Discover the Best CNC Machine for Wood Carving

By:Admin

One company that is at the forefront of this trend is {}. They have been a leader in the manufacturing of CNC machines for over 20 years and have continuously evolved their product line to meet the changing needs of their customers. Their CNC machines are known for their high quality, precision, and reliability, making them the go-to choice for woodworkers looking to improve their production processes.

The use of CNC machines for wood carving has revolutionized the woodworking industry. These machines are capable of creating intricate designs and patterns that would be nearly impossible to achieve with traditional woodworking methods. Additionally, CNC machines offer a level of consistency and accuracy that is unmatched by manual carving techniques.

One of the key advantages of using CNC machines for wood carving is the ability to automate the entire process. This not only saves time and labor costs, but also ensures that each piece is precisely carved to the exact specifications. Whether it's creating custom furniture, intricate moldings, or unique decorative pieces, CNC machines provide woodworkers with the flexibility to bring their designs to life with ease.

Another benefit of using CNC machines for wood carving is the ability to work with a wide range of wood materials. Whether it's hardwood, softwood, or engineered wood products, CNC machines are capable of handling a variety of wood types with ease. This versatility allows woodworkers to take on a diverse range of projects without having to invest in multiple specialized tools.

In addition to their woodworking capabilities, CNC machines from {} are also known for their user-friendly interface and advanced software. This makes it easy for woodworkers to design and program their carving projects with precision and efficiency. The intuitive nature of the software also allows for quick adjustments and modifications, ensuring that each piece meets the exact specifications of the design.

The impact of CNC machines on the woodworking industry has been far-reaching. Not only have these machines improved the efficiency and precision of woodworking processes, but they have also opened up new opportunities for woodworkers to expand their capabilities and take on more complex projects. With the help of CNC machines, woodworkers can now push the boundaries of their creativity and craftsmanship, knowing that they have the tools to bring their ideas to life with precision and quality.

In conclusion, the use of CNC machines for wood carving has significantly transformed the woodworking industry. With the advanced technology and precision offered by CNC machines from {}, woodworkers now have the tools they need to improve their production processes, enhance their designs, and take on new and challenging projects. As the demand for high-quality, custom wood products continues to grow, CNC machines will undoubtedly play a pivotal role in shaping the future of the woodworking industry.

Company News & Blog

High-Quality Aluminum for CNC Milling: What You Need to Know

Aluminum For CNC Milling: The Perfect Material for Precision EngineeringCNC milling is a crucial process in the manufacturing industry. It involves the use of computer-aided design (CAD) software to program milling machines and create precise and complex parts from various materials. One material that has proven to be highly effective for CNC milling is aluminum. Its high strength-to-weight ratio, machinability, and corrosion resistance make it an ideal choice for precision engineering projects.Aluminum is a non-ferrous metal that is widely used in the aerospace, automotive, and electronics industries. Its unique properties make it a perfect choice for CNC milling applications. The material is known for its exceptional strength, which allows for the creation of intricate and detailed parts. Additionally, aluminum is lightweight, making it an excellent choice for components that require a high strength-to-weight ratio.One company that has perfected the art of CNC milling aluminum is {}. With years of experience in precision engineering and CNC machining, they have established themselves as a leader in the industry. Their state-of-the-art facility is equipped with the latest CNC milling machines and a team of highly skilled engineers and machinists, allowing them to handle even the most complex projects with ease.The company's expertise in working with aluminum for CNC milling is unparalleled. They understand the unique properties of the material and have developed specialized techniques to ensure the highest quality and precision in their finished products. Whether it's creating intricate components for the aerospace industry or producing custom parts for the automotive sector, {} has the knowledge and capabilities to deliver exceptional results.In addition to its strength and machinability, aluminum is also known for its excellent corrosion resistance. This makes it an ideal choice for parts that will be exposed to harsh environmental conditions. Whether it's for outdoor applications or components that come into contact with chemicals and other corrosive substances, aluminum's resistance to corrosion ensures the longevity and reliability of the finished parts.Furthermore, aluminum is a highly versatile material that can be easily customized to meet specific project requirements. It can be anodized, painted, or coated to enhance its appearance and improve its performance. This flexibility makes it an excellent choice for a wide range of applications, from consumer electronics to industrial machinery.{}'s commitment to quality and innovation sets them apart in the industry. They are constantly investing in the latest technology and equipment to ensure that they can meet the evolving needs of their customers. Their dedication to excellence is evident in the precision and intricacy of the parts they produce, making them a trusted partner for companies looking for reliable and high-quality CNC-machined components.In conclusion, aluminum is the perfect material for CNC milling due to its exceptional strength, lightweight properties, and corrosion resistance. When combined with the expertise and capabilities of a company like {}, the result is precision-engineered parts that meet the highest standards of quality and performance. With their commitment to innovation and excellence, {} continues to be a leader in the industry, providing customized solutions for a wide range of applications.

