Top CNC Router for Wood and Metal: A Comprehensive Guide

By:Admin

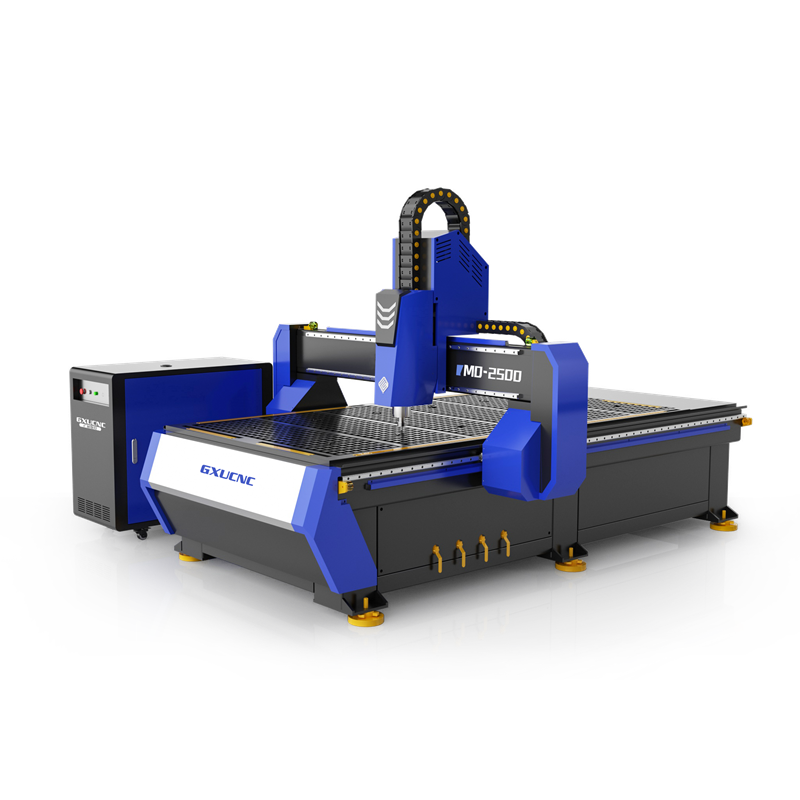

[Company Name], a pioneer in the manufacturing of advanced machinery for the woodworking and metalworking industries, has introduced a cutting-edge CNC router designed to revolutionize the way wood and metal components are fabricated. The new CNC router has been meticulously engineered to deliver unparalleled precision, speed, and versatility, making it an indispensable tool for businesses seeking to enhance their production capabilities.

The CNC router is equipped with state-of-the-art features that enable it to handle a wide range of materials with exceptional accuracy. Its robust construction and high-quality components ensure reliable performance and longevity, making it a valuable asset for businesses of all sizes. Whether it's creating intricate wooden designs or precise metal parts, this CNC router offers the flexibility and efficiency needed to meet the demands of modern manufacturing.

One of the key highlights of the CNC router is its advanced cutting technology, which allows for intricate designs and complex shapes to be achieved with precision. This is especially beneficial for industries such as furniture manufacturing, cabinetry, and metal fabrication, where intricate details and custom designs are often required. With the ability to effortlessly cut, carve, and shape various materials, this CNC router empowers businesses to bring their creative visions to life with ease.

In addition to its cutting capabilities, the CNC router is also equipped with advanced software that streamlines the programming and operation process. This user-friendly interface simplifies the design and production workflow, allowing operators to efficiently manage their projects and maximize productivity. Its intuitive controls and customizable settings provide a seamless user experience, making it accessible to both experienced professionals and newcomers to CNC technology.

Furthermore, the CNC router boasts a high-speed spindle that delivers exceptional performance and precision. This allows for rapid material removal and smooth surface finishes, ensuring that production deadlines are met without compromising on quality. Its ability to handle a variety of cutting tasks with speed and accuracy makes it a valuable asset for businesses looking to optimize their production processes.

