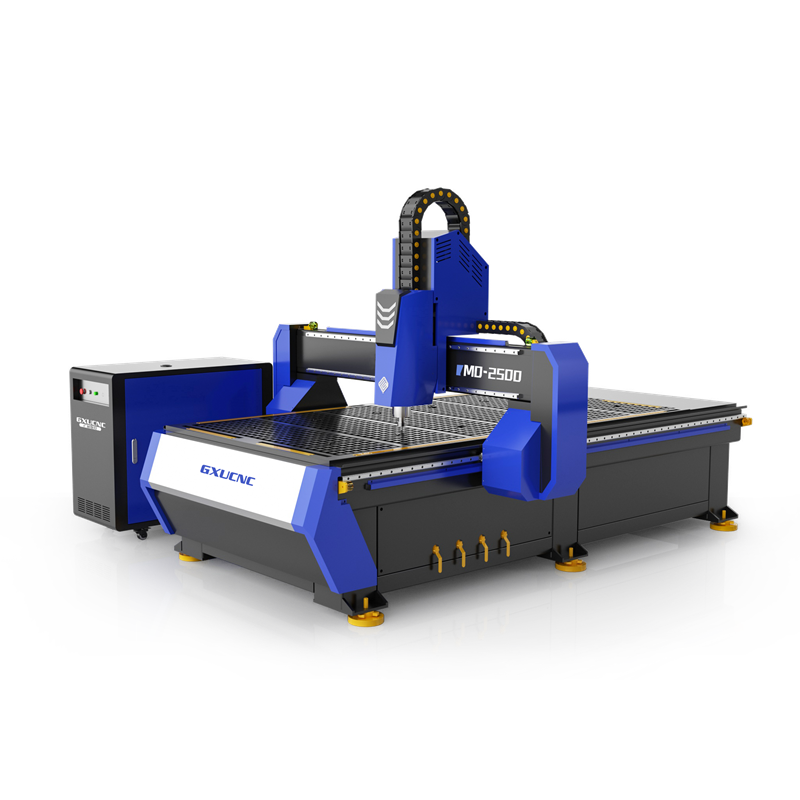

Advanced 4 Axis CNC Milling Machine for Precision Manufacturing

By:Admin

{Company Name} is a renowned manufacturer in the field of precision engineering and has a long-standing reputation for delivering high-quality machinery to a global customer base. With a commitment to innovation and excellence, the company has consistently invested in research and development to stay ahead of the curve. The introduction of the 4 Axis CNC Milling Machine is a testament to their dedication to pushing the boundaries of what is possible in modern manufacturing.

The 4 Axis CNC Milling Machine is a versatile and powerful tool that is designed to streamline the production process and deliver exceptional accuracy and precision. With its four-axis capability, it has the ability to move in multiple directions, allowing for more complex and intricate machining operations. This translates to greater flexibility in design and the ability to create more intricate and detailed components.

One of the key features of the 4 Axis CNC Milling Machine is its advanced control system, which allows for seamless integration with computer-aided design (CAD) software. This means that operators can easily program the machine to execute complex designs with a high degree of precision. This not only reduces the margin for error but also significantly speeds up the production process, resulting in cost savings and improved productivity.

Furthermore, the machine is equipped with state-of-the-art tooling and cutting technologies, which ensure that the finished products meet the highest standards of quality. Whether it is milling, drilling, or cutting, the 4 Axis CNC Milling Machine is capable of handling a wide range of materials with ease, including metals, plastics, and composites.

The introduction of the 4 Axis CNC Milling Machine is expected to have a significant impact on various industries, including aerospace, automotive, and medical. Its ability to produce intricate and complex components with a high degree of accuracy makes it an ideal choice for companies looking to stay ahead of the competition and meet the demands of a fast-paced market.

In addition to its technical capabilities, {Company Name} is also committed to providing exceptional after-sales support and training to ensure that customers are able to make the most out of their investment. With a global network of service centers and a team of highly skilled engineers, customers can have peace of mind knowing that help is always just a phone call away.

In conclusion, the introduction of the 4 Axis CNC Milling Machine by {Company Name} represents a significant leap forward in the world of manufacturing. Its advanced capabilities, combined with the company's commitment to customer satisfaction, make it a game-changer for businesses looking to take their production capabilities to the next level. As the industry continues to evolve, {Company Name} remains at the forefront, setting new standards for precision engineering and innovation.

