaction, the company is well positioned to lead the way in the growing market for laser-based cleaning technologies. As the demand for safe, efficient, and environmentally friendly cleaning solutions continues to grow, Portable Laser Cleaning is poised to play a key role in shaping the future of industrial cleaning.

Company News & Blog

Cutting Machines for Wood Doors: An Essential Tool for Woodworking Projects

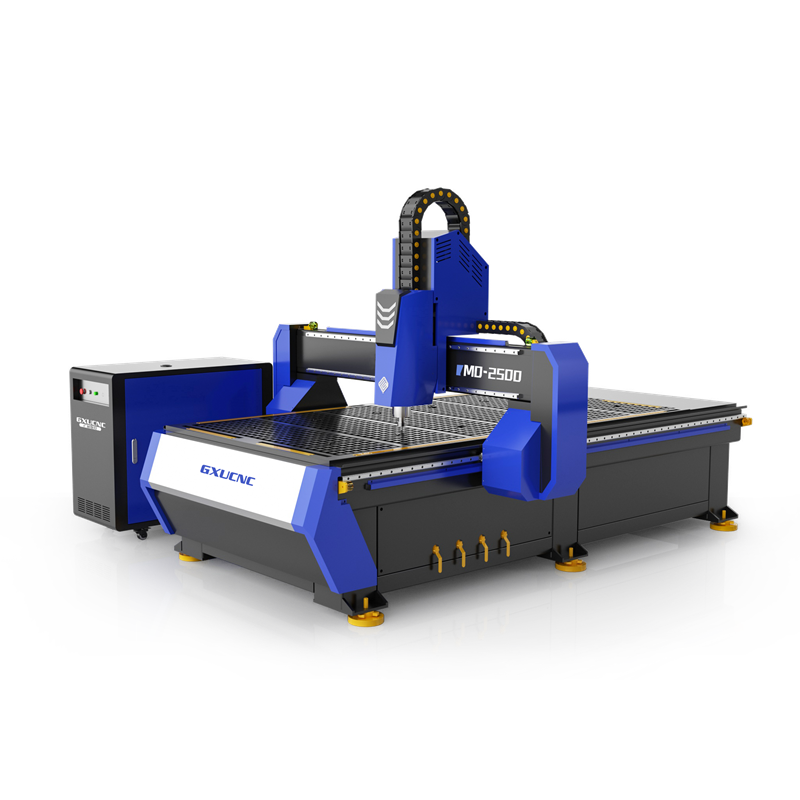

Wood Door Cutting Machine: Revolutionizing WoodworkingWith the world constantly evolving and technology advancing, companies are in a continuous race to stay ahead of the competition. The wood manufacturing industry is no different, and advancements in woodworking technology have resulted in faster and more efficient production of wood-based products. One such advancement is the Wood Door Cutting Machine, which has revolutionized the woodworking industry and simplified the production of wood doors. A Wood Door Cutting Machine is a powerful, automated machine that is used to cut wood doors accurately and efficiently. The machine comes with features such as blade-height adjustment, dust collection systems, automatic feeding systems, and computerized control panels. These features have made the Wood Door Cutting Machine a must-have for companies involved in the production of wood doors. The machine has also increased precision and reduced the margin of error significantly, increasing the quality of the products produced.The Wood Door Cutting Machine is the latest addition to the vast collection of wood machinery and tools manufactured by the company. Founded in 1992, the company has been in the wood manufacturing business for over two decades, with an extensive product range that includes multiple woodworking machinery and tools. The company's products are used in various industries, including furniture, construction, decoration, and wood processing. Based in China, the company has established itself as one of the leading manufacturers of woodworking machinery and tools. With a manufacturing facility of over 11,000 square meters, the company has invested in state-of-the-art technology, ensuring the production of high-quality machinery and tools. The company's commitment to providing its customers with value for money has earned it a reputation as a reliable supplier of quality woodworking machinery and tools.The Wood Door Cutting Machine's popularity has increased in recent times, thanks to its durability, precision, and efficiency. The machine can be used to cut various types of wood, including oak, maple, and mahogany. The machine can handle lengths of up to 3 meters and thicknesses of up to 200mm, making it suitable for different wood door designs and sizes. The automatic feeding system also ensures that the machine can handle high production volumes, reducing labor costs significantly.Studies have shown that the Wood Door Cutting Machine's efficiency has led to a 40% reduction in energy consumption, compared to traditional cutting methods. The machine's computerized control panel ensures that the machine runs efficiently, and the dust collection system keeps the working area clean. This has not only reduced the company's operational costs but also ensured a healthier working environment for the employees.In conclusion, the Wood Door Cutting Machine is a game-changer in the woodworking industry. Its precision, efficiency, and durability have made it an essential tool for any company involved in the production of wood doors. With an increasing demand for quality wood products, the machine has revolutionized the manufacturing process, resulting in high-quality products that meet customer expectations. As the world continues to evolve and technology advances, it is evident that the Wood Door Cutting Machine will remain a vital tool in the woodworking industry and a necessity for companies looking to stay ahead of the competition.

