Top Industrial Welding Machine for Efficient Welding Operations

By:Admin

{Company name} is a leading manufacturer of industrial equipment and machinery, with a strong focus on innovation and customer satisfaction. Recently, the company announced the launch of its latest product, a cutting-edge Industrial Welding Machine that is set to revolutionize the welding industry.

The new Industrial Welding Machine is designed to improve the efficiency and productivity of welding processes in industrial settings. With advanced features and state-of-the-art technology, the machine offers unparalleled precision and performance, making it a valuable addition to any manufacturing facility.

One of the key highlights of the new Industrial Welding Machine is its advanced automation capabilities. Equipped with cutting-edge robotic technology, the machine is capable of performing complex welding tasks with minimal human intervention, resulting in significant time and cost savings for businesses.

In addition, the machine is also integrated with smart sensors and data analytics capabilities, allowing for real-time monitoring and analysis of welding parameters. This not only ensures consistent and high-quality welds but also facilitates predictive maintenance, reducing the risk of unexpected downtime and costly repairs.

"We are thrilled to introduce our latest Industrial Welding Machine to the market," said a spokesperson for {Company name}. "We believe that this product will set a new standard for welding equipment, offering unprecedented levels of efficiency, precision, and reliability."

The Industrial Welding Machine is also designed with user-friendliness in mind. Its intuitive interface and ergonomic design make it easy to operate, ensuring that workers can quickly familiarize themselves with the machine and achieve optimal results in a short amount of time.

Furthermore, the machine is built to withstand the rigors of industrial environments, with a durable construction and robust components that guarantee long-term performance and reliability. This makes it an ideal investment for companies looking to enhance their welding capabilities and stay ahead of the competition.

The launch of the new Industrial Welding Machine reflects {Company name}'s commitment to innovation and continuous improvement. With a dedicated team of engineers and technicians, the company strives to develop cutting-edge solutions that address the evolving needs of the manufacturing industry, helping businesses stay competitive and achieve their operational goals.

In conclusion, the new Industrial Welding Machine from {Company name} is a game-changer for the welding industry, offering a myriad of advanced features and capabilities that are set to redefine the way welding is performed in industrial settings. With its focus on efficiency, productivity, and user-friendliness, the machine is poised to become an indispensable asset for businesses looking to streamline their welding processes and achieve superior results.