The CNC router's versatility extends to its compatibility with a wide range of tooling options, allowing businesses to adapt to different manufacturing requirements with ease. Whether it's cutting, drilling, milling, or engraving, this CNC router offers the flexibility to accommodate various applications, making it a cost-effective solution for multi-purpose production needs. Its ability to seamlessly transition between different tooling tasks makes it an efficient and reliable choice for businesses seeking to diversify their manufacturing capabilities.

With a focus on precision, speed, and versatility, [Company Name]'s new CNC router is poised to set a new standard for wood and metal fabrication. Its innovative technology and advanced features make it a valuable investment for businesses looking to enhance their production capabilities and stay ahead of the competition. As the industry continues to evolve, this CNC router stands as a testament to [Company Name]'s commitment to delivering cutting-edge solutions that empower businesses to achieve their manufacturing goals.

In conclusion, the introduction of the new CNC router for wood and metal by [Company Name] represents a significant advancement in manufacturing technology. With its advanced features, user-friendly interface, and exceptional performance, this CNC router is poised to revolutionize the way wood and metal components are fabricated. As businesses continue to embrace digital automation and precision manufacturing, [Company Name] remains at the forefront of innovation, providing the tools and solutions needed to drive the industry forward.

Company News & Blog

Affordable Laser Welding Machine: Price and Specifications

Laser welding technology has been making waves in the manufacturing industry due to its precision, speed, and cost-effectiveness. As a result, the demand for high-quality laser welding machines has been on the rise. However, the high price of these machines has been a barrier for many small and medium-sized businesses.In response to this demand, a leading laser welding machine manufacturer has announced a new, competitively priced machine that aims to make laser welding technology more accessible to a wider range of businesses.The new [Company Name] Laser Welding Machine is designed to meet the needs of businesses looking for a reliable and affordable solution for their welding processes. Despite its competitive price, the machine does not compromise on quality or performance. It offers high precision welding, fast processing speeds, and a user-friendly interface, making it suitable for a variety of applications in industries such as automotive, aerospace, electronics, and medical device manufacturing.[Company Name] has a strong reputation in the industry for providing innovative and high-quality laser welding solutions. With over [number] years of experience, the company has established itself as a trusted partner for businesses looking to improve their manufacturing processes.The new laser welding machine is the result of [Company Name]'s commitment to continuous research and development. The company's team of engineers and researchers have worked tirelessly to develop a machine that meets the needs of the market while also being cost-effective. By leveraging their expertise in laser technology, the company has been able to offer a solution that is both affordable and high-performing.In addition to its competitive price, the new laser welding machine also comes with [Company Name]'s renowned customer support and service. The company is known for its dedication to providing ongoing technical support, training, and maintenance services to its customers. This ensures that businesses can rely on their investment for years to come, with the assurance of continued assistance whenever needed.The introduction of the new laser welding machine is expected to have a significant impact on the manufacturing industry. By lowering the barrier to entry for laser welding technology, more businesses will be able to take advantage of the benefits it offers. This includes improved weld quality, reduced production time, and overall cost savings in the long run.As a result, [Company Name] expects to see an increase in demand for their laser welding machines from a wider range of businesses. This will not only benefit the company but also contribute to the overall growth and advancement of the manufacturing industry.In conclusion, the new competitively priced laser welding machine from [Company Name] is set to make a positive impact on the manufacturing industry. By providing businesses with an affordable yet high-quality solution, the company is helping to democratize access to laser welding technology. This will ultimately lead to improved efficiency, quality, and competitiveness for businesses that adopt this innovative solution.

