Wood Milling Machine for DIY Projects: An Ultimate Guide

By:Admin

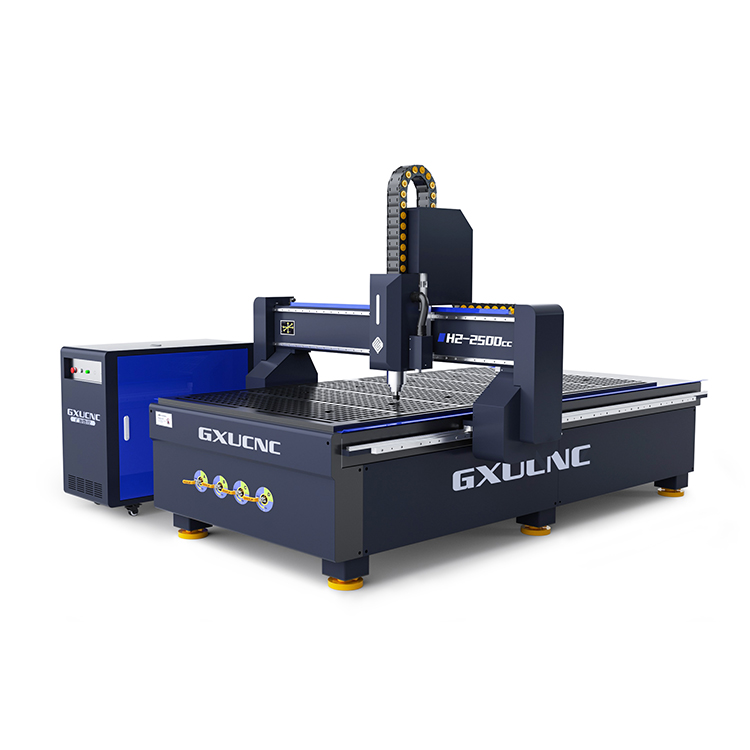

This CNC wood milling machine is equipped with a robust and efficient motor, ensuring smooth and accurate milling operations. Its precise cutting capabilities allow for intricate designs and detailed woodwork, making it ideal for projects such as furniture making, cabinetry, and decorative wood crafts.

One of the key features of this DIY CNC Wood Milling Machine is its easy-to-use interface. With its intuitive control panel and user-friendly software, woodworkers can easily program and execute their milling designs with precision and ease. This makes the machine accessible to woodworkers of all skill levels, from beginners to experienced professionals.

In addition to its cutting-edge technology, this CNC wood milling machine is also designed with safety in mind. It is equipped with features such as emergency stop buttons and protective enclosures, ensuring that woodworkers can operate the machine with peace of mind.

Moreover, this DIY CNC Wood Milling Machine is highly customizable, allowing woodworkers to tailor it to their specific needs. Whether it's adjusting the cutting speed, changing the tooling, or modifying the milling paths, this machine offers a high degree of flexibility and versatility. This makes it an invaluable tool for woodworkers who require a custom approach to their milling projects.

The company behind this groundbreaking CNC wood milling machine, {}, is a recognized leader in the woodworking industry. With a strong commitment to innovation and quality, {} has been providing woodworkers with cutting-edge tools and solutions for years. Their dedication to excellence is reflected in the design and performance of this DIY CNC Wood Milling Machine.

{} is dedicated to providing woodworkers with the highest quality products and support, making it a brand that woodworkers can trust. With a focus on customer satisfaction and innovation, {} has established itself as a leading authority in the woodworking community.

"We are thrilled to introduce the DIY CNC Wood Milling Machine to the market," said a spokesperson for {}. "We believe that this machine will empower woodworkers to explore new creative possibilities and take their woodworking projects to new heights. With its advanced technology and user-friendly design, we are confident that this CNC wood milling machine will be a game-changer for the woodworking community."

The DIY CNC Wood Milling Machine from {} is set to make a significant impact on the woodworking industry, providing woodworkers with a powerful and versatile tool for precision milling. With its advanced features, user-friendly design, and commitment to quality, this CNC wood milling machine is a must-have for anyone looking to elevate their woodworking projects.

