Top 4x8 CNC Wood Router for Precision Woodworking Projects

By:Admin

With its large working area of 4x8 feet, this CNC wood router is capable of handling a wide range of wood materials, from solid wood to plywood, MDF, and other composite materials. Its high-speed spindle and advanced motion control system allow for fast and accurate cutting, carving, and shaping of wood, resulting in finely detailed and polished woodwork.

The CNC wood router is also equipped with advanced software that enables woodworkers to design and program intricate patterns, shapes, and textures for the wood router to execute. This means that woodworkers have complete creative control over their projects, from designing unique furniture pieces to customizing wooden signs and decorative elements.

Additionally, the company behind this CNC wood router, has been a leading manufacturer of woodworking machinery for over 20 years, with a commitment to providing innovative and reliable solutions for woodworkers worldwide. Their extensive experience and expertise in the woodworking industry have allowed them to develop cutting-edge technologies, such as the 4x8 CNC wood router, that meet the evolving needs of modern woodworkers.

The company's dedication to quality and performance is evident in the design and functionality of the CNC wood router, which is built to withstand the demands of professional woodworking operations. Its robust construction, precise engineering, and user-friendly interface make it an essential tool for woodworking workshops, furniture manufacturers, and craftsmen who strive for excellence in their woodwork.

Furthermore, the company offers comprehensive technical support and training programs for their CNC wood router, ensuring that woodworkers can maximize the potential of this advanced technology. They understand that investing in a CNC wood router is a significant decision for woodworking businesses, and they are committed to providing ongoing assistance to help their customers succeed in their woodworking endeavors.

In conclusion, the 4x8 CNC wood router is a game-changer for the woodworking industry, offering unprecedented precision, efficiency, and versatility in creating high-quality woodwork. With the support of a reputable company with a proven track record of delivering top-notch woodworking machinery, woodworkers can trust in the performance and reliability of this CNC wood router to take their craft to the next level. Whether it's for creating custom furniture, intricate wood carvings, or personalized wooden products, this CNC wood router is an essential tool for woodworkers who demand excellence in their work.