High-precision Three Axis Milling Machine for Industrial Use

The Three Axis Milling Machine is an advanced piece of equipment that has greatly improved the efficiency and precision of the manufacturing process. With its ability to accurately cut and shape materials in three dimensions, this machine has become an essential tool for many industries.Manufactured by a leading machinery company, this Three Axis Milling Machine incorporates cutting-edge technology and innovative design to provide users with the highest level of performance and reliability. Whether it is used for prototyping, production, or custom machining, this machine has proven to be a valuable asset for businesses looking to streamline their manufacturing operations.One of the key features of the Three Axis Milling Machine is its precision and accuracy. The machine is equipped with state-of-the-art control systems and sensors that ensure the exact replication of programmed designs. This level of precision is essential for the manufacturing of parts and components that require tight tolerances and intricate shapes.Furthermore, the Three Axis Milling Machine is designed for versatility and flexibility. Its advanced software allows for the seamless integration of complex designs, and its multi-axis cutting capabilities enable the production of intricate parts with ease. Whether it is used for milling, drilling, or cutting, this machine can handle a wide variety of materials, including metals, plastics, and composites.The Three Axis Milling Machine also offers a high level of efficiency and productivity. Its automated features and rapid tool changing capabilities allow for quick and uninterrupted machining, reducing production times and increasing throughput. This means that businesses can produce more parts in less time, ultimately leading to increased profitability and competitiveness in the market.In addition to its performance and capabilities, the Three Axis Milling Machine is also designed with user-friendly features that make it easy to operate and maintain. Its intuitive interface and programming software allow for simple set-up and operation, while its robust construction and durable components ensure long-term reliability and minimal downtime.Overall, the Three Axis Milling Machine has had a significant impact on the manufacturing industry, helping businesses improve their production processes and deliver high-quality products to their customers. Its precision, versatility, efficiency, and user-friendly design make it a valuable asset for any company looking to stay ahead in the fast-paced world of modern manufacturing.As a leading machinery company, we are committed to providing our customers with the highest quality equipment and solutions to meet their manufacturing needs. Our Three Axis Milling Machine is a prime example of our dedication to innovation and excellence, and we are proud to offer this advanced technology to businesses around the world.With our extensive experience and expertise in the industry, we have developed a reputation for delivering reliable and cutting-edge machinery that helps our customers achieve their production goals. Our Three Axis Milling Machine is just one of the many products in our comprehensive lineup of machining solutions, and we are confident that it will continue to make a positive impact on the manufacturing sector.In conclusion, the Three Axis Milling Machine is a game-changing piece of equipment that has revolutionized the manufacturing process. Its precision, versatility, efficiency, and user-friendly design have made it an invaluable tool for businesses of all sizes. As a leading machinery company, we are proud to offer this advanced technology to our customers and help them stay ahead in the competitive world of modern manufacturing.

Top-rated CNC Wood Cutting Machine Manufacturers & Suppliers in China - Affordable Prices - Unistar Machinery

article.Unistar Machinery is a well-known CNC wood cutting machine manufacturer and supplier in China. Based in the city of Jinan, Unistar Machinery has built a reputation for its high-quality CNC machines and competitive prices. With a wide range of CNC wood cutting machines on offer, Unistar Machinery has become a popular choice for woodworkers and carpenters across the globe.One of the key advantages of Unistar Machinery is their ability to offer factory direct prices. This eliminates the need for middlemen, making it possible for customers to purchase high-quality CNC wood cutting machines at affordable prices. This is a particularly important selling point for small businesses and hobbyists who may not have the financial resources to invest in expensive machines.In addition to providing quality machines at competitive prices, Unistar Machinery is also known for their commitment to customer service. The company invests heavily in research and development to ensure that they are always offering the latest and most advanced CNC wood cutting machines. They also provide comprehensive training and support to their customers to ensure that they are able to make the most of their investments.One of the most popular machines offered by Unistar Machinery is their CNC router. This machine is designed for precision cutting and engraving of a wide range of materials including wood, plastic, and metal. The CNC router is capable of cutting complex designs with ease, making it an ideal choice for small to medium businesses who need to create high-quality products on a regular basis.Another popular machine is the CNC plasma cutting machine. This machine is designed for cutting metal, and is ideal for manufacturing businesses who need to cut large quantities of metal quickly and accurately. The CNC plasma cutting machine is also highly customizable, allowing businesses to set up their machines to meet their specific needs.Unistar Machinery also offers a range of other CNC machines, including CNC laser cutting machines, CNC engraving machines, and CNC woodworking machines. Each of these machines is designed to meet specific needs, and can be customized to fit individual requirements.Overall, Unistar Machinery is a reliable and trusted supplier of high-quality CNC wood cutting machines. With a commitment to customer satisfaction, competitive prices, and cutting-edge technology, Unistar Machinery is a great choice for anyone looking to invest in a CNC wood cutting machine. Whether you are a small business, hobbyist, or large manufacturing firm, Unistar Machinery has a machine that will meet your needs. Contact them today to learn more about their products and services.

