Top Techniques for Laser Engraving Steel Revealed

By:Admin

Laser engraving steel is a cutting-edge technology that has revolutionized product marking and branding for companies across various industries. This innovative process involves using high-powered lasers to etch permanent markings onto the surface of steel, creating a durable and long-lasting product identification solution.

One company that has been at the forefront of this technology is {company name}. With decades of experience in the manufacturing and engineering industry, {company name} has embraced laser engraving steel as a core aspect of their product marking capabilities. Their state-of-the-art facilities and highly skilled team of experts have allowed them to consistently deliver high-quality engraved steel products to their clients.

The process of laser engraving steel begins with a detailed design or logo that needs to be marked onto the surface of the steel. Using advanced software, the design is translated into a digital format and then loaded into the laser engraving machine. The high-powered laser beam is then precisely focused onto the surface of the steel, removing layers of material to create the desired marking. The result is a crisp, clear, and permanent engraving that is resistant to wear and corrosion.

One of the key advantages of laser engraving steel is its ability to create intricate and detailed markings that would be impossible to achieve using traditional methods such as stamping or etching. This makes it an ideal solution for companies that require high-resolution logos or complex product identification codes to be engraved onto their steel products.

Additionally, laser engraving steel offers unmatched durability and longevity. The markings are resistant to fading, scratching, and chemical exposure, ensuring that they remain legible and intact throughout the lifespan of the product. This is particularly important for industries such as aerospace, automotive, and medical devices, where product identification and traceability are critical factors.

{Company name}'s expertise in laser engraving steel has enabled them to serve a wide range of industries with diverse marking needs. From precision-engineered components for the aerospace industry to heavy-duty machinery parts for the industrial sector, their engraved steel products have consistently met the highest standards of quality and performance.

In addition to its practical advantages, laser engraving steel also offers environmental benefits. Unlike traditional chemical etching processes, laser engraving is a clean and environmentally friendly method of marking steel products. It does not produce any hazardous waste or emissions, making it a sustainable and eco-friendly alternative for companies looking to minimize their environmental impact.

As technology continues to advance, the possibilities for laser engraving steel are only growing. {Company name} is committed to staying at the forefront of these developments, constantly investing in the latest laser engraving equipment and techniques to offer their clients the most cutting-edge solutions for their product marking needs.

In conclusion, laser engraving steel has emerged as a game-changing technology for companies seeking durable, high-quality product marking solutions. {Company name} has proven to be a leader in this field, leveraging their expertise and state-of-the-art facilities to deliver exceptional engraved steel products to a wide range of industries. As the demand for precise, long-lasting product identification continues to rise, laser engraving steel is poised to become an essential tool for manufacturers around the world.

Company News & Blog

Innovative Portable Laser Cleaning Technology: A Game-Changer for Industrial Applications