Company News & Blog

Highly Efficient Handheld Laser Welding Machines for Precision Work Applications

Hand Laser Welding Machine: Revolutionizing the Welding IndustryInnovation has always been at the core of industrial development. Companies are constantly seeking novel ways to improve efficiency, reduce costs, and enhance the quality of their products. The welding industry is no exception. Traditionally, welding has been performed using gas torches or electric arcs, both of which have limitations in terms of precision and flexibility. However, with the advent of hand laser welding machines, a new era has dawned in the welding industry.Hand laser welding machines utilize the power of lasers to perform intricate and precise welds. They combine the accuracy of laser technology with the versatility of a handheld device, allowing welders to access hard-to-reach areas and work with complex shapes. This revolutionary technology is set to transform the welding landscape, offering numerous benefits that were previously unimaginable.One prominent player in the hand laser welding machine market is {}. Their commitment to research and development has allowed them to develop cutting-edge products that have captured the attention of industry experts worldwide. Operating at the forefront of laser technology, they have expanded the boundaries of what is possible in the welding process.The {} hand laser welding machine stands out for its exceptional performance and user-friendly design. With advanced features such as real-time power regulation, adjustable laser beam spot size, and automatic wire feeding, the machine offers unrivaled precision and control. Welders can easily adjust the power output according to their specific needs, ensuring optimal results every time. Moreover, the adjustable beam spot size enables welders to adapt to varying workpieces, accommodating different material thicknesses and geometries without compromising weld quality.One of the most significant advantages of the {} hand laser welding machine is its portability. Unlike traditional welding equipment, which is often bulky and stationary, this machine can be operated with ease in any location. Welders are no longer restricted to a designated welding area; they can bring the machine to the workpiece, eliminating the need for extensive preparation and transportation. This mobility not only saves time but also increases productivity, making it an invaluable asset in time-sensitive projects.Furthermore, the {} hand laser welding machine's user-friendly interface simplifies the welding process, reducing the learning curve for welders. With intuitive controls and clear feedback, operators can quickly familiarize themselves with the machine and achieve professional-level welds in no time. This ease of use extends to maintenance as well, with self-diagnosis systems ensuring that any potential issues are promptly addressed, minimizing downtime and maximizing efficiency.Another feature that sets the {} hand laser welding machine apart is its focus on safety. The machine is equipped with multiple safety mechanisms, such as a protective housing, interlock systems, and emergency stop functions. These safety features not only protect the operators but also safeguard the work environment, highlighting the company's commitment to ensuring a secure welding experience.The combination of technological innovation, precision, portability, and safety makes the {} hand laser welding machine a game-changer in the welding industry. It opens up new possibilities for welders, allowing them to tackle complex projects with unparalleled efficiency and accuracy. Moreover, the machine's durability and reliability ensure a long lifespan, guaranteeing a solid return on investment for companies across various sectors.As the demand for high-quality and cost-efficient welding solutions continues to rise, hand laser welding machines are becoming increasingly sought after. Companies that embrace this technology will gain a significant competitive advantage in the market. With their state-of-the-art hand laser welding machine, {} is well-positioned to lead the charge and shape the future of the welding industry.In conclusion, hand laser welding machines have redefined the boundaries of welding technology. The innovation and expertise demonstrated by {} have resulted in a remarkable product that offers unmatched precision, portability, and safety. As more industries recognize the transformative potential of this technology, hand laser welding machines will undoubtedly become an essential tool in the manufacturing process. With {} at the helm, it is clear that the welding industry is set for a revolutionary change.