10 Unique and Creative CNC Carving Projects for Your Next DIY Project

CNC Carving Projects has become an increasingly popular method for creating intricate and detailed designs in a variety of materials. From wood to plastic to metal, CNC carving technology has opened up a world of creative possibilities for artists, designers, and hobbyists alike. One company at the forefront of this cutting-edge technology is {Company Name}. With a wealth of experience and expertise in CNC carving, {Company Name} has been at the forefront of providing high-quality CNC carving products and services to clients around the world.CNC carving, also known as computer numerical control carving, is a process that uses computer software to guide the movement of a cutting tool to produce a three-dimensional design. This technology allows for precise and repetitive carving, making it an ideal choice for projects that require intricate detailing and complex shapes.The applications for CNC carving are diverse and wide-ranging. From creating custom furniture pieces to crafting intricate signage, CNC carving projects have become a staple in a variety of industries. Additionally, the ability to work with a wide range of materials has further expanded the possibilities for CNC carving, making it an indispensable tool for artists, craftsmen, and manufacturers.For {Company Name}, CNC carving projects have been a cornerstone of their business. With a state-of-the-art facility and a team of skilled technicians, they have the capability to bring even the most complex designs to life. Their dedication to quality and attention to detail has earned them a reputation as a leader in the field of CNC carving.One of the key strengths of {Company Name} lies in their ability to work closely with clients to bring their vision to reality. Whether it's a custom woodworking project or a prototype for a new product, their team is committed to delivering results that exceed expectations. By leveraging their expertise in CNC carving, they can offer a level of precision and accuracy that is unmatched in the industry.In addition to their superior craftsmanship, {Company Name} also places a strong emphasis on sustainability and environmental responsibility. With a focus on using eco-friendly materials and implementing green practices in their manufacturing processes, they are dedicated to minimizing their impact on the environment. This commitment to sustainability has not only resonated with clients but has also positioned them as an industry leader in responsible manufacturing.As CNC carving technology continues to evolve, {Company Name} remains at the forefront of innovation. They continuously invest in the latest equipment and software to ensure that they are able to deliver the highest quality results for their clients. With a commitment to staying ahead of the curve, they are well-positioned to continue meeting the evolving needs of the market.The future looks bright for CNC carving projects, and {Company Name} is poised to remain a driving force in this dynamic industry. With their unwavering dedication to quality, innovation, and sustainability, they are well-equipped to tackle even the most challenging CNC carving projects. As the demand for custom, high-quality craftsmanship continues to grow, {Company Name} stands ready to meet the needs of clients across the globe.In conclusion, CNC carving projects have become a staple in the world of design and manufacturing, and {Company Name} has established itself as a leader in this field. With their unwavering commitment to quality, innovation, and sustainability, they are well-equipped to continue pushing the boundaries of what's possible with CNC carving technology. As they look towards the future, it's clear that {Company Name} will remain a driving force in the world of CNC carving projects.

