Precision Engraving and Cutting Machine for High-Quality Results

By:Admin

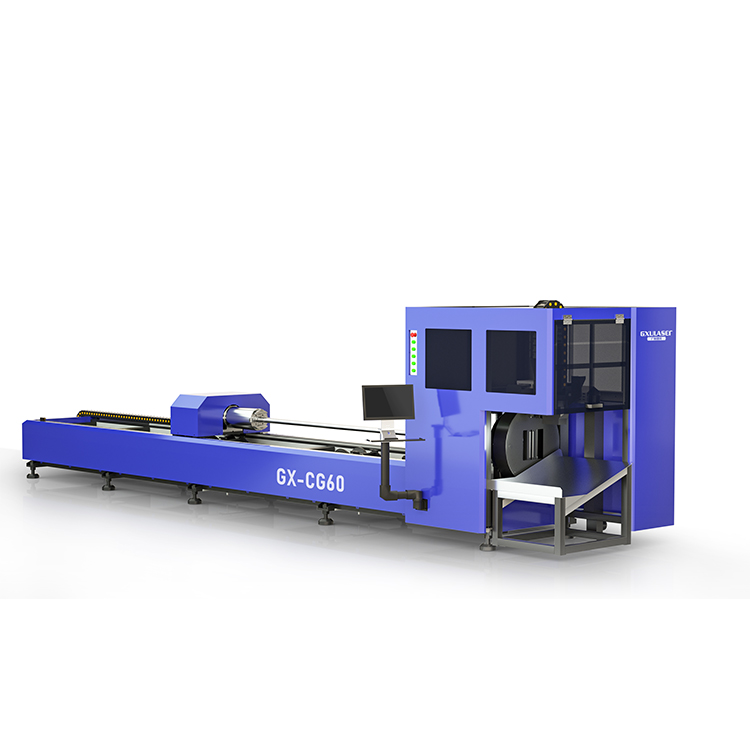

In today's fast-paced manufacturing industry, the demand for innovative and efficient machinery is constantly increasing. As businesses strive to stay ahead of the competition, the need for advanced technology that can enhance productivity and precision has become essential. With this in mind, [Company Name] is proud to introduce its latest Engraving and Cutting Machine, a cutting-edge solution that is set to revolutionize the manufacturing process.

Established in [Year], [Company Name] is a leading provider of industrial machinery and equipment. With a strong focus on research and development, the company has consistently pushed the boundaries of innovation to deliver cutting-edge solutions to its customers. The introduction of the Engraving and Cutting Machine is yet another testament to [Company Name]'s commitment to providing the highest quality products to the manufacturing industry.

The Engraving and Cutting Machine is designed to offer unparalleled precision and speed, making it the ideal solution for a wide range of manufacturing applications. Equipped with advanced laser technology, the machine is capable of engraving and cutting a variety of materials, including metal, wood, plastic, and glass. This versatility makes it an invaluable asset for businesses in various sectors, including automotive, aerospace, electronics, and jewelry manufacturing, among others.

One of the key features of the Engraving and Cutting Machine is its high level of automation, which allows for seamless integration into existing manufacturing processes. The machine is equipped with intelligent software that enables precise control over the engraving and cutting process, ensuring consistent and accurate results every time. This level of automation not only improves efficiency but also reduces the margin for error, ultimately leading to cost savings and increased productivity for businesses.

Furthermore, the Engraving and Cutting Machine is designed with user-friendly features that make it accessible to operators of all skill levels. With a intuitive interface, the machine can be easily programmed to execute complex engraving and cutting tasks with minimal training, making it an accessible and efficient solution for businesses of all sizes.

"We are extremely proud to introduce our Engraving and Cutting Machine to the market," said [CEO Name], CEO of [Company Name]. "We have invested significant resources into the development of this technology, and we believe that it has the potential to significantly impact the manufacturing industry. Our goal is to provide our customers with a cutting-edge solution that delivers exceptional results and helps them stay ahead of the competition."