Portable Laser Cleaning revolutionizes industrial cleaningPortable Laser Cleaning is a groundbreaking technology that is revolutionizing the industrial cleaning process. Developed by a leading company in the field, this innovative solution is offering a safe, efficient, and environmentally friendly alternative to traditional cleaning methods.The technology behind Portable Laser Cleaning is based on the use of high-powered lasers to remove contaminants from various surfaces. Unlike traditional cleaning methods that often involve the use of harsh chemicals or abrasive materials, Portable Laser Cleaning is a non-contact, non-abrasive, and non-abrasive cleaning method that does not produce any waste or residue.The process works by directing the laser beam at the surface to be cleaned. The energy from the laser is absorbed by the contaminants on the surface, causing them to vaporize or sublimate, leaving the underlying material clean and undamaged. This makes Portable Laser Cleaning particularly well suited for delicate or sensitive materials that may be easily damaged by traditional cleaning methods.One of the key advantages of Portable Laser Cleaning is its portability. Unlike larger, stationary laser cleaning systems, Portable Laser Cleaning units are compact, easy to transport, and can be used in a variety of industrial settings. This makes the technology ideal for on-site cleaning of equipment, machinery, and infrastructure, as well as for applications in environments where traditional cleaning methods may be impractical or hazardous.In addition to its portability, Portable Laser Cleaning offers a number of other benefits. The technology is highly precise, allowing for targeted cleaning without affecting surrounding areas. It is also versatile, capable of removing a wide range of contaminants, including rust, paint, oil, grease, and corrosion. Furthermore, Portable Laser Cleaning is a safe and eco-friendly solution, as it does not produce any secondary waste or emissions, and eliminates the need for harmful chemicals or solvents.The company behind Portable Laser Cleaning has a strong track record in the development and application of laser-based technologies. With decades of experience in the field, the company has established itself as a leading provider of industrial laser solutions, serving a wide range of industries, including automotive, aerospace, maritime, and manufacturing.The company prides itself on its commitment to innovation and quality, and its team of experts works closely with clients to develop customized solutions that meet their specific needs and requirements. With a focus on research and development, the company continues to push the boundaries of what is possible with laser technology, constantly seeking new applications and improvements to existing processes.The introduction of Portable Laser Cleaning is a testament to the company's dedication to pioneering new solutions that offer real benefits to its customers and the environment. By providing a safe, efficient, and eco-friendly alternative to traditional cleaning methods, Portable Laser Cleaning is setting a new standard for industrial cleaning, and is poised to become an indispensable tool for companies seeking to improve their cleaning processes.With its proven track record, commitment to innovation, and focus on customer satisfaction, the company is well positioned to lead the way in the growing market for laser-based cleaning technologies. As the demand for safe, efficient, and environmentally friendly cleaning solutions continues to grow, Portable Laser Cleaning is poised to play a key role in shaping the future of industrial cleaning.