Company News & Blog

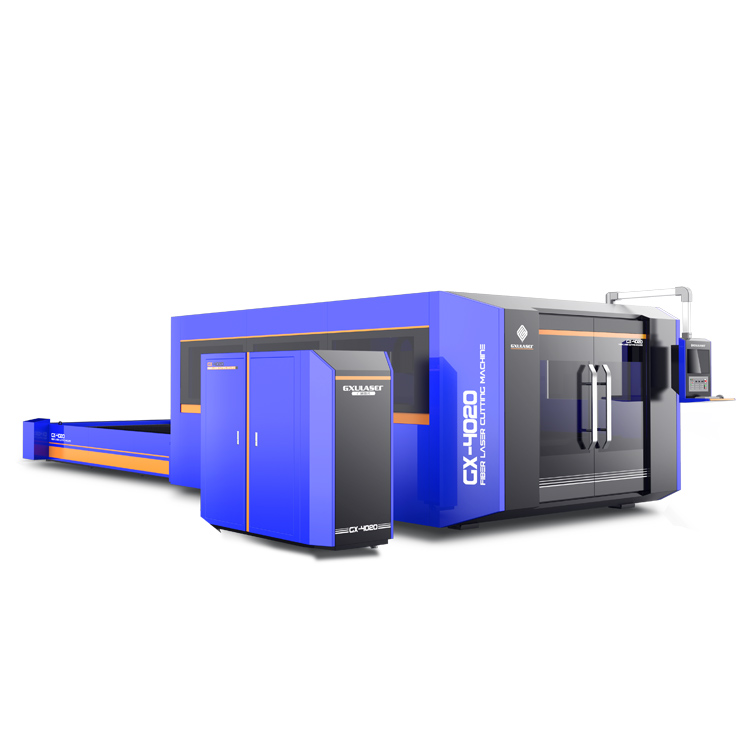

High-Power Laser Cutters for Sheet Metal Prototyping Equipment

The advancement in technology has brought about various changes and improvements in different industries including sheet metal prototyping. The use of laser cutters has revolutionized the prototyping industry by providing accurate and efficient results. The Incodema is one of the leading companies when it comes to using the latest sheet metal prototyping equipment. Their focus is on providing their customers with high-quality products using the latest technology available.The Incodema features two 5000 Watt Flying Optic lasers that are designed to provide accurate and efficient results in sheet metal prototyping. These lasers are known to be the fastest laser cutters available on the market. With their rapid feed rates cutting speeds, and large working areas these machines are capable of achieving the most complex designs with precision and speed.The 5000 Watt laser cutter has become increasingly popular in the sheet metal prototyping industry due to its versatility and ability to work with a wide range of materials. It can handle thick and thin sheets of metal, plastics, composites, and even wood. The advanced technology behind these machines allows for high-speed cutting while maintaining a level of precision that is unmatched.One of the most significant benefits of using the Incodema's 5000 Watt laser cutter is that it provides a higher level of accuracy compared to traditional cutting methods. The laser cutter uses computer-controlled technology to ensure that the cuts are precise and accurate. This eliminates the need for manual adjustments that can lead to errors.Another advantage of using these machines is that they are faster than traditional cutting methods. This means that they can handle large volumes of work in less time. The speed of the laser cutter, combined with automation, has significantly reduced the time it takes to make products. As a result, companies can increase their production capabilities without compromising quality.In addition to higher accuracy and faster speed, the Incodema's 5000 Watt laser cutter has other benefits as well. It has a lower cost of ownership, is easier to maintain, and is more environmentally friendly compared to other cutting methods. Since it uses less energy than other methods, it also helps companies to reduce their carbon footprint and contribute to a greener world.In conclusion, the Incodema's 5000 Watt laser cutter is a revolutionary machine in the sheet metal prototyping industry. Its speed, accuracy, and versatility have made it a popular choice among manufacturers. Its use of advanced technologies and automation has also reduced production times and costs while maintaining high-quality standards. As technology continues to improve, the future of sheet metal prototyping looks very promising with machines such as these.

Tens of Thousands Left Without Internet as Fiber Cables Severed – Stay Connected and Informed!