The Engraving and Cutting Machine is not only a testament to [Company Name]'s commitment to innovation, but it also highlights the company's dedication to sustainability. The machine is equipped with energy-efficient components that reduce its environmental impact, making it a responsible choice for businesses looking to minimize their carbon footprint.

In conclusion, the introduction of the Engraving and Cutting Machine by [Company Name] represents a significant advancement in the manufacturing industry. With its advanced technology, versatility, and user-friendly features, the machine is set to revolutionize the way businesses approach engraving and cutting processes. As the demand for innovative and efficient machinery continues to grow, [Company Name] is proud to be at the forefront of providing cutting-edge solutions that empower businesses to thrive in today's competitive market.

Company News & Blog

4 Spindle CNC Router Machine for Efficient Large-Area Plate Carving and Window Processing

4 Spindle CNC Router Machine for SaleCNC Router Machines have revolutionized the woodworking industry by providing an easy, efficient and cost-effective solution for cutting, carving, engraving and finishing wood products. The latest addition to the CNC Router Machines is the 4 Spindle CNC Router Machine. The machine is designed with four spindles to facilitate four different tools at one time, which makes it ideal for large-area plate carving and door and window processing.Applications of 4 Spindle CNC Router MachineThe 4 Spindle CNC Router Machine is ideally suited for engraving and milling of 3-4 types of flower knives. It is commonly used in various industries for cutting and carving of wood, MDF, particleboard, plywood, plastics, and other non-metallic materials. The machine is versatile and can be used for making toys, furniture, cabinets, signs, crafts, musical instruments, and many other products.Features of 4 Spindle CNC Router MachineThe 4 Spindle CNC Router Machine is a newly designed multi-spindle CNC router that is suitable for various large-area plate carving and door and window processing. It is equipped with several features that make it stand out from the other CNC Router Machines available in the market today. Here are some of its features:Automatic Tool Change: The machine has four-processing easy automatic tool change, which makes it easier to change tools quickly and efficiently.High Speed: The 4 Spindle CNC Router Machine has an excellent high-speed system. Its maximum working speed is 35m/min, which makes it highly efficient for cutting and carving.High Accuracy: The machine uses a high-precision linear guide, and its rack and pinion drive system ensures high accuracy and excellent performance.Powerful Motors: The CNC Router Machine is equipped with powerful motors that deliver high torque, which allows for cutting and carving of hard materials with ease.User-friendly Interface: The machine has a user-friendly interface that allows for easy operation. It also comes with software that enables users to design their products with ease.Benefits of the 4 Spindle CNC Router MachineThe 4 spindle CNC Router Machine has several benefits that make it an ideal choice for woodworking industries. Here are some of the benefits of using the 4 Spindle CNC Router Machine.Better Efficiency: The machine enables multi-tasking, which means you can work on different products simultaneously, thereby increasing productivity and efficiency.Cost-Effective: The machine is cost-effective since it has four spindles that allow you to work on different products without the need for multiple machines.High Precision: The 4 spindle CNC Router Machine has high accuracy and precision, providing a high-quality finish to your products.Versatility: The machine can work on different materials, making it highly versatile.ConclusionIf you are looking for a cost-effective, efficient, and versatile CNC Router Machine, then the 4 Spindle CNC Router Machine is the right choice for you. It is equipped with advanced features that make it highly efficient, accurate, and easy to operate. So, whether you are in the woodworking industry or any other field that requires cutting and carving of non-metallic materials, the 4 Spindle CNC Router Machine is an excellent investment for your business.Keywords: CNC Router Machine, 8x4, 4 Spindle CNC Router Machine, Engraving, Milling, Automatic Tool Change, Multi-spindle CNC Router, Cost-effective, High Precision, Versatility.