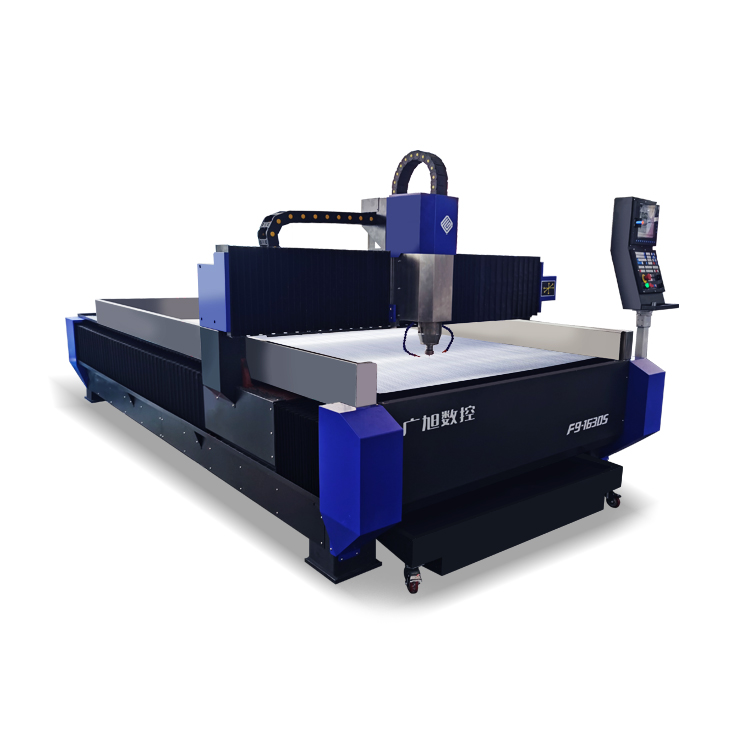

Key Maintenance Tips for Industrial CNC Routers in Woodworking

Investing in an industrial grade CNC router machine is a significant decision for any woodworking business. To ensure the longevity, performance, and dependability of the machine, it is crucial to maintain it correctly and efficiently. Daily, weekly, monthly, and quarterly maintenance measures help protect your CNC router and ensure maximum uptime. In this blog post, we will cover daily maintenance procedures that woodworkers can carry out to keep their router machines in excellent working condition.Daily Maintenance:Daily maintenance measures are quick and easy, often taking less than ten minutes. The following are some of the daily tasks that woodworkers can perform to ensure the optimal performance of their CNC router machines:1. Clean the machine: Use a soft and dry cloth to wipe down the machine's exterior and remove any dust, debris, or dirt that may accumulate on the surface. This not only keeps the machine looking clean and maintained, but it also prevents the debris from entering the internal components.2. Check the coolant level: Ensure that the coolant is at the right level for the machine's spindle and refill it if needed. Low coolant levels may cause the machine to overheat, resulting in damage to the spindle or other integral components.3. Check the air filter: Check the air filter if the router machine has one and make sure it is clean. A dirty air filter can reduce airflow to the machine's spindle or motor, causing it to overheat or malfunction.4. Check the lubrication system: Check the machine's lubrication system to ensure that it is working correctly. Make sure there is enough lubrication for the spindle and other moving parts. Running the machine without adequate lubrication can cause premature wear and tear, leading to additional maintenance costs in the long run.5. Inspect the tooling: Inspect the tooling before use. Ensure that the cutters, bits, and other tools are sharp and in good condition. Dull or damaged tools can cause the machine to work harder and produce a low-quality output.In conclusion, by carrying out these daily maintenance procedures, woodworkers can keep their CNC router machines in excellent working order and avoid unwanted downtime. It is essential to invest time and effort in maintaining the machine and follow the manufacturer's guidelines to ensure the machine's optimal performance and longevity.

Ultimate Guide to 3D Carving with a CNC Router

CNC Router 3D Carving: Revolutionizing the Manufacturing IndustryIn the rapidly evolving world of manufacturing, technological advancements have paved the way for more efficient and precise production processes. One such innovation is the CNC Router 3D Carving, a cutting-edge technology that has been gaining traction in the industry for its ability to create intricate and detailed designs with ease.CNC Router 3D Carving is a form of computer numerical control (CNC) technology that utilizes a rotating cutting tool to carve out three-dimensional designs from a variety of materials, including wood, plastic, and metal. This process is achieved through the use of a computer program that guides the movement of the cutting tool, resulting in highly accurate and detailed carvings that would be nearly impossible to achieve by hand.The benefits of CNC Router 3D Carving are vast, offering manufacturers the ability to produce complex and customized parts and products with ease. This technology also allows for greater precision and consistency in the manufacturing process, reducing the margin for error and increasing overall production efficiency.One company at the forefront of this technological revolution is {Company Name}, a leading manufacturer of CNC machinery. {Company Name} has been at the forefront of the industry for over a decade, providing cutting-edge solutions for a wide range of manufacturing needs. With a strong focus on research and development, {Company Name} has consistently pushed the boundaries of innovation, delivering state-of-the-art machinery that meets the evolving demands of the manufacturing sector.The CNC Router 3D Carving technology offered by {Company Name} has garnered widespread acclaim for its exceptional precision and versatility. This technology has been utilized in a variety of industries, from furniture and cabinetry manufacturing to aerospace and automotive production. The ability to create intricate and detailed designs has provided manufacturers with the tools necessary to stay competitive in an increasingly demanding market.One of the key advantages of {Company Name}'s CNC Router 3D Carving technology is its user-friendly interface, allowing operators of varying skill levels to effectively utilize the machinery. This accessibility has empowered manufacturers to take on more complex projects and expand their capabilities, ultimately leading to enhanced productivity and profitability.Furthermore, {Company Name} stands out in the industry for its unwavering commitment to customer satisfaction. The company's stellar reputation for providing reliable machinery and exceptional customer support has earned the trust of countless manufacturers around the world. With a global presence and a dedicated team of experts, {Company Name} continues to be a driving force in shaping the future of manufacturing.As the manufacturing landscape continues to evolve, the significance of CNC Router 3D Carving technology cannot be understated. Its impact on the industry has been profound, offering manufacturers a powerful tool to streamline production processes and push the boundaries of design and innovation. With companies like {Company Name} leading the charge, the future of manufacturing looks brighter than ever.

