Revolutionary 3D CNC Wood Cutting Machine

In recent years, the demand for CNC wood cutting machines has been on the rise, driven by the growing trend of customization and precision in the woodworking industry. To meet this demand, {{company name}} has introduced their latest 3D CNC wood cutting machine, which is set to revolutionize the way wood is cut and shaped.The 3D CNC wood cutting machine from {{company name}} is equipped with state-of-the-art technology that allows for intricate and precise cutting of wood materials. With its 3D cutting capabilities, the machine is able to produce complex designs and shapes with unparalleled accuracy and speed. This makes it an ideal choice for woodworkers who are looking to create customized and detailed wood products.One of the key features of the {{company name}} 3D CNC wood cutting machine is its ability to work with a wide range of wood materials, including hardwoods, softwoods, and engineered woods. This versatility allows woodworkers to take on a variety of projects, from intricate furniture designs to detailed carvings and sculptures. The machine also comes with advanced software that enables users to design and program their cutting patterns with ease, making the entire process efficient and seamless.In addition, the {{company name}} 3D CNC wood cutting machine is designed with user-friendly controls, making it accessible to both experienced woodworkers and beginners alike. Its intuitive interface and ergonomic design ensure that users can operate the machine with minimal training, while still achieving professional-level results.{{company name}} has a long-standing reputation for delivering high-quality woodworking machinery, and their 3D CNC wood cutting machine is no exception. With a commitment to reliability and performance, the company ensures that their machines are built to last and deliver consistent results, project after project. This reliability is further reinforced by the company's dedication to providing comprehensive customer support and service, ensuring that woodworkers can maximize the potential of their CNC wood cutting machine.The introduction of the 3D CNC wood cutting machine from {{company name}} comes at a time when the woodworking industry is experiencing a surge in demand for precision and customization. As more and more consumers seek unique and personalized wood products, woodworkers are turning to advanced machinery like the {{company name}} 3D CNC wood cutting machine to meet these evolving needs. By combining innovative technology with user-friendly design, {{company name}} is poised to make a significant impact in the woodworking industry and empower woodworkers to take their craft to new heights.Overall, the {{company name}} 3D CNC wood cutting machine represents a leap forward in the woodworking industry, offering unmatched precision, versatility, and ease of use. With its advanced features and reliable performance, this machine is set to become a game-changer for woodworkers looking to elevate their craft and deliver exceptional wood products. As the woodworking industry continues to evolve, {{company name}} remains at the forefront, driving innovation and empowering woodworkers to bring their creative visions to life.

Read More

High-Powered Multifunction Welder for All Your Welding Needs

Multifunction Welder Revolutionizes Industrial WeldingIn the fast-paced world of industrial manufacturing, efficiency and versatility are key factors in maintaining a competitive edge. With the introduction of the Multifunction Welder by [Company Name], welding technology has taken a significant leap forward. This state-of-the-art welding equipment offers a wide range of features that not only streamline the welding process but also enhance the overall productivity and quality of the output.The Multifunction Welder, developed by [Company Name], is designed to meet the diverse needs of industrial welders, from large-scale production to small-scale fabrication. With its cutting-edge technology and ergonomic design, this equipment provides a one-stop solution for a variety of welding tasks, including MIG, TIG, stick, and flux-cored welding. Its multifunction capabilities allow for seamless transition between different welding processes, eliminating the need for multiple machines and reducing the setup time.One of the key features of the Multifunction Welder is its advanced control system, which offers precise control over the welding parameters such as voltage, current, and wire feed speed. This level of control allows for a highly accurate and consistent welding process, resulting in high-quality welds with minimal rework or waste. Additionally, the equipment is equipped with a digital interface that provides real-time monitoring of the welding parameters, enabling welders to make immediate adjustments as needed.Furthermore, the Multifunction Welder is designed with user-friendly features that simplify the welding process and enhance the overall efficiency. Its intuitive interface and easy-to-use controls make it accessible to welders of all skill levels, while the ergonomic design ensures comfortable and safe operation. In addition, the equipment is equipped with advanced safety features such as thermal overload protection and voltage fluctuation protection, ensuring the safety of the welder and the integrity of the equipment.[Company Name] has a proven track record of providing high-quality welding equipment to the industrial sector. With a strong focus on innovation and customer satisfaction, the company has earned a reputation for delivering reliable and efficient solutions to its clients. The Multifunction Welder is the latest addition to its extensive product line, and it represents a significant milestone in the company's commitment to advancing welding technology.In addition to its cutting-edge technology, the Multifunction Welder is backed by [Company Name]'s comprehensive customer support and after-sales service. The company offers training, technical assistance, and spare parts availability to ensure that its clients can maximize the benefits of the equipment and operate it with confidence. This commitment to customer satisfaction further reinforces the reliability and value of the Multifunction Welder.The introduction of the Multifunction Welder by [Company Name] is set to revolutionize the industrial welding landscape. With its advanced technology, multifunction capabilities, and user-friendly design, this equipment offers a superior welding solution that meets the evolving needs of the industry. As manufacturing processes continue to become more complex and demanding, the Multifunction Welder provides a competitive edge by delivering efficiency, versatility, and quality in one comprehensive package.