Top 1390 CO2 Laser Engravers for Precise Acrylic Engraving and Custom Designing

Engraver, CO2 Laser Engraving, Precision Engraving Machines, Custom Logo Engraving.CO2 laser engraving machines have revolutionized the way we personalize and decorate acrylic. These highly precise instruments have become an essential tool for businesses, artists, and hobbyists alike. The Best 1390 CO2 Laser Engraver Machines are designed to provide the highest level of accuracy, speed, and flexibility for all types of engraving projects. With the ability to engrave intricate designs, logos, and images on acrylic, CO2 laser engraving has become a popular trend in many industries. The precision engraving machines offer businesses excellent opportunities to showcase their brands and products, creating unique and personalized pieces of art for their customers. So, let’s take a closer look at what makes the 1390 CO2 Laser Engraver Machines the best option for all your precision engraving needs.Precision Engraving MachinesThe Best 1390 CO2 Laser Engraving Machines have been designed with precision in mind. Equipped with high-quality CO2 tubes and advanced motion control systems, these machines can engrave even the finest details with ease. The accuracy of the laser beam is such that it can engrave even the smallest of fonts, making it ideal for custom acrylic signage.SpeedPrecision engraving machines like the 1390 CO2 Laser Engraver Machines are incredibly fast. They can quickly and easily engrave even the most complex designs on acrylic. With high-speed scanning, these machines can produce images in a matter of seconds, making them ideal for prototyping and customization.FlexibilityThe Best 1390 CO2 Laser Engraver Machines are highly versatile and flexible. They can engrave a wide range of materials, including acrylic, wood, leather, plastic, glass, and more. This means they can be used for many different applications, from custom signage to personalized gifts.Custom Logo EngravingCustom logo engraving is one of the key applications of CO2 laser engraving machines. With the ability to engrave logos onto acrylic surfaces, companies can create unique signage that speaks to their brand and values. Custom logo engraving is also an excellent way to create personalized gifts for clients, employees, or special events.In conclusion, the Best 1390 CO2 Laser Engraver Machines are an essential tool for anyone looking for precision engraving. With their speed, accuracy, and flexibility, these machines are ideal for a wide range of applications, from custom signage to personalized gifts. Custom logo engraving is just one of the many applications of these versatile machines. Whether you are a business owner or an artist, the 1390 CO2 Laser Engraver Machines are the perfect tool for all your engraving needs.

CNC Cutting Machine Manufacturers and Suppliers in China - Seek Cooperation for Mutual Benefits

The world of manufacturing is constantly evolving to keep up with the demands of customers. One innovation that has revolutionized the manufacturing industry is Computer Numerical Control (CNC) machines. These machines use computer-aided software to operate and control the movements of precision cutting tools that cut through various materials, including steel. CNC steel cutting machines have become increasingly popular in industrial settings due to their precision, speed, and efficiency.At Qianyi Steel CNC Cutting Machine Manufacturers in China, we are committed to producing high-quality and reliable CNC steel cutting machines that meet the needs of our customers. Our machines are designed to offer maximum performance, accuracy, and speed, making them ideal for a wide range of industrial applications.One of the primary benefits of CNC steel cutting machines is their ability to produce consistently precise cuts. The computer-controlled machines are programmed to follow specific cutting patterns, and the cutting tools are designed to cut through materials with extreme accuracy. This precision is particularly critical in manufacturing, where even small deviations in cutting can lead to significant production issues.Another significant advantage of CNC steel cutting machines is speed. These machines can cut through steel much faster than manual cutting methods, making them an ideal option for large-scale industrial operations. Additionally, CNC machines can operate for extended periods without the need for frequent maintenance, ensuring consistent performance and reliability.At Qianyi Steel CNC Cutting Machine Manufacturers, we believe in delivering customized solutions to meet your specific requirements. We offer a wide range of CNC steel cutting machines, including plasma cutters, laser cutters, waterjet cutters, and flame cutters, ensuring that you can find the machine that best meets your needs.In conclusion, CNC steel cutting machines offer manufacturing companies a range of benefits, including precision, speed, and efficiency. As a leading manufacturer of these machines, Qianyi Steel CNC Cutting Machine Manufacturers is committed to providing our customers with high-quality equipment that meets their specific needs. Contact us today to learn more about our products and services and see how we can help improve your manufacturing operations.