Discover the Benefits of Fibre Laser Cutting for Metal

In today's rapidly evolving world of technology and manufacturing, precision and efficiency are key factors in staying competitive. In the metal manufacturing industry, the introduction of Fibre Laser Cutting has revolutionized the way metal is cut and shaped, providing significant advantages over traditional methods. With its ability to cut through a wide range of metals with high precision and speed, Fibre Laser Cutting has become the go-to solution for many companies looking to stay ahead of the curve.One such company at the forefront of this technology is {Company Name}, a leading provider of metal cutting and fabrication services. With a strong commitment to innovation and quality, {Company Name} has fully embraced the potential of Fibre Laser Cutting and has integrated it into their operations with great success. This move has allowed them to consistently deliver exceptional results to their customers while also staying ahead in a highly competitive industry.Fibre Laser Cutting is a process that utilizes a high-powered laser to melt or vaporize material, resulting in exceptionally clean and precise cuts. Unlike traditional cutting methods that rely on mechanical force or heat, the laser's concentrated energy allows for greater control and accuracy, even on the thinnest and most delicate metals. This level of precision is crucial for industries such as aerospace, automotive, and electronics, where the slightest deviation can lead to serious consequences.{Company Name} has invested heavily in state-of-the-art Fibre Laser Cutting equipment, ensuring that they can meet the demands of their diverse clientele. With the ability to cut through a wide range of materials, including stainless steel, aluminum, and titanium, they have the flexibility to take on a variety of projects with different requirements. Whether it's creating intricate designs or producing large volumes of parts, the speed and precision of Fibre Laser Cutting have allowed {Company Name} to meet and exceed customer expectations.One of the key advantages of Fibre Laser Cutting is its cost-effectiveness. The efficiency of the process means that less material is wasted, and there is minimal need for secondary finishing operations. This has translated into savings for {Company Name}, as well as for their clients, making their services even more attractive in the marketplace. In addition, the speed of Fibre Laser Cutting has enabled {Company Name} to shorten lead times and meet tight deadlines without compromising on quality.Another significant benefit of Fibre Laser Cutting is its ability to handle complex designs and shapes with ease. This has opened up new possibilities for {Company Name}, allowing them to take on projects that were once considered too difficult or time-consuming. From intricate patterns to three-dimensional components, the versatility of Fibre Laser Cutting has expanded {Company Name}'s capabilities and positioned them as a leader in the industry.The integration of Fibre Laser Cutting technology has also had a positive impact on the environment. The process produces minimal waste and consumes less energy compared to other cutting methods, making it a more sustainable option. This aligns with {Company Name}'s commitment to environmental responsibility and has allowed them to offer environmentally conscious solutions to their clients.Moving forward, {Company Name} plans to further leverage the potential of Fibre Laser Cutting by exploring new applications and pushing the boundaries of what is possible in metal fabrication. With a dedicated team of experts and a spirit of continuous improvement, they are well-positioned to stay ahead of the curve and meet the evolving needs of their customers.In conclusion, Fibre Laser Cutting has proven to be a game-changer in the metal manufacturing industry, and {Company Name} is leading the way in harnessing its potential. Through strategic investment and a focus on quality, they have elevated their capabilities and set new standards for precision and efficiency. As the demand for complex and high-quality metal products continues to grow, {Company Name} is well-equipped to meet these challenges head-on, thanks to their dedication to innovation and their embrace of cutting-edge technology.