Read More

Advanced Laser Welding Machine for Sale - Find the Best Deals Now

XYZ Corporation, a leading manufacturer of industrial equipment, has recently announced the release of their latest product, the Laser Welding Machine. This state-of-the-art machine is set to revolutionize the welding industry with its advanced technology and precision capabilities.The Laser Welding Machine is designed to meet the growing demand for high-quality, accurate, and efficient welding solutions in various industries, including automotive, aerospace, electronics, and medical device manufacturing. With its advanced laser technology, the machine is capable of producing welds with superior strength and precision, making it an ideal choice for critical applications where precision and quality are paramount.One of the key features of the Laser Welding Machine is its versatility and adaptability to different materials and geometries. The machine is equipped with advanced software and control systems that allow for precise control over the welding process, ensuring consistent and reliable results across a wide range of materials, including stainless steel, aluminum, titanium, and various alloys.In addition to its advanced welding capabilities, the Laser Welding Machine is also designed with efficiency and productivity in mind. The machine's high-speed laser processing and rapid cycle times enable faster production and higher throughput, making it an ideal choice for high-volume manufacturing operations.Moreover, the machine's compact design and user-friendly interface make it easy to integrate into existing production lines, providing manufacturers with a seamless and efficient welding solution that can help streamline their operations and improve overall productivity.XYZ Corporation has a long-standing reputation for delivering innovative and reliable industrial equipment, and the release of the Laser Welding Machine is a testament to the company's commitment to providing cutting-edge solutions to meet the evolving needs of the industry.With its extensive expertise in laser technology and precision engineering, XYZ Corporation is poised to make a significant impact on the welding industry with the introduction of the Laser Welding Machine. The company's dedication to quality, reliability, and customer satisfaction has positioned it as a trusted partner for manufacturers seeking advanced welding solutions.In a statement regarding the release of the Laser Welding Machine, a spokesperson for XYZ Corporation expressed their excitement about the potential of the new product to revolutionize the welding industry. They emphasized the machine's advanced capabilities and its potential to significantly improve welding processes across various industries, ultimately leading to higher quality products and increased efficiency for manufacturers.As the welding industry continues to evolve and demand for advanced welding solutions grows, XYZ Corporation remains committed to pushing the boundaries of innovation and delivering state-of-the-art equipment that meets the needs of manufacturers worldwide. The release of the Laser Welding Machine underscores the company's dedication to advancing the industry and providing customers with the tools they need to stay competitive in today's fast-paced manufacturing environment.Manufacturers looking to enhance their welding processes and improve the quality and efficiency of their production lines can now explore the possibilities offered by the Laser Welding Machine from XYZ Corporation. With its advanced technology, precision capabilities, and proven reliability, this innovative machine is set to become a game-changer in the welding industry, offering manufacturers a competitive edge in today's demanding market.In conclusion, XYZ Corporation's release of the Laser Welding Machine represents a significant milestone in the welding industry, and the company's dedication to innovation and excellence positions it as a leader in providing cutting-edge solutions for manufacturers seeking to enhance their welding processes. With its advanced technology, versatility, and user-friendly design, the Laser Welding Machine is poised to revolutionize the industry and help manufacturers achieve higher quality welds, increased productivity, and overall operational efficiency.

