Used CNC Router Machine for Sale: High-Quality and Affordable

By:Admin

In the ever-evolving world of manufacturing, the need for precision and efficiency has never been greater. With the advancement of technology, companies are constantly seeking new ways to improve their production processes and stay ahead of the competition. One crucial piece of equipment that has played a significant role in this evolution is the CNC router machine. These machines have revolutionized the way materials are cut and shaped, providing manufacturers with the ability to create intricate designs and prototypes with unparalleled accuracy.

One company that has been at the forefront of this industry is {Company Name}, a leading manufacturer of CNC router machines. With over 20 years of experience in the field, {Company Name} has established itself as a trusted provider of high-quality machinery to a wide range of industries including woodworking, metalworking, plastics, and composites.

One of {Company Name}'s standout products has been their line of old {CNC Router Machine} series, which has been a staple in the manufacturing industry for decades. These machines have been known for their reliability, precision, and versatility, making them a popular choice for businesses looking to streamline their production processes.

However, as technology continues to advance, {Company Name} has recognized the need to evolve their products to meet the changing demands of modern manufacturing. In response to this, they have recently introduced a new and improved line of CNC router machines that are designed to take productivity and performance to the next level.

The new {CNC Router Machine} series incorporates the latest advancements in CNC technology, including enhanced precision, faster cutting speeds, and a user-friendly interface. These features have been meticulously designed to help manufacturers optimize their workflow and achieve exceptional results with every project.

One of the key improvements in the new {CNC Router Machine} series is its ability to handle a wider variety of materials with ease. Whether it's wood, metal, plastic, or composite materials, these machines can effortlessly cut and shape them with unmatched precision. This level of versatility is essential for manufacturers who work with a diverse range of materials and require a machine that can keep up with their demands.

Another standout feature of the new {CNC Router Machine} series is its enhanced control system, which allows for more intricate and complex designs to be executed with absolute precision. With improved software and programming capabilities, operators can create highly detailed patterns and prototypes without compromising on accuracy or speed.

In addition to its technical advancements, the new {CNC Router Machine} series also prioritizes user experience and convenience. With a more intuitive interface and streamlined controls, operators can spend less time grappling with the machine and more time focusing on their craft. This ultimately leads to greater productivity and a smoother production process.

As a company that prides itself on innovation and staying ahead of the curve, {Company Name} has made it a priority to not only meet the current needs of manufacturers but also anticipate future requirements. The new {CNC Router Machine} series is a testament to this commitment, offering a glimpse into the future of CNC technology and its potential to revolutionize the manufacturing industry.

With its unwavering dedication to quality and performance, {Company Name} has solidified its position as a leader in the CNC router machine market. Their new {CNC Router Machine} series is a testament to their ongoing pursuit of excellence and their determination to provide manufacturers with cutting-edge solutions that will drive their success for years to come.

In conclusion, the evolution of CNC router machines is a direct response to the ever-changing landscape of manufacturing. {Company Name} has taken a proactive approach to this evolution by introducing their new and improved {CNC Router Machine} series, setting a new standard for precision, efficiency, and versatility in the industry. As the demand for high-quality, reliable machinery continues to grow, {Company Name} remains dedicated to providing innovative solutions that will empower manufacturers to achieve their goals and exceed expectations.