Sale Begins for New Type of CNC Milling Machine: 3D Cutting Technology

Possible article:New Desktop CNC Milling Machine Enables Precision Prototyping and Small-Scale ProductionSan Francisco-based company has released a new version of its desktop CNC milling machine, which allows users to create complex designs from a wide variety of materials. The Othermill Pro improves on the original Othermill model, adding faster spindle speeds, larger working volume, and more advanced software features. With its compact size and user-friendly interface, the Othermill Pro is suitable for both professional makers and hobbyists who want to turn their ideas into physical objects with high accuracy and detail.The Othermill Pro is a type of subtractive manufacturing technology, which means that it removes material from a block or sheet of material through cutting, drilling, and engraving. This differs from additive manufacturing, such as 3D printing, which builds up layers of material to form a shape. While 3D printing has become popular for prototyping and customization, CNC milling machines are preferred for producing precise parts, molds, and fixtures that require tight tolerances, smooth surfaces, and dimensional stability.The Othermill Pro can work with a range of materials, including aluminum, brass, copper, Delrin, FR-1/4, polycarbonate, acrylic, and various types of wood and circuit board substrates. It uses a 1/8 end mill to carve out geometries from 2D or 3D CAD files, which can be imported from common design software such as Autodesk Fusion 360, Eagle PCB, and KiCAD. The spindle of the machine can rotate at speeds up to 10,000 RPM, allowing for fast and efficient machining of parts.One key feature of the Othermill Pro is its automatic tool calibration system, which enables the machine to adjust the height and position of the cutting tool based on the thickness and flatness of the material. This ensures that the milling process is accurate and consistent, even when working with irregular or non-uniform surfaces. The machine also has a built-in dust collection system, which collects debris and prevents the workspace from getting messy or hazardous.The Othermill Pro comes with a software package that is designed to be user-friendly and intuitive, even for those with little or no experience in CNC milling. The software allows users to import their designs, select the material type and thickness, set the cutting parameters, preview the toolpath, and simulate the machining process. The software also includes features such as engraving, pocketing, drilling, and chamfering, as well as the ability to create PCB traces and pads for electronics projects.According to the company, the Othermill Pro is ideal for prototyping, research and development, small-batch manufacturing, and even educational purposes. It can be used to make precision mechanical parts, artistic sculptures, custom jewelry, signage, molds for casting, and electronic circuits. The machine is also compatible with a range of fixtures and clamps, which allow for secure and efficient material handling. With its quiet operation, compact footprint, and stylish design, the Othermill Pro can fit into any workspace or home lab.The Othermill Pro is available for purchase on the website and through authorized resellers. The machine comes with a one-year warranty and free technical support, as well as a starter kit that includes cutting tools, materials, and accessories. The company also offers online tutorials, forums, and user community resources to help users get the most out of their machine. With the release of the Othermill Pro, aims to empower makers and inventors to turn their ideas into reality, one precision cut at a time.

Versatile Woodworking Machine for Multiple Uses

Multi Use Woodworking Machine Revolutionizing the IndustryIn recent years, the woodworking industry has seen a significant shift towards more efficient and versatile woodworking machines. One such machine that has been making waves in the industry is the Multi Use Woodworking Machine from {}. This innovative piece of equipment has revolutionized the way woodworkers approach their craft, offering a wide range of functions and capabilities that were previously only possible with multiple machines.The Multi Use Woodworking Machine is the brainchild of {}, a leading manufacturer of woodworking machinery with a reputation for innovation and quality. With over 30 years of experience in the industry, {} has consistently pushed the boundaries of what is possible in woodworking machinery, and the Multi Use Woodworking Machine is a testament to their dedication to advancing the industry.So, what exactly sets the Multi Use Woodworking Machine apart from traditional woodworking machines? The answer lies in its versatility and functionality. This all-in-one machine is capable of performing a wide range of woodworking tasks, including planing, sawing, drilling, and shaping. This means that woodworkers no longer need to invest in multiple machines to achieve the same results, saving both space and money in their workshops.Not only does the Multi Use Woodworking Machine offer a wide range of functions, but it also does so with precision and efficiency. The machine is equipped with advanced technology that allows for highly accurate and consistent results, making it ideal for both professional woodworkers and hobbyists alike. With the ability to handle both small-scale and large-scale projects, this machine is truly versatile and adaptable to the needs of any woodworker.In addition to its impressive capabilities, the Multi Use Woodworking Machine is also designed with user convenience in mind. Its intuitive interface and user-friendly controls make it easy to operate, even for those new to woodworking machinery. This accessibility has been a key factor in the machine's widespread adoption, as it has helped to democratize advanced woodworking capabilities for a wider audience.Furthermore, the Multi Use Woodworking Machine is built to last, with a durable construction and high-quality components that ensure years of reliable performance. This reliability is further backed by {}'s commitment to customer support and service, ensuring that woodworkers can rely on their machine for years to come.With its combination of versatility, precision, and user-friendly design, the Multi Use Woodworking Machine has quickly become a game-changer in the woodworking industry. It is no surprise that woodworkers around the world are singing its praises, touting its ability to streamline their workflow and expand their creative possibilities.Looking ahead, the future of woodworking machinery is sure to be shaped by innovative products like the Multi Use Woodworking Machine. As technology continues to advance and industry demands evolve, companies like {} will continue to lead the charge in developing cutting-edge solutions that empower woodworkers to achieve more than ever before.In conclusion, the Multi Use Woodworking Machine from {} is a true game-changer in the woodworking industry. Its versatility, precision, and user-friendly design have set a new standard for woodworking machinery, offering woodworkers a powerful tool for bringing their creative visions to life. As the industry continues to evolve, products like the Multi Use Woodworking Machine are sure to play a pivotal role in shaping its future.