Fiber Cutting: Paving the Way for Advanced ConnectivityIn today's fast-paced world, connectivity is crucial for individuals and businesses alike. Whether it's for communication, education, entertainment, or commerce, a reliable and high-speed internet connection has become a necessity. That's where Fiber Cutting, a leading provider of cutting-edge fiber optic solutions, comes into play. With their commitment to innovation and technical expertise, Fiber Cutting has revolutionized the way we connect, communicate, and collaborate.Headquartered in [], Fiber Cutting has established itself as a global leader in the field of fiber optic technology. With a strong focus on research and development, the company has consistently pushed the boundaries of what is possible in terms of internet connectivity. By leveraging the power of fiber optics, Fiber Cutting enables faster data transmission rates, lower latency, and improved reliability compared to traditional copper-based networks.One of Fiber Cutting's most noteworthy achievements is the development of their proprietary fiber optic cables, which are designed to meet the ever-increasing demands of today's digital landscape. These cables are constructed using the finest quality materials and advanced techniques, ensuring maximum performance and durability. The company's commitment to quality and attention to detail have earned them a stellar reputation in the industry.What sets Fiber Cutting apart from its competitors is their end-to-end approach to connectivity solutions. From initial design and installation to ongoing maintenance and support, the company provides a comprehensive suite of services tailored to meet the specific needs of their clients. This holistic approach ensures a seamless integration of their fiber optic solutions into existing infrastructure, resulting in a hassle-free and future-proof network.Furthermore, Fiber Cutting's solutions are not limited to a particular sector or industry. The company caters to a wide range of clients, including telecommunications providers, data centers, educational institutions, hospitals, and government agencies. By offering scalable and customizable solutions, Fiber Cutting ensures that their clients can adapt to the ever-changing technological landscape and stay ahead of the competition.One of the key advantages of Fiber Cutting's fiber optic solutions is the ability to support the growing demand for bandwidth. As the world becomes increasingly interconnected, the need for faster and more reliable internet connections continues to rise. Fiber Cutting's solutions address this need by providing ultra-high-speed connectivity, allowing businesses and individuals to transfer large amounts of data seamlessly.Moreover, Fiber Cutting's fiber optic solutions offer exceptional security features, protecting sensitive data from unauthorized access. With the increasing threat of cyberattacks and data breaches, this aspect has become paramount for individuals and organizations alike. Fiber Cutting's commitment to data security ensures peace of mind for their clients, knowing that their information is safeguarded.In addition to their technological prowess, Fiber Cutting is also dedicated to environmentally friendly practices. The company understands the importance of sustainability and has implemented various initiatives to reduce their carbon footprint. By using energy-efficient components, recycling materials, and implementing environmentally conscious manufacturing processes, Fiber Cutting ensures that their solutions contribute to a greener future.Looking ahead, Fiber Cutting has ambitious plans to further expand its market presence and continue driving innovation in the field of fiber optic technology. The company aims to develop even faster and more reliable solutions, capitalizing on emerging technologies such as 5G and the Internet of Things (IoT). By staying at the forefront of technological advancements, Fiber Cutting aims to empower individuals and businesses with the connectivity they need to thrive in a digital world.In conclusion, Fiber Cutting's focus on innovation, technical expertise, and commitment to customer satisfaction have positioned them as a global leader in the fiber optic industry. With their state-of-the-art solutions, the company has transformed the way we connect and communicate. As the world becomes increasingly reliant on fast and reliable connectivity, Fiber Cutting remains at the forefront, paving the way for a more connected and efficient future.

Top Laser Engraving Machines for Small-Scale Projects: Discover the Best Options Available

Title: Advanced Laser Engraving Machine Revolutionizes the IndustryIntroduction:Today, we explore an innovative solution that is set to transform the engraving industry. The Small Laser Engraving Machine, developed by a pioneering company focused on laser technology, has emerged as a game-changer in this field. This cutting-edge device promises to streamline and enhance the engraving process, paving the way for unprecedented efficiency and precision. In this article, we will delve into the features and benefits of this revolutionary machine, as well as explore the impact it is set to have on various industries.Paragraph 1:With its compact design and advanced features, the Small Laser Engraving Machine is garnering attention as the go-to solution for businesses and individuals seeking unparalleled engraving capabilities. The machine's precise laser technology allows for detailed and intricate designs to be etched onto a wide range of materials, including wood, plastics, metals, and even organic substances. This versatility makes it an attractive option for multiple industries, from manufacturing and craftsmanship to personalized gift shops and hobbyists.Paragraph 2:One key feature that sets this engraving machine apart is its intuitive software interface, designed to simplify the engraving process. The user-friendly software seamlessly integrates with various design file formats, allowing for quick imports and efficient editing. The machine's compatibility with popular design programs ensures that users can easily convert their creative visions into stunning realities. Additionally, the software provides a live preview of the engraving process, allowing users to make any necessary adjustments before initiating the engraving sequence.Paragraph 3:Laser engraving traditionally required expertise and time-consuming manual labor. However, the Small Laser Engraving Machine is poised to change this narrative. Equipped with an advanced laser system, this cutting-edge device enables users to achieve precise results swiftly. Its high-power laser module, coupled with intelligent height sensing technology, ensures that engravings are executed with remarkable accuracy. This automation not only reduces the margin for human error but also significantly decreases production time, making it a cost-effective solution for both small-scale operations and large-scale manufacturing facilities.Paragraph 4:Durability and reliability are paramount when investing in any high-tech equipment. The Small Laser Engraving Machine does not disappoint in this aspect either. Manufactured using premium materials and constructed to withstand continuous use, it is built to withstand the demands of the most rigorous production environments. With its solid-state design and dependable components, the machine offers a long operational lifespan, minimizing downtime and maintenance costs.Paragraph 5:The Small Laser Engraving Machine's impact extends beyond its immediate benefits. By revolutionizing the engraving process, this device has opened up a multitude of possibilities for creative industries. Craftsmen and designers can now explore intricate and novel designs with ease, while businesses can innovate their product offerings and enhance their branding efforts. This technology is perfectly poised to take industries such as jewelry, personalization, and signage to the next level, ushering in an era of customizability and precision.Conclusion:The advent of the Small Laser Engraving Machine marks a significant milestone in precision engraving. Its advanced features, intuitive interface, and exceptional engraving capabilities position it as a transformative tool for businesses and creative individuals alike. With the ability to engrave a wide range of materials with unparalleled precision, this machine is set to revolutionize industries across the board. As it continues to gain traction, it is clear that the Small Laser Engraving Machine will redefine the way we perceive and engage with personalized products and craftsmanship.