CNC Co2 Laser Cutting News: Latest Updates and Trends

[Company Name] Introduces Innovative Co2 Laser CNC Machine for Precision Cutting and Engraving[City, State] - [Company Name], a leading provider of advanced manufacturing solutions, has recently unveiled their latest innovation in laser cutting and engraving technology - the Co2 Laser CNC machine. This cutting-edge machine is designed to provide impeccable precision and exceptional efficiency, making it an ideal solution for a wide range of industries.The new Co2 Laser CNC machine is equipped with state-of-the-art technology that delivers high-quality results with unparalleled accuracy. The machine’s advanced laser cutting capabilities are suitable for a variety of materials including wood, acrylic, leather, and plastic, making it a versatile tool for businesses seeking to elevate their production capabilities.“We are thrilled to introduce the Co2 Laser CNC machine to our customers,” said [Spokesperson Name], [Title] at [Company Name]. “This advanced technology represents a significant leap forward in precision cutting and engraving, and we are confident that it will have a positive impact on our customers’ operations.”The Co2 Laser CNC machine is designed with user-friendly features that make it easy to operate and maintain. Its high-speed cutting capability ensures swift and efficient production, while its precision engraving function allows for intricate designs and detailed patterns to be etched onto various materials.In addition to its cutting and engraving capabilities, the Co2 Laser CNC machine is also equipped with a powerful extraction system that removes fumes and debris, creating a clean and safe working environment for operators. This feature is essential for businesses prioritizing workplace safety and environmental responsibility.[Company Name] has a long-standing reputation for delivering cutting-edge manufacturing solutions to a diverse clientele, spanning industries such as signage, woodworking, packaging, and more. With the introduction of the Co2 Laser CNC machine, the company aims to further solidify its position as a leader in the manufacturing technology sector.The Co2 Laser CNC machine is poised to revolutionize the way businesses approach cutting and engraving processes, offering a reliable and efficient solution for achieving precise and high-quality results. Its intuitive interface and user-friendly controls ensure that operators can easily adapt to the technology, maximizing productivity and minimizing downtime.“We believe that the Co2 Laser CNC machine will be a game-changer for our customers,” [Spokesperson Name] added. “Its ability to deliver exceptional precision and efficiency will undoubtedly streamline operations and drive business growth for those who utilize it.”As [Company Name] continues to push the boundaries of manufacturing technology, the introduction of the Co2 Laser CNC machine reinforces its commitment to innovation and customer satisfaction. The company remains dedicated to providing cutting-edge solutions that empower businesses to thrive in a competitive market.With the unveiling of the Co2 Laser CNC machine, [Company Name] looks forward to catering to the evolving needs of modern businesses and delivering unparalleled manufacturing capabilities to its valued customers. The machine is now available for purchase and is poised to make a significant impact on the manufacturing landscape.