High-Performance Fiber Cutting Machine for Efficient Production

The Fiber Cutting Machine (name removed for privacy) has become a game-changer in the world of manufacturing, enabling companies to increase efficiency and precision in their production processes. This advanced technology is revolutionizing the way industries cut materials such as metal, wood, and plastic, and is quickly becoming a staple in modern manufacturing facilities.The Fiber Cutting Machine is designed and manufactured by a leading company in the industry, which has been at the forefront of innovation for decades. With a strong commitment to research and development, this company has continuously pushed the boundaries of what is possible in the realm of industrial machinery. Their expertise in engineering and designing cutting-edge solutions has earned them a prominent position in the global market, with a reputation for delivering high-quality products that exceed customer expectations.The Fiber Cutting Machine is a testament to the company's dedication to excellence, boasting a range of features that set it apart from traditional cutting methods. Its advanced laser technology allows for incredibly precise and clean cuts, with the ability to work on a wide variety of materials with ease. The machine's high-speed cutting capabilities make it ideal for large-scale production, allowing for rapid and efficient processing of materials without sacrificing accuracy.One of the standout features of the Fiber Cutting Machine is its versatility. Unlike traditional cutting tools, this machine is able to handle complex and intricate designs with ease, opening up new possibilities for manufacturers looking to push the boundaries of what they can create. Whether it's intricate metal parts for the aerospace industry or detailed wooden components for furniture production, the Fiber Cutting Machine is up to the task, delivering results that were once thought to be unattainable.Furthermore, the Fiber Cutting Machine offers significant advantages in terms of cost savings and environmental impact. With its precise cutting capabilities, this machine minimizes material waste, helping companies to maximize their resources and reduce their environmental footprint. Additionally, its high-speed performance means faster production times, which can directly translate to increased efficiency and cost-effectiveness for businesses.In addition to its technical capabilities, the Fiber Cutting Machine is also designed with user-friendliness in mind. The company has incorporated intuitive controls and interface, making it easy for operators to program and operate the machine, minimizing the need for extensive training or specialized skills. This accessibility makes the Fiber Cutting Machine an attractive option for a wide range of industries, from small-scale operations to large manufacturing facilities.The impact of the Fiber Cutting Machine is already being felt across various sectors, with companies reporting significant improvements in their production processes since adopting this technology. From increased productivity to enhanced product quality, the machine has proven to be a valuable asset for businesses looking to stay ahead in a competitive market.Looking ahead, the company behind the Fiber Cutting Machine is committed to further innovation, with ongoing research and development efforts aimed at pushing the boundaries of what the machine can achieve. Through continuous improvement and a dedication to meeting the evolving needs of their customers, this company is poised to remain a leader in the industry for years to come.In conclusion, the Fiber Cutting Machine represents a significant leap forward in manufacturing technology, offering unprecedented precision, efficiency, and versatility. With a company behind it that is dedicated to excellence and innovation, this machine is poised to revolutionize the way industries across the globe approach the cutting and shaping of materials. As the demand for high-quality, efficient production continues to rise, the Fiber Cutting Machine is set to play a pivotal role in shaping the future of manufacturing.