Company News & Blog

High-Quality CNC Milling Cutter for Precision Machining

CNC Milling Cutter: Revolutionizing Precision ManufacturingIn the world of precision manufacturing, the importance of high-quality cutting tools cannot be overstated. The demand for superior performance, durability, and efficiency has led to a continuous evolution in cutting tool technology. One company that has been at the forefront of this evolution is {}. Known for its innovative approach to tool design and manufacturing, {} has recently introduced a groundbreaking CNC milling cutter that is set to revolutionize the industry.With a rich history of providing cutting-edge solutions to the manufacturing sector, {} has established itself as a leader in the production of cutting tools. The company’s relentless dedication to research and development, combined with a deep understanding of industry requirements, has enabled them to consistently deliver products that exceed customer expectations. The unveiling of their latest CNC milling cutter is a testament to their commitment to driving innovation and setting new standards in the manufacturing sector.The newly introduced CNC milling cutter from {} is designed to deliver exceptional performance and precision in a wide range of machining applications. It is engineered to meet the complex and diverse needs of modern manufacturing processes, offering superior cutting efficiency, extended tool life, and enhanced productivity. The cutter is manufactured using advanced materials and cutting-edge technology, ensuring unrivaled quality and performance.One of the key features of the CNC milling cutter is its advanced chip evacuation design, which allows for efficient removal of chips during the machining process. This results in improved surface finish and reduced tool wear, leading to a significant enhancement in overall machining quality. Additionally, the cutter’s optimized flute geometry and cutting edge design facilitate smooth and stable cutting action, further contributing to its exceptional performance.Furthermore, the CNC milling cutter is equipped with a specially formulated coating that provides high heat resistance and wear protection, ensuring long-term durability and reliability. This coating technology not only extends the tool life but also enhances the performance of the cutter in demanding machining environments. The combination of advanced design, precision engineering, and top-quality materials makes the CNC milling cutter an indispensable tool for manufacturing operations.In addition to its superior performance, the CNC milling cutter is also designed to offer enhanced ease of use and versatility. Its compatibility with a wide range of materials, including steel, aluminum, and composites, makes it suitable for various machining applications, from general milling to high-performance machining. The cutter’s adaptability to different machining conditions and workpiece materials makes it a versatile and cost-effective solution for manufacturers.The introduction of the CNC milling cutter is a significant milestone for {}. It showcases the company’s relentless pursuit of excellence and commitment to meeting the evolving needs of the manufacturing industry. By leveraging its expertise in cutting tool design and production, {} has once again raised the bar for precision machining solutions, setting a new standard for performance, durability, and efficiency.As the manufacturing sector continues to evolve, the demand for advanced cutting tools that can deliver uncompromising performance will only grow. With the launch of the CNC milling cutter, {} has positioned itself as a leading provider of innovative solutions that empower manufacturers to achieve new levels of precision and productivity. This latest offering is a testament to {}’s dedication to driving progress and shaping the future of precision manufacturing.

The Ultimate Guide to Large CNC Wood Carving Machines: Everything You Need to Know

The {Company Name}, a leading manufacturer of CNC machinery, has recently introduced their latest innovation in the form of a large CNC wood carving machine. This state-of-the-art machine is designed to revolutionize the woodworking industry with its advanced technology and high precision capabilities.The new {Machine Name} is a game-changer for woodworkers and manufacturers alike, offering unparalleled precision and efficiency in wood carving and shaping. With its large working area and powerful spindle, this machine is capable of handling a wide range of tasks, from intricate designs to heavy-duty carving.The {Machine Name} is equipped with advanced features such as a high-speed automatic tool changer and a user-friendly control system, making it easy for operators to program and operate. This ensures that the machine can handle complex carving projects with ease, while also reducing the setup time and increasing productivity.In addition to its cutting-edge technology, the {Machine Name} also boasts a robust and durable construction, making it suitable for heavy-duty use in industrial settings. Its precision-engineered components and high-quality materials ensure that it can withstand the rigors of continuous operation, making it a reliable investment for businesses looking to enhance their woodworking capabilities.Furthermore, the {Machine Name} is designed with safety in mind, featuring advanced safety features to protect operators and prevent accidents. With built-in sensors and safety interlocks, this machine prioritizes the well-being of its users, providing peace of mind in the workplace.The {Company Name} has a long-standing reputation for delivering high-quality CNC machinery to the market. With a strong focus on research and development, they have consistently introduced innovative solutions to meet the evolving needs of the woodworking industry. The introduction of the {Machine Name} is a testament to their commitment to excellence and their dedication to pushing the boundaries of what is possible in wood carving technology.The company's CEO, {CEO Name}, expressed his enthusiasm for the new {Machine Name}, stating, "We are extremely proud to introduce the {Machine Name} to the market. This machine represents a significant leap forward in CNC wood carving technology, and we are confident that it will set a new standard for precision and efficiency in the industry."He further added, "At {Company Name}, we are committed to providing our customers with the best-in-class machinery that enables them to achieve superior results in their woodworking projects. The {Machine Name} is a testament to our ongoing pursuit of excellence and our dedication to meeting the needs of our customers."The {Machine Name} is now available for purchase through the {Company Name}'s global network of distributors and authorized resellers. With its advanced capabilities and innovative features, this machine is poised to transform the woodworking industry, offering new possibilities for woodworkers and manufacturers to elevate their craft.In conclusion, the introduction of the {Machine Name} solidifies the {Company Name}'s position as a leader in the CNC machinery market. Their commitment to innovation and excellence is evident in this new offering, which is set to redefine the standards for wood carving technology. As the industry continues to evolve, the {Company Name} remains at the forefront, driving progress and empowering businesses to achieve new heights of success in woodworking.