Company News & Blog

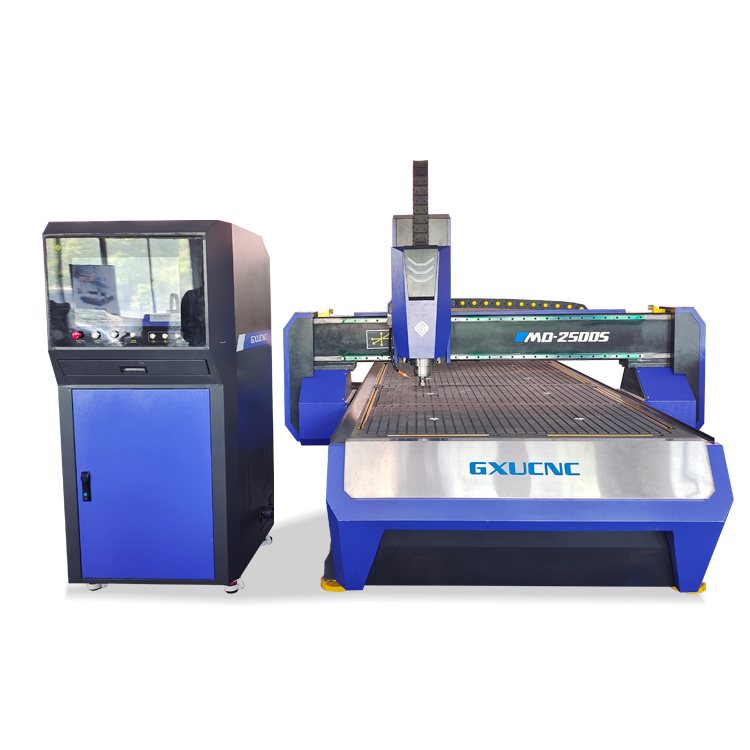

Top Benefits of Using an Old CNC Router Machine

Old CNC Router Machine Gets Upgraded to Boost Company's Productivity{Company Name}, a leading manufacturer in the industrial machinery industry, has recently completed the upgrade of their old CNC Router machine. The company, known for its dedication to innovation and quality, has invested time and resources to improve their manufacturing processes and ensure that they remain at the forefront of technology in the industry.The old CNC router machine, which has been in use for over a decade, was starting to show signs of wear and tear, affecting the company's productivity and efficiency. Recognizing the need for an upgrade, {Company Name} embarked on a project to overhaul the machine and bring it up to modern standards.The upgrade process involved the installation of new state-of-the-art components, including a more powerful spindle, improved cutting tools, and advanced control software. Additionally, the machine's mechanical and electrical systems were thoroughly inspected and refurbished to ensure optimal performance.The decision to upgrade the old CNC router machine was driven by {Company Name}'s commitment to delivering high-quality products to their customers. By modernizing their equipment, the company aims to improve the accuracy and precision of their manufacturing processes, resulting in better-finished products that meet the highest standards of quality.Furthermore, the upgraded machine will enable {Company Name} to expand their capabilities and take on more complex projects. With enhanced speed and accuracy, the company will be able to increase their production capacity and meet the growing demands of their customers."We are thrilled to have completed the upgrade of our old CNC router machine. This investment demonstrates our dedication to providing our customers with the best products possible," said {Spokesperson's Name}, the CEO of {Company Name}. "By modernizing our equipment, we are confident that we will be able to boost our productivity and maintain our position as a leader in the industry."The upgrade of the old CNC router machine is just one of the many initiatives that {Company Name} has undertaken to enhance their manufacturing processes. The company continues to invest in research and development to stay abreast of the latest technological advancements in the industry.In addition, {Company Name} places a strong emphasis on training and development for their employees to ensure that they are equipped with the knowledge and skills to operate the upgraded equipment effectively. By investing in their workforce, the company can maximize the potential of their upgraded CNC router machine and deliver superior products to their customers.The completion of the upgrade project marks a significant milestone for {Company Name}, showcasing their dedication to continuous improvement and innovation. With the newly upgraded CNC router machine, the company is poised to elevate their production capabilities and maintain their reputation for excellence in the industry.As {Company Name} looks to the future, they remain committed to pushing the boundaries of technology and setting new standards for quality and performance in the industrial machinery industry. The upgrade of the old CNC router machine is a testament to their unwavering pursuit of excellence and their determination to stay ahead of the curve.

Top CNC Router for Milling Metal Offers Precision and Efficiency

Title: Cutting-Edge CNC Router Revolutionizes Metal Milling IndustryIntroduction:In today's rapidly advancing manufacturing industry, precision and efficiency have become critical factors for businesses. A breakthrough innovation in the form of a new CNC router for metal milling has emerged, promising to revolutionize the industry. This new machine incorporates cutting-edge technology, offering unparalleled speed, accuracy, and versatility in metal milling operations. Developed by a pioneering company known for its commitment to innovation and quality, the new CNC router opens up a world of possibilities for metalworking professionals. This article delves into the numerous capabilities and advantages of this groundbreaking technology.Unleashing the Power of the New CNC Router:The newly developed CNC router for metal milling offers exceptional performance and versatility, making it a game-changer for the industry. This state-of-the-art machine combines advanced robotics, computer numerical control, and high-powered cutting tools to deliver exceptional precision, speed, and efficiency. The router's robust structure ensures stability during the most demanding milling tasks, guaranteeing consistent and accurate results. With precise motor controls and servo mechanisms, the CNC router delivers smooth movements with minimized vibrations, further enhancing its performance.One of the key advantages of this CNC router is its compatibility with a wide range of metal materials, including aluminum, steel, brass, and copper. This versatility allows manufacturers to expand their capabilities by exploring new design possibilities, materials, and finishes. Whether it's intricate detailing, large-scale production, or complex geometries, this CNC router handles each task with exceptional ease and precision.Integration of Advanced Software:To maximize efficiency and streamline the milling process, the CNC router is equipped with advanced software that enables seamless integration with computer-aided design (CAD) and computer-aided manufacturing (CAM) systems. This integration ensures precise replication of even the most intricate designs, reducing production time and minimizing material waste. The user-friendly software interface allows operators to program and customize milling operations effortlessly, making it accessible to both seasoned professionals and those new to CNC technology.Improved Productivity and Cost Savings:By harnessing the power of robotics and automation, the new CNC router significantly improves productivity and reduces manufacturing costs. The machine's high-speed milling capabilities allow for rapid material removal, resulting in shorter production cycles. The precise and accurate operations minimize the need for post-machining processes, thereby reducing the overall time and cost involved in manufacturing. Additionally, the automated nature of the CNC router reduces the risk of errors due to human factors, ensuring consistent quality and improved safety in the workplace.Industry Applications and Future Prospects:The applications of the new CNC router for metal milling extend across various industries, including aerospace, automotive, electronics, and construction. With its ability to handle complex geometries and create intricate patterns, the router is ideal for manufacturing aircraft components, automobile parts, electronics enclosures, and architectural fittings. Its compatibility with different metal materials gives manufacturers the flexibility to experiment with various alloys, further expanding their possibilities. As the industry continues to evolve, this innovative CNC router paves the way for future advancements, such as integration with artificial intelligence and monitoring systems, ensuring continuous improvement in metal milling processes.Conclusion:The advent of the new CNC router for metal milling has brought about a paradigm shift in the industry. Its exceptional precision, versatility, and efficiency redefine the possibilities of metalworking, enabling manufacturers to push boundaries and achieve superior results. The integration of advanced software, compatibility with various metal materials, and the promise of improved productivity make this CNC router an indispensable tool for modern manufacturing. As the industry progresses, there is no doubt that the CNC router will continue to evolve, offering new functionalities and driving the industry forward into a future of innovation and excellence.