High Precision 4-Axis CNC Router for Advanced Woodworking and Manufacturing

4-axis CNC routers are making headlines in the manufacturing industry for their advanced capabilities in creating intricate and complex designs with precision and accuracy. These state-of-the-art machines are revolutionizing the way companies produce a wide range of products, from furniture and cabinetry to aerospace components and automotive parts.One company leading the way in the development and production of 4-axis CNC routers is {}. With over 20 years of experience in the industry, {} has established itself as a pioneer in the field of CNC machining, offering a wide range of cutting-edge solutions for businesses of all sizes.The {} 4-axis CNC routers are equipped with advanced technology and features that set them apart from traditional 3-axis machines. The additional axis allows for more complex cutting and shaping capabilities, making it possible to create three-dimensional designs with ease. This opens up a world of possibilities for manufacturers, enabling them to produce more intricate and detailed products with greater efficiency.In addition to their cutting-edge technology, {} 4-axis CNC routers are known for their reliability and precision. The company takes pride in ensuring that their machines are built to the highest standards, using the best quality materials and components to guarantee optimal performance and longevity. This commitment to quality has earned {} a stellar reputation in the industry, with many businesses relying on their products to meet their production needs.One of the key advantages of using a {} 4-axis CNC router is the ability to streamline the manufacturing process. With its advanced capabilities, this machine can perform multiple operations in a single setup, reducing the need for manual intervention and minimizing production time. This not only increases efficiency but also lowers production costs, making it a cost-effective solution for businesses looking to improve their manufacturing capabilities.Furthermore, {} offers a range of customizable options and add-ons for their 4-axis CNC routers, allowing businesses to tailor the machine to their specific needs. Whether it's a particular cutting tool, a specialized clamping system, or a custom-designed worktable, {} works closely with their clients to ensure that their CNC router is optimized for their unique manufacturing requirements.The applications for {} 4-axis CNC routers are diverse and wide-ranging. From creating intricate wood carvings and moldings to producing complex metal components and prototypes, these machines can handle a variety of materials with precision and efficiency. This versatility makes them an indispensable tool for manufacturers across a range of industries, from woodworking and metalworking to aerospace and automotive.Looking ahead, {} is committed to furthering the advancement of 4-axis CNC router technology, with ongoing research and development to push the boundaries of what is possible in manufacturing. The company is dedicated to staying at the forefront of innovation, constantly seeking out new ways to improve their machines and empower their clients to achieve even greater levels of productivity and quality in their production processes.In conclusion, 4-axis CNC routers are transforming the manufacturing industry, and {} is at the forefront of this revolution. With their cutting-edge technology, commitment to quality, and dedication to innovation, {} is redefining what is possible in CNC machining and empowering businesses to achieve new levels of precision, efficiency, and productivity. As the demand for more complex and intricate designs continues to grow, 4-axis CNC routers are poised to become an essential tool for manufacturers looking to stay ahead in the competitive global market. And with {} leading the way, the future of CNC machining looks brighter than ever.