Customizable CNC Carving Services for Your Business Needs

CNC Carving: Revolutionizing Manufacturing ProcessesIn the rapidly evolving world of manufacturing, there is a constant demand for innovative solutions that can enhance efficiency, precision, and productivity. One such solution that has been gaining significant traction in recent years is CNC carving. This advanced technology has been revolutionizing the way products are designed and manufactured, offering unparalleled precision and flexibility in the production process.CNC (Computer Numerical Control) carving is a sophisticated manufacturing technique that utilizes computer-aided design (CAD) software to create highly detailed and intricate designs on various materials such as wood, plastic, metal, and composites. The process involves using a computer-controlled machine equipped with cutting tools to precisely carve out the desired design from the material, resulting in a finished product with exceptional accuracy and consistency.At the forefront of this cutting-edge technology is {company name}, a leading provider of CNC carving solutions for a wide range of industries. With a rich history of innovation and excellence, {company name} has established itself as a trusted partner for businesses looking to incorporate CNC carving into their manufacturing processes.{company name} offers a diverse portfolio of CNC carving machines that are designed to meet the unique needs of different industries. From small-scale desktop machines for hobbyists and craftsmen to large-scale industrial systems for mass production, {company name} provides a comprehensive range of solutions to suit various applications. The company's commitment to delivering high-quality, reliable, and user-friendly machines has earned it a reputation for excellence in the industry.One of the key advantages of CNC carving is its ability to automate and streamline the manufacturing process, thereby reducing production time and costs. By utilizing CAD software to design intricate patterns and shapes, manufacturers can produce highly detailed and complex products with minimal manual intervention. This level of precision and efficiency is particularly valuable in industries such as aerospace, automotive, furniture, and signage, where intricate designs and tight tolerances are paramount.Furthermore, CNC carving offers unparalleled flexibility in terms of design capabilities. With the ability to program the machine to create complex geometric shapes and patterns, manufacturers can bring even the most intricate designs to life with ease. This level of versatility opens up a world of possibilities for product customization and personalization, allowing businesses to cater to the unique needs and preferences of their customers.In addition to its precision and flexibility, CNC carving also offers significant improvements in material utilization. By optimizing the cutting process to minimize waste, manufacturers can maximize the yield from raw materials, resulting in cost savings and environmental benefits. This level of efficiency is crucial for businesses looking to minimize their environmental footprint and operate in a sustainable manner.As the demand for custom, high-quality products continues to grow, the adoption of CNC carving technology is expected to rise across various industries. Whether it's creating intricate wooden furniture, precision-cut metal parts, or personalized signage, CNC carving offers a level of craftsmanship and precision that is unparalleled by traditional manufacturing methods.With its commitment to innovation, quality, and customer satisfaction, {company name} is poised to play a key role in driving the widespread adoption of CNC carving technology. As the manufacturing landscape continues to evolve, businesses looking to stay ahead of the curve will undoubtedly turn to CNC carving as a game-changing solution for producing high-quality, customized products efficiently and cost-effectively.In conclusion, CNC carving is reshaping the manufacturing industry by offering a level of precision, flexibility, and efficiency that is unmatched by traditional methods. With {company name} leading the way in providing state-of-the-art CNC carving solutions, businesses across various industries can look forward to achieving new levels of productivity and excellence in their manufacturing processes. As the technology continues to advance and evolve, the possibilities for innovation and creativity in product design are truly limitless.