Boost Your Metal Fabrication Process: Discover the Power of Stainless Steel CNC Cutting

Title: Revamping Precision in Metal Fabrication with Stainless Steel CNC CuttingIntroduction (100 words):In an era fueled by technological advancements, the manufacturing industry strives to enhance precision and efficiency to meet evolving demands. One such innovation revolutionizing metal fabrication is stainless steel CNC cutting. By harnessing the power of computer numerical control (CNC) technology, this cutting-edge process caters to a diverse range of industries. This article explores the capabilities of stainless steel CNC cutting and highlights how it contributes to the company's commitment to delivering high-quality and precise metal fabrication solutions.Body:1. The Advantages of Stainless Steel CNC Cutting (200 words):Stainless steel CNC cutting is rapidly gaining popularity due to its exceptional benefits. The process combines the advantages of stainless steel, renowned for its durability and corrosion resistance, with the precise cutting capabilities of CNC technology. The inclusion of this technique in the company's metal fabrication arsenal allows for the efficient production of intricate and complex designs without compromising on the material's integrity.The CNC cutting system boasts unmatched precision, repeatability, and speed, ensuring consistent and accurate results batch after batch. By utilizing cutting-edge computer programming, the company can accommodate various design specifications, creating customized solutions to meet specific client requirements. Moreover, stainless steel CNC cutting minimizes material wastage, ultimately leading to cost savings and environmental sustainability.2. Industry Application and Diverse Uses (250 words):Stainless steel CNC cutting has found widespread application across several industries due to its versatility. From automotive and aerospace to architecture and medical equipment, this technology imparts immense value by fabricating high-quality metal components. The company leads the way by leveraging stainless steel CNC cutting to cater to the unique demands of its clients.In the automotive sector, precision is paramount. Stainless steel CNC cutting ensures the production of accurate parts for critical systems, including suspension, exhaust, and engine components. By adhering to strict quality controls and flawlessly executing complex designs, the company aligns with industry standards to deliver superior products.Likewise, the aerospace industry relies heavily on stainless steel CNC cutting for aircraft parts such as turbine blades, airframes, and structural components. The precise and intricate nature of these components demands the employment of cutting-edge CNC technology, ensuring not only structural integrity, but also upholding safety standards.Architecture and interior design benefit from stainless steel CNC cutting as it provides the opportunity for innovative and visually stunning metalwork. From intricate metal furniture designs to striking building facades, the company's CNC cutting expertise offers architects and designers the freedom to explore their creative boundaries while maintaining structural integrity.Additionally, stainless steel CNC cutting serves the medical industry, crafting intricate surgical instruments, orthopedic implants, and medical devices with utmost precision and detail. The technology affords superior surface quality for biocompatible stainless steel, enhancing patient safety and medical professionals' peace of mind.3. Company Name: Pioneering Excellence and Innovation in Stainless Steel CNC Cutting (200 words):Company {} (please insert the company name) stands at the forefront of revolutionizing the metal fabrication landscape with its expertise in stainless steel CNC cutting. With a commitment to excellence and innovation, the company strives to deliver superior quality products by leveraging the potential of cutting-edge technologies.{} (Please include company introduction, such as history, values, certifications, and commitment to customer satisfaction). As an industry leader, the company's state-of-the-art facilities and highly trained technicians ensure precise execution of designs, delivering exceptional results to clients across diverse industries.Furthermore, the company's dedication to consistent improvement and investment in research and development enables them to stay ahead in a highly competitive market. By staying up-to-date with the latest advancements in stainless steel CNC cutting, they continually expand their capabilities, providing customers with cutting-edge metal fabrication solutions.Conclusion (150 words):Stainless steel CNC cutting has ignited a revolution in precision metal fabrication, enabling the manufacturing industry to achieve unparalleled accuracy and efficiency. The company's expertise in this field has facilitated the delivery of robust and intricate metal components across diverse sectors, including automotive, aerospace, architecture, and healthcare.Through adopting this cutting-edge technology, the company remains committed to providing clients with superior quality, customizable metal fabrication solutions that adhere to the highest industry standards. The fusion of stainless steel's remarkable properties with CNC cutting's exemplary precision ensures that the company remains at the forefront of manufacturing excellence, meeting the evolving needs of their valued customers efficiently and sustainably.