Highly Efficient Handheld Laser Welding Machines for Precision Work Applications

Hand Laser Welding Machine: Revolutionizing the Welding IndustryInnovation has always been at the core of industrial development. Companies are constantly seeking novel ways to improve efficiency, reduce costs, and enhance the quality of their products. The welding industry is no exception. Traditionally, welding has been performed using gas torches or electric arcs, both of which have limitations in terms of precision and flexibility. However, with the advent of hand laser welding machines, a new era has dawned in the welding industry.Hand laser welding machines utilize the power of lasers to perform intricate and precise welds. They combine the accuracy of laser technology with the versatility of a handheld device, allowing welders to access hard-to-reach areas and work with complex shapes. This revolutionary technology is set to transform the welding landscape, offering numerous benefits that were previously unimaginable.One prominent player in the hand laser welding machine market is {}. Their commitment to research and development has allowed them to develop cutting-edge products that have captured the attention of industry experts worldwide. Operating at the forefront of laser technology, they have expanded the boundaries of what is possible in the welding process.The {} hand laser welding machine stands out for its exceptional performance and user-friendly design. With advanced features such as real-time power regulation, adjustable laser beam spot size, and automatic wire feeding, the machine offers unrivaled precision and control. Welders can easily adjust the power output according to their specific needs, ensuring optimal results every time. Moreover, the adjustable beam spot size enables welders to adapt to varying workpieces, accommodating different material thicknesses and geometries without compromising weld quality.One of the most significant advantages of the {} hand laser welding machine is its portability. Unlike traditional welding equipment, which is often bulky and stationary, this machine can be operated with ease in any location. Welders are no longer restricted to a designated welding area; they can bring the machine to the workpiece, eliminating the need for extensive preparation and transportation. This mobility not only saves time but also increases productivity, making it an invaluable asset in time-sensitive projects.Furthermore, the {} hand laser welding machine's user-friendly interface simplifies the welding process, reducing the learning curve for welders. With intuitive controls and clear feedback, operators can quickly familiarize themselves with the machine and achieve professional-level welds in no time. This ease of use extends to maintenance as well, with self-diagnosis systems ensuring that any potential issues are promptly addressed, minimizing downtime and maximizing efficiency.Another feature that sets the {} hand laser welding machine apart is its focus on safety. The machine is equipped with multiple safety mechanisms, such as a protective housing, interlock systems, and emergency stop functions. These safety features not only protect the operators but also safeguard the work environment, highlighting the company's commitment to ensuring a secure welding experience.The combination of technological innovation, precision, portability, and safety makes the {} hand laser welding machine a game-changer in the welding industry. It opens up new possibilities for welders, allowing them to tackle complex projects with unparalleled efficiency and accuracy. Moreover, the machine's durability and reliability ensure a long lifespan, guaranteeing a solid return on investment for companies across various sectors.As the demand for high-quality and cost-efficient welding solutions continues to rise, hand laser welding machines are becoming increasingly sought after. Companies that embrace this technology will gain a significant competitive advantage in the market. With their state-of-the-art hand laser welding machine, {} is well-positioned to lead the charge and shape the future of the welding industry.In conclusion, hand laser welding machines have redefined the boundaries of welding technology. The innovation and expertise demonstrated by {} have resulted in a remarkable product that offers unmatched precision, portability, and safety. As more industries recognize the transformative potential of this technology, hand laser welding machines will undoubtedly become an essential tool in the manufacturing process. With {} at the helm, it is clear that the welding industry is set for a revolutionary change.