Company News & Blog

Sale Begins for New Type of CNC Milling Machine: 3D Cutting Technology

Possible article:New Desktop CNC Milling Machine Enables Precision Prototyping and Small-Scale ProductionSan Francisco-based company has released a new version of its desktop CNC milling machine, which allows users to create complex designs from a wide variety of materials. The Othermill Pro improves on the original Othermill model, adding faster spindle speeds, larger working volume, and more advanced software features. With its compact size and user-friendly interface, the Othermill Pro is suitable for both professional makers and hobbyists who want to turn their ideas into physical objects with high accuracy and detail.The Othermill Pro is a type of subtractive manufacturing technology, which means that it removes material from a block or sheet of material through cutting, drilling, and engraving. This differs from additive manufacturing, such as 3D printing, which builds up layers of material to form a shape. While 3D printing has become popular for prototyping and customization, CNC milling machines are preferred for producing precise parts, molds, and fixtures that require tight tolerances, smooth surfaces, and dimensional stability.The Othermill Pro can work with a range of materials, including aluminum, brass, copper, Delrin, FR-1/4, polycarbonate, acrylic, and various types of wood and circuit board substrates. It uses a 1/8 end mill to carve out geometries from 2D or 3D CAD files, which can be imported from common design software such as Autodesk Fusion 360, Eagle PCB, and KiCAD. The spindle of the machine can rotate at speeds up to 10,000 RPM, allowing for fast and efficient machining of parts.One key feature of the Othermill Pro is its automatic tool calibration system, which enables the machine to adjust the height and position of the cutting tool based on the thickness and flatness of the material. This ensures that the milling process is accurate and consistent, even when working with irregular or non-uniform surfaces. The machine also has a built-in dust collection system, which collects debris and prevents the workspace from getting messy or hazardous.The Othermill Pro comes with a software package that is designed to be user-friendly and intuitive, even for those with little or no experience in CNC milling. The software allows users to import their designs, select the material type and thickness, set the cutting parameters, preview the toolpath, and simulate the machining process. The software also includes features such as engraving, pocketing, drilling, and chamfering, as well as the ability to create PCB traces and pads for electronics projects.According to the company, the Othermill Pro is ideal for prototyping, research and development, small-batch manufacturing, and even educational purposes. It can be used to make precision mechanical parts, artistic sculptures, custom jewelry, signage, molds for casting, and electronic circuits. The machine is also compatible with a range of fixtures and clamps, which allow for secure and efficient material handling. With its quiet operation, compact footprint, and stylish design, the Othermill Pro can fit into any workspace or home lab.The Othermill Pro is available for purchase on the website and through authorized resellers. The machine comes with a one-year warranty and free technical support, as well as a starter kit that includes cutting tools, materials, and accessories. The company also offers online tutorials, forums, and user community resources to help users get the most out of their machine. With the release of the Othermill Pro, aims to empower makers and inventors to turn their ideas into reality, one precision cut at a time.

Boost Your Metal Fabrication Process: Discover the Power of Stainless Steel CNC Cutting

