Affordable Metal Engraving Machine for Small Projects

By:Admin

The metal engraving industry has seen a significant transformation with the introduction of the Mini Metal Engraving Machine by a leading company in the field. This innovative machine has revolutionized the way metal engraving is done, making the process faster, more precise, and efficient.

The Mini Metal Engraving Machine is a compact and versatile tool that is designed to meet the growing demand for high-quality metal engraving in various industries such as jewelry making, metalworking, and signage production. This machine offers a range of features that make it an ideal choice for both small-scale businesses and large industrial operations.

One of the standout features of the Mini Metal Engraving Machine is its precision and accuracy. Equipped with advanced technology and high-quality components, the machine is capable of engraving intricate designs and patterns with remarkable detail. This level of precision is essential for industries where the quality of the engraving is paramount, such as jewelry making where every detail matters.

In addition to its precision, the Mini Metal Engraving Machine also offers speed and efficiency. With its fast engraving speed and automated functions, the machine can significantly reduce production time and increase output. This is particularly beneficial for businesses looking to streamline their operations and meet tight deadlines without compromising on quality.

Furthermore, the Mini Metal Engraving Machine is user-friendly and easy to operate. Its intuitive interface and simple controls make it accessible to both experienced engravers and those new to the industry. This ensures that businesses can quickly integrate the machine into their production processes without the need for extensive training or specialized skills.

The versatility of the Mini Metal Engraving Machine is another key advantage. It is capable of engraving a wide range of metals including stainless steel, aluminum, brass, and copper, as well as other materials such as plastics and acrylics. This flexibility allows businesses to expand their offerings and cater to a diverse range of customer needs.

The company behind the Mini Metal Engraving Machine has a strong reputation in the industry for delivering high-quality and reliable engraving solutions. With years of experience and a commitment to innovation, they have continually pushed the boundaries of what is possible in metal engraving technology. Their dedication to excellence is evident in the performance and capabilities of the Mini Metal Engraving Machine.

In addition to the machine itself, the company also provides comprehensive customer support and service. From installation and training to ongoing maintenance and technical assistance, they ensure that their clients are fully supported in maximizing the potential of the Mini Metal Engraving Machine. This level of dedication to customer satisfaction sets them apart as a trusted partner in the industry.

Overall, the Mini Metal Engraving Machine is a game-changer for the metal engraving industry. Its combination of precision, speed, efficiency, and versatility has raised the bar for what is possible in metal engraving technology. With the backing of a reputable company and a strong emphasis on customer support, the machine is set to become a must-have tool for businesses looking to elevate their metal engraving capabilities.