Ultimate Guide to Three Axis Milling Machine: Everything You Need to Know

In the world of manufacturing, precision and efficiency are key components to achieving success. One company that has been leading the way in the industry is {company name}. With a strong emphasis on innovation and technology, {company name} has recently introduced their latest cutting-edge product, the Three Axis Milling Machine.The Three Axis Milling Machine is a highly advanced piece of equipment that is designed to deliver precise and accurate machining for a wide range of materials. With its state-of-the-art technology and robust construction, this machine is capable of producing intricate and complex components with ease. The three-axis design allows for simultaneous movement along the X, Y, and Z axes, enabling the machine to achieve high levels of precision and efficiency.One of the key features of the Three Axis Milling Machine is its versatility. It is capable of handling a wide variety of materials, including metals, plastics, and composites. This makes it an ideal choice for manufacturers who need to produce a diverse range of components. Additionally, the machine is equipped with advanced automation features, which help to streamline the production process and reduce the need for manual intervention. This not only increases productivity but also ensures consistent quality across all manufactured parts.Another notable aspect of the Three Axis Milling Machine is its user-friendly interface. Despite its advanced capabilities, the machine is designed to be intuitive and easy to operate. This is thanks to the inclusion of modern control systems that allow operators to program and monitor the machining process with ease. Furthermore, the machine is equipped with advanced safety features to protect both the operator and the equipment, ensuring a secure working environment.{company name} has a long-standing reputation for delivering high-quality products and services to its customers. The introduction of the Three Axis Milling Machine is yet another example of the company's commitment to innovation and excellence. With its cutting-edge technology and unmatched performance, this machine is set to revolutionize the manufacturing industry and help businesses achieve new levels of success.In addition to its impressive product lineup, {company name} also offers comprehensive support services to its customers. This includes installation, training, and ongoing maintenance to ensure that the Three Axis Milling Machine operates at peak performance. Furthermore, the company's team of knowledgeable professionals are always on hand to provide expert advice and assistance to customers, helping them make the most of their investment in this advanced equipment.With the introduction of the Three Axis Milling Machine, {company name} has once again solidified its position as a leader in the manufacturing industry. This cutting-edge machine is set to empower businesses to achieve new levels of precision, efficiency, and quality in their production processes. As the industry continues to evolve, {company name} remains committed to pushing the boundaries of innovation and delivering solutions that meet the needs of modern manufacturing.In conclusion, the Three Axis Milling Machine is a testament to {company name}'s dedication to excellence and innovation. With its advanced technology, versatility, and user-friendly design, this machine is set to revolutionize the manufacturing industry. As businesses continue to seek ways to enhance their production processes, the Three Axis Milling Machine stands out as a game-changing solution that is set to drive success in the industry.