Read More

High Precision Laser Cutting Machines for 4060 Materials

Laser cutting technology has revolutionized the manufacturing industry, offering precision, speed, and efficiency in the cutting of various materials. One company that has been at the forefront of the development and implementation of laser cutting machines is {Company Name}. Their latest innovation, the Laser Cutting Machine 4060, is set to further enhance the capabilities of manufacturers in various fields.{Company Name} is a leading manufacturer of laser cutting machines, with a strong focus on innovation and technological advancements. Their commitment to quality and reliability has earned them a stellar reputation in the industry, and their machines are used by businesses around the world for a wide range of applications.The Laser Cutting Machine 4060 is the latest addition to {Company Name}'s line of cutting-edge equipment. With a cutting area of 400mm x 600mm, this machine is designed to handle a variety of materials, including wood, acrylic, fabric, leather, and more. Equipped with a high-powered laser, the 4060 is capable of delivering precise and clean cuts, making it ideal for intricate designs and complex patterns.One of the standout features of the Laser Cutting Machine 4060 is its user-friendly interface. The machine is equipped with intuitive software that allows for easy programming and control, making it accessible to both experienced professionals and newcomers to the world of laser cutting. This ease of use is further enhanced by the machine's speed and efficiency, allowing businesses to increase their productivity and meet tight deadlines without sacrificing quality.In addition to its cutting capabilities, the Laser Cutting Machine 4060 is also equipped with a range of safety features to ensure the well-being of operators. These include a fully enclosed design to prevent exposure to the laser beam, as well as emergency stop buttons and safety interlocks. As a result, businesses can have peace of mind knowing that their employees are protected while working with the machine.{Company Name} has a long history of providing exceptional customer support, and the launch of the Laser Cutting Machine 4060 is no exception. The company offers comprehensive training and technical assistance to help businesses integrate the machine into their operations seamlessly. Furthermore, they provide ongoing maintenance and support to ensure that the machine continues to perform at its best for years to come.The introduction of the Laser Cutting Machine 4060 represents {Company Name}'s commitment to pushing the boundaries of laser cutting technology. With its precision, efficiency, and user-friendly design, this machine is poised to become a valuable asset for businesses across various industries. Whether it's creating custom signage, intricate decorative pieces, or precision parts, the 4060 is capable of delivering exceptional results.In conclusion, {Company Name}'s Laser Cutting Machine 4060 is a testament to their dedication to innovation and excellence in the manufacturing industry. With its advanced features, user-friendly interface, and comprehensive support, this machine is set to empower businesses to unlock new possibilities in the world of laser cutting. As the demand for high-quality, precision-cut products continues to grow, {Company Name} remains at the forefront of providing cutting-edge solutions to meet these evolving needs.