Company News & Blog

Advanced Fiber Laser Welding Technology: A Game-Changer in Manufacturing

Fiber Laser Welding Technology Revolutionizes the Manufacturing IndustryAs the manufacturing industry continues to evolve, new technologies are constantly being developed to improve efficiency and productivity. One of the latest innovations to impact the industry is fiber laser welding, a breakthrough technology that has the potential to revolutionize the way products are manufactured.Fiber laser welding is a cutting-edge technique that uses a high-powered laser to join metals together. Unlike traditional welding methods, which rely on heat generated by an electric arc or flame, fiber laser welding achieves the same result through the use of a concentrated beam of light. This results in a more precise and efficient welding process, with the ability to produce stronger and more durable welds.The introduction of fiber laser welding technology has been a game-changer for manufacturers across a wide range of industries, including automotive, aerospace, and electronics. By incorporating this advanced welding technique into their production processes, companies are able to significantly reduce the time and cost associated with manufacturing, while also improving the overall quality of their products.One company that has been at the forefront of the fiber laser welding revolution is {}. With a strong focus on innovation and technological advancement, {} has been able to leverage fiber laser welding technology to enhance their manufacturing capabilities and stay ahead of the competition.{} is a leading manufacturer of metal components and assemblies, serving a diverse customer base that includes some of the world's largest automotive and aerospace companies. With a reputation for delivering high-quality products and exceptional customer service, {} is committed to staying at the forefront of technological advancements in the industry. This commitment has led the company to invest in state-of-the-art fiber laser welding equipment, and to train its employees in the latest welding techniques.By incorporating fiber laser welding into their production processes, {} has been able to achieve several key benefits. The precise and efficient nature of fiber laser welding has enabled the company to increase their manufacturing speed, lower their production costs, and improve the overall quality of their products. This has allowed {} to better meet the needs of their customers, while also positioning the company for future growth and success.In addition to the tangible benefits of improved efficiency and product quality, fiber laser welding has also had a positive impact on the environmental sustainability of {}'s manufacturing operations. The technology's ability to reduce energy consumption and minimize waste has allowed {} to operate in a more environmentally responsible manner, aligning with the company's commitment to sustainability and corporate social responsibility.As fiber laser welding technology continues to gain traction in the manufacturing industry, {} is well-positioned to capitalize on the opportunities that it presents. By leveraging this advanced welding technique, the company is able to differentiate itself from competitors, while also delivering greater value to its customers. With a strong foundation built on innovation, quality, and customer satisfaction, {} is poised to remain a leader in the industry for years to come.In conclusion, the introduction of fiber laser welding technology has had a profound impact on the manufacturing industry, and companies like {} are leading the way in embracing this revolutionary technique. With its ability to improve efficiency, reduce costs, and enhance product quality, fiber laser welding is set to transform the way products are manufactured across a wide range of industries. As the demand for high-quality, innovative manufacturing solutions continues to grow, fiber laser welding is poised to play a central role in shaping the future of the industry.

The Most Powerful 2000 Watt Laser Cutter for All Your Cutting Needs

article about the latest advancements in laser technology and their impact on manufacturing.The latest innovation in laser technology has been revealed with the unveiling of a 2000-watt laser cutter. This new technology promises to revolutionize the manufacturing industry, offering a fast, efficient and cost-effective solution to cutting a wide range of materials. This new development comes from one of the leading companies in the industry, who have been working tirelessly to develop the latest cutting-edge technology.The use of laser cutting technology has been around for several years, but with the introduction of the 2000-watt laser cutter, it is safe to say that the industry has been taken to a whole new level. This cutting-edge technology is set to have a significant impact on various sectors, including aerospace, defense, automotive, and jewellery. As companies look to seek out top quality products while still maintaining low production overheads, this new technology is set to revolutionize the manufacturing industry.The 2000-watt laser cutter is an exceptional machine that utilizes precise light amplification technology (PLT) to deliver unmatched cutting performance. It has the capability to cut through almost any material, including stainless steel, aluminum, acrylic, plastics, and wood. The technology is so advanced that it can accurately cut intricate designs with great ease and precision.The company behind this new innovation has rightly been dubbed as one of the frontrunners in the industry. They specialize in the production of a wide range of laser cutting machines, and with the introduction of the 2000-watt laser cutter, they have once again proven their commitment to providing their clients with cutting-edge technology.The company is known for its dedication to quality, and the 2000-watt laser cutter lives up to that reputation. The machine has been built with advanced components, which have been carefully selected and rigorously tested to ensure optimal performance.One of the most notable advantages of this technology is its speed. The 2000-watt laser cutter is capable of cutting through thick materials at an impressive rate, making it an ideal solution for manufacturers who require high-volume production. The machine is also designed with maximum efficiency in mind, with a low-power consumption that reduces the risk of overheating and ensures that it is cost-effective in the long run.In addition to its speed and efficiency, the 2000-watt laser cutter comes with several safety features. The machine is designed with advanced safety features that make it easier to use, even for inexperienced operators. This significantly limits the risk of accidents in the workplace, which is why this technology is fast gaining popularity in manufacturing firms across the globe.This latest innovation in laser technology is set to have a significant impact on the manufacturing industry. It is ideal for creating high-quality products in a short period, which is essential in today's fast-paced environment. The 2000-watt laser cutter is expected to be a game-changer for manufacturers, allowing them to streamline their production processes and boost their profits.In conclusion, the introduction of the 2000-watt laser cutter is a testament to the continued advancements in laser technology. The machine is fast, efficient, versatile and safe, making it an ideal solution for manufacturers across various industries. With the increasing demand for top-quality products, manufacturers need to invest in the latest technology to remain competitive. As the demand for the 2000-watt laser cutter continues to grow, it is bound to become the go-to machine for manufacturers looking to achieve a competitive edge.