High-quality CNC milling machines: everything you need to know

Precision Machines Inc. is revolutionizing the manufacturing industry with their state-of-the-art CNC machine milling technology. This cutting-edge machinery is changing the game for businesses across the globe, offering unprecedented precision and efficiency in the production process.The CNC machine milling technology, which is widely used in the aerospace, automotive, and medical industries, has become an integral part of Precision Machines Inc.'s commitment to providing superior manufacturing solutions. This advanced technology allows for the automated control of machining tools through computer programming, resulting in highly accurate and intricate components.The company's dedication to staying ahead of the curve in manufacturing technology has propelled them to the forefront of the industry. With their expertise in CNC machining, Precision Machines Inc. has been able to offer their clients unparalleled quality and precision in their products. By investing in the latest machinery and software, the company has set itself apart as a leader in the manufacturing sector.One of the key advantages of CNC machine milling technology is its ability to produce complex parts with a level of precision that is simply unattainable through manual machining methods. This not only results in higher quality products, but also allows for increased productivity and reduced lead times. As a result, Precision Machines Inc. has been able to accommodate the demands of their clients while maintaining the highest standards of quality.Moreover, the CNC machine milling technology has enabled the company to diversify their capabilities, offering a wider range of services to their clients. With the ability to machine a variety of materials, from metals to plastics, Precision Machines Inc. has become a one-stop shop for all of their customers' manufacturing needs. This versatility has solidified the company's reputation as a reliable and innovative partner in the industry.In addition to their cutting-edge technology, Precision Machines Inc. prides itself on its team of highly skilled and knowledgeable professionals. With years of experience in CNC machining, their staff possesses the expertise to navigate the complexities of the technology and deliver exceptional results. This combination of advanced machinery and expert personnel has made Precision Machines Inc. a trusted name in the manufacturing world.Furthermore, the company's commitment to continuous improvement and innovation has led them to regularly invest in the latest CNC machine milling technology. By staying at the forefront of technological advancements, Precision Machines Inc. ensures that they are always able to offer their clients the most efficient and cost-effective solutions for their manufacturing needs.As the manufacturing industry continues to evolve and demand for high-quality, precision products increases, the role of CNC machine milling technology in shaping the future of manufacturing cannot be overstated. Precision Machines Inc. understands the importance of staying ahead of the curve in this ever-changing landscape, and their investment in cutting-edge machinery puts them in a prime position to lead the charge.With their dedication to excellence and innovation, Precision Machines Inc. is poised to continue pushing the boundaries of what is possible in the world of manufacturing. Their commitment to harnessing the power of CNC machine milling technology has set them apart as a leader in the industry, and the impact of their work is sure to be felt for years to come.