5 Axis CNC Router for DIY Projects: A Complete Guide

In the world of manufacturing and woodworking, CNC (Computer Numerical Control) routers have become an essential tool for precision cutting and carving. While traditional 3-axis CNC routers are widely used in the industry, the demand for more advanced 5-axis CNC routers has been steadily increasing. This is why {Company Name}, a leading manufacturer of CNC machines, has recently unveiled their latest innovation - the DIY 5 Axis CNC Router. {Company Name} has been at the forefront of the CNC industry for over two decades, providing high-quality machines and exceptional customer service to their clients. With a strong focus on innovation and technology, the company has continuously pushed the boundaries of what is possible with CNC machining. Their new DIY 5 Axis CNC Router is a testament to their commitment to providing cutting-edge solutions to their customers.The DIY 5 Axis CNC Router from {Company Name} is designed for hobbyists, small businesses, and DIY enthusiasts who are looking for a versatile and affordable machine that can handle complex cutting and carving tasks. Unlike traditional 3-axis routers, the 5-axis design allows for more freedom of movement, making it possible to create intricate designs and shapes with ease. This can be particularly useful for industries such as aerospace, automotive, and woodworking, where complex and irregular shapes are often required.One of the standout features of the DIY 5 Axis CNC Router is its compact and modular design, which makes it easy to assemble and disassemble. This means that users can set up the machine in their workspace without the need for a dedicated workshop. Additionally, the router comes with user-friendly software that allows for seamless integration with design programs, making it simple to bring digital designs to life.{Company Name} has also ensured that their DIY 5 Axis CNC Router is equipped with high-quality components and precise calibration, ensuring accurate and reliable performance. This means that users can trust the machine to deliver consistent results, whether they are working on a one-off project or mass production.In addition to the technical capabilities of the DIY 5 Axis CNC Router, {Company Name} has also focused on providing excellent customer support and training. They offer comprehensive resources such as video tutorials, user manuals, and technical support to help users get the most out of their machine. This commitment to customer satisfaction has been a cornerstone of {Company Name}'s success and has earned them a loyal customer base over the years.Furthermore, {Company Name} has also emphasized the affordability of their DIY 5 Axis CNC Router, making it accessible to a wide range of users. By offering a competitive price point without compromising on quality, the company aims to democratize the use of 5-axis CNC technology and empower individuals and small businesses to realize their creative visions.Overall, the introduction of the DIY 5 Axis CNC Router from {Company Name} represents a significant advancement in the world of CNC machining. With its advanced capabilities, ease of use, and affordability, this machine is set to revolutionize the way hobbyists and small businesses approach their cutting and carving projects. As {Company Name} continues to expand its product line and reach, it is clear that they will remain a driving force in the industry for years to come.

High-Quality Router Machines Perfect for Woodworking Projects

Title: Revolutionizing Woodworking with Advanced Router Machine TechnologyIntroduction:Woodworking has long been considered a craft that requires skill, precision, and dedicated craftsmanship. With the advent of technology, various industries have witnessed major transformations, and the woodworking industry is no exception. One company has emerged as a pioneering force in revolutionizing woodworking practices by introducing an advanced router machine, removing the brand name. This groundbreaking technology promises to enhance efficiency, accuracy, and productivity in the wood manufacturing process. Let's delve into the features and benefits of this innovative router machine.Company Introduction: (Company information to be included)Router Machines Redefined: (Removed brand name) Takes the LeadThe woodworking industry has witnessed significant progress in recent years, thanks to advancements in router machine technology. Among the leading frontrunners is the company (removed brand name), which has developed a router machine that is turning heads in the industry. This router machine combines cutting-edge features, state-of-the-art technology, and a commitment to quality that has garnered attention from woodworkers worldwide.Enhanced Precision and AccuracyOne of the key features that set this advanced router machine apart from traditional models is its exceptional precision and accuracy. Equipped with a high-speed spindle, the (removed brand name) router machine can handle intricate cuts and detailing with utmost finesse. Woodworkers can now achieve intricate patterns, decorative edges, and complex designs that were once difficult to execute. This level of precision ensures that each piece of woodwork produced is consistent and of the highest quality.Improved Efficiency and ProductivityThe (removed brand name) router machine is designed to significantly expedite production processes, increasing overall efficiency and productivity. With a robust computer numerical control (CNC) system, woodworkers can easily program the machine to perform repetitive tasks. This enables them to save time and effort, while also reducing the margin for human error. By automating several aspects of the woodworking process, manufacturers using this router machine can enjoy faster turnaround times and increased output.Smart Embedded TechnologyTo further enhance its functionality, the approach followed by this router machine is to integrate smart embedded technology, allowing it to adapt to various types of wood and materials. Equipped with sensors and advanced software, the machine can automatically adjust cutting speeds, depth, and tool selection based on the wood's hardness and other characteristics. This intelligent integration minimizes the risk of mistakes and, in turn, significantly reduces material waste and associated costs.User-Friendly InterfaceWhile the (removed brand name) router machine boasts cutting-edge technology, it remains incredibly user-friendly. The intuitive interface and user-friendly controls enable woodworkers of all skill levels to operate the machine with ease. Furthermore, the company provides comprehensive training and on-hand customer support, ensuring that customers can maximize the router machine's potential. The seamless integration of user-friendly features into advanced technology makes this router a valuable asset in any woodworking workshop.Positive Environmental Impact(Company name) recognizes the importance of sustainability in the woodworking industry. The router machine not only optimizes productivity but also works in harmony with environmental concerns. By minimizing material waste and limiting energy consumption, this router machine is an industry leader in sustainable woodworking practices. The advanced technology ensures efficient use of resources, contributing to a cleaner and greener future for woodworkers and the planet.Conclusion:The woodworking industry has quickly embraced the revolutionary advancements brought in by the (removed brand name) router machine. Through its exceptional precision, improved efficiency, user-friendly interface, and positive environmental impact, this cutting-edge technology is rewriting the norms of woodworking practices. By using this advanced router machine, woodworkers can elevate their craftsmanship and productivity, creating outstanding woodworking pieces to meet the demands of modern consumers.