The Ultimate Guide to 3D Fiber Laser Marking Machines

[Company Introduction - Please fill in the necessary details as required]In a world driven by technological advancements, innovative solutions continue to shape our daily lives. One such groundbreaking invention is the 3D Fiber Laser Marking Machine, developed by the highly reputable company [Company Name]. This cutting-edge technology has revolutionized the world of laser marking, providing endless possibilities for various industries.[Company Name], a pioneer in laser technology, has been at the forefront of innovation, consistently delivering state-of-the-art solutions that cater to different industrial needs. With a rich history spanning over [Number of Years] years, the company has established itself as a leader in the field, gaining recognition for its commitment to excellence and customer satisfaction.Now, with the introduction of their latest marvel, the 3D Fiber Laser Marking Machine, [Company Name] is set to not only transform the way products are marked but also enhance the overall efficiency and productivity of countless businesses.This cutting-edge technology utilizes a fiber laser, taking advantage of its exceptional precision and speed. The 3D capability of the machine allows for the marking of complex shapes and patterns on a variety of materials, including metals, plastics, ceramics, and more. With the ability to mark both 2D and 3D surfaces, this machine opens up endless possibilities for product customization, identification, and branding.One of the key features that sets the 3D Fiber Laser Marking Machine apart is its remarkable speed and accuracy. Through the use of advanced scanning systems and software algorithms, the machine ensures precise and reliable marking, even on intricate and delicate surfaces. The speed at which it operates enables manufacturers to significantly increase production rates and meet demanding deadlines.Furthermore, the 3D Fiber Laser Marking Machine boasts a user-friendly interface, allowing operators of all skill levels to utilize its full potential. The intuitive software provides a range of customization options, enabling businesses to create unique and eye-catching designs tailored to their specific requirements. With just a few simple steps, manufacturers can effortlessly set up the machine and achieve impeccable results in no time.Another advantage of this advanced technology is its ability to generate high-quality and permanent marks without compromising the structural integrity of the marked surface. The non-contact nature of the laser ensures that the material remains intact, eliminating the risk of damage or distortion. This makes it an ideal choice for industries such as medical device manufacturing, automotive, aerospace, and electronics, where precision and durability are of utmost importance.Furthermore, the 3D Fiber Laser Marking Machine is more environmentally friendly compared to traditional marking methods. As it operates without the need for inks or chemicals, it minimizes waste and reduces the overall carbon footprint. This aligns with [Company Name]'s commitment to sustainability and underscores its dedication to responsible manufacturing practices.As businesses worldwide are constantly seeking innovative solutions, the launch of the 3D Fiber Laser Marking Machine by [Company Name] comes at a crucial time. Its ability to enhance productivity, ensure precision, and create stunning visual effects is set to revolutionize the marking industry. By harnessing the power of laser technology, [Company Name] continues to reaffirm its position as a trailblazer in the global market.As the demand for customized and visually appealing products grows, the 3D Fiber Laser Marking Machine provides manufacturers with the tools necessary to meet ever-changing consumer expectations. Its versatility, speed, and reliability make it an essential asset for any business looking to set themselves apart in a competitive market.In conclusion, the introduction of the 3D Fiber Laser Marking Machine by [Company Name] is set to reshape the world of laser marking. With its exceptional capabilities, user-friendly interface, and dedication to sustainability, this cutting-edge technology will undoubtedly have a profound impact on a wide range of industries. As [Company Name] continues to push the boundaries of innovation, the future looks brighter than ever for the world of laser marking.

Discover the Benefits of Fibre Laser Cutting for Metal

In today's rapidly evolving world of technology and manufacturing, precision and efficiency are key factors in staying competitive. In the metal manufacturing industry, the introduction of Fibre Laser Cutting has revolutionized the way metal is cut and shaped, providing significant advantages over traditional methods. With its ability to cut through a wide range of metals with high precision and speed, Fibre Laser Cutting has become the go-to solution for many companies looking to stay ahead of the curve.One such company at the forefront of this technology is {Company Name}, a leading provider of metal cutting and fabrication services. With a strong commitment to innovation and quality, {Company Name} has fully embraced the potential of Fibre Laser Cutting and has integrated it into their operations with great success. This move has allowed them to consistently deliver exceptional results to their customers while also staying ahead in a highly competitive industry.Fibre Laser Cutting is a process that utilizes a high-powered laser to melt or vaporize material, resulting in exceptionally clean and precise cuts. Unlike traditional cutting methods that rely on mechanical force or heat, the laser's concentrated energy allows for greater control and accuracy, even on the thinnest and most delicate metals. This level of precision is crucial for industries such as aerospace, automotive, and electronics, where the slightest deviation can lead to serious consequences.{Company Name} has invested heavily in state-of-the-art Fibre Laser Cutting equipment, ensuring that they can meet the demands of their diverse clientele. With the ability to cut through a wide range of materials, including stainless steel, aluminum, and titanium, they have the flexibility to take on a variety of projects with different requirements. Whether it's creating intricate designs or producing large volumes of parts, the speed and precision of Fibre Laser Cutting have allowed {Company Name} to meet and exceed customer expectations.One of the key advantages of Fibre Laser Cutting is its cost-effectiveness. The efficiency of the process means that less material is wasted, and there is minimal need for secondary finishing operations. This has translated into savings for {Company Name}, as well as for their clients, making their services even more attractive in the marketplace. In addition, the speed of Fibre Laser Cutting has enabled {Company Name} to shorten lead times and meet tight deadlines without compromising on quality.Another significant benefit of Fibre Laser Cutting is its ability to handle complex designs and shapes with ease. This has opened up new possibilities for {Company Name}, allowing them to take on projects that were once considered too difficult or time-consuming. From intricate patterns to three-dimensional components, the versatility of Fibre Laser Cutting has expanded {Company Name}'s capabilities and positioned them as a leader in the industry.The integration of Fibre Laser Cutting technology has also had a positive impact on the environment. The process produces minimal waste and consumes less energy compared to other cutting methods, making it a more sustainable option. This aligns with {Company Name}'s commitment to environmental responsibility and has allowed them to offer environmentally conscious solutions to their clients.Moving forward, {Company Name} plans to further leverage the potential of Fibre Laser Cutting by exploring new applications and pushing the boundaries of what is possible in metal fabrication. With a dedicated team of experts and a spirit of continuous improvement, they are well-positioned to stay ahead of the curve and meet the evolving needs of their customers.In conclusion, Fibre Laser Cutting has proven to be a game-changer in the metal manufacturing industry, and {Company Name} is leading the way in harnessing its potential. Through strategic investment and a focus on quality, they have elevated their capabilities and set new standards for precision and efficiency. As the demand for complex and high-quality metal products continues to grow, {Company Name} is well-equipped to meet these challenges head-on, thanks to their dedication to innovation and their embrace of cutting-edge technology.