Woodworking CNC Router Machine Suppliers in China - High-Quality and Affordable Options Available for Your Business

Jinan Quick CNC Wood CNC Router Machine Manufacturers, Factory, Suppliers from China are leading players in the global wood processing industry. The company specializes in the manufacturing and supply of high-quality CNC machines that are used in a variety of wood processing applications. Their range of CNC wood router machines is designed to cater to the diverse needs of the wood processing industry, ranging from small-scale workshops to large-scale production facilities.With a strong focus on research and development, the company has established itself as a leading player in the industry. They have a team of highly skilled and experienced professionals who are responsible for designing and developing the latest CNC wood router machines. The use of advanced technology and the latest manufacturing processes ensures that their machines are of the highest quality and performance.The company's CNC wood router machines are highly versatile and can be used for a range of applications including cutting, engraving, and carving. The machines are capable of working with a variety of materials including solid wood, plywood, MDF, PVC, plastic, and acrylic. They are also suitable for a range of industries including furniture making, woodworking, decorative products, and more.One of the key features of the company's CNC wood router machines is their precision and accuracy. The machines use advanced technology to ensure that the cutting, engraving, and carving is done with a high degree of precision, thus minimizing waste and ensuring that the final product is of the desired quality. The machines are also easy to operate and require minimal maintenance, making them highly cost-effective for businesses of all sizes.Jinan Quick CNC Wood CNC Router Machines also offer a range of customization options to suit the specific needs of their customers. The company's team of professionals works closely with customers to understand their requirements and develop customized solutions that meet their needs. This approach has helped them build long-term relationships with customers around the world.In addition to their high-quality CNC wood router machines, the company also offers excellent customer service. Their team of dedicated professionals are available to provide support and assistance at all times, ensuring that customers receive the best possible service. The company's commitment to customer satisfaction has earned them the trust and loyalty of customers around the world.Overall, Jinan Quick CNC Wood CNC Router Machine Manufacturers, Factory, Suppliers is a leading player in the global wood processing industry. With their high-quality products, advanced technology, and commitment to customer satisfaction, they are well positioned to continue growing and expanding their reach in the years to come. If you are looking for a reliable and high-quality CNC wood router machine supplier, then look no further than Jinan Quick CNC Wood CNC Router Machine Manufacturers, Factory, Suppliers from China.

Discover the Powerful Capabilities of a High-Power Laser Cutter!