Top 10 Wood Routers to Consider for Your Carpentry Projects

[Company] Unveils Innovative Wood Router for DIY Enthusiasts[City, State – Date] – Woodworking enthusiasts can now enjoy the benefits of [Company]'s latest innovation – the powerful and versatile wood router. With decades of experience in the industry, [Company] has a reputation for delivering high-quality and reliable tools for both professionals and hobbyists. The new wood router is set to revolutionize the woodworking experience with its advanced features and user-friendly design.The wood router is designed to meet the needs of both beginner and experienced woodworkers, offering a range of features that make it easy to use and highly efficient. Its powerful motor and precision cutting capabilities make it perfect for a wide range of woodworking projects, from simple household repairs to intricate furniture making. The variable speed control allows users to adjust the router's performance to suit the demands of different materials and tasks, ensuring clean and precise cuts every time.In addition to its performance, the wood router is also designed with user comfort and safety in mind. The ergonomic handle and smooth operation reduce fatigue during extended use, while the built-in safety features provide added peace of mind for users. With [Company]'s commitment to quality and durability, users can rely on the router to deliver outstanding performance for years to come.“Our goal is to empower woodworking enthusiasts with the tools they need to bring their creative ideas to life,” said [Spokesperson], [Company]'s spokesperson. “With our new wood router, we are providing a versatile and reliable tool that will enhance the woodworking experience for both professionals and hobbyists. We are confident that this innovation will set a new standard for wood routers in the industry.”Aside from its technical specifications, the wood router also features a sleek and modern design, reflecting [Company]'s dedication to both functionality and aesthetics. The router's compact and lightweight build makes it easy to handle and store, while its high-quality construction ensures long-term performance.The launch of the wood router marks another milestone for [Company], as it continues to expand its range of innovative and high-performance tools. With a strong focus on research and development, [Company] is committed to pushing the boundaries of what is possible in the industry, striving to create tools that meet the evolving needs of its customers.The wood router is now available for purchase through [Company]'s authorized retailers and online stores, offering woodworking enthusiasts easy access to this game-changing tool. As a leading provider of woodworking tools, [Company] aims to support its customers with excellent customer service and reliable after-sales support, ensuring that they can make the most of their new wood router.For woodworking enthusiasts looking to elevate their craft, the new wood router from [Company] offers a compelling solution that combines performance, user-friendliness, and value. With its innovative features and stylish design, this wood router is set to become an essential tool for DIY enthusiasts and professional woodworkers alike.For more information about the wood router and other products from [Company], visit [Company]'s website or contact their customer service team at [contact information].[Company] is a leading manufacturer of high-quality and innovative woodworking tools, serving a diverse range of customers around the world. With a commitment to excellence and customer satisfaction, [Company] continues to push the boundaries of what is possible in the industry, delivering reliable tools that empower woodworking enthusiasts to bring their creative ideas to life.