High precision and efficient laser welding machine for steel industry

Steel Laser Welding Machine Revolutionizes Metal FabricationThe metal fabrication industry has seen a significant advancement with the introduction of the Steel Laser Welding Machine. This revolutionary technology, developed by a leading manufacturer in the field of industrial machinery, has taken the welding process to a new level of precision and efficiency.The Steel Laser Welding Machine, equipped with cutting-edge laser technology, has the capability to weld various types of steel with unmatched accuracy and speed. This innovative machine has been specifically designed to meet the demands of modern metal fabrication, offering a range of benefits that are unmatched by traditional welding methods.With the ability to weld steel of different thicknesses and compositions, the Steel Laser Welding Machine is a versatile tool that can be used in a wide range of applications. Whether it is for automotive, aerospace, construction, or any other industry that relies on metal fabrication, this machine delivers exceptional results.One of the key advantages of the Steel Laser Welding Machine is its ability to produce high-quality welds with minimal heat input. This is made possible by the precise control and focus of the laser beam, which minimizes distortion and warping of the welded material. As a result, the finished welds have superior strength and integrity, making them suitable for even the most demanding of applications.In addition, the speed at which the Steel Laser Welding Machine operates is a game-changer for the metal fabrication industry. With its high welding speed, this machine dramatically reduces production time, leading to increased efficiency and cost savings. This not only benefits manufacturers in terms of productivity but also allows them to meet the tight deadlines of their clients.Furthermore, the Steel Laser Welding Machine offers a significant improvement in terms of automation and ease of use. Its advanced control system and user-friendly interface enable operators to set up and execute welding tasks with minimal effort. This not only reduces the need for highly skilled labor but also enhances the overall safety of the welding process.In addition to its technical capabilities, the manufacturer behind the Steel Laser Welding Machine prides itself on its commitment to quality and customer satisfaction. With a proven track record of delivering cutting-edge industrial machinery, the company is dedicated to providing reliable and durable equipment that exceeds the expectations of its clients.The company's team of engineers and technicians are constantly working to improve and innovate their products, ensuring that they remain at the forefront of the industry. Through ongoing research and development, they have succeeded in creating a welding machine that sets new standards in terms of performance and reliability.Moreover, the manufacturer places a strong emphasis on customer support, offering comprehensive training and technical assistance to ensure that their clients fully maximize the potential of the Steel Laser Welding Machine. This level of commitment has earned them a reputation as a trusted partner in the metal fabrication industry.In conclusion, the Steel Laser Welding Machine represents a significant advancement in the field of metal fabrication, offering unmatched precision, speed, and efficiency. With its innovative laser technology and advanced capabilities, this machine has the potential to revolutionize the way steel is welded, setting new standards for quality and productivity.By combining the technical expertise of the manufacturer with a dedication to customer satisfaction, the Steel Laser Welding Machine is set to become an essential tool for any metal fabrication operation. As the industry continues to evolve, this revolutionary technology is poised to play a pivotal role in shaping its future.