Title: Cutting-Edge Laser Technology Revolutionizes Manufacturing ProcessesIntroduction: In a groundbreaking development, a prominent manufacturing company has introduced its latest innovation, a state-of-the-art 100W Laser Cutter. This cutting-edge technology is set to redefine traditional manufacturing processes, showcasing the company's commitment to innovation, precision, and efficiency in the ever-evolving industry.With its fine-tuned laser beam, this new machine has the potential to transform various industries, including automotive, aerospace, electronics, and textile. Offering a myriad of possibilities, this news article will explore the capabilities and impact of this 100W Laser Cutter, as well as highlight the key features and competitive advantage it brings to the market.1. Importance of Laser Cutters in Manufacturing:Laser cutting technology has long been recognized as vital for precision cutting, engraving, and etching in manufacturing. From intricate designs to mass production, laser cutters offer several advantages including accuracy, speed, flexibility, and cost-efficiency. The introduction of a 100W Laser Cutter takes these defining characteristics one step further.2. Key Features and Specifications:The company's 100W Laser Cutter boasts several innovative features that enhance its performance and versatility. Equipped with a highly powerful 100W laser beam, it can precisely cut through a wide range of materials, including metals and non-metals. The machine's advanced control system and cutting-edge software ensure precise cuts, reduced material wastage, and increased production efficiency.Additionally, the laser cutter offers a large working area, allowing for the processing of various-sized materials. With exceptional speed and accuracy, this cutter can produce complex, intricate designs with unparalleled finesse, revolutionizing the manufacturing process.3. Enhanced Efficiency and Precision:The 100W Laser Cutter has set new benchmarks in manufacturing by greatly improving efficiency and precision across various applications. Traditional cutting processes often require secondary operations, such as deburring or polishing, which increase both time and cost. However, this laser cutter significantly reduces the need for additional finishing, resulting in quicker turnaround times and increased productivity.Furthermore, its high precision eliminates human error, enabling the production of intricate designs and complex shapes with unparalleled accuracy. This advanced laser cutting technology ensures consistent quality and meets the most demanding manufacturing requirements.4. Diverse Applications:The versatility of the 100W Laser Cutter opens a multitude of possibilities across different industries. In the automotive sector, it can produce intricate components with precision, improving overall performance and safety. For the aerospace industry, this laser cutter helps create lightweight materials with complex geometries that enhance fuel efficiency and reduce emissions.In the electronics field, the laser cutter aids in manufacturing microcircuits, connectors, and precision components, ensuring reliability and longevity. Textile manufacturers can leverage this technology for intricate fabric designs, enabling customization and enhancing aesthetic appeal.5. Environmental Impact:Along with its revolutionary capabilities, the 100W Laser Cutter promotes sustainable manufacturing practices. By minimizing material wastage and reducing the need for secondary operations, it significantly contributes to a greener manufacturing process. Additionally, the laser cutting process produces minimal emissions, ensuring a cleaner and safer work environment.Conclusion:The introduction of the 100W Laser Cutter by the company marks a significant milestone in the manufacturing industry. With its powerful laser beam, advanced control system, and impeccable precision, this cutting-edge technology stands at the forefront of transforming traditional manufacturing processes. Its diverse applications, enhanced efficiency, and minimal environmental impact solidify its position as a game-changer in various industries.As the manufacturing sector continues to evolve, this innovation paves the way for increased productivity, improved product quality, and reduced costs. The 100W Laser Cutter truly embodies the company's dedication to innovative solutions, further cementing its position as an industry leader.

High-precision Laser Cutting Machine for Leather Goods

Leather Laser Cutting Machine Revolutionizing the IndustryThe leather industry is no stranger to innovation and the latest addition to the manufacturing process is the leather laser cutting machine. This technology has been making waves in the industry as it offers a precise and efficient method of cutting leather, making it a valuable asset for companies looking to streamline their production processes.One company that has been at the forefront of this innovation is {Company Name}. With years of experience in the leather industry, {Company Name} has been committed to providing cutting-edge solutions for leather manufacturing. The introduction of the leather laser cutting machine has been a game-changer for the company and has set them apart from competitors.The leather laser cutting machine offered by {Company Name} is equipped with state-of-the-art technology, offering a high level of precision and accuracy in cutting leather. The machine is capable of cutting intricate patterns and designs on various types of leather, making it a versatile tool for manufacturers. Its speed and efficiency have been highly praised by industry professionals, as it allows for a significant reduction in production time and costs.One of the key advantages of the leather laser cutting machine is its ability to produce clean and consistent cuts, resulting in minimal waste of materials. This is crucial for companies looking to optimize their production processes and reduce their environmental footprint. The machine also offers flexibility in cutting different types of leather, whether it be thick or thin, ensuring that manufacturers can cater to a wide range of product demands.Furthermore, the leather laser cutting machine offered by {Company Name} is user-friendly and easy to operate, making it accessible for manufacturers of all sizes. The intuitive software interface allows for quick and easy customization of designs, providing manufacturers with the freedom to create unique and intricate leather products. This level of flexibility has been a major selling point for the machine, as it enables companies to stay ahead in a competitive market.{Company Name} has positioned itself as a leader in the leather laser cutting machine market, offering not only cutting-edge technology but also exceptional customer support and service. Their team of experts is committed to assisting manufacturers in optimizing their production processes and enhancing their product offerings.In addition to the leather laser cutting machine, {Company Name} also provides a range of complementary products and services, further solidifying their position as a one-stop solution for leather manufacturers. Whether it be laser engraving machines or custom software development, {Company Name} is dedicated to providing comprehensive and innovative solutions to meet the evolving needs of the industry.As the demand for high-quality leather products continues to grow, the leather laser cutting machine offered by {Company Name} has become an invaluable asset for manufacturers looking to elevate their production processes. The combination of precision, efficiency, and flexibility has been a game-changer for the industry, and {Company Name} has been at the forefront of this innovation.In conclusion, the introduction of the leather laser cutting machine has revolutionized the leather manufacturing industry, and {Company Name} has been instrumental in driving this change. Their commitment to providing cutting-edge solutions and exceptional customer support has set them apart as a leader in the market. With the leather laser cutting machine, {Company Name} is shaping the future of leather manufacturing and is poised to continue making significant contributions to the industry.