High-Precision Fiber Laser Cutting Machine for Efficient Metal Processing

CNC Fiber Laser Cutting Machine: The Innovation in Metal Cutting TechnologyOver the years, different advancements in technology have been made for different industries. One of the biggest beneficiaries of technological advancements is the manufacturing industry, and specifically the metal cutting industry. With the introduction of CNC Fiber Laser Cutting machines, manufacturers can cut different kinds of metal materials with a high precision and speed like never before.CNC Fiber Laser Cutting machines have gained immense popularity in the manufacturing industry. Companies like Shandong Pengwo Laser Technology Co., Ltd. have been at the forefront of designing and manufacturing CNC Fiber Laser Cutting machines that are efficient, precise, and reliable. The machine uses a fiber laser generator and ball screw moving system that enable it to cut and punch different types of metal materials without compromising on quality.Features of CNC Fiber Laser Cutting Machines1. High Cutting Precision:CNC Fiber Laser Cutting Machines have a high cutting precision that enables them to deliver top-notch end products. The laser is transmitted through a fiber, which ensures that there is no loss of energy, and hence precision cutting is achieved. Whether you need to cut intricate designs or thick metals, CNC Fiber Laser Cutting Machines will deliver.2. High Speeds:The use of advanced fiber laser technology with ball screw moving systems enables CNC Fiber Laser Cutting machines to achieve high speeds while cutting, without compromising the precision. By increasing the production speed, your manufacturing process will become more efficient, and your business will be more profitable.3. Low Maintenance:One of the biggest advantages of installing CNC Fiber Laser Cutting Machines is its low maintenance. Since the laser is transmitted through a fiber, there is no need to adjust or maintain the laser optical path. In contrast, traditional laser cutting machines require frequent maintenance, which can be costly and time-consuming.4. Energy Efficiency:CNC Fiber Laser Cutting Machines have excellent energy efficiency compared to other traditional metal cutting methods. The advanced fiber laser technology used in these machines significantly reduces the amount of energy consumed, which in turn helps to lower your operating costs. It is an environmentally friendly cutting option with no emissions of harmful substances.5. Versatile:CNC Fiber Laser Cutting Machines can cut different types of metals, including steel, stainless steel, aluminum, copper, and brass. This versatility makes them indispensable in the manufacturing process as they offer a wide variety of options to cut different shapes and sizes of metal materials.Conclusion:CNC Fiber Laser Cutting Machines are the latest innovation in the metal cutting industry. They offer a plethora of features that make them indispensable to the manufacturing process. High precision, high speed, low maintenance, energy efficiency, and versatility are some of the unique selling points of CNC Fiber Laser Cutting Machines. By incorporating them into your manufacturing process, you will increase efficiency, profitability, and precision cutting. So, if you are looking for an efficient and reliable way to cut metals, CNC Fiber Laser Cutting Machines are definitely worth considering.

Maximizing Woodworking Efficiency with CNC Wood Engraving Machines

Title: Advanced CNC Wood Engraving Machine Redefines Precision and Efficiency in Woodworking IndustryIntroduction:The woodworking industry has constantly evolved with advancements in technology. One such breakthrough that has revolutionized precision and efficiency in woodworking is the state-of-the-art CNC Wood Engraving Machine. Developed by a leading company in the field (brand name omitted), this groundbreaking machine has undoubtedly raised the bar for wood engraving and carving processes.High Precision and Accuracy:The CNC Wood Engraving Machine boasts unparalleled precision and accuracy, ensuring flawless results in wood engraving. Equipped with cutting-edge technology, this machine utilizes computer programming and numerical control to produce intricate and detailed designs with utmost consistency. The advanced mechanisms and high-quality components of this machine guarantee minimal errors and smooth operations, resulting in exceptional output every time.Efficient Workflow:With its automated features and user-friendly interface, the CNC Wood Engraving Machine streamlines the woodworking process, significantly reducing human effort and time. The incorporation of computer-aided design (CAD) software allows designers and operators to conveniently create and modify designs seamlessly. Its fast and efficient production capability ensures that projects are completed in a fraction of the time compared to traditional woodworking methods, enhancing overall productivity and profitability for businesses.Versatility and Customization:One of the key advantages of the CNC Wood Engraving Machine is its versatility in accommodating a wide range of woodworking applications. From intricate designs on furniture to decorative patterns on doors and panels, this machine delivers exceptional results for various woodworking projects. Its ability to work with different types of wood, including hardwoods, softwoods, and composite materials, makes it a valuable asset for both small-scale workshops and large manufacturing facilities. Moreover, the machine's adaptability allows for customization, offering endless possibilities for personalized designs and unique creations.Enhanced Safety and Operator Comfort:This CNC Wood Engraving Machine prioritizes the safety and well-being of its operators. Equipped with advanced safety features, such as emergency stop buttons and protective barriers, it ensures a secure working environment. Additionally, the machine's ergonomic design takes into consideration the comfort of operators, mitigating strain and fatigue during prolonged use. These combined safety and comfort features not only safeguard the operators but also contribute to increased productivity and higher-quality output.Eco-friendly Operations:In an era where environmental sustainability is paramount, the CNC Wood Engraving Machine stands out as an eco-friendly solution. The machine utilizes modern energy-efficient technologies, reducing power consumption and minimizing environmental impact. Furthermore, its precise cutting capabilities minimize material wastage, optimizing resource utilization and promoting sustainability in the woodworking industry.Training and Technical Support:To ensure seamless integration and maximum utilization of the CNC Wood Engraving Machine, the company (brand name omitted) provides comprehensive training programs and technical support. Knowledgeable experts offer guidance on programming, operation, and maintenance of the machine, enabling users to unlock its full potential. Ongoing assistance and upgrades ensure that clients stay up-to-date with the latest advancements in this rapidly evolving field.Future Advancements and Market Outlook:The CNC Wood Engraving Machine has revolutionized woodworking with its unmatched precision, efficiency, and versatility. As technology continues to advance, this machine is expected to witness continuous enhancements that further improve its performance and capabilities. With a growing demand for intricately designed and customized wood products, the market outlook for such advanced CNC machines remains highly promising.Conclusion:The CNC Wood Engraving Machine has established itself as a game-changer in the woodworking industry. Its precision, efficiency, versatility, and eco-friendly operations have propelled it to the forefront of wood engraving and carving processes. With the support of the company behind its development, this advanced machine is set to redefine woodworking standards and drive innovation in the industry for years to come.