Effective Rust and Stain Remover for Steel and Cast Iron Tools

Rust is a common enemy for all metal materials, including power tools and hand tools, that can make them less effective and shorten their lifespan. It is essential to keep your tools clean and rust-free to ensure they are always ready to deliver optimal performance during your DIY projects or professional work. If you're looking for a reliable and fast-acting rust remover for your tools, the Boeshield Rust Free Rust and Stain Remover may just be the solution you need.This 8 oz. spray bottle is specially created for steel, cast iron, and other metal surfaces that are prone to rust, oxidation, and staining. It contains a powerful rust remover formula that dissolves rust and makes it easy to wipe away with a cloth or brush. You don't have to worry about damage to your tools' surfaces because the solution is gentle and non-abrasive. Plus, it works quickly, saving you time and effort in cleaning and restoring your tools' condition.One of the advantages of using Boeshield Rust Free Rust and Stain Remover is that it comes in a handy spray bottle that allows for easy application. You can spray it directly onto your tools' surface, and the solution will penetrate deep to dissolve the rust and stains. Also, the spray bottle's compact size makes it perfect for on-the-go use, so you can take it with you to job sites or keep it in your toolbox.Another remarkable feature of the Boeshield Rust Free Rust and Stain Remover is its versatility. You can use it not only on your power tools and hand tools but also on other metal surfaces, including automotive parts, marine equipment, household appliances, and more. It is an all-purpose rust remover that provides excellent value for your money.Are you wondering if the Boeshield Rust Free Rust and Stain Remover is safe for you and the environment? The answer is yes! It is a non-toxic and non-hazardous formula that does not contain harsh chemicals or acids. This means you can use it without worrying about health risks or environmental pollution. It is a safe and sustainable way to keep your tools and metal items rust-free.If you're looking for a more powerful and advanced solution to remove rust from your tools, you may consider using a laser paint rust remover. This technology uses high-intensity light beams to heat the rust and convert it into vapors that can be easily removed. It is a fast, efficient, and safe way to eliminate rust without damaging the metal surface.In conclusion, the Boeshield Rust Free Rust and Stain Remover is an excellent choice for anyone looking for a fast-acting and versatile rust remover for their tools. Its gentle formula, easy application, and eco-friendly nature make it a top-rated product in the market. If you're looking for a more advanced solution, you may consider a laser paint rust remover that can provide you with even better results. Keep your tools rust-free, and they will serve you for many years to come!