Read More

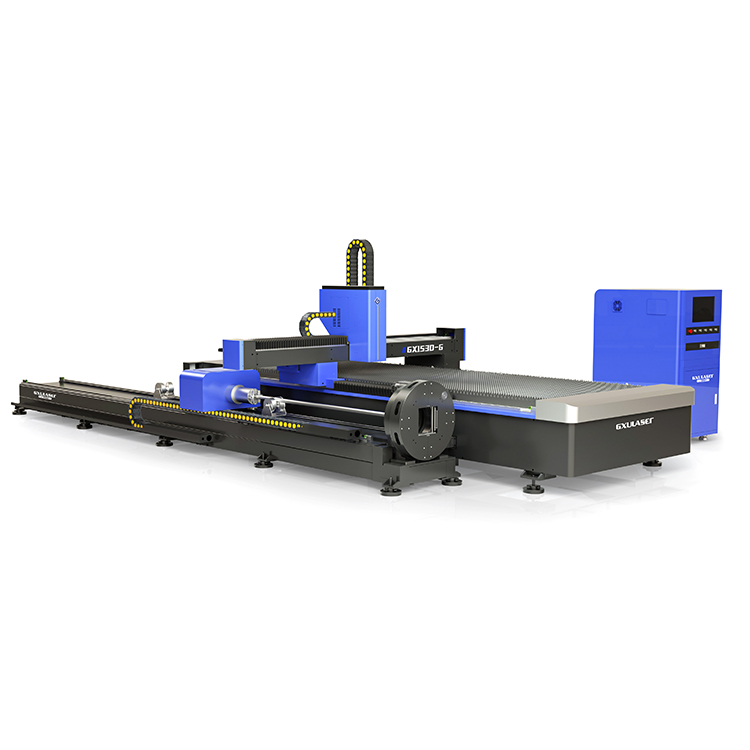

Fiber Laser Cutting Machine for Efficient Metal Cutting - 500W/1000W Options

Read More

Precision Plastic Laser Cutting Machine for Efficient Production

Plastic Laser Cutting Machine Revolutionizes ManufacturingThe manufacturing industry is constantly evolving, and one of the most significant advancements in recent years has been the development of plastic laser cutting technology. This innovative process has revolutionized the way plastic materials are cut and shaped, allowing for greater precision, efficiency, and flexibility in the manufacturing process.One company at the forefront of this technology is [Company Name], a leading provider of cutting-edge industrial equipment. Their [Machine Name] has been hailed as a game-changer in the industry, offering a wide range of capabilities and benefits for manufacturers looking to enhance their production processes.The [Machine Name] is equipped with state-of-the-art laser technology, allowing for the precise cutting of various types of plastic materials. From acrylics and polycarbonates to PVC and polyethylene, this machine can handle a diverse range of plastics with ease and accuracy. This level of versatility has made it a preferred choice for manufacturers across various industries, including automotive, aerospace, electronics, and more.One of the key advantages of the [Machine Name] is its ability to produce complex shapes and intricate designs with unmatched precision. Traditional cutting methods often struggle with intricate designs and patterns, leading to a compromise in the final product's quality. However, the [Machine Name] overcomes this limitation by utilizing advanced laser technology to achieve precise cuts and intricate shapes, ensuring that the final products meet the highest quality standards.In addition to precision cutting, the [Machine Name] also offers enhanced efficiency and speed in the manufacturing process. The laser technology enables rapid cutting speeds, significantly reducing production times and increasing overall productivity. This means that manufacturers can fulfill orders in a fraction of the time it would take with traditional cutting methods, leading to increased output and a competitive edge in the market.Moreover, the [Machine Name] is designed with user-friendly features, making it accessible to operators of varying skill levels. The intuitive interface and controls allow for easy setup and operation, minimizing the need for extensive training and streamlining production processes. This accessibility has made the [Machine Name] a popular choice for manufacturers looking to integrate advanced technology into their operations without facing significant learning curves or operational complexities.Another key benefit of the [Machine Name] is its contribution to sustainability and environmental responsibility. By utilizing laser technology for cutting plastic materials, the machine minimizes material waste and reduces the environmental footprint of the manufacturing process. This aligns with the growing emphasis on sustainability within the industry, as manufacturers seek to minimize waste and adopt more eco-friendly production practices.As a result of these capabilities and benefits, the [Machine Name] has garnered widespread acclaim and recognition within the manufacturing industry. Countless companies have integrated this cutting-edge technology into their operations, reaping the rewards of enhanced precision, efficiency, and sustainability in their manufacturing processes.The [Company Name] remains committed to advancing the field of plastic laser cutting technology, continuously innovating and refining their products to meet the evolving needs of manufacturers. With a focus on quality, performance, and customer satisfaction, the company continues to be a driving force in shaping the future of manufacturing through its groundbreaking solutions.In conclusion, the [Machine Name] from [Company Name] represents a significant leap forward in plastic laser cutting technology, offering manufacturers a superior alternative to traditional cutting methods. With its precision, efficiency, versatility, and sustainability benefits, the [Machine Name] is poised to play a pivotal role in shaping the future of manufacturing across various industries. As technology continues to advance, it's clear that the [Machine Name] and its innovative capabilities will remain at the forefront of the industry, driving progress and empowering manufacturers to achieve new heights of success.