New CO2 Laser Cutting Machine Revolutionizes Manufacturing Processes

[Company Introduction][Company name], a renowned leader in the laser cutting industry, has recently launched its latest product, the CNC CO2 Laser Cutting Machine. With years of experience and expertise in manufacturing high-quality laser cutting equipment, [Company name] continues to revolutionize the industry with its cutting-edge technology and innovative solutions.The CNC CO2 Laser Cutting Machine is a powerful tool that offers precision cutting, accuracy, and high efficiency for various materials, including metals, plastics, wood, and more. With its advanced CO2 laser technology, this cutting-edge machine provides users with unmatched capabilities to handle a wide range of cutting applications. From intricate designs to large-scale productions, this machine guarantees exceptional results.[Company name]'s commitment to delivering excellence can be seen through its use of high-quality components and advanced systems. The CNC CO2 Laser Cutting Machine is equipped with the latest motion control technology, ensuring smooth and precise movements during the cutting process. The machine's excellent stability and durability enable users to achieve consistent, high-quality cuts with minimal wastage.Furthermore, the CNC CO2 Laser Cutting Machine is designed with user-friendly features that streamline the overall cutting process. Its intuitive control panel allows operators to easily navigate and adjust settings, ensuring maximum productivity and efficiency. The machine's automatic material detection and focusing system further enhance its usability, making it ideal for both experienced professionals and beginners.The versatility of the CNC CO2 Laser Cutting Machine is another standout feature. With its wide variety of compatible materials, businesses from various industries can benefit from its capabilities. Whether for signage, automotive parts, prototype development, or any other cutting needs, this machine offers the flexibility to meet diverse requirements. Its precise cutting also reduces the need for further finishing processes, saving time and resources.In addition to its exceptional performance, the CNC CO2 Laser Cutting Machine prioritizes user safety. It is built with comprehensive safety features, including protective enclosures and sensors that prevent accidental exposure to the laser beam. This ensures a secure working environment for operators.[Company name] stands apart from its competitors through its commitment to customer satisfaction. The company is known for its excellent customer service, providing comprehensive technical support, training, and after-sales maintenance. Customers can rely on their expertise throughout the entire lifecycle of their CNC CO2 Laser Cutting Machine.The launch of the CNC CO2 Laser Cutting Machine marks another milestone for [Company name] as it continues to innovate and excel in the laser cutting industry. The machine's exceptional capabilities, user-friendly design, and commitment to safety make it the ideal choice for businesses looking to enhance their cutting operations.With [Company name]'s CNC CO2 Laser Cutting Machine, businesses can expect increased productivity, improved precision, and cost-effective cutting solutions. By investing in this state-of-the-art technology, users can stay ahead in today's competitive market and achieve remarkable results in their cutting applications.About [Company name]:[Company name] is a leading manufacturer in the laser cutting industry, specializing in the production of high-quality laser cutting machines for various materials. With years of experience, advanced technology, and a commitment to customer satisfaction, the company continues to deliver cutting-edge solutions that exceed expectations. For more information about [Company name] and its products, visit [company website].

Unlock Your Woodworking Potential with a High-Quality CNC Router - Tribune Online A computer-controlled router tool, known as a CNC router, can make intricate and accurate cuts in a range of materials like wood, plastic, metal, and even decorative items.