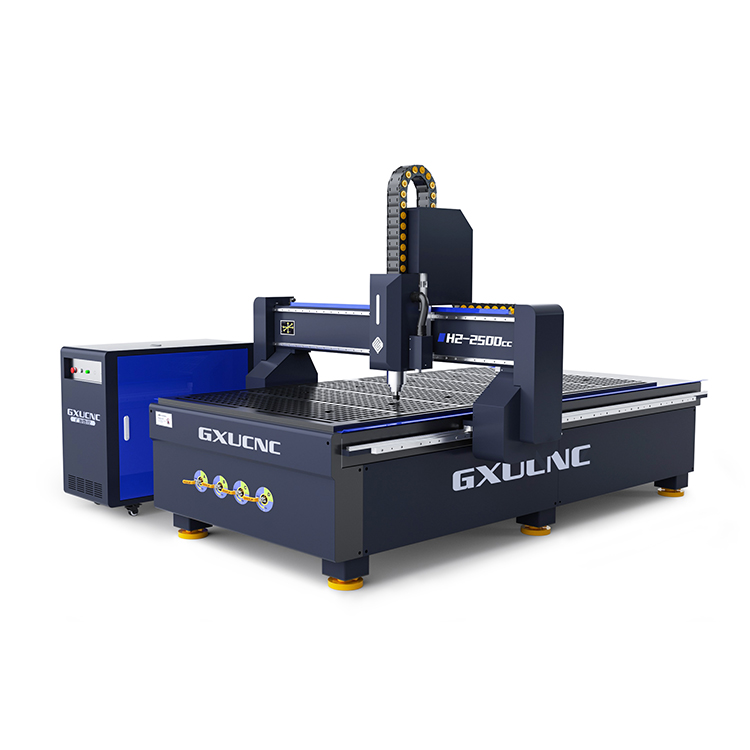

Unlock Your Woodworking Potential with a High-Quality CNC Router - Tribune Online A computer-controlled router tool, known as a CNC router, can make intricate and accurate cuts in a range of materials like wood, plastic, metal, and even decorative items.

Maximize Your Woodworking Potential with a Top-Quality CNC RouterIf you are a woodworking enthusiast, you know how important precision and accuracy are in creating beautiful and functional pieces. A CNC router may just be the tool you need to take your woodworking skills to the next level. A CNC (computer numerical control) router is a cutting machine that uses computer programs to produce intricate and precise cuts.A 12x12 CNC router is the perfect size for home woodworking projects. It allows you to cut and carve various materials, including wood, glass, plastic, and even metals, with remarkable precision. Additionally, it is a versatile machine that can produce items ranging from decorative pieces to functional furniture.Benefits of a CNC Router in WoodworkingBetter Precision: One of the most significant advantages of using a CNC router in woodworking is the level of precision it offers. The use of digital technology and computer programs eliminates human errors, producing precise cuts and carvings.Increased Efficiency: With a CNC router, you can produce multiple and identical pieces in a shorter period. This is because a computer program controls the machine, allowing you to work on multiple pieces simultaneously without having to measure and mark each piece several times.Enhanced Creativity: A CNC router allows you to achieve intricate and complex designs easily, giving you the freedom to exercise your creativity and imagination fully.Ease of Use: A 12x12 CNC router is straightforward to operate, even for beginners. Once you have a design, all you need to do is upload it to the machine via a computer, and the machine does the rest.Things to Consider When Buying a CNC RouterSize: The size of a CNC router determines the size of the material you can work on. Before purchasing a router, consider the size of the projects you intend to undertake and choose a machine that accommodates your needs.Power: A more powerful router translates to faster cutting speeds. However, a more powerful router also means higher costs. Consider your budget and the type of projects you intend to work on when choosing a router.Cost: CNC routers come in different sizes, powers, and prices. While it may be tempting to purchase the cheapest option, it is essential to weigh the performance and quality you get against the price.ConclusionA CNC router is a valuable tool for any woodworking enthusiast. It allows you to create precise and detailed cuts in various materials, producing high-quality functional and decorative pieces. A 12x12 CNC router is an excellent option for home woodworking projects as it is versatile, easy to use, and takes up minimal space.

Woodworking CNC Routers - Top Manufacturers and Suppliers in China

In the world of woodworking, precision and accuracy are two key factors that can make or break a project. That’s why woodworkers of all skill levels rely on tools like the wood CNC router to ensure the best possible results. In China, manufacturers and suppliers are leading the way in creating high-quality wood CNC routers, including mini wood routers that are ideal for smaller projects.One of the main advantages of using a wood CNC router is its ability to create intricate designs with ease. The machine uses computer numerical control (CNC) technology to precisely cut, carve, and shape wood according to a digital design. This means that woodworkers can create complex designs and shapes that would be difficult, if not impossible, to achieve by hand.Another advantage of using a wood CNC router is speed. These machines can work quickly and efficiently, which is especially useful for those who make woodworking a profession. With a wood CNC router, woodworkers can save time on each project without losing quality.In China, wood CNC router manufacturers and suppliers are known for producing high-quality machines that are both reliable and affordable. For example, mini wood routers are becoming increasingly popular in the market due to their compact size and affordability. These machines are perfect for hobbyists and small businesses that need to produce smaller wood pieces quickly and accurately.Overall, the benefits of using a wood CNC router cannot be overstated. These machines offer precision, speed, and flexibility, making them a must-have tool for every woodworker. Whether you are a beginner or an experienced woodworker, a wood CNC router is an investment that will pay off in the long run. If you’re in the market for a wood CNC router, be sure to check out the various manufacturers and suppliers in China, who offer high-quality machines at competitive prices.