Revolutionary 3D Laser Marking Machine: Perfect for Marking on Curved Surfaces and Step Gaps with 100% Reader Identification and Zero Consumables

In today's fast-paced and ever-evolving world, technology is an essential aspect of every industry. One of the latest technologies that have revolutionized the manufacturing industry is the 3D laser marking machine. This machine uses high-energy laser beams to engrave or etch a design or text onto a surface, creating a permanent, lasting mark. The growing demand for high-quality, permanent markings on various surfaces has made 3D laser marking machines an indispensable tool in the manufacturing industry.The 3D laser marking machine is a versatile and efficient tool that can mark any curve surface and different step gaps simultaneously. This advanced technology ensures 100% reader identification, making it an ideal choice for applications that require high precision and accuracy. It is widely used in various industries such as automotive, aerospace, medical, electronics, and jewelry making. The machine can mark on materials like plastic, metal, hard alloy, glass, ceramic, and more, making it one of the most versatile machines in the market.One of the primary advantages of 3D laser marking machine is its ability to mark uneven surfaces and complex geometries that traditional marking methods cannot achieve. The 3D laser technology creates a permanent mark that is resistant to scratching, fading, and other forms of wear and tear. The markings produced by the machine are not only aesthetically appealing but also provide important information such as barcodes, serial numbers, and safety warnings.Another significant advantage of the 3D laser marking machine is that it is a non-contact process, which eliminates the need for physical contact between the machine and the surface being marked. This feature reduces the risk of damage to delicate surfaces and enables the machine to work on a wide range of materials without causing any distortion or deformation.Unlike traditional marking methods such as stamping, engraving, or printing, 3D laser marking machines do not require consumables such as ink or toner. This saves costs and eliminates the need for frequent maintenance. The machine's precision and accuracy result in a high-quality finish, which minimizes the need for rework, thereby reducing costs and improving productivity.In conclusion, the 3D laser marking machine is a game-changer in the manufacturing industry. Its versatility, precision, and accuracy have made it an indispensable tool in creating permanent and high-quality markings on a wide range of surfaces. This advanced technology has not only improved the quality of products but has also contributed to the efficiency and productivity of the manufacturing industry. If you are looking for a reliable and advanced marking solution, consider investing in a 3D laser marking machine today.