Maximize Your Woodworking Potential with a Top-Quality CNC RouterIf you are a woodworking enthusiast, you know how important precision and accuracy are in creating beautiful and functional pieces. A CNC router may just be the tool you need to take your woodworking skills to the next level. A CNC (computer numerical control) router is a cutting machine that uses computer programs to produce intricate and precise cuts.A 12x12 CNC router is the perfect size for home woodworking projects. It allows you to cut and carve various materials, including wood, glass, plastic, and even metals, with remarkable precision. Additionally, it is a versatile machine that can produce items ranging from decorative pieces to functional furniture.Benefits of a CNC Router in WoodworkingBetter Precision: One of the most significant advantages of using a CNC router in woodworking is the level of precision it offers. The use of digital technology and computer programs eliminates human errors, producing precise cuts and carvings.Increased Efficiency: With a CNC router, you can produce multiple and identical pieces in a shorter period. This is because a computer program controls the machine, allowing you to work on multiple pieces simultaneously without having to measure and mark each piece several times.Enhanced Creativity: A CNC router allows you to achieve intricate and complex designs easily, giving you the freedom to exercise your creativity and imagination fully.Ease of Use: A 12x12 CNC router is straightforward to operate, even for beginners. Once you have a design, all you need to do is upload it to the machine via a computer, and the machine does the rest.Things to Consider When Buying a CNC RouterSize: The size of a CNC router determines the size of the material you can work on. Before purchasing a router, consider the size of the projects you intend to undertake and choose a machine that accommodates your needs.Power: A more powerful router translates to faster cutting speeds. However, a more powerful router also means higher costs. Consider your budget and the type of projects you intend to work on when choosing a router.Cost: CNC routers come in different sizes, powers, and prices. While it may be tempting to purchase the cheapest option, it is essential to weigh the performance and quality you get against the price.ConclusionA CNC router is a valuable tool for any woodworking enthusiast. It allows you to create precise and detailed cuts in various materials, producing high-quality functional and decorative pieces. A 12x12 CNC router is an excellent option for home woodworking projects as it is versatile, easy to use, and takes up minimal space.

New Laser Technology Removes Rust From Metal Surface

Title: Revolutionary Laser Metal Rust Remover Gains Traction in the MarketIntroduction: Rust has been a persistent foe for metal equipment and structures, causing damage, reducing effectiveness, and leading to costly repairs. However, a groundbreaking innovation has recently arrived in the market that promises to revolutionize rust removal. The Laser Metal Rust Remover, developed by a leading technology company, harnesses the power of laser technology to effortlessly eliminate rust from metal surfaces, offering a more efficient and eco-friendly solution compared to traditional methods.[Company Introduction]In this article, we take a closer look at the Laser Metal Rust Remover, exploring its features, benefits, and potential impact on various industries.1. Cutting-edge Technology: The Laser Metal Rust Remover employs a cutting-edge laser system that is highly effective in removing rust from metal surfaces. With its precise laser beam, the rust particles are instantaneously vaporized, leaving the surface clean and ready for further treatment or application. This advanced technology ensures minimal damage to the metal surface, eliminating the need for aggressive mechanical or chemical cleaning procedures.2. Efficiency and Versatility: The Laser Metal Rust Remover is designed to tackle rust on a wide variety of metal surfaces, including steel, iron, aluminum, and more. Its high-powered laser beam can penetrate even the smallest crevices, reaching rust particles that are often inaccessible to traditional cleaning methods. Moreover, thanks to its non-contact nature, the device can be used on delicate or intricate structures without causing any damage, making it an ideal solution for industries such as automotive, aerospace, and construction.3. Time and Cost Saving: Traditional rust removal methods often require time-consuming manual labor or chemical treatments, which can be costly and pose potential risks to workers and the environment. The Laser Metal Rust Remover significantly reduces the time and effort required to remove rust, thereby increasing overall productivity. With its ability to swiftly eliminate rust in a single pass, the device can help industries save both time and money in maintenance and repair tasks.4. Environmental Friendliness: Unlike chemical rust removers that release harmful substances into the air or water, the Laser Metal Rust Remover is an environmentally friendly solution. Since it uses laser energy, it does not require the use of hazardous chemicals. This significantly reduces the ecological impact associated with rust removal processes and promotes sustainability in various industries.5. Ease of Use: The Laser Metal Rust Remover has been designed to ensure convenience and ease of use. The device features a user-friendly interface, allowing operators to select and adjust the laser settings according to the specific rust removal requirements. Its compact and portable design enables easy movement between different work areas, ensuring flexibility and efficiency in rust removal operations.6. Future Potential: The introduction of the Laser Metal Rust Remover presents exciting prospects for various industries, which heavily rely on metals. The device's unique capabilities and numerous advantages make it a promising tool for streamlining maintenance processes and prolonging the lifespan of metal equipment. Additionally, continuous advancements in laser technology may lead to further refinements and applications, expanding its potential in industries such as manufacturing, infrastructure, and shipbuilding.Conclusion: The Laser Metal Rust Remover stands as a game-changing solution in the battle against rust. With its state-of-the-art laser technology, efficiency, and environmental benefits, this device promises to reshape the way industries address metal corrosion. By introducing a faster, safer, and more sustainable alternative to traditional rust removal methods, this innovative technology has the potential to revolutionize maintenance practices across various sectors.