Premium Woodworking Machine for All Your Woodworking Needs

Introducing the Latest Universal Woodworking MachineWoodworking has been an essential craft for centuries, and as technology has advanced, so have the tools and machines used in the industry. The latest innovation in woodworking machinery comes from {Company Name}, a leading manufacturer of high-quality industrial and commercial equipment.The new Universal Woodworking Machine is set to revolutionize the woodworking industry with its cutting-edge features and innovative design. This versatile machine is capable of performing a wide range of woodworking tasks, making it an essential addition to any woodworking workshop or factory.One of the key features of the Universal Woodworking Machine is its ability to handle multiple woodworking processes in a single, compact unit. This includes planing, sawing, drilling, and shaping, reducing the need for multiple machines and streamlining the woodworking process. By combining these functions into one machine, {Company Name} has created a space-saving and efficient solution for woodworking professionals.In addition to its versatility, the Universal Woodworking Machine is built to the highest standards of quality and durability. The machine is constructed from heavy-duty materials and features precision-engineered components, ensuring reliable performance and long-term reliability. With proper maintenance and care, this machine is built to last, making it a sound investment for any woodworking business.Furthermore, the Universal Woodworking Machine is designed with user-friendliness in mind. The controls and interface are intuitive and easy to use, allowing operators to quickly and efficiently switch between different woodworking processes. This not only improves productivity but also reduces the need for extensive training and skill development, making it accessible to woodworking professionals of all levels.{Company Name} has a long-standing reputation for producing high-quality industrial and commercial equipment, and the Universal Woodworking Machine is no exception. With a commitment to excellence and a focus on innovation, the company has positioned itself as a leader in the woodworking machinery market. Their products are trusted by woodworking professionals around the world, and the new Universal Woodworking Machine is sure to continue this tradition of excellence.With the introduction of the Universal Woodworking Machine, {Company Name} is setting a new standard for woodworking machinery. This versatile and efficient machine is a game-changer for woodworking professionals, providing a comprehensive solution for a wide range of woodworking tasks. Whether it's in a small workshop or a large-scale production facility, this machine is set to enhance productivity and streamline operations.In conclusion, the Universal Woodworking Machine from {Company Name} represents the future of woodworking machinery. Its versatility, durability, and user-friendly design make it an essential addition to any woodworking workshop or factory. With a commitment to quality and innovation, {Company Name} continues to lead the way in the woodworking machinery industry, and the Universal Woodworking Machine is the latest example of their dedication to excellence.

High-Quality Laser Cutting Machine for Leather

[Company Name], a leading manufacturer of advanced manufacturing equipment, has recently unveiled its latest product, the Leather Laser Cutting Machine. This cutting-edge machine is set to revolutionize the leather cutting industry with its precision and efficiency.The Leather Laser Cutting Machine is equipped with advanced laser technology, which allows for high-precision cutting of various types of leather. This machine is designed to meet the growing demand for high-quality leather products in the fashion, automotive, and furniture industries.With a cutting speed of up to 1000mm/s and an accuracy of ±0.01mm, the Leather Laser Cutting Machine ensures that every piece of leather is cut with the utmost precision. This level of precision is crucial in the leather industry, where even the smallest deviation can result in significant wastage and loss of material.In addition to its precision cutting capabilities, the Leather Laser Cutting Machine also offers a high level of flexibility. It can handle a wide range of leather thicknesses, from the thinnest lambskin to the thickest cowhide, making it suitable for a variety of applications.Furthermore, the machine is equipped with a user-friendly interface, allowing for easy operation and control. This means that even operators with minimal training can quickly learn to operate the machine, resulting in increased productivity and efficiency.The Leather Laser Cutting Machine is also designed with safety in mind. It features a range of safety features, including a protective enclosure and sensors to ensure the safety of the operators.According to [Company Name] spokesperson, "The Leather Laser Cutting Machine is the result of years of research and development. We have incorporated the latest advancements in laser technology to create a machine that meets the needs of the modern leather industry. We are confident that this machine will set a new standard for leather cutting technology."The Leather Laser Cutting Machine is expected to have a significant impact on the leather industry. Its high precision and efficiency will enable manufacturers to produce higher quality leather products in less time, ultimately reducing production costs and increasing profitability.In addition to its cutting-edge technology, [Company Name] is also known for its exceptional customer service and support. The company provides comprehensive training and technical support to ensure that its customers get the most out of their investment in the Leather Laser Cutting Machine.As the demand for high-quality leather products continues to grow, the Leather Laser Cutting Machine is set to become an essential tool for manufacturers in the industry. Its precision, efficiency, and flexibility make it a valuable asset for companies looking to stay ahead of the competition.With the unveiling of the Leather Laser Cutting Machine, [Company Name] once again demonstrates its commitment to pushing the boundaries of manufacturing technology. This latest innovation is set to solidify the company's position as a leader in the advanced manufacturing equipment industry.In conclusion, the Leather Laser Cutting Machine from [Company Name] is set to revolutionize the leather cutting industry with its precision and efficiency. With its cutting-edge technology and user-friendly design, this machine is the perfect solution for manufacturers looking to stay ahead of the competition in the growing leather industry.