Tabletop Laser Welder with Cutting-Edge Technology and Engineering Features

Benchtop Laser Welder: The Future of Precision WeldingThe world of welding has seen a significant transformation over the years, with the introduction of innovative technologies such as the benchtop laser welder. This new welding technology has revolutionized the industry, providing precision, versatility, and speed in welding applications. In this blog, we will delve into the world of benchtop laser welder and explore its features, benefits, and applications.What is a benchtop laser welder?A benchtop laser welder, also known as a desktop laser welder, is a high-precision welding machine that utilizes laser technology to fuse metals together. Unlike traditional welding methods that use heat to melt and fuse metals, a laser welder uses a high-intensity laser beam to melt and bond the metals together. The precision and accuracy of a laser welder are unmatched, making it a popular choice for welding applications that require intricate and detailed work.Features of a benchtop laser welderBenchtop laser welders come in different models and designs, but they all share some common features that make them stand out from traditional welding machines. Some of the notable features of benchtop laser welders include:Precision: Laser welders offer unmatched precision and accuracy when compared to other welding methods. With a laser welder, you can control the spot size, energy density, and pulse duration, ensuring that the welding is done with the highest level of precision.Speed: Laser welders are fast and efficient, making them ideal for industries that require high-speed welding. With a laser welder, you can weld metals at a speed of up to 100 inches per minute, saving you time and money on production.Ease of use: Benchtop laser welders are easy to use, even for non-professionals. They come with intuitive controls and user-friendly interfaces that allow even the most novice users to operate them with ease.Benefits of a benchtop laser welderBenchtop laser welders offer numerous benefits that make them an ideal choice for welding applications. Some of the benefits of using a benchtop laser welder include:Improved quality: With a benchtop laser welder, you can achieve high-quality, consistent welds that are free from defects. Laser welding is a non-contact process, which means there is no risk of physical damage to the materials being welded, ensuring that the welded joints are of the highest quality.Versatility: Laser welders can weld various metals, including aluminum, copper, brass, and stainless steel. This makes them versatile for use in different industries, including automotive, aerospace, and medical device manufacturing.Cost-effective: Laser welding is a cost-effective welding method, as it requires less material and labor compared to traditional welding methods. The precision of laser welding reduces the need for post-welding finishing, saving you money on production costs.Applications of a benchtop laser welderBenchtop laser welders are versatile tools that find applications in various industries. Some of the applications of benchtop laser welders include:Jewelry and watchmaking: Laser welders are popular in the jewelry and watchmaking industry due to their precision and accuracy. They are used to weld tiny components, such as clasps, chains, and watch dials.Automotive industry: Benchtop laser welders are used to weld small components in the automotive industry, such as sensors, connectors, and electrical systems.Medical device manufacturing: Benchtop laser welders are used in the medical device manufacturing industry to weld small components in medical devices, such as stents and catheters.ConclusionBenchtop laser welders are the future of welding. They provide precision, versatility, and speed, making them an ideal choice for different industries. The benefits of using benchtop laser welders, such as improved quality and cost-effectiveness, make them an attractive option for businesses looking to optimize their production processes. If you're in the market for a welding machine, consider investing in a benchtop laser welder for high-quality, consistent welds in your production line.