Powerful 60W Laser Engraver: Enhance Precision and Efficiency in Engraving Tasks

New Laser Engraver Revolutionizes the Industry with High-Precision PerformanceXYZ Company, a leading innovator in laser technology, introduces its latest cutting-edge 60W laser engraver, set to transform the industry with its exceptional precision and efficiency. This state-of-the-art engraver promises to bring a new level of quality and versatility to businesses and individuals involved in the engraving and marking processes.The 60W laser engraver boasts remarkable power that enables it to handle a wide range of materials with unparalleled accuracy. From wood and plastic to metals and leather, this engraver guarantees clean and precise engravings, ensuring stunning results every time. Its remarkable capabilities make it an ideal choice for industries such as crafting, manufacturing, and even personal customization.This powerful laser engraver stands out in terms of speed as well. With its high-performance motor and advanced motion control system, it can complete engravings in record time, significantly increasing productivity and efficiency. This makes it the perfect solution for businesses that require a fast turnaround without compromising on quality.Moreover, XYZ Company has incorporated cutting-edge software into the engraver to further surpass industry standards. Through an intuitive user interface, operators can easily manage all aspects of the engraving process. The software allows for precise control over parameters such as engraving depth, speed, and design complexity, ensuring optimal customization options for users.The safety features of the 60W laser engraver are also worth noting. XYZ Company has implemented advanced safety measures to protect both the operator and the machine itself during operation. These features include an emergency stop button, automatic shutdown in case of a malfunction, and protective shields to prevent accidental exposure to the laser beam.With its compact yet sturdy design, the 60W laser engraver is not only powerful but also easily adaptable to various work environments. Its size makes it suitable for small businesses, workshops, or even home use. This versatility allows different users to access the professional-grade capabilities of this engraver without compromising on space or convenience.XYZ Company, known for its commitment to customer satisfaction, offers comprehensive technical support to ensure smooth operations in using the 60W laser engraver. Their team of experts provides assistance in installation, training, and troubleshooting, guaranteeing that customers can fully harness the full potential of this remarkable machine.The market response to XYZ Company's new 60W laser engraver has been overwhelmingly positive. Early adopters of this technology have reported outstanding results, emphasizing the engraver's ability to produce intricate designs with lifelike precision. The reliability and speed of the 60W laser engraver have transformed many businesses, enabling them to meet growing demands while maintaining exceptional quality.As the industry continues to evolve, XYZ Company remains committed to pushing the boundaries of laser engraving technology. The introduction of the 60W laser engraver marks yet another milestone in their journey to provide superior solutions to the market. With its combination of power, speed, and versatility, this engraver is set to revolutionize the way businesses and individuals approach the art of engraving.In conclusion, XYZ Company's 60W laser engraver introduces a new era of precision and efficiency to the industry. Its remarkable capabilities, combined with state-of-the-art software and safety features, offer an unparalleled engraving experience. By delivering exceptional quality, speed, and versatility, this engraver is on the path to becoming a game-changer in the laser engraving industry.