Boost Your Metal Fabrication Process: Discover the Power of Stainless Steel CNC Cutting

Title: Revamping Precision in Metal Fabrication with Stainless Steel CNC CuttingIntroduction (100 words):In an era fueled by technological advancements, the manufacturing industry strives to enhance precision and efficiency to meet evolving demands. One such innovation revolutionizing metal fabrication is stainless steel CNC cutting. By harnessing the power of computer numerical control (CNC) technology, this cutting-edge process caters to a diverse range of industries. This article explores the capabilities of stainless steel CNC cutting and highlights how it contributes to the company's commitment to delivering high-quality and precise metal fabrication solutions.Body:1. The Advantages of Stainless Steel CNC Cutting (200 words):Stainless steel CNC cutting is rapidly gaining popularity due to its exceptional benefits. The process combines the advantages of stainless steel, renowned for its durability and corrosion resistance, with the precise cutting capabilities of CNC technology. The inclusion of this technique in the company's metal fabrication arsenal allows for the efficient production of intricate and complex designs without compromising on the material's integrity.The CNC cutting system boasts unmatched precision, repeatability, and speed, ensuring consistent and accurate results batch after batch. By utilizing cutting-edge computer programming, the company can accommodate various design specifications, creating customized solutions to meet specific client requirements. Moreover, stainless steel CNC cutting minimizes material wastage, ultimately leading to cost savings and environmental sustainability.2. Industry Application and Diverse Uses (250 words):Stainless steel CNC cutting has found widespread application across several industries due to its versatility. From automotive and aerospace to architecture and medical equipment, this technology imparts immense value by fabricating high-quality metal components. The company leads the way by leveraging stainless steel CNC cutting to cater to the unique demands of its clients.In the automotive sector, precision is paramount. Stainless steel CNC cutting ensures the production of accurate parts for critical systems, including suspension, exhaust, and engine components. By adhering to strict quality controls and flawlessly executing complex designs, the company aligns with industry standards to deliver superior products.Likewise, the aerospace industry relies heavily on stainless steel CNC cutting for aircraft parts such as turbine blades, airframes, and structural components. The precise and intricate nature of these components demands the employment of cutting-edge CNC technology, ensuring not only structural integrity, but also upholding safety standards.Architecture and interior design benefit from stainless steel CNC cutting as it provides the opportunity for innovative and visually stunning metalwork. From intricate metal furniture designs to striking building facades, the company's CNC cutting expertise offers architects and designers the freedom to explore their creative boundaries while maintaining structural integrity.Additionally, stainless steel CNC cutting serves the medical industry, crafting intricate surgical instruments, orthopedic implants, and medical devices with utmost precision and detail. The technology affords superior surface quality for biocompatible stainless steel, enhancing patient safety and medical professionals' peace of mind.3. Company Name: Pioneering Excellence and Innovation in Stainless Steel CNC Cutting (200 words):Company {} (please insert the company name) stands at the forefront of revolutionizing the metal fabrication landscape with its expertise in stainless steel CNC cutting. With a commitment to excellence and innovation, the company strives to deliver superior quality products by leveraging the potential of cutting-edge technologies.{} (Please include company introduction, such as history, values, certifications, and commitment to customer satisfaction). As an industry leader, the company's state-of-the-art facilities and highly trained technicians ensure precise execution of designs, delivering exceptional results to clients across diverse industries.Furthermore, the company's dedication to consistent improvement and investment in research and development enables them to stay ahead in a highly competitive market. By staying up-to-date with the latest advancements in stainless steel CNC cutting, they continually expand their capabilities, providing customers with cutting-edge metal fabrication solutions.Conclusion (150 words):Stainless steel CNC cutting has ignited a revolution in precision metal fabrication, enabling the manufacturing industry to achieve unparalleled accuracy and efficiency. The company's expertise in this field has facilitated the delivery of robust and intricate metal components across diverse sectors, including automotive, aerospace, architecture, and healthcare.Through adopting this cutting-edge technology, the company remains committed to providing clients with superior quality, customizable metal fabrication solutions that adhere to the highest industry standards. The fusion of stainless steel's remarkable properties with CNC cutting's exemplary precision ensures that the company remains at the forefront of manufacturing excellence, meeting the evolving needs of their valued customers efficiently and sustainably.