Title: Revamping Precision in Metal Fabrication with Stainless Steel CNC CuttingIntroduction (100 words):In an era fueled by technological advancements, the manufacturing industry strives to enhance precision and efficiency to meet evolving demands. One such innovation revolutionizing metal fabrication is stainless steel CNC cutting. By harnessing the power of computer numerical control (CNC) technology, this cutting-edge process caters to a diverse range of industries. This article explores the capabilities of stainless steel CNC cutting and highlights how it contributes to the company's commitment to delivering high-quality and precise metal fabrication solutions.Body:1. The Advantages of Stainless Steel CNC Cutting (200 words):Stainless steel CNC cutting is rapidly gaining popularity due to its exceptional benefits. The process combines the advantages of stainless steel, renowned for its durability and corrosion resistance, with the precise cutting capabilities of CNC technology. The inclusion of this technique in the company's metal fabrication arsenal allows for the efficient production of intricate and complex designs without compromising on the material's integrity.The CNC cutting system boasts unmatched precision, repeatability, and speed, ensuring consistent and accurate results batch after batch. By utilizing cutting-edge computer programming, the company can accommodate various design specifications, creating customized solutions to meet specific client requirements. Moreover, stainless steel CNC cutting minimizes material wastage, ultimately leading to cost savings and environmental sustainability.2. Industry Application and Diverse Uses (250 words):Stainless steel CNC cutting has found widespread application across several industries due to its versatility. From automotive and aerospace to architecture and medical equipment, this technology imparts immense value by fabricating high-quality metal components. The company leads the way by leveraging stainless steel CNC cutting to cater to the unique demands of its clients.In the automotive sector, precision is paramount. Stainless steel CNC cutting ensures the production of accurate parts for critical systems, including suspension, exhaust, and engine components. By adhering to strict quality controls and flawlessly executing complex designs, the company aligns with industry standards to deliver superior products.Likewise, the aerospace industry relies heavily on stainless steel CNC cutting for aircraft parts such as turbine blades, airframes, and structural components. The precise and intricate nature of these components demands the employment of cutting-edge CNC technology, ensuring not only structural integrity, but also upholding safety standards.Architecture and interior design benefit from stainless steel CNC cutting as it provides the opportunity for innovative and visually stunning metalwork. From intricate metal furniture designs to striking building facades, the company's CNC cutting expertise offers architects and designers the freedom to explore their creative boundaries while maintaining structural integrity.Additionally, stainless steel CNC cutting serves the medical industry, crafting intricate surgical instruments, orthopedic implants, and medical devices with utmost precision and detail. The technology affords superior surface quality for biocompatible stainless steel, enhancing patient safety and medical professionals' peace of mind.3. Company Name: Pioneering Excellence and Innovation in Stainless Steel CNC Cutting (200 words):Company {} (please insert the company name) stands at the forefront of revolutionizing the metal fabrication landscape with its expertise in stainless steel CNC cutting. With a commitment to excellence and innovation, the company strives to deliver superior quality products by leveraging the potential of cutting-edge technologies.{} (Please include company introduction, such as history, values, certifications, and commitment to customer satisfaction). As an industry leader, the company's state-of-the-art facilities and highly trained technicians ensure precise execution of designs, delivering exceptional results to clients across diverse industries.Furthermore, the company's dedication to consistent improvement and investment in research and development enables them to stay ahead in a highly competitive market. By staying up-to-date with the latest advancements in stainless steel CNC cutting, they continually expand their capabilities, providing customers with cutting-edge metal fabrication solutions.Conclusion (150 words):Stainless steel CNC cutting has ignited a revolution in precision metal fabrication, enabling the manufacturing industry to achieve unparalleled accuracy and efficiency. The company's expertise in this field has facilitated the delivery of robust and intricate metal components across diverse sectors, including automotive, aerospace, architecture, and healthcare.Through adopting this cutting-edge technology, the company remains committed to providing clients with superior quality, customizable metal fabrication solutions that adhere to the highest industry standards. The fusion of stainless steel's remarkable properties with CNC cutting's exemplary precision ensures that the company remains at the forefront of manufacturing excellence, meeting the evolving needs of their valued customers efficiently and sustainably.

Top High Power Laser Cutting Techniques for Precision Cutting

High Power Laser Cutting Technology Revolutionizing Industrial ManufacturingIn recent years, the industrial manufacturing sector has witnessed a significant transformation with the emergence of high power laser cutting technology. This innovative process allows for the precise and efficient cutting of a wide range of materials, including metals, plastics, and composites. The introduction of this advanced technology has not only revolutionized the manufacturing process but has also opened up new possibilities for the production of complex and intricate components.One company at the forefront of this technology revolution is [Company Name], a leading provider of cutting-edge laser cutting solutions. With a strong focus on innovation and continuous improvement, [Company Name] has been instrumental in driving the adoption of high power laser cutting across various industries. Their advanced laser cutting systems have set new standards for accuracy, speed, and reliability, making them a preferred choice for manufacturers looking to stay ahead in a competitive market.The key to the success of [Company Name]'s high power laser cutting technology lies in its state-of-the-art laser systems, which are designed to deliver exceptional performance and precision. These systems utilize advanced fiber laser technology, allowing for increased power output and beam quality, resulting in superior cutting capabilities. Additionally, the integration of advanced motion control and automation features ensures maximum efficiency and productivity, making [Company Name]'s laser cutting systems the ideal choice for high-volume production environments.One of the primary advantages of high power laser cutting is its ability to produce high-quality cuts with minimal material waste. Traditional cutting methods often result in significant material loss due to the imprecise nature of the process. However, high power laser cutting technology offers a more sustainable solution, allowing manufacturers to minimize material waste and optimize their production processes. This not only leads to cost savings but also contributes to the overall sustainability of the manufacturing industry.Another significant benefit of high power laser cutting is its versatility in handling a wide range of materials. Whether it's stainless steel, aluminum, carbon steel, or even non-metallic materials such as ceramics and plastics, [Company Name]'s laser cutting systems are capable of delivering clean, precise cuts with exceptional edge quality. This versatility has opened up new opportunities for manufacturers to explore innovative designs and material combinations, enabling them to meet the evolving demands of their customers.Furthermore, high power laser cutting has proven to be a game-changer in the production of complex and intricate components. The fine beam width and high cutting speeds of [Company Name]'s laser systems enable the accurate shaping and profiling of intricate designs, regardless of the material's thickness. This level of precision and flexibility has empowered manufacturers to take on challenging projects while maintaining the highest standards of quality and performance.In addition to its cutting-edge technology, [Company Name] has established itself as a trusted partner for its customers through its comprehensive service and support offerings. From initial consultation and system installation to ongoing maintenance and training, [Company Name] is dedicated to ensuring the success of its customers at every stage of the process. Their team of experienced engineers and technical experts are committed to providing tailored solutions that align with the unique needs and requirements of each customer, resulting in a seamless integration of high power laser cutting technology into their manufacturing operations.As the demand for high precision and efficient manufacturing continues to grow, the role of high power laser cutting technology is only set to become more prominent. With [Company Name] leading the way in driving innovation and excellence in laser cutting, the future of industrial manufacturing looks brighter than ever. By harnessing the power of high power laser cutting, manufacturers can expect to achieve unmatched levels of productivity, quality, and operational efficiency, positioning themselves at the forefront of their respective industries.In conclusion, high power laser cutting technology is redefining the manufacturing landscape, and [Company Name] is at the forefront of this revolution. With its cutting-edge laser systems and unwavering commitment to customer success, [Company Name] is empowering manufacturers to push the boundaries of what's possible, setting new standards for quality and performance in industrial manufacturing. As the world embraces the era of advanced manufacturing, high power laser cutting is undoubtedly a game-changer, and [Company Name] is leading the charge towards a future of limitless possibilities.