Discover the Portability and Efficiency of Laser Welding Machines

[Headline]: Revolutionary Portable Laser Welding Machine Redefines Industrial Manufacturing[Subheading]: Cutting-Edge Innovation Leverages Technology and Portability for Superior Welding Capabilities[date]In a major breakthrough, [Company Name] has unveiled its latest technological innovation – a Portable Laser Welding Machine that is set to transform the manufacturing industry. This cutting-edge device combines the power of laser technology with unparalleled portability, revolutionizing the way industries approach welding. Experts predict that this state-of-the-art invention will catapult manufacturing productivity to new heights, making it an indispensable tool across various sectors.[Company Name], a recognized industry leader in laser-based solutions, has always been at the forefront of technological advancement. The newly launched Portable Laser Welding Machine truly signifies their commitment to innovation and their vision of providing seamless solutions to complex manufacturing challenges.The brilliance of this Portable Laser Welding Machine lies in its ability to bring laser welding capabilities to previously inaccessible areas. Unlike traditional bulky and stationary welding machines, this revolutionary device offers unmatched portability. Weighing a mere [weight], it can be effortlessly transported to different locations, making it ideal for both large-scale manufacturing plants and small-scale operations.What sets this Portable Laser Welding Machine apart from its competitors is its exceptional precision and control. With advanced laser technology, this cutting-edge device ensures high-quality and flawless welds, consistently maintaining superior workmanship. The machine is equipped with ultra-high-speed cameras and sophisticated sensors that enable real-time monitoring and adjustment, guaranteeing precise weld positioning and impeccable results.[Company Name]'s Portable Laser Welding Machine has been crafted with meticulous attention to detail. Its ergonomic design ensures maximum efficiency by providing the operator with exceptional ease of use. The device is fitted with an intuitive touchscreen interface, making it easy to navigate and operate. This user-friendly interface, combined with the machine's swift response time, ensures increased productivity and reduced downtime.Moreover, this state-of-the-art machine boasts remarkable versatility. It can be utilized across a wide range of industries, catering to various welding requirements. From automotive and aerospace industries to construction and electronics, this Portable Laser Welding Machine offers an all-encompassing solution. Its adaptability and ease of integration into existing production systems make it an attractive prospect for numerous manufacturers.In addition to its unprecedented capabilities, [Company Name] emphasizes sustainability in their product design. The Portable Laser Welding Machine has been engineered to minimize energy consumption, resulting in significant cost savings for industrial manufacturers. This commitment to eco-friendly technology further solidifies [Company Name]'s reputation as a responsible corporate citizen."We are extremely proud to present this ground-breaking Portable Laser Welding Machine to the world," says [Name], the CEO of [Company Name]. "Our aim has always been to push the boundaries of innovation and redefine manufacturing practices. With this new invention, we are confident that we have achieved just that."Industry experts and professionals have eagerly awaited a portable laser welding machine that combines cutting-edge technology with user-friendly design. This revolutionary invention by [Company Name] has surpassed expectations, marking a paradigm shift in the welding industry. It is expected to enhance manufacturing processes, improve output quality, and boost overall operational efficiency.The Portable Laser Welding Machine will undoubtedly establish [Company Name] as an industry leader in laser-based technologies. Its ability to redefine manufacturing practices and its commitment to sustainable solutions will undeniably shape the future of industrial manufacturing.In conclusion, [Company Name] has introduced a game-changing Portable Laser Welding Machine that has the potential to revolutionize the manufacturing industry. With unparalleled portability, precision, and versatility, this cutting-edge innovation optimizes welding processes and takes productivity to unprecedented heights. As manufacturers embrace this remarkable technology, the production landscape is set to undergo significant transformation, propelling industries towards a more efficient and sustainable future.