The Ultimate Guide to 3D Fiber Laser Marking Machines

[Company Introduction - Please fill in the necessary details as required]In a world driven by technological advancements, innovative solutions continue to shape our daily lives. One such groundbreaking invention is the 3D Fiber Laser Marking Machine, developed by the highly reputable company [Company Name]. This cutting-edge technology has revolutionized the world of laser marking, providing endless possibilities for various industries.[Company Name], a pioneer in laser technology, has been at the forefront of innovation, consistently delivering state-of-the-art solutions that cater to different industrial needs. With a rich history spanning over [Number of Years] years, the company has established itself as a leader in the field, gaining recognition for its commitment to excellence and customer satisfaction.Now, with the introduction of their latest marvel, the 3D Fiber Laser Marking Machine, [Company Name] is set to not only transform the way products are marked but also enhance the overall efficiency and productivity of countless businesses.This cutting-edge technology utilizes a fiber laser, taking advantage of its exceptional precision and speed. The 3D capability of the machine allows for the marking of complex shapes and patterns on a variety of materials, including metals, plastics, ceramics, and more. With the ability to mark both 2D and 3D surfaces, this machine opens up endless possibilities for product customization, identification, and branding.One of the key features that sets the 3D Fiber Laser Marking Machine apart is its remarkable speed and accuracy. Through the use of advanced scanning systems and software algorithms, the machine ensures precise and reliable marking, even on intricate and delicate surfaces. The speed at which it operates enables manufacturers to significantly increase production rates and meet demanding deadlines.Furthermore, the 3D Fiber Laser Marking Machine boasts a user-friendly interface, allowing operators of all skill levels to utilize its full potential. The intuitive software provides a range of customization options, enabling businesses to create unique and eye-catching designs tailored to their specific requirements. With just a few simple steps, manufacturers can effortlessly set up the machine and achieve impeccable results in no time.Another advantage of this advanced technology is its ability to generate high-quality and permanent marks without compromising the structural integrity of the marked surface. The non-contact nature of the laser ensures that the material remains intact, eliminating the risk of damage or distortion. This makes it an ideal choice for industries such as medical device manufacturing, automotive, aerospace, and electronics, where precision and durability are of utmost importance.Furthermore, the 3D Fiber Laser Marking Machine is more environmentally friendly compared to traditional marking methods. As it operates without the need for inks or chemicals, it minimizes waste and reduces the overall carbon footprint. This aligns with [Company Name]'s commitment to sustainability and underscores its dedication to responsible manufacturing practices.As businesses worldwide are constantly seeking innovative solutions, the launch of the 3D Fiber Laser Marking Machine by [Company Name] comes at a crucial time. Its ability to enhance productivity, ensure precision, and create stunning visual effects is set to revolutionize the marking industry. By harnessing the power of laser technology, [Company Name] continues to reaffirm its position as a trailblazer in the global market.As the demand for customized and visually appealing products grows, the 3D Fiber Laser Marking Machine provides manufacturers with the tools necessary to meet ever-changing consumer expectations. Its versatility, speed, and reliability make it an essential asset for any business looking to set themselves apart in a competitive market.In conclusion, the introduction of the 3D Fiber Laser Marking Machine by [Company Name] is set to reshape the world of laser marking. With its exceptional capabilities, user-friendly interface, and dedication to sustainability, this cutting-edge technology will undoubtedly have a profound impact on a wide range of industries. As [Company Name] continues to push the boundaries of innovation, the future looks brighter than ever for the world of laser marking.

Revolutionary Laser Technology Takes Rust Removal to New Heights!

Laser Paint Rust Removal Technology is Paving the Way for Cleaner Air QualityIn today's world, environmental responsibility is playing a crucial role in the development of new technologies. With industries expanding at an exponential rate, environmental pollution and waste management are becoming increasingly important issues. The use of advanced technologies that can help in tackling environmental issues is therefore highly desirable. This is where, the revolutionary technology of Laser Paint Rust Removal comes into play.Laser Paint Rust Removal, introduced by {company name}, is a game-changer in the field of surface preparation and cleaning. This technology is a cutting-edge solution that allows for the removal of rust, paint, and contaminants in a highly efficient, eco-friendly and cost-effective manner.Previously, rust and paint removal was carried out by using abrasive blasting, a method that generated a lot of dust and was highly labor-intensive. The dust generated was harmful to the environment, causing pollution, and making it dangerous for workers. In today's world, the need for a more efficient and environmentally friendly solution has been a top priority. The answer to this need came in the form of Laser Paint Rust Removal technology.{Company name} is one of the pioneers in the Laser Paint Rust Removal industry. The company has been providing innovative solutions to a range of industries including aerospace, automotive, defense, marine and oil pipeline. Its technology saves time and resources while ensuring minimal environmental impact.The process of Laser Paint Rust Removal has numerous advantages. Firstly, the Laser Paint Rust Removal method is dustless and therefore significantly reduces the risk of respiratory hazards and eliminates the need for protective equipment, making it a much safer work environment for workers. Secondly, it is a non-contact process, making it highly efficient with little to no damage to the underlying surface. Thirdly, the process removes not only the paint but also underlying rust and contaminants, providing a cleaner surface to work with.{Company name} uses state-of-the-art equipment that is capable of removing rust, paint and contaminants in a single pass, thereby drastically reducing the time required for surface preparation. This process also retains the integrity of the surface and the underlying metal, ensuring it is not damaged during the cleaning process.The Laser Paint Rust Removal technology offered by {company name} has been tested and approved by several government agencies like the Department of Defense, the Navy, and the Air Force. This has helped them gain recognition from the military and other government agencies, making them the go-to solution provider for all their surface preparation and cleaning needs.In conclusion, the Laser Paint Rust Removal technology introduced by {company name} is a groundbreaking solution that is revolutionizing the way surface preparation and cleaning is carried out. Its highly efficient and eco-friendly process has made it the most preferred choice for industries across the globe. The technology’s patented process, state-of-the-art equipment, and superior customer service have helped {company name} achieve success in what used to be a highly competitive market. This innovative technology will play a significant role in ensuring a cleaner planet by helping industries reduce their carbon footprint and implement sustainable work practices.