High-Powered Multifunction Welder for All Your Welding Needs

Multifunction Welder Revolutionizes Industrial WeldingIn the fast-paced world of industrial manufacturing, efficiency and versatility are key factors in maintaining a competitive edge. With the introduction of the Multifunction Welder by [Company Name], welding technology has taken a significant leap forward. This state-of-the-art welding equipment offers a wide range of features that not only streamline the welding process but also enhance the overall productivity and quality of the output.The Multifunction Welder, developed by [Company Name], is designed to meet the diverse needs of industrial welders, from large-scale production to small-scale fabrication. With its cutting-edge technology and ergonomic design, this equipment provides a one-stop solution for a variety of welding tasks, including MIG, TIG, stick, and flux-cored welding. Its multifunction capabilities allow for seamless transition between different welding processes, eliminating the need for multiple machines and reducing the setup time.One of the key features of the Multifunction Welder is its advanced control system, which offers precise control over the welding parameters such as voltage, current, and wire feed speed. This level of control allows for a highly accurate and consistent welding process, resulting in high-quality welds with minimal rework or waste. Additionally, the equipment is equipped with a digital interface that provides real-time monitoring of the welding parameters, enabling welders to make immediate adjustments as needed.Furthermore, the Multifunction Welder is designed with user-friendly features that simplify the welding process and enhance the overall efficiency. Its intuitive interface and easy-to-use controls make it accessible to welders of all skill levels, while the ergonomic design ensures comfortable and safe operation. In addition, the equipment is equipped with advanced safety features such as thermal overload protection and voltage fluctuation protection, ensuring the safety of the welder and the integrity of the equipment.[Company Name] has a proven track record of providing high-quality welding equipment to the industrial sector. With a strong focus on innovation and customer satisfaction, the company has earned a reputation for delivering reliable and efficient solutions to its clients. The Multifunction Welder is the latest addition to its extensive product line, and it represents a significant milestone in the company's commitment to advancing welding technology.In addition to its cutting-edge technology, the Multifunction Welder is backed by [Company Name]'s comprehensive customer support and after-sales service. The company offers training, technical assistance, and spare parts availability to ensure that its clients can maximize the benefits of the equipment and operate it with confidence. This commitment to customer satisfaction further reinforces the reliability and value of the Multifunction Welder.The introduction of the Multifunction Welder by [Company Name] is set to revolutionize the industrial welding landscape. With its advanced technology, multifunction capabilities, and user-friendly design, this equipment offers a superior welding solution that meets the evolving needs of the industry. As manufacturing processes continue to become more complex and demanding, the Multifunction Welder provides a competitive edge by delivering efficiency, versatility, and quality in one comprehensive package.

Discover the latest Mini CNC Router Machine for your woodworking needs

The increasing demand for smaller and more precise CNC machines has led to the development of the CNC Router Mini Machine. This versatile and compact machine is designed to meet the needs of small businesses and hobbyists who require precision cutting, engraving, and milling. With its user-friendly interface and advanced capabilities, the CNC Router Mini Machine is set to revolutionize the world of small-scale manufacturing and personal craftsmanship.The CNC Router Mini Machine is equipped with advanced features such as high-speed spindle, precision ball screws, and a rigid frame to ensure exceptional accuracy and reliability. Its compact size and lightweight design make it perfect for small workshops and home use. The machine also comes with a range of accessories and software options, allowing users to customize their machine to suit their specific needs.According to {company name}, the manufacturer of the CNC Router Mini Machine, the company is dedicated to providing innovative and high-quality CNC machines for a wide range of industries. With a team of experienced engineers and designers, {company name} is committed to pushing the boundaries of CNC technology and delivering cutting-edge solutions to its customers."We are excited to introduce the CNC Router Mini Machine to the market," said a spokesperson for {company name}. "We believe that this machine will empower small businesses and hobbyists to take their manufacturing capabilities to the next level. With its precision and versatility, the CNC Router Mini Machine is a game-changer for anyone looking to create intricate and detailed parts."The CNC Router Mini Machine is designed to handle a variety of materials, including wood, plastic, acrylic, and soft metals. Its high-speed spindle can reach speeds of up to 24,000 RPM, allowing for fast and efficient cutting and milling. The machine's precision ball screws ensure smooth and accurate movement, while its rigid frame minimizes vibration and flex for superior cutting quality.In addition to its advanced hardware features, the CNC Router Mini Machine also comes with intuitive software that allows users to create and edit designs with ease. The machine is compatible with a range of CAD/CAM software, giving users the flexibility to work with their preferred design programs.{Company name} is offering comprehensive customer support and training for the CNC Router Mini Machine, ensuring that customers can get the most out of their investment. The company's technical team is available to provide assistance with installation, troubleshooting, and maintenance, allowing users to maximize the performance and lifespan of their machine.The CNC Router Mini Machine is now available for purchase in select markets, with plans to expand availability in the near future. With its compact size, advanced features, and comprehensive support, the CNC Router Mini Machine is poised to become a valuable asset for small businesses, craftsmen, and makers seeking to accelerate their production capabilities.As the demand for precision cutting and milling continues to grow, the CNC Router Mini Machine stands out as a groundbreaking solution for small-scale manufacturing and personal craftsmanship. With its advanced features, compact size, and comprehensive support, this machine is set to make a significant impact on the industry and empower a new generation of makers and manufacturers.