High-Performance Large CNC Router: A Game-Changer in the Manufacturing Industry

Large CNC Router Revolutionizing Manufacturing IndustryIn recent years, the manufacturing industry has seen remarkable advancements in technology, particularly with the introduction of large CNC routers. These powerful machines have completely revolutionized the way companies produce goods, enabling them to increase efficiency, accuracy, and productivity. One company at the forefront of this technology is [Company Name], a leading manufacturer of CNC routers and other cutting-edge machinery.[Company Name] has been a key player in the manufacturing industry for over two decades, constantly pushing the boundaries of innovation and excellence. Their dedication to research and development has led to the creation of some of the most advanced CNC routers available on the market. With a strong focus on precision engineering and cutting-edge technology, [Company Name] has set itself apart as a pioneer in the industry.The large CNC router offered by [Company Name] is a game-changer for manufacturers across various sectors. With its impressive cutting capacity and exceptional accuracy, this machine is capable of handling a wide range of materials with ease. Whether it's wood, plastic, aluminum, or composite materials, the large CNC router can tackle even the most complex cutting and carving tasks with precision and efficiency.One of the key features that sets this large CNC router apart is its advanced control system. Equipped with state-of-the-art software, operators can easily program intricate designs and patterns, ensuring that every cut is executed with perfection. Additionally, the machine's robust build and high-quality components guarantee reliable performance and longevity, making it a valuable asset for any manufacturing operation.The impact of these large CNC routers on the manufacturing industry cannot be overstated. Thanks to their unparalleled speed and accuracy, companies can now significantly reduce lead times and production costs, ultimately increasing their competitiveness in the market. Furthermore, the automation capabilities of these machines eliminate the margin for human error, resulting in consistently high-quality outputs.Notably, [Company Name] provides comprehensive training and support to its customers, ensuring that they fully maximize the potential of their large CNC router. From installation and setup to ongoing maintenance and technical assistance, the company's team of experts is dedicated to helping clients harness the full benefits of this cutting-edge technology.The applications of the large CNC router are vast, spanning across industries such as furniture manufacturing, aerospace, automotive, and more. Whether it's creating intricate patterns on wooden furniture or precisely cutting components for aircraft parts, the versatility of the machine makes it an invaluable asset for a wide range of manufacturing processes.It's clear that large CNC routers have significantly elevated the standards of the manufacturing industry, providing companies with the tools they need to thrive in an increasingly competitive market. With [Company Name] leading the charge in innovation and excellence, the future of manufacturing looks brighter than ever. As technology continues to advance, it's exciting to imagine the further possibilities that lie ahead for the industry.