4 Spindle CNC Router Machine for Efficient Large-Area Plate Carving and Window Processing

4 Spindle CNC Router Machine for SaleCNC Router Machines have revolutionized the woodworking industry by providing an easy, efficient and cost-effective solution for cutting, carving, engraving and finishing wood products. The latest addition to the CNC Router Machines is the 4 Spindle CNC Router Machine. The machine is designed with four spindles to facilitate four different tools at one time, which makes it ideal for large-area plate carving and door and window processing.Applications of 4 Spindle CNC Router MachineThe 4 Spindle CNC Router Machine is ideally suited for engraving and milling of 3-4 types of flower knives. It is commonly used in various industries for cutting and carving of wood, MDF, particleboard, plywood, plastics, and other non-metallic materials. The machine is versatile and can be used for making toys, furniture, cabinets, signs, crafts, musical instruments, and many other products.Features of 4 Spindle CNC Router MachineThe 4 Spindle CNC Router Machine is a newly designed multi-spindle CNC router that is suitable for various large-area plate carving and door and window processing. It is equipped with several features that make it stand out from the other CNC Router Machines available in the market today. Here are some of its features:Automatic Tool Change: The machine has four-processing easy automatic tool change, which makes it easier to change tools quickly and efficiently.High Speed: The 4 Spindle CNC Router Machine has an excellent high-speed system. Its maximum working speed is 35m/min, which makes it highly efficient for cutting and carving.High Accuracy: The machine uses a high-precision linear guide, and its rack and pinion drive system ensures high accuracy and excellent performance.Powerful Motors: The CNC Router Machine is equipped with powerful motors that deliver high torque, which allows for cutting and carving of hard materials with ease.User-friendly Interface: The machine has a user-friendly interface that allows for easy operation. It also comes with software that enables users to design their products with ease.Benefits of the 4 Spindle CNC Router MachineThe 4 spindle CNC Router Machine has several benefits that make it an ideal choice for woodworking industries. Here are some of the benefits of using the 4 Spindle CNC Router Machine.Better Efficiency: The machine enables multi-tasking, which means you can work on different products simultaneously, thereby increasing productivity and efficiency.Cost-Effective: The machine is cost-effective since it has four spindles that allow you to work on different products without the need for multiple machines.High Precision: The 4 spindle CNC Router Machine has high accuracy and precision, providing a high-quality finish to your products.Versatility: The machine can work on different materials, making it highly versatile.ConclusionIf you are looking for a cost-effective, efficient, and versatile CNC Router Machine, then the 4 Spindle CNC Router Machine is the right choice for you. It is equipped with advanced features that make it highly efficient, accurate, and easy to operate. So, whether you are in the woodworking industry or any other field that requires cutting and carving of non-metallic materials, the 4 Spindle CNC Router Machine is an excellent investment for your business.Keywords: CNC Router Machine, 8x4, 4 Spindle CNC Router Machine, Engraving, Milling, Automatic Tool Change, Multi-spindle CNC Router, Cost-effective, High Precision, Versatility.