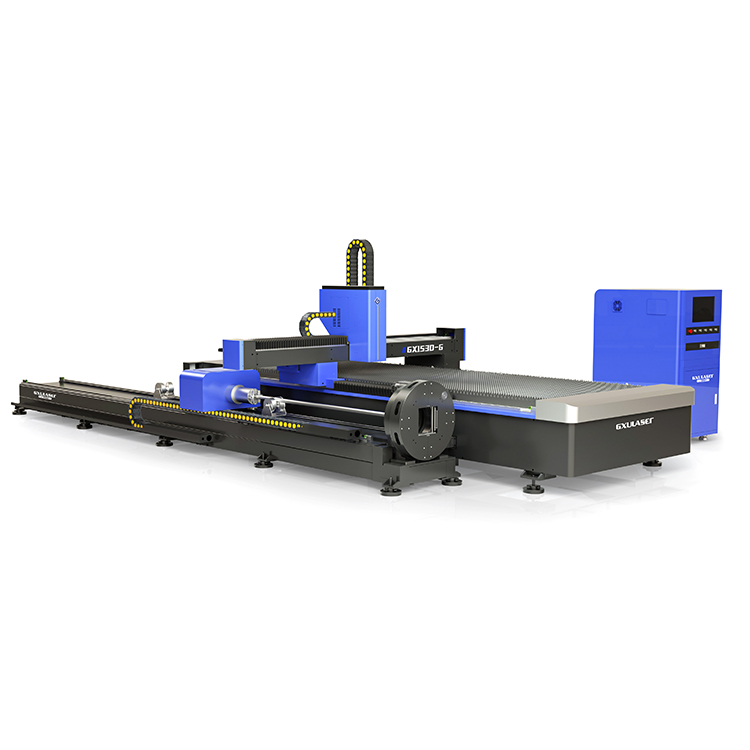

Top Laser Cutting Machine for Precision Cutting and Engraving

Laser Cutting Machine Revolutionizes Manufacturing at {Company Name}{City, Date} – The manufacturing industry is constantly evolving with new technologies and innovations that allow companies to increase efficiency and productivity. {Company Name} is at the forefront of this evolution, with the recent introduction of a state-of-the-art Laser Cutting Machine that has revolutionized their manufacturing process.The new {Laser Cutting Machine}, which was installed in the company's production facility in {City}, has greatly enhanced the speed and precision of their manufacturing operations. This cutting-edge machine utilizes advanced laser technology to precisely cut through various materials such as metal, plastic, and wood with unparalleled accuracy.The introduction of the {Laser Cutting Machine} has significantly reduced the production time for {Company Name}, allowing them to fulfill orders at a much faster pace while maintaining the highest quality standards. This has not only resulted in increased customer satisfaction but has also opened up new opportunities for the company to take on larger and more complex projects.{Company Name} is known for its commitment to innovation and continuous improvement in its manufacturing processes. The recent addition of the {Laser Cutting Machine} is a reflection of this philosophy, as it demonstrates the company's dedication to investing in cutting-edge technology that elevates their capabilities in the industry.According to {Spokesperson Name}, the {Title} at {Company Name}, "The {Laser Cutting Machine} has been a game-changer for us. It has allowed us to take on more complex projects and fulfill orders at a much faster pace. This has given us a competitive edge in the market and has strengthened our position as a leader in the manufacturing industry."The {Laser Cutting Machine} is not only a testament to {Company Name}'s commitment to innovation but also to their dedication to sustainability. The machine's precision cutting capabilities result in minimal material waste, contributing to the company's efforts to minimize their environmental impact.In addition to the benefits that the {Laser Cutting Machine} has brought to {Company Name}, it has also created new opportunities for their employees. The company has invested in training programs to ensure that their workforce is equipped with the skills and knowledge to operate and maximize the potential of the new machine.As {Company Name} continues to grow and expand its operations, the introduction of the {Laser Cutting Machine} represents a significant milestone in their journey towards excellence in manufacturing. With its ability to deliver unparalleled precision and efficiency, the machine has set a new standard for the company and has positioned them as an industry leader.Looking ahead, {Company Name} is dedicated to further leveraging the capabilities of the {Laser Cutting Machine} to innovate and stay ahead of the curve in the ever-evolving manufacturing landscape. With their commitment to excellence and the latest technology, {Company Name} is poised to continue delivering exceptional products and services to their customers while setting new benchmarks for their industry peers.In conclusion, the introduction of the {Laser Cutting Machine} at {Company Name} has marked a significant turning point in their manufacturing capabilities. With its precision, speed, and sustainability benefits, the machine has not only enhanced the company's operations but has also set a new standard for manufacturing excellence. As {Company Name} continues to embrace innovation, their commitment to delivering high-quality products and services remains unwavering, solidifying their position as a leader in the industry.For more information about {Company Name} and their innovative manufacturing capabilities, visit their website at {website address}.