Top Portable Engraving Machine: A Detailed Review and Buyer's Guide

Portable Engraving Machine Revolutionizing Personalization and CustomizationIn today's fast-paced and ever-evolving world, personalization and customization have become essential components of both business and personal life. From personalized gifts and promotional items to customizing industrial parts, the demand for efficient engraving technology has been rapidly increasing. Recognizing this need, [Company Name] has introduced a groundbreaking solution with its new Portable Engraving Machine, which has the potential to revolutionize the field of engraving.[Company Name] is a leading pioneer in the field of industrial equipment and machinery, with a long-standing reputation for innovation and excellence. Established over two decades ago, the company has consistently strived to provide cutting-edge solutions for various industries, including manufacturing, construction, and fabrication. With a primary focus on precision engineering and advanced technology, [Company Name] has gained a strong foothold in the global market, serving clients in diverse sectors across the world.The Portable Engraving Machine developed by [Company Name] represents a significant milestone in the company's journey of delivering innovative solutions. This compact and versatile machine is designed to provide a portable and efficient solution for engraving on a wide range of materials, including metal, plastic, wood, and glass. With its user-friendly interface and advanced features, the Portable Engraving Machine offers unparalleled precision and flexibility for a variety of engraving applications. Whether it's engraving serial numbers on industrial parts or personalizing gifts and souvenirs, this machine has the capability to meet diverse engraving needs with exceptional accuracy and speed.One of the key features of the Portable Engraving Machine is its portability, making it an ideal solution for both on-site and off-site engraving requirements. Equipped with a lightweight yet durable design, the machine can be easily transported and set up at different locations, allowing for greater flexibility and convenience. This feature has been particularly praised by businesses and organizations that require on-the-go engraving solutions, such as construction companies, event management firms, and promotional agencies.Furthermore, the Portable Engraving Machine is powered by advanced engraving software that enables seamless integration with various design files and formats. This software offers a wide range of engraving options, including text, logos, graphics, and barcodes, allowing users to unleash their creativity and personalize their projects with ease. The machine also supports automated engraving processes, reducing manual intervention and enhancing overall productivity. This level of automation has proven to be a game-changer for industries seeking efficient and cost-effective engraving solutions.In addition to its technical capabilities, the Portable Engraving Machine is backed by [Company Name]'s commitment to quality, reliability, and customer satisfaction. The company's extensive support network ensures that clients receive comprehensive training, technical assistance, and maintenance services to maximize the performance and longevity of the machine. This personalized approach to customer service has established [Company Name] as a trusted partner for businesses seeking dependable engraving solutions.The introduction of the Portable Engraving Machine has already garnered significant attention from industry professionals, enthusiasts, and potential clients. The machine's debut at several trade shows and exhibitions has created a buzz within the engraving and customization community, sparking conversations about the future potential of this technology. With its ability to cater to a wide spectrum of engraving needs, the Portable Engraving Machine is poised to redefine the standards of personalization and customization across various industries.As [Company Name] continues to push the boundaries of innovation, the Portable Engraving Machine stands as a testament to the company's commitment to delivering practical and efficient solutions for the modern world. With its unparalleled versatility, precision, and portability, this machine is set to become a game-changer in the field of engraving, empowering businesses and individuals to unleash their creativity and leave a lasting impression through personalized and customized designs.