Metal Sheet Cleaning Made Easy with Fiber Laser Technology

Metal Sheet With Fiber Laser Cleaner - Benefice of Bransgore and Hinton AdmiralThe world is changing and industries are fast adopting modern technologies to improve their efficiency and productivity. The metal sheet cleaning industry is no exception. In fact, the industry has been one of the early adopters of fiber laser cleaning technology. Fiber laser cleaning has revolutionized the metal sheet cleaning industry, and Bransgore and Hinton Admiral are now beneficiaries of this technology.Fiber lasers are highly efficient and reliable sources of laser beams. The cavity converts the low-quality diode light into single-mode laser light. One of the fiber Bragg gratings acts as a total reflector, while the other serves as a partial reflector or output coupler. The solid-state architecture of fiber lasers makes them insusceptible to environmental factors such as dust, moisture, and free-space air perturbations.The technology is not only efficient but also eco-friendly. It replaces traditional cleaning methods that use chemicals, which are not only harmful to the environment but also have the potential to cause long-term harm to humans. Fiber laser cleaning completely eliminates the need for chemicals and produces no toxic waste that could find its way into the environment.Lockdown across the globe has, undoubtedly, had a negative impact on the economy. Many businesses have had to shut down or work at limited capacity, and the metal sheet cleaning industry has not been spared. However, some businesses have managed to find ways to thrive, and one such company is Bransgore and Hinton Admiral. They have been able to leverage the benefits of fiber laser cleaning to offer their clients a safe and affordable cleaning service.Unlike traditional cleaning methods, fiber laser cleaning does not damage the substrate material. The laser beam selectively removes contaminants on the surface of the metal sheet while leaving the substrate material intact. This has been a major selling point for Bransgore and Hinton Admiral, as damage to the substrate material could result in additional costs for their clients.The cleaning system offered by Bransgore and Hinton Admiral is fast, efficient, and reliable. The system uses state-of-the-art scanners that are capable of removing contaminants quickly and accurately. The system allows their clients to clean large surface areas in a short amount of time thus improving their productivity. This has been particularly helpful for clients who have had to work under limited capacity during the lockdown.The technology is not only efficient but also safe for the operators. Fiber laser cleaning does not produce harmful fumes that could put the operators at risk. The system is also easy to operate, and Bransgore and Hinton Admiral have invested in the training of their operators to ensure that they can offer their clients a seamless service.The fiber laser cleaning technology has been a game-changer in the metal sheet cleaning industry. It has not only improved the efficiency and productivity of businesses but also has had a positive impact on the environment. Bransgore and Hinton Admiral have been able to leverage the technology to offer their clients a safe and affordable cleaning service. The lockdown may have had a negative impact on the economy, but businesses like Bransgore and Hinton Admiral have shown that it is possible to thrive in difficult times with the right technology and mindset.In conclusion, the technology offers numerous benefits to the metal sheet cleaning industry. It is fast, efficient, and reliable, and has a positive impact on the environment. With more businesses adopting the technology, the industry can look forward to a more productive and eco-friendly future.

Automatic Door Carving Machine: The Latest Innovation in Woodworking Technology

Door Carving Machine Revolutionizes Woodworking IndustryWoodworking industry has seen a significant revolution with the introduction of the latest Door Carving Machine by a leading machinery manufacturing company. This innovative machine has taken the woodworking industry by storm, offering unparalleled precision and efficiency in carving and shaping wooden doors.The Door Carving Machine is equipped with the latest technology and advanced features to cater to the growing demands of the woodworking industry. Its high-speed cutting and carving capabilities have made it a popular choice among woodworking professionals, enabling them to produce intricate and detailed designs with ease.With its user-friendly interface and automated functions, the Door Carving Machine has significantly reduced the production time and labor costs for woodworking businesses. This has resulted in higher productivity and profitability for companies using this cutting-edge machine.The company behind this revolutionary Door Carving Machine has been a pioneer in the manufacturing of woodworking machinery for over two decades. With a strong focus on innovation and quality, the company has built a reputation for delivering reliable and high-performance machinery to its customers.The Door Carving Machine is the latest addition to the company's diverse range of woodworking equipment, further solidifying its position as a leader in the industry. The machine has been designed and developed by a team of skilled engineers and technicians who have extensive experience in woodworking machinery.One of the standout features of the Door Carving Machine is its ability to work with various types of wood, including hardwoods, softwoods, and engineered wood. This versatility has made it an essential tool for woodworking businesses that deal with a wide range of wooden doors and furniture products.Moreover, the machine's precise cutting and carving capabilities have enabled woodworking professionals to bring their creative designs to life with exceptional accuracy and detail. This has opened up new opportunities for custom door designs and intricate patterns that were previously challenging to achieve.The company's commitment to customer satisfaction is evident in the Door Carving Machine, as it comes with comprehensive technical support and after-sales service. This ensures that woodworking businesses can get the most out of the machine while having peace of mind in its reliability and performance.In addition to its technological advancements, the Door Carving Machine also prioritizes safety and efficiency in its operations. With built-in safety features and ergonomic design, the machine provides a secure and comfortable working environment for woodworking professionals.As the woodworking industry continues to evolve, the Door Carving Machine has emerged as a game-changer for businesses looking to stay ahead of the competition. Its ability to streamline production processes and deliver superior results has made it a valuable investment for woodworking companies of all sizes.With its successful launch and positive reception in the market, the Door Carving Machine is expected to set new industry standards and inspire further innovations in woodworking machinery. It is a testament to the company's dedication to pushing the boundaries of technology and delivering cutting-edge solutions to its customers.In conclusion, the Door Carving Machine has undoubtedly made a significant impact on the woodworking industry, redefining the way wooden doors are crafted and designed. With its advanced capabilities, versatility, and user-friendly features, it has become a must-have tool for woodworking professionals who strive for precision and excellence in their craft. As the company continues to lead the way in woodworking machinery, the future looks promising for further advancements and groundbreaking solutions in the industry.