Demand for High-Powered Laser Cutters on the Rise

Innovative laser technology has transformed the manufacturing sector by enabling superior precision in cutting and shaping various materials. With global advancements in manufacturing, the need for more efficient and effective machinery in the industry continues to grow. Responding to this industry gap, {} has introduced its latest 200w laser cutter – a state-of-the-art technology machine that revolutionizes manufacturing processes.The 200w laser cutter boasts of advanced features that optimize cutting and engraving while ensuring durability and reliability. One of its standout features is its high cutting speed, which is so remarkable that it can process a wide range of materials, including wood, acrylic, paper, and textiles, with precision and speed. This unique feature is particularly useful in mass production situations, where manufacturers need to produce products efficiently and with high quality.The machine is also easy to operate and maintain, thanks to its user-friendly interface and robust design. The laser cutter is designed with an intuitive interface that ensures that even novice operators can use it without experiencing any problems. Moreover, its design is optimized for easy maintenance and servicing, which increases the lifespan of the machine and keeps it functioning optimally throughout its lifespan.With the 200w laser cutter, {} has provided a solution that addresses the manufacturing industry's efficiency and accuracy concerns. The technology is designed to provide a laser beam that is more focused, ensuring high precision cutting and engraving in less time. This level of precision is critical, particularly in tasks that require intricate details such as jewelry making or toy manufacturing.{} has established itself as a leading manufacturer and supplier of laser cutting machines, and the introduction of the 200w laser cutter demonstrates the company's commitment to innovation and technological advancement. The company has a dedicated team that continually researches and develops the latest laser cutting and engraving technology to provide cost-effective, reliable, and user-friendly products.In addition to its innovative products, {}'s customer service is exceptional, offering expert assistance and support throughout the product installation, training, and continuous usage. The company's focus on excellence and quality has positioned it as a preferred supplier and distinguished it from other players in the industry.{}'s 200w laser cutter is an excellent addition to the manufacturing sector, and its innovative features will increase productivity while decreasing production costs. The technology offers a significant advantage to manufacturers looking to increase their production capacity while maintaining an excellent product quality standard.In conclusion, the 200w laser cutter's introduction by {} is a game-changer for the manufacturing industry. Its advanced features, ease of use, and low maintenance costs position it as an excellent option for manufacturers seeking to invest in high-quality, efficient, and reliable machinery that ultimately leads to business growth. With this technology, {} continues to provide innovative solutions that meet the industry's evolving demands, securing its position as a leading supplier of laser cutting and engraving machines.

High-Quality Aluminum for CNC Milling: What You Need to Know

Aluminum For CNC Milling: The Perfect Material for Precision EngineeringCNC milling is a crucial process in the manufacturing industry. It involves the use of computer-aided design (CAD) software to program milling machines and create precise and complex parts from various materials. One material that has proven to be highly effective for CNC milling is aluminum. Its high strength-to-weight ratio, machinability, and corrosion resistance make it an ideal choice for precision engineering projects.Aluminum is a non-ferrous metal that is widely used in the aerospace, automotive, and electronics industries. Its unique properties make it a perfect choice for CNC milling applications. The material is known for its exceptional strength, which allows for the creation of intricate and detailed parts. Additionally, aluminum is lightweight, making it an excellent choice for components that require a high strength-to-weight ratio.One company that has perfected the art of CNC milling aluminum is {}. With years of experience in precision engineering and CNC machining, they have established themselves as a leader in the industry. Their state-of-the-art facility is equipped with the latest CNC milling machines and a team of highly skilled engineers and machinists, allowing them to handle even the most complex projects with ease.The company's expertise in working with aluminum for CNC milling is unparalleled. They understand the unique properties of the material and have developed specialized techniques to ensure the highest quality and precision in their finished products. Whether it's creating intricate components for the aerospace industry or producing custom parts for the automotive sector, {} has the knowledge and capabilities to deliver exceptional results.In addition to its strength and machinability, aluminum is also known for its excellent corrosion resistance. This makes it an ideal choice for parts that will be exposed to harsh environmental conditions. Whether it's for outdoor applications or components that come into contact with chemicals and other corrosive substances, aluminum's resistance to corrosion ensures the longevity and reliability of the finished parts.Furthermore, aluminum is a highly versatile material that can be easily customized to meet specific project requirements. It can be anodized, painted, or coated to enhance its appearance and improve its performance. This flexibility makes it an excellent choice for a wide range of applications, from consumer electronics to industrial machinery.{}'s commitment to quality and innovation sets them apart in the industry. They are constantly investing in the latest technology and equipment to ensure that they can meet the evolving needs of their customers. Their dedication to excellence is evident in the precision and intricacy of the parts they produce, making them a trusted partner for companies looking for reliable and high-quality CNC-machined components.In conclusion, aluminum is the perfect material for CNC milling due to its exceptional strength, lightweight properties, and corrosion resistance. When combined with the expertise and capabilities of a company like {}, the result is precision-engineered parts that meet the highest standards of quality and performance. With their commitment to innovation and excellence, {} continues to be a leader in the industry, providing customized solutions for a wide range of applications.