Powerful CNC Router for Stone Cutting and Engraving

Introducing the Next Generation Stone CNC Router In today’s ever-evolving world of technology, precision and efficiency are key factors in the manufacturing industry. And when it comes to stone processing, nothing beats the performance of the latest Stone CNC Router from (remove brand name).With over 20 years of experience in the field of stone CNC routers, (company name) has established itself as a global leader in the manufacturing of high-quality and high-precision CNC machines. Their dedication to research and development has led to the creation of the most advanced stone CNC routers on the market, and the latest addition to their lineup is no exception. The new Stone CNC Router is set to revolutionize the way stone is processed, setting a new standard for efficiency and accuracy in the industry.The key feature that sets (company name)’s Stone CNC Router apart from the rest is its advanced cutting and carving capabilities. Designed with precision in mind, this machine is able to accurately carve intricate designs and patterns onto stone surfaces with unparalleled accuracy. This level of precision is achieved through the use of state-of-the-art technology and high-quality components, making this machine the go-to choice for stone processing professionals who demand nothing but the best.Furthermore, the new Stone CNC Router boasts a user-friendly interface that allows for easy operation and programming. This means that even those with limited experience in CNC machining can quickly learn how to operate this machine, making it accessible to a wider range of users. Additionally, the machine is equipped with advanced safety features to ensure the well-being of its operators, making it a reliable and safe choice for any stone processing facility.In addition to its cutting and carving capabilities, the new Stone CNC Router is also equipped with a high-speed spindle that is capable of handling a wide range of stone materials. This means that whether you are working with marble, granite, or any other type of stone, this machine can handle the job with ease, providing a consistent and high-quality finish every time.The (company name)’s commitment to superior craftsmanship is reflected in the design and construction of this machine. Every component is carefully selected and tested to ensure that it meets the highest standards of quality and reliability. This dedication to excellence is what sets (company name) apart from its competitors and has earned them a reputation as a trusted and respected name in the industry.The introduction of the new Stone CNC Router is a testament to (company name)’s ongoing commitment to innovation and customer satisfaction. By continuously pushing the boundaries of what is possible in CNC machining, they have set a new standard for excellence in the industry. With the new Stone CNC Router, customers can expect nothing but the best in terms of performance, reliability, and precision.As the global demand for high-quality stone products continues to grow, (company name) is staying ahead of the curve by providing cutting-edge solutions that meet the needs of today’s stone processing industry. Their new Stone CNC Router is set to revolutionize the way stone is processed, providing a level of efficiency and precision that is unmatched by any other machine on the market.In conclusion, the new Stone CNC Router from (company name) is a game-changer for the stone processing industry. With its advanced cutting and carving capabilities, user-friendly interface, and high-speed spindle, this machine sets a new standard for precision and efficiency. As (company name) continues to lead the way in CNC machining innovation, customers can rest assured that they are investing in the very best when they choose (company name)’s new Stone CNC Router.