Mastering CNC 3D Machine Carving: Tips on Choosing the Best Bits

CNC 3D Machine Carving: Bringing Your Woodworking to LifeWoodworking has been a popular hobby for centuries, but technology has taken it to a whole new level in recent years. The development of CNC (computer numerical control) machines has revolutionized the woodworking industry, allowing for precision cuts and intricate designs to be made with minimal effort. One of the most exciting things you can do with a CNC router is 3D carving, bringing your woodworking projects to life like never before.But what exactly is 3D carving? Simply put, it's the process of using a CNC machine to carve intricate three-dimensional designs into wood. Instead of simply cutting a flat surface, a 3D carving can add depth and texture to your projects, making them truly stand out. However, choosing the right bits for the job is crucial to achieving the desired results.When it comes to 3D carving, the most commonly used bits are ball nose and bull nose bits. Ball nose bits are great for carving curved surfaces and contours, while bull nose bits are better suited for flat bottoms and sharp edges. Other popular bits include tapered bits, which are great for carving tight spaces and deep grooves, and V-bits, which can create sharp corners and angles.It's important to note that different materials will require different bits. For example, harder woods like oak or maple will require larger, stronger bits than softer woods like pine or cedar. It's also important to consider the depth and complexity of your design when selecting bits. A shallower design may require a smaller bit, while a more intricate design may need a larger bit to properly capture all the details.Once you've selected the right bits for your project, it's time to start carving. The key to successful 3D carving is patience and precision. Take your time and make sure your machine is properly calibrated to avoid any mistakes or errors. It's always a good idea to test your design on a scrap piece of wood before committing to your final project.In conclusion, 3D carving on a CNC machine is a fantastic way to take your woodworking projects to the next level. With the right bits and some patience, you can create stunning, intricate designs that will have everyone asking, How did you do that? So why not give it a try? Who knows what amazing designs you'll come up with on your 3D woodworking machine.