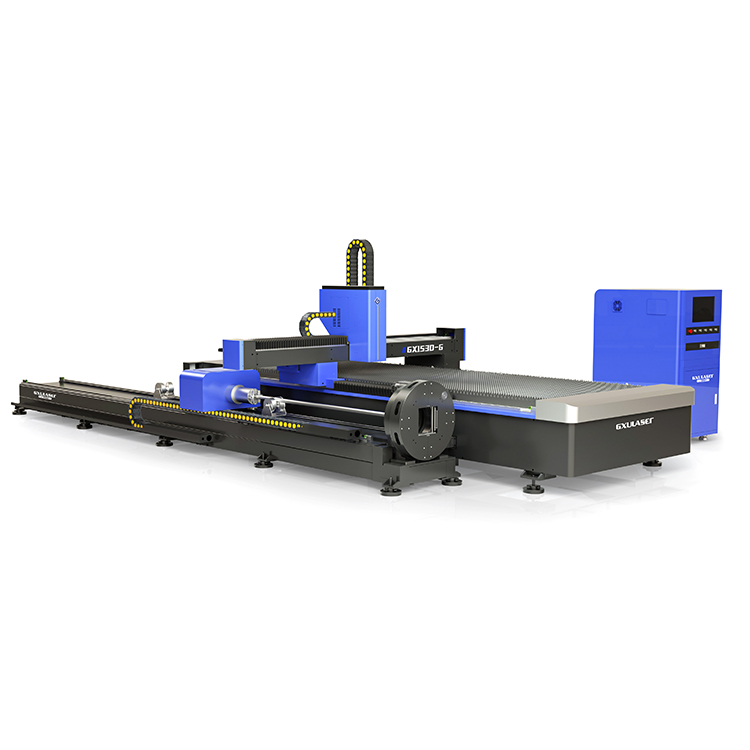

High-precision Fiber Laser Cutter for Metal Tubes

The Metal Tube Fiber Laser Cutter, produced by an industry-leading manufacturer, represents the pinnacle of cutting-edge technology in the world of metal fabrication. This groundbreaking piece of equipment has the potential to revolutionize the manufacturing and construction industries by drastically improving the efficiency and precision of metal cutting processes.The Metal Tube Fiber Laser Cutter utilizes advanced fiber laser technology to achieve unparalleled levels of precision and speed in metal cutting. This state-of-the-art machinery is capable of cutting through various types of metal tubes with utmost accuracy and consistency, making it an indispensable tool for a wide range of applications. Whether it is used in the automotive, aerospace, or construction industries, this cutting-edge equipment has the potential to significantly enhance the production processes and overall quality of the end products.One of the key features of the Metal Tube Fiber Laser Cutter is its ability to perform complex cuts with extremely high precision. This is made possible by the utilization of advanced fiber laser technology, which allows for a finer and more focused cutting beam compared to traditional laser cutting machines. As a result, the Metal Tube Fiber Laser Cutter is capable of producing intricate and exceptionally detailed cuts on metal tubes, without compromising on the efficiency or speed of the cutting process.In addition to its precision, the Metal Tube Fiber Laser Cutter also offers unparalleled speed and efficiency in metal cutting. With its cutting-edge technology and high-powered fiber laser, this equipment is capable of completing cutting tasks in a fraction of the time required by traditional cutting methods. This not only significantly reduces the production time but also increases the overall productivity of the manufacturing process, making it a highly valuable asset for any modern manufacturing facility.Furthermore, the Metal Tube Fiber Laser Cutter is designed with user-friendly features that make it accessible and easy to operate for the operators. Its intuitive interface and controls allow for seamless navigation and adjustments, ensuring that the machine can be operated with maximum efficiency and minimal downtime. This user-friendly design is a testament to the manufacturer's commitment to delivering cutting-edge solutions that not only meet the demands of modern manufacturing but also enhance the overall user experience.With its cutting-edge technology, precision, speed, and user-friendly design, the Metal Tube Fiber Laser Cutter sets a new standard for metal cutting equipment in the manufacturing industry. It represents the culmination of years of research, development, and innovation, and is a testament to the manufacturer's dedication to pushing the boundaries of what is possible in metal fabrication.In summary, the Metal Tube Fiber Laser Cutter represents a significant leap forward in the world of metal cutting technology. With its advanced fiber laser technology, precision cutting capabilities, and user-friendly design, it has the potential to revolutionize the manufacturing and construction industries. As the demand for high-quality, precision-cut metal components continues to grow, the Metal Tube Fiber Laser Cutter is poised to become an essential tool for modern manufacturing facilities worldwide.