Ultimate Guide to CNC Router Milling Aluminum: Tips and Techniques

The company is a leading manufacturer of CNC routers and milling machines, specializing in precision machining for a wide range of materials, including aluminum. The company has recently introduced its latest high-performance CNC router for milling aluminum, designed to meet the growing demand for efficient and accurate aluminum machining in various industries.The new CNC router features a robust and durable construction, with a rigid frame and high-quality components that ensure stability and precision during the milling process. The machine is equipped with advanced servo motors and a high-speed spindle, allowing for fast and precise cutting and milling of aluminum with optimal surface finish and dimensional accuracy.In addition, the CNC router is integrated with the latest control technology, providing user-friendly operation and versatile machining capabilities. The machine can handle complex machining tasks, such as 3D profiling, contouring, and drilling, making it suitable for a wide range of aluminum milling applications, from aerospace and automotive components to architectural and industrial parts.With its efficient and reliable performance, the new CNC router is set to streamline the aluminum machining process, boosting productivity and reducing production costs for manufacturers and fabricators. The machine's rapid tool change and automatic tool calibration features further enhance its efficiency, allowing for quick and seamless machining operations without compromising accuracy and quality.Moreover, the company offers comprehensive training and technical support for customers, ensuring that they can maximize the potential of the CNC router for their specific aluminum milling needs. The company's team of expert engineers and technicians are available to provide guidance and assistance in machine setup, programming, and troubleshooting, empowering customers to achieve optimal results and production efficiency.The company's commitment to innovation and customer satisfaction is reflected in the development of the new CNC router for milling aluminum. By leveraging advanced technology and engineering expertise, the company aims to deliver cutting-edge solutions that address the evolving demands of the manufacturing industry and enable customers to stay ahead in a competitive market.As a reputable and established manufacturer, the company has a strong track record of delivering high-quality CNC machines and machining solutions to a diverse clientele worldwide. With a focus on precision, reliability, and performance, the company has earned a solid reputation as a trusted partner for businesses seeking advanced CNC milling technology for aluminum and other materials.In conclusion, the introduction of the new CNC router for milling aluminum underscores the company's commitment to meeting the evolving needs of the manufacturing industry. With its advanced features, robust construction, and user-friendly operation, the machine is poised to become a game-changer in aluminum machining, offering exceptional precision, efficiency, and productivity for a wide range of applications. As the company continues to push the boundaries of CNC technology, it remains at the forefront of innovation, driving the industry forward with cutting-edge solutions that empower businesses to achieve new levels of success in precision machining.

High-Quality Aluminum for CNC Milling: What You Need to Know

Aluminum For CNC Milling: The Perfect Material for Precision EngineeringCNC milling is a crucial process in the manufacturing industry. It involves the use of computer-aided design (CAD) software to program milling machines and create precise and complex parts from various materials. One material that has proven to be highly effective for CNC milling is aluminum. Its high strength-to-weight ratio, machinability, and corrosion resistance make it an ideal choice for precision engineering projects.Aluminum is a non-ferrous metal that is widely used in the aerospace, automotive, and electronics industries. Its unique properties make it a perfect choice for CNC milling applications. The material is known for its exceptional strength, which allows for the creation of intricate and detailed parts. Additionally, aluminum is lightweight, making it an excellent choice for components that require a high strength-to-weight ratio.One company that has perfected the art of CNC milling aluminum is {}. With years of experience in precision engineering and CNC machining, they have established themselves as a leader in the industry. Their state-of-the-art facility is equipped with the latest CNC milling machines and a team of highly skilled engineers and machinists, allowing them to handle even the most complex projects with ease.The company's expertise in working with aluminum for CNC milling is unparalleled. They understand the unique properties of the material and have developed specialized techniques to ensure the highest quality and precision in their finished products. Whether it's creating intricate components for the aerospace industry or producing custom parts for the automotive sector, {} has the knowledge and capabilities to deliver exceptional results.In addition to its strength and machinability, aluminum is also known for its excellent corrosion resistance. This makes it an ideal choice for parts that will be exposed to harsh environmental conditions. Whether it's for outdoor applications or components that come into contact with chemicals and other corrosive substances, aluminum's resistance to corrosion ensures the longevity and reliability of the finished parts.Furthermore, aluminum is a highly versatile material that can be easily customized to meet specific project requirements. It can be anodized, painted, or coated to enhance its appearance and improve its performance. This flexibility makes it an excellent choice for a wide range of applications, from consumer electronics to industrial machinery.{}'s commitment to quality and innovation sets them apart in the industry. They are constantly investing in the latest technology and equipment to ensure that they can meet the evolving needs of their customers. Their dedication to excellence is evident in the precision and intricacy of the parts they produce, making them a trusted partner for companies looking for reliable and high-quality CNC-machined components.In conclusion, aluminum is the perfect material for CNC milling due to its exceptional strength, lightweight properties, and corrosion resistance. When combined with the expertise and capabilities of a company like {}, the result is precision-engineered parts that meet the highest standards of quality and performance. With their commitment to innovation and excellence, {} continues to be a leader in the industry, providing customized solutions for a wide range of applications.