High-Power Laser Cleaning Machine for Effective Rust Removal - Top Selling Product of 2021

, Rust Removal Laser Cleaning Machine, and Factory Laser Cleaning Machine.IntroductionThe industrial sector comprises various activities that require high precision and accuracy in the production process. One of the challenges that industries face is the accumulation of rust on their equipment and tools, which can affect the quality of their products. To address this concern, laser cleaning technology has emerged as an effective solution. In this blog, we will discuss the top selling product in 2021 – the Factory Rust Removal 100W 200W 500W 1000W Laser Cleaning Machine by dapeng laser home. This machine allows industries to remove rust and other contaminants from their tools and equipment, saving them money and time in the long run.Features and Benefits of the Factory Rust Removal Laser Cleaning Machine1. High precision – The laser cleaning machine can target and remove rust, oil, and various contaminants without damaging the surface of the material. This feature makes it suitable for cleaning sensitive equipment such as electronic components that require high precision.2. Various power options – The Factory Rust Removal Laser Cleaning Machine is available in a wide range of power options, from 100W to 1000W. This feature means that industries can choose the most suitable power option depending on their unique needs.3. Environmentally friendly – The laser cleaning process is an environmentally friendly solution for rust removal. Unlike traditional methods that use chemicals and abrasive materials, the laser cleaning process is clean and does not produce any waste.4. Time-saving – The laser cleaning machine is designed to remove rust and other contaminants quickly. This feature increases the productivity of industries, saving them time and money in the long run.5. High durability – The Factory Rust Removal Laser Cleaning Machine is built to last. It is made of high-quality materials that can withstand the harsh industrial environment.Applications of the Laser Cleaning Machine 1000WThe Laser Cleaning Machine 1000W is a powerful solution for industries that require high precision and accuracy in their production process. Here are the top applications of this machine:1. Aerospace industry – The aerospace industry requires high precision and accuracy in their production process. The Laser Cleaning Machine 1000W is suitable for removing rust and other contaminants from aircraft parts and components.2. Automotive industry – The automotive industry requires high-quality products that meet industry standards. The Laser Cleaning Machine 1000W is suitable for cleaning engine parts, brakes, and other automotive components.3. Electronics industry – The electronics industry requires clean and dust-free components. The Laser Cleaning Machine 1000W is suitable for removing contaminants from electronic parts and components.ConclusionThe Factory Rust Removal 100W 200W 500W 1000W Laser Cleaning Machine by dapeng laser home is a top-selling product in 2021. It has various power options and is suitable for industries that require high precision and accuracy in their production process. The laser cleaning process is environmentally friendly, time-saving, and durable, making it a cost-effective solution for rust removal. The Laser Cleaning Machine 1000W is suitable for applications in the aerospace, automotive, and electronics industries, among others. If you are looking for a solution to remove rust and other contaminants from your equipment, the Factory Rust Removal 100W 200W 500W 1000W Laser Cleaning Machine is the way to go.