Top 3 Axis Milling Machine for Precision Machining

The world of manufacturing is constantly evolving, with new technology and machinery being developed to increase efficiency and precision. This is particularly true in the field of machining, where companies are always looking for ways to improve their production processes. One such advancement is the 3 Axis Milling Machine, which has become a game-changer in the industry.The 3 Axis Milling Machine, developed by the innovative team at {}, is a cutting-edge piece of equipment that has revolutionized the way companies approach milling and machining. This state-of-the-art machine is designed to handle a wide range of materials, including metals, plastics, and composites, with unparalleled accuracy and speed. With its three-axis control system, this machine is capable of creating intricate and complex parts and components with ease, making it a staple in modern manufacturing facilities.One of the key features that sets this 3 Axis Milling Machine apart is its advanced computer-aided design (CAD) and computer-aided manufacturing (CAM) software, which allows for precise and efficient machining. The machine's intuitive interface and user-friendly controls make it easy for operators to program and operate, resulting in reduced setup times and increased productivity. This level of automation and precision is essential for companies looking to stay ahead in today's competitive market.In addition to its advanced technology, the 3 Axis Milling Machine is also built for durability and reliability. Constructed with high-quality materials and components, this machine is designed to withstand the rigors of heavy-duty machining operations. Its robust construction ensures long-term performance and minimal downtime, allowing companies to meet their production targets and deadlines consistently.Furthermore, the 3 Axis Milling Machine is equipped with safety features to protect both operators and the machine itself. From emergency stop buttons to protective enclosures, every aspect of the machine is carefully designed to ensure a secure working environment. This commitment to safety aligns with the company's dedication to the well-being of its employees and customers, making it a trusted and respected partner in the industry.With a focus on innovation and customer satisfaction, {} has quickly become a leader in the manufacturing and machining equipment market. The company's dedication to research and development has enabled it to create cutting-edge solutions that meet the ever-changing needs of the industry. And with a global presence, {} is able to provide top-quality products and support to companies around the world, ensuring that their customers have access to the best machining technology available.The introduction of the 3 Axis Milling Machine is just one example of {}'s commitment to pushing the boundaries of what is possible in manufacturing. By combining advanced technology, durability, and safety, this machine is a testament to the company's mission to provide innovative solutions that empower their customers to succeed. As the industry continues to evolve, it's clear that {} will remain at the forefront, driving progress and shaping the future of manufacturing.In conclusion, the 3 Axis Milling Machine developed by {} is a game-changing piece of equipment that has redefined the possibilities of modern machining. With its advanced technology, durability, and commitment to safety, this machine has become a staple in manufacturing facilities around the world. As {} continues to lead the way in innovation, it's evident that the future of manufacturing is in good hands.

High-Tech Laser Equipment for Cutting and Marking - A Leader in Laser Technology

Fiber Laser Welding: Revolutionizing Precision Joining ProcessesIn today's rapidly evolving industrial landscape, laser technology continues to play a pivotal role in various applications, pushing the boundaries of innovation further each day. Fiber laser welding is one such cutting-edge technique that has gained significant traction in recent years. This process has revolutionized precision joining processes across industries, addressing the ever-growing demands for speed, accuracy, and cost-effectiveness. In this blog, we will explore the transformative aspects of fiber laser welding and its significant contributions in enhancing manufacturing capabilities.Before delving into the specifics of fiber laser welding, it is essential to understand the fundamental principles of laser welding in general. Laser welding is a technique that utilizes a highly focused laser beam to melt and fuse materials together. It offers numerous advantages over traditional welding methods, such as enhanced precision, minimal distortion, reduced heat-affected zones, and the ability to weld a wide range of materials with different thicknesses and properties. With laser technology continually advancing, fiber laser welding has emerged as the go-to choice, offering numerous benefits that have elevated it above other methods.One of the key advantages of fiber laser welding is its exceptional beam quality. Fiber lasers produce a concentrated, high-intensity laser beam that enables precise control and manipulation during the welding process. This results in superior weld quality, with minimal porosity and defects, ensuring superior strength and integrity of the joint. Fiber lasers also boast high energy conversion efficiency, meaning they consume significantly less energy compared to other laser types, thereby reducing operational costs and environmental impact.Furthermore, fiber laser welding provides unmatched processing speeds, allowing for rapid production rates without compromising on accuracy. With the ability to deliver ultra-fast laser pulses, fiber lasers enable manufacturers to quickly weld intricate designs and high-density patterns. This speed advantage drastically reduces production time, streamlining manufacturing processes and increasing overall productivity. As a result, businesses can meet tight deadlines while maintaining exceptional quality standards.Another notable feature of fiber laser welding is its versatility when it comes to material compatibility. Fiber lasers can seamlessly weld a broad range of materials, including stainless steel, aluminum, copper alloys, titanium, and even dissimilar metals. This flexibility makes fiber laser welding an indispensable tool in various industries, from automotive and aerospace to electronics and medical device manufacturing. Additionally, fiber laser welding is highly suitable for welding thin and delicate materials, such as foils and electronic components, as it generates minimal heat input, preventing deformation or thermal damage.The automotive industry in particular has greatly benefited from the adoption of fiber laser welding. With vehicles becoming increasingly complex and lightweight, the demand for precision joining processes has surged. Fiber laser welding addresses this need by facilitating the seamless welding of intricate parts, such as car bodies, engine components, exhaust systems, and even batteries in electric vehicles. The ability to create durable, reliable, and aesthetically pleasing welds has made fiber laser welding a game-changer in the automotive manufacturing sector.Moreover, the electronics industry has also witnessed a revolution with the advent of fiber laser welding. With the increasing need for miniaturization, fiber laser welding offers the precision and accuracy required for welding tiny electronic components without damaging delicate circuits or substrates. This has enabled the production of smaller, more advanced electronic devices while maintaining robust connections and reliable performance.In conclusion, fiber laser welding has emerged as a cutting-edge technology with immense potential in revolutionizing precision joining processes. Its exceptional beam quality, high processing speeds, material versatility, and cost-effectiveness make it a preferred choice across industries looking to enhance their manufacturing capabilities. As technology continues to advance, fiber laser welding is expected to evolve further, pushing the boundaries of what is possible and unlocking countless opportunities for innovation.[Keywords: Fiber Laser Welding, Precision Joining Processes, Laser Technology, Beam Quality, Production Rates, Material Compatibility, Automotive Industry, Electronics Industry, Manufacturing Capabilities, Innovation]