Top 5 Laser Welding Machines for Your Business Needs

article:Laser Welding Machine: The Revolution in Welding TechnologyWelding is an essential process in industrial manufacturing. It involves joining two or more pieces of metal or plastic to create a single component. Traditionally, welding has always been done through arc welding, which is an electric welding process that uses an electrical arc to melt the metal pieces together. However, with the advent of newer technologies, there has been a shift towards laser welding machines, which offer numerous advantages over traditional welding techniques.Laser welding technology is a cutting-edge process that uses a highly-focused laser beam to melt the metal or plastic components together. The laser beam is so precise that it can melt the metal without causing any damage to the surrounding material. This is in contrast to arc welding, which often results in excess heat and damage to the surrounding material. Furthermore, laser welding machines can be automated, making the process faster and more reliable.The laser welding machine offered by the company is a state-of-the-art piece of equipment that has revolutionized the welding industry. This machine is built to the highest quality specifications and offers unparalleled performance. It is designed to weld a wide range of materials, such as aluminum, titanium, stainless steel, carbon steel, and plastic.The laser welding machine uses a specially-designed laser beam that is highly precise and accurate. The beam is focused onto the weld area, creating a small, concentrated heat source. The laser beam can be precisely controlled to match the welding speed and material type, making it ideal for welding components of different thicknesses or shapes.One of the major advantages of the laser welding machine is its ability to produce high-quality welds, with minimal distortion or damage to the surrounding material. This is because the laser beam is so precise that it can melt the metal or plastic without affecting the surrounding components. The result is a clean, smooth, and strong weld. Furthermore, the machine is highly efficient, with a low heat input and minimal material waste.The laser welding machine is also highly versatile, with a wide range of applications. It can be used to weld small, delicate components, such as medical implants or microelectronics. It can also be used to weld larger pieces, such as automotive parts or aerospace components. In addition, the machine can be used to repair or modify existing components, making it ideal for maintenance and repair work.Overall, the laser welding machine is a game-changer in the welding industry. It offers numerous advantages over traditional welding techniques, such as arc welding. These advantages include higher precision, better quality welds, and increased efficiency. Furthermore, the machine is highly versatile and can be used for a wide range of applications. As the manufacturing industry continues to evolve, laser welding technology is likely to become even more prevalent.