Wood Engraver And Cutter: A Guide to Laser-based Technology

Woodworking enthusiasts and professionals have a new tool to add to their arsenal with the introduction of the Laser Wood Engraver and Cutter. This innovative machine is brought to you by a leading company in the laser cutting and engraving industry, and it promises to revolutionize the way wood is worked with.The Laser Wood Engraver and Cutter is designed to offer precision and efficiency in wood engraving and cutting. With its advanced laser technology, it can achieve intricate designs and accurate cuts on various types of wood, making it a versatile tool for a wide range of woodworking projects. Whether you are a hobbyist creating intricate art pieces or a professional crafting high-quality furniture, this machine is sure to meet your needs.One of the key features of this laser wood engraver and cutter is its user-friendly interface. The machine is equipped with intuitive controls that make it easy to operate, even for those who are new to laser engraving and cutting. This means that users can quickly get started on their projects without having to spend a lot of time learning how to use the machine.Additionally, the laser wood engraver and cutter is equipped with a powerful laser that is capable of engraving and cutting with high precision. This ensures that every design or cut is executed with the utmost accuracy, resulting in a professional-quality finish. Whether you are working on intricate patterns or intricate cuts, this machine can deliver results that are sure to impress.In addition to its precision, the laser wood engraver and cutter is also designed for efficiency. The machine is equipped with a high-speed laser that can complete projects in a fraction of the time it would take with traditional woodworking tools. This means that users can increase their productivity and complete more projects in less time, ultimately saving time and effort.Furthermore, the laser wood engraver and cutter is equipped with safety features to ensure that it can be used with peace of mind. The machine is designed with protective housing and safety sensors to prevent accidents and injuries. This makes it suitable for use in a variety of settings, including workshops and production facilities.The company behind the Laser Wood Engraver and Cutter is a leader in the laser cutting and engraving industry. With years of experience and a dedication to innovation, the company has earned a reputation for delivering high-quality and reliable laser machines. The Laser Wood Engraver and Cutter is the latest addition to their lineup of cutting-edge products, and it is a testament to their commitment to meeting the needs of their customers.In addition to producing top-of-the-line laser machines, the company also provides exceptional customer support. They offer comprehensive training and resources to help users get the most out of their machines. Whether you need assistance with setup, operation, or troubleshooting, the company’s team of experts is always on hand to provide the guidance you need.Overall, the introduction of the Laser Wood Engraver and Cutter is an exciting development for woodworking enthusiasts and professionals. With its precision, efficiency, and user-friendly design, this machine is poised to become a valuable tool for a wide range of woodworking projects. Backed by a reputable company with a track record of excellence, the Laser Wood Engraver and Cutter is a game-changing tool that is sure to garner a lot of attention in the woodworking industry.