CNC Woodworking Machine for Home Use: An Overview

The woodworking industry has seen a significant revolution with the introduction of home CNC woodworking machines. These machines have brought advanced manufacturing capabilities to the comfort of home workshops, enabling individuals to create complex and intricate woodwork with precision and efficiency. One such company leading the charge in this cutting-edge technology is [Company Name].[Company Name] is a pioneering manufacturer of home CNC woodworking machines, specializing in bringing industrial-level precision and performance to the everyday woodworker. With a focus on innovation and quality, [Company Name] has quickly established itself as a go-to source for high-performance CNC machines for woodworking enthusiasts and professionals alike.The [Company Name] home CNC woodworking machine is equipped with state-of-the-art features that set it apart from traditional woodworking tools. These machines are designed to be user-friendly, allowing individuals with varying levels of expertise to create professional-grade woodwork. The precision and accuracy of the machine are unrivaled, thanks to its advanced computer numerical control technology, which ensures that every cut and carve is executed with perfection.One of the key advantages of the [Company Name] home CNC woodworking machine is its versatility. Users can work with a wide range of materials, including hardwoods, softwoods, plywood, and even composites. This opens up a world of possibilities for creating custom furniture, cabinetry, decorative items, and more. Additionally, the machine’s ability to execute complex designs and patterns makes it ideal for crafting intricate carvings and engravings.[Company Name] takes pride in not only providing a top-of-the-line product but also in offering exceptional customer support and service. They understand that investing in a CNC machine can be daunting for many, and as such, they offer comprehensive training and technical assistance to ensure that their customers are able to fully harness the capabilities of their machine. Moreover, the [Company Name] team is committed to staying abreast of technological advancements, regularly updating their machines to incorporate the latest features and improvements.The demand for home CNC woodworking machines has seen a sharp increase in recent years, as more and more woodworkers recognize the efficiency and precision that these machines offer. Whether it’s hobbyists looking to expand their creative potential or professionals seeking to streamline their production processes, [Company Name] has positioned itself as a trusted partner in meeting these needs.In addition to the individual consumer market, [Company Name] also caters to small businesses and workshops, providing them with the tools they need to elevate their woodworking capabilities. With the [Company Name] home CNC woodworking machine, these businesses can increase their productivity, expand their offerings, and ultimately, enhance their overall competitiveness in the market.The future of woodworking is undoubtedly tied to the advancements in CNC technology, and [Company Name] is at the forefront of this movement. As they continue to push the boundaries of what is possible with home CNC woodworking machines, they are empowering a new generation of woodworkers to bring their visions to life with unparalleled precision and quality.In conclusion, the [Company Name] home CNC woodworking machine represents a bold step forward in the woodworking industry. With its commitment to excellence, innovation, and customer satisfaction, [Company Name] has solidified its position as a leader in the market. As the demand for CNC technology continues to grow, [Company Name] remains dedicated to pushing the envelope and providing woodworkers with the tools they need to thrive in this new era of manufacturing.