Top CNC Router Machine for Precision Cutting and Carving

ATC CNC Router Machine Revolutionizes Woodworking IndustryThe woodworking industry has seen a significant transformation with the introduction of advanced technology such as the Automatic Tool Changer (ATC) CNC Router Machine. This revolutionary machine has been a game-changer for woodworking businesses, enabling them to achieve higher levels of precision, efficiency, and productivity.One of the leading manufacturers of ATC CNC Router Machines, {Company Name}, has been at the forefront of this technological innovation. With a strong focus on research and development, the company has been able to develop cutting-edge CNC routers that are setting new standards in the industry.The ATC CNC Router Machine offered by {Company Name} is equipped with an automatic tool changer system, which allows for seamless and swift tool changes during the machining process. This eliminates the need for manual tool changes, saving valuable time and improving overall productivity. With the ability to accommodate multiple cutting tools simultaneously, the machine is capable of performing a wide range of machining operations with precision and speed.In addition to the ATC system, {Company Name}'s CNC routers are designed with state-of-the-art control systems that enable operators to program intricate designs and execute complex machining tasks with ease. The intuitive user interface and advanced software make it possible to produce intricate cuts, shapes, and designs with unparalleled accuracy.Furthermore, the robust construction and high-quality components of {Company Name}'s ATC CNC Router Machine ensure exceptional reliability and durability, making it an ideal investment for woodworking businesses seeking to enhance their manufacturing capabilities.The versatility of the ATC CNC Router Machine makes it suitable for a variety of woodworking applications, including furniture manufacturing, cabinet making, sign production, and architectural millwork. Its ability to handle different types of wood, composite materials, plastics, and non-ferrous metals makes it a versatile solution for diverse manufacturing needs.With the integration of advanced technology and precision engineering, {Company Name} has set a new benchmark in the woodworking industry, offering CNC routers that deliver unparalleled performance and efficiency. The company's commitment to continuous improvement and innovation has earned them a reputation for providing cutting-edge solutions that meet the evolving needs of the woodworking market.By investing in an ATC CNC Router Machine from {Company Name}, woodworking businesses can expect to experience a significant boost in productivity, reduced operational costs, and the ability to produce high-quality products that meet the most demanding standards.The impact of ATC CNC Router Machines on the woodworking industry has been profound, as it has enabled manufacturers to elevate their capabilities and compete in a rapidly evolving market. With the incorporation of advanced automation and precision technology, {Company Name} is leading the way in empowering woodworking businesses to achieve new levels of quality and efficiency.In conclusion, the introduction of ATC CNC Router Machines has brought about a transformative shift in the woodworking industry, and {Company Name} has played a pivotal role in driving this change. As the demand for high-quality, precision machining continues to grow, {Company Name}'s ATC CNC Router Machines are poised to shape the future of woodworking manufacturing, offering unparalleled performance, reliability, and versatility. For woodworking businesses looking to stay ahead of the competition, investing in a state-of-the-art ATC CNC Router Machine from {Company Name} is a strategic decision that will yield long-term benefits and success.

Polyurethane Belt Welding Machine for Seamless Connectors - 220V, Temperature Range of 180-200 Degrees, Achieves Perfect Belt Forming