Revolutionary Portable Laser Cleaning: Transforming Surfaces Effortlessly

Title: Innovations in Surface Cleaning: Portable Laser Technology Revolutionizes Industrial Cleaning ProcessesIntroduction:Innovative cleaning technology has always been at the forefront of industrial efficiency and environmental sustainability. In recent years, the advent of portable laser cleaning has brought significant advancements to the field of surface cleaning, offering a safe, effective, and eco-friendly solution across various industries. One notable player in this field is a leading manufacturer that has emerged as a pioneer in developing cutting-edge cleaning solutions. This article aims to explore the remarkable capabilities of their portable laser cleaning technology and its potential impact on industrial cleaning processes.Portable Laser Cleaning: A Game-Changing Technology:Portable laser cleaning has revolutionized traditional surface cleaning methods by harnessing the power of laser beams to remove contaminants without any direct contact with the surface. This state-of-the-art technology utilizes high-intensity lasers to vaporize unwanted substances, leaving behind a clean, residue-free surface. Complemented by advanced optics and computer control systems, portable laser cleaners have made significant strides in terms of versatility, precision, and efficiency.Eliminating the Need for Chemicals:Traditionally, chemical-based cleaning agents have been widely used in various industries. However, these substances often present risks of toxicity and environmental harm. In contrast, portable laser cleaning eliminates the need for such chemicals altogether. By utilizing lasers, this technology provides a safer, greener alternative that ensures both the longevity of industrial equipment and the preservation of the environment.Versatility Across Industries:Portable laser cleaning technology has found applications across a wide range of industries. In manufacturing, it has proven particularly effective for surface preparation before painting, coating, or bonding processes. By removing rust, scales, oil, and other contaminants, the laser cleaning technique fosters optimal adhesion and extends the lifespan of machinery and structures.Additionally, the aerospace industry has benefited greatly from this cutting-edge technology. Portable laser cleaning has proven highly efficient in removing paint, oxides, and thermal barrier coatings from aircraft surfaces, without causing any damage. The non-contact nature of laser cleaning means delicate components can be cleaned without distortion or deterioration, ensuring the highest level of safety and quality.Not to be outdone, the automotive industry has also embraced portable laser cleaning for its ability to remove weld residues, coatings, and stubborn dirt from vehicle parts. By effectively cleaning engine components, fuel injectors, and brake systems, this technology optimizes performance, reduces downtime, and enhances overall efficiency.Safety and Precision:The portable laser cleaning technology developed by the aforementioned company boasts enhanced safety features and advanced scanning systems. These systems meticulously scan the surface to be cleaned, ensuring that only the target contaminants are affected. By focusing solely on the intended surface, this laser cleaning solution prevents any unnecessary damage or removal of surrounding materials or coatings. The precise control of the laser beam ensures that even delicate and sensitive surfaces can be effectively cleansed without harm.Looking Ahead:As the demand for eco-friendly and efficient cleaning methods continues to grow, portable laser cleaning technology is poised to become an indispensable tool across industries. The company's commitment to innovation and safety has allowed it to develop a versatile and highly effective solution for tackling a plethora of cleaning challenges. With ongoing research and development, it is expected that portable laser cleaning technology will continue to evolve, further revolutionizing industrial cleaning processes in the years to come.Conclusion:Portable laser cleaning technology represents a significant leap forward in the realm of industrial surface cleaning. Its ability to remove contaminants without the use of chemicals ensures a safer and environmentally friendly approach. The precise nature of this technology, combined with its versatility across industries, makes it an attractive solution for various cleaning needs. With the pioneering efforts of companies like the aforementioned manufacturer, portable laser cleaning is poised to reshape the industrial cleaning landscape, offering unprecedented efficiency, safety, and sustainability.

Discover the Top Features of a 4-Axis Small ATC CNC Router for 3D Woodworking

The world of woodworking is constantly evolving with new tools and technologies being introduced to make the process faster, more efficient and more accurate. One such technology that has revolutionized the field of woodworking is CNC routers. These computer-controlled machines are capable of executing complex cuts and designs on a variety of materials with ease and precision. Among the numerous CNC routers available in the market, the 1212 4 Axis Small ATC CNC Router for 3D Wood Workpieces is one machine that stands out. In this article, we will review this Elephant CNC router and highlight its features.The 1212 4 Axis Small ATC CNC Router for 3D Wood Workpieces is manufactured by a renowned company that specializes in CNC machines. With years of experience in the field, the company has established itself as a leader in the industry, known for its quality products and exceptional customer service. The Elephant CNC router is a testament to the company's commitment to excellence and innovation.One of the most notable features of the 1212 4 Axis Small ATC CNC Router for 3D Wood Workpieces is its automatic tool changer. The machine is equipped with a high-speed spindle that can reach speeds of up to 24,000 RPM. This means that it can handle a wide range of materials, from softwood to hardwood, MDF, and acrylic. With its automatic tool changer, the machine can switch between tools automatically, without the need for manual intervention. This feature not only saves time but also ensures precision and accuracy in every cut and design.Another impressive feature of the Elephant CNC router is its 4-axis capability. Unlike traditional routers that can only move in three directions, the Elephant CNC router can move in four directions: X, Y, Z, and A. This allows the machine to execute complex designs and cuts with ease. It also means that the machine can produce 3D workpieces, making it ideal for architectural and interior design applications.In addition to its 4-axis capability, the Elephant CNC router is also equipped with a powerful control system. The machine comes with a user-friendly control panel that allows users to select and execute designs quickly and easily. The control system is also capable of running multiple programs simultaneously, making it possible to produce several workpieces in a short amount of time.The 1212 4 Axis Small ATC CNC Router for 3D Wood Workpieces also features a sturdy and durable frame. The machine is made of high-quality materials, ensuring its longevity and reliability. It is also designed with safety in mind, with features such as emergency stop buttons and safety guards that prevent accidents and injuries.One of the best things about the Elephant CNC router is its affordability. Despite its advanced features and capabilities, the machine is priced competitively, making it accessible to small and medium-sized woodworking businesses. This means that even startups and hobbyists can benefit from the technology and produce high-quality workpieces.In conclusion, the 1212 4 Axis Small ATC CNC Router for 3D Wood Workpieces is an impressive machine that offers advanced features and capabilities at an affordable price. It is ideal for small and medium-sized woodworking businesses that want to enhance their productivity and produce high-quality workpieces. With its automatic tool changer, 4-axis capability, powerful control system, and sturdy frame, the Elephant CNC router is a reliable and efficient machine that can take your woodworking to the next level.