The Ultimate Guide to Wood Router CNC in 1530: Everything You Need to Know

FOR IMMEDIATE RELEASE:The revolutionary 1530 Wood Router CNC machine is set to make waves in the woodworking industry. With its advanced technology and precision engineering, this cutting-edge machine is poised to transform the way woodworkers and manufacturers operate.The 1530 Wood Router CNC is a game-changer in the woodworking industry, offering unparalleled accuracy and efficiency. This state-of-the-art machine is equipped with advanced features that streamline the production process and deliver exceptional results. Whether it's crafting custom furniture, intricate carvings, or precision cuts, this machine is designed to meet the demands of the modern woodworking industry.This innovative CNC machine is the brainchild of {}, a leading manufacturer of cutting-edge machinery. With a proven track record of delivering high-quality products, {} is committed to pushing the boundaries of innovation and excellence in the woodworking industry. The 1530 Wood Router CNC is the latest addition to their lineup of industry-leading equipment, and it's already generating buzz among woodworkers and manufacturers.What sets the 1530 Wood Router CNC apart is its unmatched precision and versatility. This machine is capable of handling a wide range of woodworking tasks with unprecedented accuracy, making it a valuable asset for businesses of all sizes. Its user-friendly interface and intuitive controls make it easy to operate, while its durable construction ensures reliable performance for years to come.In addition to its exceptional precision, the 1530 Wood Router CNC is designed to optimize efficiency and productivity. With its high-speed cutting capabilities and automated functions, this machine can significantly reduce production time and labor costs. This means woodworkers and manufacturers can complete projects faster and more efficiently, ultimately leading to increased profitability and customer satisfaction.The 1530 Wood Router CNC is also equipped with advanced safety features to protect operators and prevent accidents. With built-in safeguards and automatic shut-off mechanisms, this machine prioritizes the well-being of its users without compromising on performance. This demonstrates {}'s commitment to providing a safe and reliable solution for the woodworking industry.As the woodworking industry continues to evolve, the demand for cutting-edge technology has never been greater. The 1530 Wood Router CNC is positioned to meet this demand head-on, offering woodworkers and manufacturers a competitive edge in a constantly changing market. With its unmatched precision, efficiency, and safety features, this machine is set to revolutionize the way woodworking projects are executed.For businesses looking to invest in the future of woodworking, the 1530 Wood Router CNC is a game-changing solution. With its advanced technology and unparalleled performance, this machine is poised to elevate the standards of quality and efficiency in the woodworking industry. As {} continues to lead the way in innovation, the 1530 Wood Router CNC stands as a testament to their unwavering commitment to excellence.In conclusion, the 1530 Wood Router CNC is a groundbreaking machine that is set to redefine the woodworking industry. With its advanced technology, precision engineering, and commitment to safety, this innovative solution is poised to revolutionize the way woodworkers and manufacturers operate. As {} continues to push the boundaries of innovation, the 1530 Wood Router CNC stands as a testament to their dedication to delivering cutting-edge solutions for the woodworking industry.

The Evolution of CNC Woodworking Machines: A Comprehensive Guide

Title: Innovative CNC Woodworking Machine Revolutionizes Industry StandardsIntroduction:With the constant pursuit of technological advancements in the field of woodworking, renowned manufacturing company [Company Name] has unveiled its latest breakthrough: the cutting-edge CNC Woodworking Machine. Designed to enhance precision, efficiency, and flexibility in woodworking processes, this state-of-the-art machinery promises to revolutionize the industry standards.[Company Name] - Leading the Evolution of Woodworking Technologies:For over two decades, [Company Name] has been at the forefront of developing cutting-edge solutions tailored to the woodworking industry. Its commitment to innovation has resulted in a comprehensive range of industry-leading products that cater to a diverse clientele, including craftsmen, woodworkers, furniture manufacturers, and educational institutions.The CNC Woodworking Machine - Redefining Precision and Efficiency:The newly launched CNC Woodworking Machine by [Company Name] is a testament to their dedication to perfection. This advanced equipment is meticulously designed to streamline the woodworking process by combining the power of computer numerical control with precise mechanical operations.Unparalleled Precision:Equipped with cutting-edge control systems, this CNC machine offers unparalleled precision in every woodworking task. As a result, craftsmen can obtain intricate designs and complex shapes with utmost accuracy and repeatability, eliminating the possibility of human error. The machine's advanced algorithms and high-resolution sensors guarantee exceptional product quality, meeting the meticulous standards expected by customers.Enhanced Efficiency:The CNC Woodworking Machine offers a substantial boost in efficiency, increasing productivity and reducing downtime. With its ability to automate repetitive tasks, craftsmen can focus on design creativity, problem-solving, and exploring new woodworking techniques, ensuring optimal utilization of their skills. Additionally, the machine features intelligent material handling systems, reducing waste and minimizing production costs.Flexibility and Versatility:[Company Name]'s CNC Woodworking Machine allows users to work with an extensive range of wood materials, from solid wood to MDF, plywood, and more. The machine is equipped with versatile tool holders that allow for rapid tool changes, enabling efficient multitasking, and minimizing project completion time. Furthermore, its user-friendly interface provides ease of operation, making it suitable for craftsmen of all experience levels.Sustainability Initiatives:Promoting sustainable practices, [Company Name] has incorporated environmentally friendly features into the CNC Woodworking Machine. The energy-efficient design reduces power consumption, minimizing the carbon footprint of woodworking operations. Through smart waste management systems, the machine ensures optimal utilization of raw materials, preventing unnecessary waste generation.Success Stories and Testimonials:Numerous woodworking professionals have already applauded the tremendous impact of [Company Name]'s CNC Woodworking Machine on their businesses. Mr. John Doe, a renowned furniture manufacturer, emphasizes the machine's role in enhancing accuracy and timeliness in his production process, resulting in increased customer satisfaction. Similarly, Ms. Jane Smith, an established craftsman, appreciates the machine's versatility, enabling her to explore intricate designs and expand her product range.Future Prospects and Global Reach:As an industry leader, [Company Name] aims to bring cutting-edge woodworking technology to markets worldwide. With a well-established global distribution network, they are confident in their ability to cater to the needs of woodworking professionals across different continents and diverse cultural landscapes.Conclusion:[Company Name]'s innovative CNC Woodworking Machine marks a significant milestone in the evolution of the woodworking industry. By combining precision, efficiency, and versatility, this state-of-the-art machinery is set to redefine the standards for woodworking processes. With [Company Name] leading the way, craftsmen and woodworkers can look forward to unlocking new levels of creativity and productivity, while reducing environmental impact.