High-Quality Wood Cutter Router Machine for Your Woodworking Needs

Woodworking is an age-old craft that has been revolutionized with the introduction of modern machinery. One such machine that has been making its mark in the woodworking industry is the Wood Cutter Router Machine (brand name removed for privacy), a powerful and versatile tool that has become a favorite among woodworkers and craftsmen.The Wood Cutter Router Machine is designed to cut, shape, and sculpt wood with precision and efficiency. It is equipped with a high-speed motor that allows for quick and accurate cuts, making it ideal for both professional and amateur woodworkers. The machine also features a durable and sturdy construction, ensuring years of reliable performance.This state-of-the-art machine is suitable for a wide range of woodworking applications, including cabinetry, furniture making, and architectural millwork. Its versatility and ease of use make it a valuable addition to any woodworking shop, allowing craftsmen to bring their creative visions to life with ease.In addition to its impressive performance, the Wood Cutter Router Machine is also equipped with advanced safety features to protect users from potential hazards. With a reliable braking system and ergonomic design, this machine provides a safe and comfortable working environment for woodworkers of all skill levels.The company behind the Wood Cutter Router Machine, (company name removed for privacy), is a leading manufacturer of woodworking machinery. With a commitment to quality and innovation, the company has earned a reputation for producing high-performance machines that meet the needs of modern woodworkers.Established in (year of establishment), (company name) has been at the forefront of the woodworking industry, providing a wide range of machinery and equipment for professionals and enthusiasts alike. The company's dedication to excellence is reflected in the design and construction of the Wood Cutter Router Machine, which is built to deliver exceptional performance and reliability.In addition to producing high-quality machinery, (company name) also offers comprehensive customer support and service. Whether it's technical assistance, maintenance, or spare parts, the company is dedicated to ensuring that woodworkers have access to the resources they need to maximize the potential of their machines.Furthermore, (company name) is committed to sustainability and environmental consciousness. The Wood Cutter Router Machine is designed to minimize waste and energy consumption, making it an eco-friendly choice for woodworkers who are mindful of their environmental impact.In conclusion, the Wood Cutter Router Machine is a game-changer in the woodworking industry, offering unparalleled performance, safety, and versatility. With the backing of (company name), woodworkers can trust that this machine is a reliable and durable investment for their craft. As woodworking continues to evolve, the Wood Cutter Router Machine remains a vital tool for bringing creativity and precision to life in the workshop.

Ultimate Guide to 3D Carving with a CNC Router

CNC Router 3D Carving: Revolutionizing the Manufacturing IndustryIn the rapidly evolving world of manufacturing, technological advancements have paved the way for more efficient and precise production processes. One such innovation is the CNC Router 3D Carving, a cutting-edge technology that has been gaining traction in the industry for its ability to create intricate and detailed designs with ease.CNC Router 3D Carving is a form of computer numerical control (CNC) technology that utilizes a rotating cutting tool to carve out three-dimensional designs from a variety of materials, including wood, plastic, and metal. This process is achieved through the use of a computer program that guides the movement of the cutting tool, resulting in highly accurate and detailed carvings that would be nearly impossible to achieve by hand.The benefits of CNC Router 3D Carving are vast, offering manufacturers the ability to produce complex and customized parts and products with ease. This technology also allows for greater precision and consistency in the manufacturing process, reducing the margin for error and increasing overall production efficiency.One company at the forefront of this technological revolution is {Company Name}, a leading manufacturer of CNC machinery. {Company Name} has been at the forefront of the industry for over a decade, providing cutting-edge solutions for a wide range of manufacturing needs. With a strong focus on research and development, {Company Name} has consistently pushed the boundaries of innovation, delivering state-of-the-art machinery that meets the evolving demands of the manufacturing sector.The CNC Router 3D Carving technology offered by {Company Name} has garnered widespread acclaim for its exceptional precision and versatility. This technology has been utilized in a variety of industries, from furniture and cabinetry manufacturing to aerospace and automotive production. The ability to create intricate and detailed designs has provided manufacturers with the tools necessary to stay competitive in an increasingly demanding market.One of the key advantages of {Company Name}'s CNC Router 3D Carving technology is its user-friendly interface, allowing operators of varying skill levels to effectively utilize the machinery. This accessibility has empowered manufacturers to take on more complex projects and expand their capabilities, ultimately leading to enhanced productivity and profitability.Furthermore, {Company Name} stands out in the industry for its unwavering commitment to customer satisfaction. The company's stellar reputation for providing reliable machinery and exceptional customer support has earned the trust of countless manufacturers around the world. With a global presence and a dedicated team of experts, {Company Name} continues to be a driving force in shaping the future of manufacturing.As the manufacturing landscape continues to evolve, the significance of CNC Router 3D Carving technology cannot be understated. Its impact on the industry has been profound, offering manufacturers a powerful tool to streamline production processes and push the boundaries of design and innovation. With companies like {Company Name} leading the charge, the future of manufacturing looks brighter than ever.