BAOSHISHAN PU Round Belt Welding Machine: The New Revolution in Polyurethane Belt Hot Melt TechnologyBAOSHISHAN, a leading technology company that specializes in the development of advanced welding machines, has recently released a new product on the market - the PU Round Belt Welding Machine. This machine is designed to weld polyurethane round belts using a hot melt process, thus providing a much stronger and more efficient connection between the belts.The machine is made from the highest quality materials and is available in several different models, each with its own unique features and capabilities. Regardless of which model you choose, you can be sure that your welding projects will be completed quickly and efficiently, with minimal downtime and high-quality results.One of the most significant advantages of the BAOSHISHAN PU Round Belt Welding Machine is its temperature range. The welding machine usually ranges from 180 to 200 degrees Celsius, which is perfect for welding polyurethane belts without damaging them. This ensures that your belts will remain strong and durable, even after years of continuous use.Another feature that sets the PU Round Belt Welding Machine apart from its competitors is its belt forming effect. With this machine, you can easily form belts into a perfect circle, which gives them a cleaner and more professional look. Plus, this feature guarantees a much tighter connection between the belts, ensuring that they stay in place even under heavy loads.The machine is also very versatile, making it suitable for use in a wide range of industries, including automotive, packaging, construction, and many more. Whether you need to weld belts for conveyor systems, packaging machines, or industrial equipment, the BAOSHISHAN PU Round Belt Welding Machine can handle it all.Furthermore, the machine is incredibly easy to use, thanks to its simple design and intuitive controls. Even if you're not familiar with welding machines, you'll be able to operate this machine with ease, thanks to its user-friendly interface and detailed instructions.In conclusion, the BAOSHISHAN PU Round Belt Welding Machine is an excellent choice for anyone looking to improve the quality and durability of their polyurethane belts. With its advanced features, high-quality materials, and ease of use, this machine is sure to exceed your expectations and provide you with the best possible results. So why wait? Order your BAOSHISHAN PU Round Belt Welding Machine today and experience the new revolution in polyurethane belt hot melt technology!

Laser Cutting Job Opening in Dudley, UK: Apply Now with ASC Connections!

If you're looking for a job in the engineering and manufacturing sectors, then the Laser Cutter job with ASC Connections Ltd could be the perfect opportunity for you. Located in Dudley, UK, this job is ideal for those who have experience in using steel laser cutters and are looking for a challenging and rewarding role.The use of laser cutters is becoming increasingly popular in the engineering and manufacturing industries due to their accuracy, speed, and versatility. Steel laser cutters can cut through a variety of materials, including steel, aluminum, and copper, making them an essential tool for producing precision parts and components.As a Laser Cutter with ASC Connections Ltd, you will be responsible for operating and maintaining the steel laser cutter to produce high-quality parts. You will be required to read and follow technical drawings and specifications, and have a good understanding of CNC programming. You may also be required to carry out minor repairs and adjustments to ensure the laser cutter is operating at maximum efficiency.To be successful in this role, you will need to have experience in using steel laser cutters, a good understanding of engineering principles, and excellent attention to detail. You will also need to be a good communicator and work well as part of a team.This Laser Cutter job with ASC Connections Ltd offers an excellent salary package and opportunities for career development within the company. You will be working in a modern and well-equipped manufacturing facility, alongside a team of experienced engineers and technicians.If you're looking to take your career in the engineering and manufacturing industries to the next level, then this Laser Cutter job with ASC Connections Ltd could be the perfect opportunity for you. Apply today and take the first step towards a challenging and rewarding career in this exciting sector.