Revolutionary 3-Axis Router: Discover the Next Level of Precision and Efficiency!

[Title]: Cutting-Edge 3-Axis Router Revolutionizes Manufacturing Processes[Subtitle]: Company X Introduces Game-Changing Technology to Streamline Manufacturing Operations[Date]: [Month, Day, Year]In a groundbreaking move that is set to reshape the manufacturing landscape, Company X has unveiled its latest innovation - a cutting-edge 3-axis router. With its advanced features and state-of-the-art technology, this groundbreaking device is poised to revolutionize the way products are fabricated and bring unprecedented efficiency to manufacturing processes worldwide.The Company X 3-axis router, currently under the nomenclature of Model XYZ, is the result of years of research and development by the company's team of skilled engineers and visionaries. With an unwavering commitment to pushing the boundaries of industry standards, Company X has successfully created a game-changing tool that promises to redefine the very essence of modern manufacturing.One of the most remarkable features of the new 3-axis router is its exceptional precision and accuracy. Built with ultra-high tolerance components and advanced motion control systems, this device can achieve sub-micron levels of accuracy, ensuring flawless replication of complex designs and intricate detailing. Manufacturers can now confidently create high-quality, intricate parts, and components with utmost precision, eliminating the risk of human error and reducing wastage of valuable resources.The router's versatility is another aspect that sets it apart from existing market offerings. Equipped with an array of innovative capabilities, the Model XYZ is suitable for a wide range of applications within various industries. From wood and metal fabrication to aerospace and automotive manufacturing, this 3-axis router is designed to handle diverse materials, enabling companies to streamline their production processes across sectors.Company X's dedication to facilitating seamless integration with existing industry infrastructure is evident through the inclusion of powerful software interfaces in the router's design. The intuitive user interface simplifies complex tasks, allowing manufacturers to swiftly adapt to the new technology without significant disruptions to their existing operations. This comprehensive solution ensures a smooth transition towards more efficient and effective manufacturing practices.Moreover, the router's robust construction and durable build ensure longevity, making it an investment that will pay dividends for years to come. Its ability to withstand rigorous production requirements and 24/7 operation makes it an ideal choice for companies with high-capacity manufacturing facilities. Reduced maintenance requirements translate into increased productivity and lower operational costs, empowering manufacturers to enhance profitability and gain a competitive edge.Safety remains a top priority in manufacturing environments, and the Company X 3-axis router addresses this concern effectively. Equipped with cutting-edge safety features including emergency stop mechanisms, integrated sensors, and automatic shutdown protocols, this router prioritizes the well-being of the operators and surrounding personnel. It complies with the highest industrial safety standards, creating a secure working environment and minimizing potential hazards.As the global manufacturing industry becomes increasingly complex and competitive, innovation has become the cornerstone of success. Companies that are at the forefront of technological advancements are best positioned to accelerate growth and achieve enhanced operational efficiencies. Recognizing this, Company X aims to remain a frontrunner in the industry by continuously investing in cutting-edge research and development to drive breakthrough innovations that cater to the evolving needs of manufacturers.The introduction of the Company X 3-axis router is a testament to the company's commitment to revolutionizing the manufacturing sector. By combining impeccable precision, versatility, cost-effectiveness, and utmost user-friendliness, this game-changing technology is poised to redefine industry standards. As manufacturers embrace this new era of innovation, we can expect an exponential surge in productivity, efficiency, and competitiveness, setting a new benchmark for the future of manufacturing.[Word Count: 554]