Discover the Portability and Efficiency of Laser Welding Machines

[Headline]: Revolutionary Portable Laser Welding Machine Redefines Industrial Manufacturing[Subheading]: Cutting-Edge Innovation Leverages Technology and Portability for Superior Welding Capabilities[date]In a major breakthrough, [Company Name] has unveiled its latest technological innovation – a Portable Laser Welding Machine that is set to transform the manufacturing industry. This cutting-edge device combines the power of laser technology with unparalleled portability, revolutionizing the way industries approach welding. Experts predict that this state-of-the-art invention will catapult manufacturing productivity to new heights, making it an indispensable tool across various sectors.[Company Name], a recognized industry leader in laser-based solutions, has always been at the forefront of technological advancement. The newly launched Portable Laser Welding Machine truly signifies their commitment to innovation and their vision of providing seamless solutions to complex manufacturing challenges.The brilliance of this Portable Laser Welding Machine lies in its ability to bring laser welding capabilities to previously inaccessible areas. Unlike traditional bulky and stationary welding machines, this revolutionary device offers unmatched portability. Weighing a mere [weight], it can be effortlessly transported to different locations, making it ideal for both large-scale manufacturing plants and small-scale operations.What sets this Portable Laser Welding Machine apart from its competitors is its exceptional precision and control. With advanced laser technology, this cutting-edge device ensures high-quality and flawless welds, consistently maintaining superior workmanship. The machine is equipped with ultra-high-speed cameras and sophisticated sensors that enable real-time monitoring and adjustment, guaranteeing precise weld positioning and impeccable results.[Company Name]'s Portable Laser Welding Machine has been crafted with meticulous attention to detail. Its ergonomic design ensures maximum efficiency by providing the operator with exceptional ease of use. The device is fitted with an intuitive touchscreen interface, making it easy to navigate and operate. This user-friendly interface, combined with the machine's swift response time, ensures increased productivity and reduced downtime.Moreover, this state-of-the-art machine boasts remarkable versatility. It can be utilized across a wide range of industries, catering to various welding requirements. From automotive and aerospace industries to construction and electronics, this Portable Laser Welding Machine offers an all-encompassing solution. Its adaptability and ease of integration into existing production systems make it an attractive prospect for numerous manufacturers.In addition to its unprecedented capabilities, [Company Name] emphasizes sustainability in their product design. The Portable Laser Welding Machine has been engineered to minimize energy consumption, resulting in significant cost savings for industrial manufacturers. This commitment to eco-friendly technology further solidifies [Company Name]'s reputation as a responsible corporate citizen."We are extremely proud to present this ground-breaking Portable Laser Welding Machine to the world," says [Name], the CEO of [Company Name]. "Our aim has always been to push the boundaries of innovation and redefine manufacturing practices. With this new invention, we are confident that we have achieved just that."Industry experts and professionals have eagerly awaited a portable laser welding machine that combines cutting-edge technology with user-friendly design. This revolutionary invention by [Company Name] has surpassed expectations, marking a paradigm shift in the welding industry. It is expected to enhance manufacturing processes, improve output quality, and boost overall operational efficiency.The Portable Laser Welding Machine will undoubtedly establish [Company Name] as an industry leader in laser-based technologies. Its ability to redefine manufacturing practices and its commitment to sustainable solutions will undeniably shape the future of industrial manufacturing.In conclusion, [Company Name] has introduced a game-changing Portable Laser Welding Machine that has the potential to revolutionize the manufacturing industry. With unparalleled portability, precision, and versatility, this cutting-edge innovation optimizes welding processes and takes productivity to unprecedented heights. As manufacturers embrace this remarkable technology, the production landscape is set to undergo significant transformation, propelling industries towards a more efficient and sustainable future.

Discover the Ultimate DIY CNC Wood Milling Machine for Your Projects

article.DIY CNC Wood Milling Machine Revolutionizes Woodworking IndustryWoodworking has always been an essential craft and hobby all over the world. From furniture to interior decoration, the art of woodwork has taken many forms throughout the centuries. In recent years, however, technology has revolutionized the woodworking industry, making it easier and more accessible to produce intricate designs and prototypes. One such technology is the DIY CNC wood milling machine, which is quickly becoming a game-changer in the woodworking industry.This new technology has made it possible to produce high-quality, intricate, and highly detailed designs on almost any type of wood. With the help of computer-aided design (CAD) software and a CNC wood milling machine, woodworking enthusiasts and professionals alike can create intricate designs with precision, speed, and accuracy. This technology has even made it possible to create 3D models of designs, making it much easier to visualize the final product before actually creating it.One of the newest and most advanced DIY CNC wood milling machines on the market today is the {brand name removed}. This machine has been designed to be user-friendly and easy to operate, even for beginners. The machine’s compact size and ergonomic design make it easy to move, store and set up. Its innovative control system allows the user to adjust the speed, depth, and direction of the cutting process, as well as the ability to pause, resume, or stop the milling process at any time.By using this state-of-the-art machine, craftsmen and hobbyists can avoid the tedious and often time-consuming process of manual carving, which can take hours, or even days, to complete. With the {removed brand name} CNC milling machine, intricate details can be created in a fraction of the time, with unparalleled accuracy and precision.{Brand name removed} is committed to innovation and quality, ensuring that their users have access to the latest technology and tools necessary to create the best possible designs. The company’s mission is to provide an affordable, reliable, and easy-to-use CNC milling machine that will help its customers achieve their woodworking goals, whether it’s creating personal projects, or running a professional woodworking business.The {removed brand name} CNC milling machine has a wide range of capabilities and features that make it one of the most advanced and effective machines on the market. Some of the unique features of this machine include:- The machine is equipped with a high-performance spindle that can reach speeds of up to 24,000 rpm, which means it can cut through even the toughest types of wood with ease.- The control system of the machine comes with a user-friendly interface, which means even beginners can quickly start milling their designs. The machine's software is also customizable, so users can adjust the system according to their specific needs and preferences.- The machine is also equipped with an advanced safety system that ensures the user's safety at all times. The system includes an emergency stop button, automatic shut-off in case of power failure, and other safety mechanisms that protect both the user and the machine.- The machine also features a dust collection system that keeps the work area clean and free of sawdust, debris, and other waste material. This means users can work without worrying about creating a mess, and the machine itself will last longer due to the reduced wear and tear.The DIY CNC wood milling machine has revolutionized the woodworking industry, making it more accessible, efficient, and precise than ever before. With the {removed brand name} CNC milling machine, woodworking enthusiasts and professionals can create intricate designs with ease, accuracy, and unparalleled precision.Overall, the {removed brand name} CNC milling machine is an outstanding example of the impact of technology on the woodworking industry. With this machine, users can bring their woodworking dreams to life, creating intricate designs and prototypes that would have been impossible just a few years ago. Whether it's for personal projects or professional work, the CNC milling machine is a game-changer, and {removed brand name} is leading the way in providing affordable and high-quality machines to the woodworking industry.