New CO2 Laser Cutting Machine Revolutionizes Manufacturing Processes

[Company Introduction][Company name], a renowned leader in the laser cutting industry, has recently launched its latest product, the CNC CO2 Laser Cutting Machine. With years of experience and expertise in manufacturing high-quality laser cutting equipment, [Company name] continues to revolutionize the industry with its cutting-edge technology and innovative solutions.The CNC CO2 Laser Cutting Machine is a powerful tool that offers precision cutting, accuracy, and high efficiency for various materials, including metals, plastics, wood, and more. With its advanced CO2 laser technology, this cutting-edge machine provides users with unmatched capabilities to handle a wide range of cutting applications. From intricate designs to large-scale productions, this machine guarantees exceptional results.[Company name]'s commitment to delivering excellence can be seen through its use of high-quality components and advanced systems. The CNC CO2 Laser Cutting Machine is equipped with the latest motion control technology, ensuring smooth and precise movements during the cutting process. The machine's excellent stability and durability enable users to achieve consistent, high-quality cuts with minimal wastage.Furthermore, the CNC CO2 Laser Cutting Machine is designed with user-friendly features that streamline the overall cutting process. Its intuitive control panel allows operators to easily navigate and adjust settings, ensuring maximum productivity and efficiency. The machine's automatic material detection and focusing system further enhance its usability, making it ideal for both experienced professionals and beginners.The versatility of the CNC CO2 Laser Cutting Machine is another standout feature. With its wide variety of compatible materials, businesses from various industries can benefit from its capabilities. Whether for signage, automotive parts, prototype development, or any other cutting needs, this machine offers the flexibility to meet diverse requirements. Its precise cutting also reduces the need for further finishing processes, saving time and resources.In addition to its exceptional performance, the CNC CO2 Laser Cutting Machine prioritizes user safety. It is built with comprehensive safety features, including protective enclosures and sensors that prevent accidental exposure to the laser beam. This ensures a secure working environment for operators.[Company name] stands apart from its competitors through its commitment to customer satisfaction. The company is known for its excellent customer service, providing comprehensive technical support, training, and after-sales maintenance. Customers can rely on their expertise throughout the entire lifecycle of their CNC CO2 Laser Cutting Machine.The launch of the CNC CO2 Laser Cutting Machine marks another milestone for [Company name] as it continues to innovate and excel in the laser cutting industry. The machine's exceptional capabilities, user-friendly design, and commitment to safety make it the ideal choice for businesses looking to enhance their cutting operations.With [Company name]'s CNC CO2 Laser Cutting Machine, businesses can expect increased productivity, improved precision, and cost-effective cutting solutions. By investing in this state-of-the-art technology, users can stay ahead in today's competitive market and achieve remarkable results in their cutting applications.About [Company name]:[Company name] is a leading manufacturer in the laser cutting industry, specializing in the production of high-quality laser cutting machines for various materials. With years of experience, advanced technology, and a commitment to customer satisfaction, the company continues to deliver cutting-edge solutions that exceed expectations. For more information about [Company name] and its products, visit [company website].

High Precision Cnc Router Machine for Woodworking and Metal Fabrication

The 6090 CNC router machine is a cutting-edge piece of equipment that has revolutionized the manufacturing industry. This machine is designed to provide high precision and efficiency in cutting, carving, and milling various materials such as wood, plastic, and metal. With its advanced technology and capabilities, it has become an indispensable tool for many manufacturing companies around the world.The 6090 CNC router machine, manufactured by {}, is known for its superior quality and performance. Equipped with a high-speed spindle and a rigid frame, this machine is capable of handling a wide range of materials with ease. Its precision and accuracy make it ideal for intricate designs and complex patterns, making it a valuable asset for companies in the furniture, sign-making, and prototype industries.One of the key features of the 6090 CNC router machine is its user-friendly interface, which allows operators to easily program and control the machine for various cutting and carving tasks. Whether it's a small-scale production or a large-scale manufacturing project, this machine can be customized to meet the specific needs of the business, offering flexibility and versatility.In addition, the 6090 CNC router machine is equipped with advanced software that enables 3D modeling and simulation, allowing users to visualize the end product before the actual production process. This not only reduces the risk of errors but also enhances the overall efficiency of the manufacturing process.With its cutting-edge technology and reliable performance, the 6090 CNC router machine has garnered praise and recognition from professionals in the industry. Many companies have reported significant improvements in their production processes, thanks to the precision and speed offered by this machine. As a result, it has become a popular choice for businesses looking to enhance their manufacturing capabilities and stay ahead of the competition.Furthermore, the 6090 CNC router machine is backed by exceptional customer support and service from {}. Their team of experts is dedicated to providing assistance with installation, training, and ongoing maintenance, ensuring that businesses can maximize the benefits of this machine for years to come.In conclusion, the 6090 CNC router machine has set a new standard in the manufacturing industry with its advanced technology and exceptional performance. As businesses strive to improve their production processes and deliver high-quality products, this machine has become an essential tool for achieving success. With its precision, efficiency, and versatility, it has become a game-changer for many companies, paving the way for innovation and growth in the manufacturing sector.