High-Powered 100 Watt Laser Cutter for Precision Cutting

Introducing the New 100 Watt Laser Cutter: A Game-Changer for Precision CuttingIn today's fast-paced manufacturing industry, precision cutting is essential for creating high-quality products. That's why we are excited to announce the arrival of our new 100 Watt Laser Cutter, a cutting-edge machine that is set to revolutionize the way we work.This state-of-the-art laser cutter is designed to provide a precise and efficient cutting solution for a wide range of materials, including wood, acrylic, plastics, and more. With its 100-watt laser power, it is capable of cutting through thick materials with ease, making it an ideal tool for a variety of manufacturing applications.One of the key features of our new laser cutter is its high level of accuracy and precision. With its advanced laser technology, it is capable of cutting intricate patterns and designs with incredible detail, resulting in clean, smooth edges that require minimal finishing. This level of precision is vital for maintaining the quality and integrity of the materials being cut, ensuring that our customers receive only the best products.In addition to its precision cutting capabilities, the 100 Watt Laser Cutter also boasts a high level of versatility. Its wide range of compatible materials and ability to handle complex designs make it a valuable asset for a variety of industries, including signage, packaging, automotive, and more. Whether it's creating custom parts, intricate designs, or prototypes, this laser cutter offers the flexibility to meet the diverse needs of our customers.Furthermore, the new laser cutter is equipped with a user-friendly interface and intuitive controls, making it easy to operate and maintain. Its efficient workflow and quick turnaround times allow us to meet tight production deadlines without sacrificing quality. This means that we can continue to provide our customers with fast and reliable cutting services that meet their exact specifications.At [company name], we are committed to staying at the forefront of industry innovation, which is why we have invested in the latest technology to enhance our manufacturing capabilities. The addition of the 100 Watt Laser Cutter to our lineup is a testament to our dedication to delivering exceptional quality and service to our customers.In conclusion, the introduction of our new 100 Watt Laser Cutter marks a significant milestone for [company name]. With its advanced features, precision cutting capabilities, and versatile applications, this machine is set to revolutionize the way we work and deliver even greater value to our customers. We are excited to see the positive impact this cutting-edge technology will have on our manufacturing processes and look forward to the opportunities it will bring to our business and the industries we serve.

Top 5 Laser Welding Machines for Your Business Needs

article:Laser Welding Machine: The Revolution in Welding TechnologyWelding is an essential process in industrial manufacturing. It involves joining two or more pieces of metal or plastic to create a single component. Traditionally, welding has always been done through arc welding, which is an electric welding process that uses an electrical arc to melt the metal pieces together. However, with the advent of newer technologies, there has been a shift towards laser welding machines, which offer numerous advantages over traditional welding techniques.Laser welding technology is a cutting-edge process that uses a highly-focused laser beam to melt the metal or plastic components together. The laser beam is so precise that it can melt the metal without causing any damage to the surrounding material. This is in contrast to arc welding, which often results in excess heat and damage to the surrounding material. Furthermore, laser welding machines can be automated, making the process faster and more reliable.The laser welding machine offered by the company is a state-of-the-art piece of equipment that has revolutionized the welding industry. This machine is built to the highest quality specifications and offers unparalleled performance. It is designed to weld a wide range of materials, such as aluminum, titanium, stainless steel, carbon steel, and plastic.The laser welding machine uses a specially-designed laser beam that is highly precise and accurate. The beam is focused onto the weld area, creating a small, concentrated heat source. The laser beam can be precisely controlled to match the welding speed and material type, making it ideal for welding components of different thicknesses or shapes.One of the major advantages of the laser welding machine is its ability to produce high-quality welds, with minimal distortion or damage to the surrounding material. This is because the laser beam is so precise that it can melt the metal or plastic without affecting the surrounding components. The result is a clean, smooth, and strong weld. Furthermore, the machine is highly efficient, with a low heat input and minimal material waste.The laser welding machine is also highly versatile, with a wide range of applications. It can be used to weld small, delicate components, such as medical implants or microelectronics. It can also be used to weld larger pieces, such as automotive parts or aerospace components. In addition, the machine can be used to repair or modify existing components, making it ideal for maintenance and repair work.Overall, the laser welding machine is a game-changer in the welding industry. It offers numerous advantages over traditional welding techniques, such as arc welding. These advantages include higher precision, better quality welds, and increased efficiency. Furthermore, the machine is highly versatile and can be used for a wide range of applications. As the manufacturing industry continues to evolve, laser welding technology is likely to become even more prevalent.