Top High Power Laser Cutting Techniques for Precision Cutting

High Power Laser Cutting Technology Revolutionizing Industrial ManufacturingIn recent years, the industrial manufacturing sector has witnessed a significant transformation with the emergence of high power laser cutting technology. This innovative process allows for the precise and efficient cutting of a wide range of materials, including metals, plastics, and composites. The introduction of this advanced technology has not only revolutionized the manufacturing process but has also opened up new possibilities for the production of complex and intricate components.One company at the forefront of this technology revolution is [Company Name], a leading provider of cutting-edge laser cutting solutions. With a strong focus on innovation and continuous improvement, [Company Name] has been instrumental in driving the adoption of high power laser cutting across various industries. Their advanced laser cutting systems have set new standards for accuracy, speed, and reliability, making them a preferred choice for manufacturers looking to stay ahead in a competitive market.The key to the success of [Company Name]'s high power laser cutting technology lies in its state-of-the-art laser systems, which are designed to deliver exceptional performance and precision. These systems utilize advanced fiber laser technology, allowing for increased power output and beam quality, resulting in superior cutting capabilities. Additionally, the integration of advanced motion control and automation features ensures maximum efficiency and productivity, making [Company Name]'s laser cutting systems the ideal choice for high-volume production environments.One of the primary advantages of high power laser cutting is its ability to produce high-quality cuts with minimal material waste. Traditional cutting methods often result in significant material loss due to the imprecise nature of the process. However, high power laser cutting technology offers a more sustainable solution, allowing manufacturers to minimize material waste and optimize their production processes. This not only leads to cost savings but also contributes to the overall sustainability of the manufacturing industry.Another significant benefit of high power laser cutting is its versatility in handling a wide range of materials. Whether it's stainless steel, aluminum, carbon steel, or even non-metallic materials such as ceramics and plastics, [Company Name]'s laser cutting systems are capable of delivering clean, precise cuts with exceptional edge quality. This versatility has opened up new opportunities for manufacturers to explore innovative designs and material combinations, enabling them to meet the evolving demands of their customers.Furthermore, high power laser cutting has proven to be a game-changer in the production of complex and intricate components. The fine beam width and high cutting speeds of [Company Name]'s laser systems enable the accurate shaping and profiling of intricate designs, regardless of the material's thickness. This level of precision and flexibility has empowered manufacturers to take on challenging projects while maintaining the highest standards of quality and performance.In addition to its cutting-edge technology, [Company Name] has established itself as a trusted partner for its customers through its comprehensive service and support offerings. From initial consultation and system installation to ongoing maintenance and training, [Company Name] is dedicated to ensuring the success of its customers at every stage of the process. Their team of experienced engineers and technical experts are committed to providing tailored solutions that align with the unique needs and requirements of each customer, resulting in a seamless integration of high power laser cutting technology into their manufacturing operations.As the demand for high precision and efficient manufacturing continues to grow, the role of high power laser cutting technology is only set to become more prominent. With [Company Name] leading the way in driving innovation and excellence in laser cutting, the future of industrial manufacturing looks brighter than ever. By harnessing the power of high power laser cutting, manufacturers can expect to achieve unmatched levels of productivity, quality, and operational efficiency, positioning themselves at the forefront of their respective industries.In conclusion, high power laser cutting technology is redefining the manufacturing landscape, and [Company Name] is at the forefront of this revolution. With its cutting-edge laser systems and unwavering commitment to customer success, [Company Name] is empowering manufacturers to push the boundaries of what's possible, setting new standards for quality and performance in industrial manufacturing. As the world embraces the era of advanced manufacturing, high power laser cutting is undoubtedly a game-changer, and [Company Name] is leading the charge towards a future of limitless possibilities.