Expert Guide: Unveiling the Art of Precision Metal Cutting in CNC Machinery

CNC Precision Metal Cutting Revolutionizes Manufacturing IndustryIn today's rapidly evolving manufacturing landscape, companies across various industries are constantly seeking innovative and efficient ways to enhance their production processes. The introduction of CNC precision metal cutting technology has brought a transformative shift to the industry, enabling businesses to achieve exceptional levels of accuracy, productivity, and cost-effectiveness.CNC (Computer Numerical Control) precision metal cutting utilizes advanced computer-controlled machinery to automate the cutting, shaping, and machining operations of various metal components. By integrating computer-aided design (CAD) and computer-aided manufacturing (CAM), this technology allows for highly complex and precise metal cutting capabilities, surpassing the limitations of traditional manual approaches.One of the leading players in the CNC precision metal cutting market is {Company Name}. Established over a decade ago, {Company Name} has revolutionized the manufacturing industry with its cutting-edge solutions. By consistently investing in research and development, they have successfully engineered state-of-the-art machines that redefine precision and efficiency in metal cutting processes.With a team of highly skilled engineers and technicians, {Company Name} has developed a diverse range of CNC precision metal cutting machines, catering to a wide array of industrial needs. From small-scale operations to large production facilities, their machines offer unparalleled versatility, ensuring exceptional results across various applications.A key advantage of {Company Name}'s CNC precision metal cutting machines is their ability to handle a wide range of materials, including steel, aluminum, titanium, brass, and more. This flexibility allows manufacturers to expand their capabilities and undertake projects with diverse material requirements, eliminating the need for multiple machines and enhancing operational efficiency.Furthermore, the precision offered by these machines is truly unparalleled. With high-speed spindle options and advanced cutting tools, {Company Name}'s CNC precision metal cutting machines can achieve intricate designs, tight tolerances, and smooth finishes, guaranteeing consistently superior quality products.In addition to precision, efficiency is a paramount consideration in modern manufacturing. Recognizing this, {Company Name} has integrated innovative features into their CNC precision metal cutting machines to optimize productivity and minimize downtime. These include automatic tool changers, real-time monitoring systems, and intelligent software solutions that enable seamless workflow management.Beyond their cutting-edge technologies, {Company Name} is committed to providing exceptional customer service and support. Their team of experienced engineers not only assists clients in selecting the most suitable machine for their requirements but also offers comprehensive training and maintenance services to ensure optimal performance and longevity.The impact of CNC precision metal cutting technology extends far beyond individual manufacturing facilities. By streamlining production processes, reducing material waste, and enhancing product quality, this technology contributes to a more sustainable and eco-friendly industry. With its focus on precision, efficiency, and customer satisfaction, {Company Name} has positioned itself as a reliable partner for businesses seeking to embrace these benefits.Looking ahead, the future of CNC precision metal cutting appears promising. As technology continues to advance, manufacturers can expect even greater precision, efficiency, and automation in their operations. {Company Name} remains at the forefront of this revolution, constantly pushing the boundaries of CNC precision metal cutting to shape the manufacturing industry of tomorrow.In conclusion, CNC precision metal cutting technology, led by industry leaders like {Company Name}, has revolutionized the way manufacturers approach their production processes. With its unparalleled precision, efficiency, and versatility, this technology offers businesses a competitive edge in an increasingly demanding marketplace. As it continues to evolve, CNC precision metal cutting is transforming the manufacturing landscape, fostering innovation and driving progress.

4 Spindle CNC Router Machine for Efficient Large-Area Plate Carving and Window Processing

4 Spindle CNC Router Machine for SaleCNC Router Machines have revolutionized the woodworking industry by providing an easy, efficient and cost-effective solution for cutting, carving, engraving and finishing wood products. The latest addition to the CNC Router Machines is the 4 Spindle CNC Router Machine. The machine is designed with four spindles to facilitate four different tools at one time, which makes it ideal for large-area plate carving and door and window processing.Applications of 4 Spindle CNC Router MachineThe 4 Spindle CNC Router Machine is ideally suited for engraving and milling of 3-4 types of flower knives. It is commonly used in various industries for cutting and carving of wood, MDF, particleboard, plywood, plastics, and other non-metallic materials. The machine is versatile and can be used for making toys, furniture, cabinets, signs, crafts, musical instruments, and many other products.Features of 4 Spindle CNC Router MachineThe 4 Spindle CNC Router Machine is a newly designed multi-spindle CNC router that is suitable for various large-area plate carving and door and window processing. It is equipped with several features that make it stand out from the other CNC Router Machines available in the market today. Here are some of its features:Automatic Tool Change: The machine has four-processing easy automatic tool change, which makes it easier to change tools quickly and efficiently.High Speed: The 4 Spindle CNC Router Machine has an excellent high-speed system. Its maximum working speed is 35m/min, which makes it highly efficient for cutting and carving.High Accuracy: The machine uses a high-precision linear guide, and its rack and pinion drive system ensures high accuracy and excellent performance.Powerful Motors: The CNC Router Machine is equipped with powerful motors that deliver high torque, which allows for cutting and carving of hard materials with ease.User-friendly Interface: The machine has a user-friendly interface that allows for easy operation. It also comes with software that enables users to design their products with ease.Benefits of the 4 Spindle CNC Router MachineThe 4 spindle CNC Router Machine has several benefits that make it an ideal choice for woodworking industries. Here are some of the benefits of using the 4 Spindle CNC Router Machine.Better Efficiency: The machine enables multi-tasking, which means you can work on different products simultaneously, thereby increasing productivity and efficiency.Cost-Effective: The machine is cost-effective since it has four spindles that allow you to work on different products without the need for multiple machines.High Precision: The 4 spindle CNC Router Machine has high accuracy and precision, providing a high-quality finish to your products.Versatility: The machine can work on different materials, making it highly versatile.ConclusionIf you are looking for a cost-effective, efficient, and versatile CNC Router Machine, then the 4 Spindle CNC Router Machine is the right choice for you. It is equipped with advanced features that make it highly efficient, accurate, and easy to operate. So, whether you are in the woodworking industry or any other field that requires cutting and carving of non-metallic materials, the 4 Spindle CNC Router Machine is an excellent investment for your business.Keywords: CNC Router Machine, 8x4, 4 Spindle CNC Router Machine, Engraving, Milling, Automatic Tool Change, Multi-spindle CNC Router, Cost-effective, High Precision, Versatility.