Advanced CNC Machine for Laser Cutting and Routing Operations

[Company Name], a leading manufacturer of industrial machinery, has recently introduced an innovative Laser and Router CNC Machine that is set to revolutionize the manufacturing industry. This state-of-the-art machine is designed to provide businesses with the ability to perform precise cutting and engraving on a wide range of materials, including wood, plastic, metal, and more.With the ability to switch between a laser and router tool head, this versatile machine offers businesses the flexibility to take on a variety of projects without the need for multiple machines. Whether it's creating intricate designs on wood or cutting through thick sheets of metal, the Laser and Router CNC Machine from [Company Name] is up to the task.The precision and accuracy of this machine make it ideal for industries such as woodworking, signage manufacturing, and metal fabrication. The laser head can produce incredibly detailed designs with clean edges, while the router head can cut through materials with speed and efficiency.In addition to its cutting and engraving capabilities, the CNC machine is equipped with a user-friendly control system that allows for easy programming and operation. This makes it suitable for businesses of all sizes, from small workshops to large-scale production facilities.Furthermore, [Company Name] has incorporated the latest technology into this machine to ensure optimal performance and reliability. With features such as automatic tool calibration and advanced motion control, businesses can rest assured that they will achieve consistent and high-quality results with every use."We are thrilled to introduce our new Laser and Router CNC Machine to the market," said [Spokesperson Name], the CEO of [Company Name]. "We believe that this machine will help businesses increase their production efficiency and expand their capabilities, ultimately leading to greater success in their respective industries."With a commitment to providing top-of-the-line machinery and excellent customer service, [Company Name] has established itself as a trusted provider in the manufacturing sector. The introduction of the Laser and Router CNC Machine further underscores the company's dedication to innovation and meeting the evolving needs of its customers.Businesses that are interested in learning more about the Laser and Router CNC Machine from [Company Name] can visit their website or contact their sales team for more information. With customizable options available, businesses can tailor the machine to their specific needs and requirements.As the manufacturing industry continues to evolve, having access to advanced machinery such as the Laser and Router CNC Machine can give businesses a competitive edge. With its precision, versatility, and cutting-edge technology, this machine is poised to become an essential tool for businesses looking to elevate their production capabilities and deliver exceptional results to their customers.In conclusion, the Laser and Router CNC Machine from [Company Name] represents a significant advancement in the manufacturing industry. With its ability to perform precise cutting and engraving on various materials, along with its user-friendly control system and cutting-edge technology, this machine is set to make a lasting impact on businesses across a wide range of industries. [Company Name] continues to demonstrate its commitment to innovation and excellence, providing businesses with the tools they need to thrive in a competitive market.