Discover the Artistry of 3D Wood Carving Machines

Wood Carving Machine 3D Revolutionizes the Artistic WorldIn the realm of craftsmanship and artistic creativity, the advent of technology has consistently propelled innovation to new heights. One such breakthrough is the Wood Carving Machine 3D, a cutting-edge device that has revolutionized the wood carving industry. Designed to provide unparalleled precision and efficiency, this innovative tool is set to transform the art of wood carving.Manufactured by a renowned company at the forefront of technological advancements, the Wood Carving Machine 3D embodies the perfect blend of tradition and modernity. With a commitment to excellence, the company has endeavored to create a device that caters to the needs of both beginners and seasoned professionals.The Wood Carving Machine 3D employs the latest computer-controlled technology, enabling users to bring their artistic visions to life with unmatched precision. With its user-friendly interface and intuitive design, this revolutionary machine allows users to create intricate 3D wood carvings effortlessly. Gone are the days of laborious manual work; the Wood Carving Machine 3D streamlines the carving process, saving time and effort without compromising on quality.One of the key features of this cutting-edge device is its versatility. Whether you are a hobbyist or a professional artist, the Wood Carving Machine 3D provides endless possibilities for creativity. Users can choose from a wide array of design options and templates or simply import their own designs, allowing for a truly personalized carving experience. The machine's adaptability ensures that it caters to the unique requirements of every user.In addition to its versatility, the Wood Carving Machine 3D boasts remarkable precision. Equipped with advanced sensors and digital calibration, it ensures that each cut is executed with pinpoint accuracy. This level of precision allows artists to delve into intricate details, producing wood carvings that are both visually stunning and structurally sound.Moreover, the Wood Carving Machine 3D is thoughtfully designed to prioritize the safety of its users. It comes with multiple safety features, including a protective casing and emergency stop buttons, guaranteeing peace of mind during operation. This commitment to safety ensures that artists can focus on their craft without any unnecessary concerns.The Wood Carving Machine 3D has garnered immense appreciation from the artistic community. Established wood craftsmen have embraced this innovation, incorporating it into their repertoire to enhance their creative abilities. The newfound ease and speed offered by the machine have paved the way for increased productivity, allowing artists to dedicate more time to refining their craft.Additionally, the Wood Carving Machine 3D has played a pivotal role in attracting newcomers to the art of wood carving. The simplicity of the device, coupled with its exceptional results, has made wood carving more accessible to beginners. Aspiring artists can now experience the joy of carving intricate designs without the years of practice typically required. This democratization of wood carving has created a burgeoning community of artists eager to explore and experiment.With its unrivaled precision, versatility, and safety features, the Wood Carving Machine 3D has carved a niche for itself in the artistic world. This innovative tool marks a significant leap forward in the art of wood carving, bridging the gap between traditional craft techniques and modern technology. As more artists embrace this transformative device, the boundaries of creativity within the wood carving industry are bound to be pushed further.In conclusion, the Wood Carving Machine 3D has emerged as a game-changer, culminating the expertise and craftsmanship of its manufacturer. Its ability to blend tradition with innovation, coupled with its outstanding precision and versatility, has propelled wood carving into the modern era. Through this revolutionary tool, artists can transcend the limitations of manual techniques and bring their imagination to life, ultimately redefining the boundaries of wood carving.