High-Quality Wood Engraving Machine for Precise and Detailed Designs

Wood Engraving Machine Revolutionizes Woodworking IndustryWoodworking has always been a blend of art and craftsmanship, combining creativity with precise techniques to create stunning pieces of furniture, art and thoughtful designs. With the advancement of technology, wood engraving machines have played a pivotal role in enhancing the quality and efficiency of the woodworking industry. One such groundbreaking wood engraving machine is the latest model developed by ***, a leading innovator in the field of woodworking machinery. With its state-of-the-art technology and advanced features, the new wood engraving machine is set to revolutionize the woodworking industry and elevate the standards of craftsmanship.Established in the early 1990s, ** has been dedicated to providing cutting-edge machinery and equipment to woodworking professionals around the world. With a strong emphasis on research and development, the company has continually strived to innovate and improve its products to meet the evolving needs of the industry. The latest wood engraving machine is a testament to the company's commitment to excellence and innovation.The new wood engraving machine is equipped with advanced precision and control, allowing woodworkers to create intricate and detailed engravings with unparalleled accuracy. Its high-speed engraving capabilities ensure efficient production times without compromising on quality. The machine also features a user-friendly interface, making it accessible to woodworking professionals of all skill levels.In addition to its cutting-edge technology, the wood engraving machine is also designed with the environment in mind. ** has integrated eco-friendly features into the machine, reducing its carbon footprint and promoting sustainable practices within the woodworking industry. This commitment to sustainability aligns with the company's values and reflects its dedication to responsible manufacturing.The new wood engraving machine has quickly garnered attention within the woodworking community, receiving praise for its exceptional performance and innovative design. Woodworkers who have had the opportunity to utilize the machine have lauded its precision and efficiency, emphasizing its impact on their craft. Some have even described it as a game-changer, elevating their woodworking projects to new heights of intricacy and quality.In a recent demonstration of the wood engraving machine, ** showcased its capabilities by engraving a complex design onto a piece of hardwood in a matter of minutes. The precision and detail achieved by the machine left observers in awe, highlighting its potential to revolutionize the way woodworking is approached. The demonstration solidified the machine's reputation as a game-changing tool for woodworking professionals.As the woodworking industry continues to evolve, the demand for advanced machinery and equipment is on the rise. **'s new wood engraving machine has arrived at an opportune time, offering a solution that meets the needs of modern woodworkers. With its combination of cutting-edge technology, eco-friendly design, and user-friendly interface, the machine is poised to become an essential tool for professionals and enthusiasts alike.Moreover, **’s dedication to customer satisfaction has been a driving force behind the development of the wood engraving machine. The company remains committed to providing ongoing support and training to ensure that woodworkers can harness the full potential of the machine. This level of dedication sets ** apart in the industry, as it prioritizes the success and satisfaction of its customers.In conclusion, the introduction of **’s new wood engraving machine marks a significant milestone in the woodworking industry. By combining advanced technology, sustainability, and user-friendly design, the machine has the potential to redefine the standards of craftsmanship and elevate woodworking to new heights. As ** continues to push the boundaries of innovation, the woodworking industry can look forward to a future shaped by the possibilities of this groundbreaking machine.