Customizable CNC Carving Services for Your Business Needs

CNC Carving: Revolutionizing Manufacturing ProcessesIn the rapidly evolving world of manufacturing, there is a constant demand for innovative solutions that can enhance efficiency, precision, and productivity. One such solution that has been gaining significant traction in recent years is CNC carving. This advanced technology has been revolutionizing the way products are designed and manufactured, offering unparalleled precision and flexibility in the production process.CNC (Computer Numerical Control) carving is a sophisticated manufacturing technique that utilizes computer-aided design (CAD) software to create highly detailed and intricate designs on various materials such as wood, plastic, metal, and composites. The process involves using a computer-controlled machine equipped with cutting tools to precisely carve out the desired design from the material, resulting in a finished product with exceptional accuracy and consistency.At the forefront of this cutting-edge technology is {company name}, a leading provider of CNC carving solutions for a wide range of industries. With a rich history of innovation and excellence, {company name} has established itself as a trusted partner for businesses looking to incorporate CNC carving into their manufacturing processes.{company name} offers a diverse portfolio of CNC carving machines that are designed to meet the unique needs of different industries. From small-scale desktop machines for hobbyists and craftsmen to large-scale industrial systems for mass production, {company name} provides a comprehensive range of solutions to suit various applications. The company's commitment to delivering high-quality, reliable, and user-friendly machines has earned it a reputation for excellence in the industry.One of the key advantages of CNC carving is its ability to automate and streamline the manufacturing process, thereby reducing production time and costs. By utilizing CAD software to design intricate patterns and shapes, manufacturers can produce highly detailed and complex products with minimal manual intervention. This level of precision and efficiency is particularly valuable in industries such as aerospace, automotive, furniture, and signage, where intricate designs and tight tolerances are paramount.Furthermore, CNC carving offers unparalleled flexibility in terms of design capabilities. With the ability to program the machine to create complex geometric shapes and patterns, manufacturers can bring even the most intricate designs to life with ease. This level of versatility opens up a world of possibilities for product customization and personalization, allowing businesses to cater to the unique needs and preferences of their customers.In addition to its precision and flexibility, CNC carving also offers significant improvements in material utilization. By optimizing the cutting process to minimize waste, manufacturers can maximize the yield from raw materials, resulting in cost savings and environmental benefits. This level of efficiency is crucial for businesses looking to minimize their environmental footprint and operate in a sustainable manner.As the demand for custom, high-quality products continues to grow, the adoption of CNC carving technology is expected to rise across various industries. Whether it's creating intricate wooden furniture, precision-cut metal parts, or personalized signage, CNC carving offers a level of craftsmanship and precision that is unparalleled by traditional manufacturing methods.With its commitment to innovation, quality, and customer satisfaction, {company name} is poised to play a key role in driving the widespread adoption of CNC carving technology. As the manufacturing landscape continues to evolve, businesses looking to stay ahead of the curve will undoubtedly turn to CNC carving as a game-changing solution for producing high-quality, customized products efficiently and cost-effectively.In conclusion, CNC carving is reshaping the manufacturing industry by offering a level of precision, flexibility, and efficiency that is unmatched by traditional methods. With {company name} leading the way in providing state-of-the-art CNC carving solutions, businesses across various industries can look forward to achieving new levels of productivity and excellence in their manufacturing processes. As the technology continues to advance and evolve, the possibilities for innovation and creativity in product design are truly limitless.