Read More

Innovative Handheld Laser Rust Remover: A Game-Changer for Rust Removal

The handheld laser rust remover has revolutionized the way in which rust can be removed from metal surfaces. This groundbreaking technology has been developed by the [company name] and is set to change the way in which industries deal with rust on a day-to-day basis.The [company name] was established in [year] and has been at the forefront of innovation in the field of industrial materials and technology. The company prides itself on its commitment to research and development with the aim of bringing cutting-edge solutions to the market. Their latest creation, the handheld laser rust remover, is a testament to their dedication to pushing the boundaries of what is possible in the world of industrial technology.The handheld laser rust remover works by using a high-powered laser to vaporize rust, leaving behind a clean and smooth metal surface. This method is not only incredibly efficient but also environmentally friendly, as it eliminates the need for harsh chemicals or abrasive materials. In addition to being more effective than traditional rust removal methods, the laser rust remover is also much quicker, making it a valuable tool for industries that rely on the efficient maintenance of metal surfaces.The [company name] has been working tirelessly to ensure that the handheld laser rust remover meets the highest standards of safety and quality. Through rigorous testing and refinement, they have developed a product that is not only highly effective but also incredibly safe to use. This dedication to excellence is a hallmark of the [company name]'s approach to innovation and has earned them a reputation as a leader in their field.The applications of the handheld laser rust remover are wide-ranging, with potential uses in industries such as manufacturing, construction, and automotive. Whether it's removing rust from large metal structures or preparing surfaces for painting and coating, the handheld laser rust remover offers a versatile and efficient solution. Its portability and ease of use make it a valuable tool for professionals who need to maintain metal surfaces in a variety of settings.One of the key advantages of the handheld laser rust remover is its ability to remove rust without damaging the underlying metal. This not only saves time and money but also ensures that the integrity of the metal is preserved. This makes it an ideal solution for industries where the quality and longevity of metal surfaces are of the utmost importance.The [company name] is committed to making the handheld laser rust remover accessible to industries of all sizes. They understand the value that this technology can bring to businesses and are dedicated to ensuring that it is available at a competitive price point. This commitment to accessibility and affordability reflects the [company name]'s ethos of making cutting-edge technology available to a wide range of industries.As the handheld laser rust remover continues to gain traction in the market, the [company name] is poised to solidify its position as a leader in industrial technology. With its unrivaled efficiency, safety, and versatility, this groundbreaking product is set to become an essential tool for industries that rely on the maintenance of metal surfaces. The [company name] is proud to be at the forefront of this technological advancement and looks forward to the positive impact that the handheld laser rust remover will have on industries around the world.

Read More

High Precision and Efficient CNC Router for Woodworking and Metalworking

The 1325 CNC Router has been making waves in the manufacturing industry with its cutting-edge technology and precision engineering. Manufactured by a leading company in the industry, this CNC router has gained a strong reputation for its high-quality performance and reliability. With a wide range of applications, this machine is perfectly suited for various industries, such as woodworking, advertising, mold making, and more.Equipped with a powerful spindle and an advanced control system, the 1325 CNC Router offers exceptional precision and efficiency in cutting, carving, and engraving various materials such as wood, plastic, acrylic, and even non-ferrous metals. Its high-speed and high-accuracy features provide users with the perfect solution for both large-scale production and small-scale projects.As the demand for precision manufacturing continues to rise, the 1325 CNC Router has quickly become a popular choice for businesses looking to streamline their production processes. Whether it is for creating intricate wooden furniture designs or crafting detailed signage for advertising purposes, this CNC router offers unparalleled performance and versatility.The company behind the 1325 CNC Router has been a pioneer in the development of cutting-edge CNC machinery for several years. With a strong focus on research and development, they have continually improved their products to meet the evolving needs of the industry. The company's commitment to innovation and quality has earned them a solid reputation as a trusted supplier of CNC machinery.One of the key advantages of the 1325 CNC Router is its user-friendly interface, which makes it easy for operators to set up and operate the machine with minimal training. The intuitive control system allows for quick and precise adjustments, ensuring that users can achieve the exact specifications required for their projects. This level of flexibility and ease of use has made the 1325 CNC Router a popular choice for both experienced professionals and newcomers to the industry.In addition to its exceptional performance, the 1325 CNC Router also boasts a robust and durable construction, ensuring long-term reliability and minimal maintenance requirements. This makes it an ideal investment for businesses looking to enhance their production capabilities without worrying about frequent breakdowns or costly repairs.The versatility of the 1325 CNC Router is further enhanced by its compatibility with a wide range of design software, allowing users to seamlessly integrate their existing design workflows with the machine. This ensures a smooth transition from design to production, saving time and reducing the likelihood of errors.With the increasing demand for high-quality manufactured products, the 1325 CNC Router has emerged as a game-changer in the industry. Its combination of precision, speed, and reliability has made it a go-to solution for businesses looking to stay ahead in a competitive market.As the company continues to push the boundaries of CNC technology, the 1325 CNC Router is expected to set new benchmarks for performance and innovation in the manufacturing industry. With its proven track record and ongoing commitment to excellence, it is poised to remain a top choice for businesses seeking state-of-the-art CNC solutions.