The Evolution of CNC Woodworking Machines: A Comprehensive Guide

Title: Innovative CNC Woodworking Machine Revolutionizes Industry StandardsIntroduction:With the constant pursuit of technological advancements in the field of woodworking, renowned manufacturing company [Company Name] has unveiled its latest breakthrough: the cutting-edge CNC Woodworking Machine. Designed to enhance precision, efficiency, and flexibility in woodworking processes, this state-of-the-art machinery promises to revolutionize the industry standards.[Company Name] - Leading the Evolution of Woodworking Technologies:For over two decades, [Company Name] has been at the forefront of developing cutting-edge solutions tailored to the woodworking industry. Its commitment to innovation has resulted in a comprehensive range of industry-leading products that cater to a diverse clientele, including craftsmen, woodworkers, furniture manufacturers, and educational institutions.The CNC Woodworking Machine - Redefining Precision and Efficiency:The newly launched CNC Woodworking Machine by [Company Name] is a testament to their dedication to perfection. This advanced equipment is meticulously designed to streamline the woodworking process by combining the power of computer numerical control with precise mechanical operations.Unparalleled Precision:Equipped with cutting-edge control systems, this CNC machine offers unparalleled precision in every woodworking task. As a result, craftsmen can obtain intricate designs and complex shapes with utmost accuracy and repeatability, eliminating the possibility of human error. The machine's advanced algorithms and high-resolution sensors guarantee exceptional product quality, meeting the meticulous standards expected by customers.Enhanced Efficiency:The CNC Woodworking Machine offers a substantial boost in efficiency, increasing productivity and reducing downtime. With its ability to automate repetitive tasks, craftsmen can focus on design creativity, problem-solving, and exploring new woodworking techniques, ensuring optimal utilization of their skills. Additionally, the machine features intelligent material handling systems, reducing waste and minimizing production costs.Flexibility and Versatility:[Company Name]'s CNC Woodworking Machine allows users to work with an extensive range of wood materials, from solid wood to MDF, plywood, and more. The machine is equipped with versatile tool holders that allow for rapid tool changes, enabling efficient multitasking, and minimizing project completion time. Furthermore, its user-friendly interface provides ease of operation, making it suitable for craftsmen of all experience levels.Sustainability Initiatives:Promoting sustainable practices, [Company Name] has incorporated environmentally friendly features into the CNC Woodworking Machine. The energy-efficient design reduces power consumption, minimizing the carbon footprint of woodworking operations. Through smart waste management systems, the machine ensures optimal utilization of raw materials, preventing unnecessary waste generation.Success Stories and Testimonials:Numerous woodworking professionals have already applauded the tremendous impact of [Company Name]'s CNC Woodworking Machine on their businesses. Mr. John Doe, a renowned furniture manufacturer, emphasizes the machine's role in enhancing accuracy and timeliness in his production process, resulting in increased customer satisfaction. Similarly, Ms. Jane Smith, an established craftsman, appreciates the machine's versatility, enabling her to explore intricate designs and expand her product range.Future Prospects and Global Reach:As an industry leader, [Company Name] aims to bring cutting-edge woodworking technology to markets worldwide. With a well-established global distribution network, they are confident in their ability to cater to the needs of woodworking professionals across different continents and diverse cultural landscapes.Conclusion:[Company Name]'s innovative CNC Woodworking Machine marks a significant milestone in the evolution of the woodworking industry. By combining precision, efficiency, and versatility, this state-of-the-art machinery is set to redefine the standards for woodworking processes. With [Company Name] leading the way, craftsmen and woodworkers can look forward to unlocking new levels of creativity and productivity, while reducing environmental impact.