Read More

Customizable CNC Carving Services for Your Business Needs

CNC Carving: Revolutionizing Manufacturing ProcessesIn the rapidly evolving world of manufacturing, there is a constant demand for innovative solutions that can enhance efficiency, precision, and productivity. One such solution that has been gaining significant traction in recent years is CNC carving. This advanced technology has been revolutionizing the way products are designed and manufactured, offering unparalleled precision and flexibility in the production process.CNC (Computer Numerical Control) carving is a sophisticated manufacturing technique that utilizes computer-aided design (CAD) software to create highly detailed and intricate designs on various materials such as wood, plastic, metal, and composites. The process involves using a computer-controlled machine equipped with cutting tools to precisely carve out the desired design from the material, resulting in a finished product with exceptional accuracy and consistency.At the forefront of this cutting-edge technology is {company name}, a leading provider of CNC carving solutions for a wide range of industries. With a rich history of innovation and excellence, {company name} has established itself as a trusted partner for businesses looking to incorporate CNC carving into their manufacturing processes.{company name} offers a diverse portfolio of CNC carving machines that are designed to meet the unique needs of different industries. From small-scale desktop machines for hobbyists and craftsmen to large-scale industrial systems for mass production, {company name} provides a comprehensive range of solutions to suit various applications. The company's commitment to delivering high-quality, reliable, and user-friendly machines has earned it a reputation for excellence in the industry.One of the key advantages of CNC carving is its ability to automate and streamline the manufacturing process, thereby reducing production time and costs. By utilizing CAD software to design intricate patterns and shapes, manufacturers can produce highly detailed and complex products with minimal manual intervention. This level of precision and efficiency is particularly valuable in industries such as aerospace, automotive, furniture, and signage, where intricate designs and tight tolerances are paramount.Furthermore, CNC carving offers unparalleled flexibility in terms of design capabilities. With the ability to program the machine to create complex geometric shapes and patterns, manufacturers can bring even the most intricate designs to life with ease. This level of versatility opens up a world of possibilities for product customization and personalization, allowing businesses to cater to the unique needs and preferences of their customers.In addition to its precision and flexibility, CNC carving also offers significant improvements in material utilization. By optimizing the cutting process to minimize waste, manufacturers can maximize the yield from raw materials, resulting in cost savings and environmental benefits. This level of efficiency is crucial for businesses looking to minimize their environmental footprint and operate in a sustainable manner.As the demand for custom, high-quality products continues to grow, the adoption of CNC carving technology is expected to rise across various industries. Whether it's creating intricate wooden furniture, precision-cut metal parts, or personalized signage, CNC carving offers a level of craftsmanship and precision that is unparalleled by traditional manufacturing methods.With its commitment to innovation, quality, and customer satisfaction, {company name} is poised to play a key role in driving the widespread adoption of CNC carving technology. As the manufacturing landscape continues to evolve, businesses looking to stay ahead of the curve will undoubtedly turn to CNC carving as a game-changing solution for producing high-quality, customized products efficiently and cost-effectively.In conclusion, CNC carving is reshaping the manufacturing industry by offering a level of precision, flexibility, and efficiency that is unmatched by traditional methods. With {company name} leading the way in providing state-of-the-art CNC carving solutions, businesses across various industries can look forward to achieving new levels of productivity and excellence in their manufacturing processes. As the technology continues to advance and evolve, the possibilities for innovation and creativity in product design are truly limitless.

Read More