Innovative Design for Cnc Router Machines

By:Admin

The design of CNC router machines has evolved over the years, incorporating the latest technological advancements to improve efficiency and productivity. One of the key aspects of the design of a CNC router machine is its structure and rigidity. The machine needs to be able to withstand the forces and vibrations generated during the cutting process, while maintaining dimensional accuracy. This is achieved through the use of high-quality materials and precision engineering.

Another important aspect of the design of a CNC router machine is its motion control system. This system is responsible for guiding the cutting tool along the desired path with precision. It utilizes advanced software and high-precision components to ensure accurate and reliable performance. The design of the motion control system is crucial in determining the overall performance of the CNC router machine.

Furthermore, the spindle system is a critical component in the design of a CNC router machine. The spindle is responsible for holding and rotating the cutting tool, and its design directly impacts the machine's cutting capabilities. A high-quality spindle system is essential for achieving smooth and accurate cuts across a variety of materials.

In addition to these key components, the design of a CNC router machine also takes into account factors such as dust and debris management, cooling systems, and user interface. These features are designed to improve the overall user experience and ensure the longevity of the machine.

The company {} has been at the forefront of CNC router machine design and manufacturing. With years of experience and expertise in the industry, they have developed a range of CNC router machines that are renowned for their precision, reliability, and performance.

Their CNC router machines are designed with a focus on rigidity and stability, ensuring that they can withstand the demands of heavy-duty cutting operations. The motion control system in their machines is equipped with state-of-the-art technology, allowing for high-speed and high-precision cutting. With a range of spindle options, their CNC router machines are capable of handling a wide variety of cutting tasks with ease.

Furthermore, their CNC router machines are designed with user convenience in mind. The machines feature a user-friendly interface that allows for easy operation and programming. They also incorporate advanced dust and debris management systems to ensure a clean and safe working environment.

The company's commitment to design excellence and innovation has earned them a reputation as a leading manufacturer of CNC router machines. With a focus on quality and performance, their machines have been widely adopted across industries such as woodworking, metalworking, and plastic fabrication.

In conclusion, the design of CNC router machines plays a crucial role in their overall performance and capabilities. With a focus on rigidity, motion control, spindle systems, and user interface, companies like {} are leading the way in developing advanced CNC router machines that are shaping the future of manufacturing.

Company News & Blog

New Laser Machine for Metal Innovations: High-Quality and Efficient Solutions

Laser Machine for Metal Provides Cutting-Edge Solutions for Industrial ApplicationsIn today's rapidly evolving industrial landscape, the demand for precision and efficiency in metalworking processes is greater than ever. In response to this need, the cutting-edge technology of Laser Machine for Metal provides innovative solutions for a wide range of industrial applications. This state-of-the-art machine, manufactured by a leading company in the field of metalworking, has revolutionized the way metal parts are fabricated and processed.The Laser Machine for Metal is designed to meet the specific needs of the modern industrial environment. With its advanced laser cutting technology, it offers a level of precision and accuracy that is unmatched by traditional metalworking methods. This machine is capable of cutting a wide variety of metals, including steel, aluminum, and copper, with exceptional speed and efficiency. Whether it is for the production of complex components, the fabrication of precision parts, or the customization of metal products, this cutting-edge technology provides the flexibility and capability to meet the demands of the most challenging industrial applications.One of the key features of the Laser Machine for Metal is its versatility. It is equipped with a high-powered laser beam that can be precisely controlled to cut metal with extreme precision. This machine offers a wide range of cutting capabilities, from fine, intricate details to rapid, high-speed cutting, making it suitable for a diverse array of industrial applications. In addition, its advanced software allows for the customization of cutting parameters, ensuring that the machine can adapt to the specific requirements of each project.Furthermore, the Laser Machine for Metal is designed with efficiency in mind. Its high-powered laser beam enables rapid cutting speeds, resulting in increased productivity and reduced lead times for metalworking processes. This machine is equipped with an efficient cooling system that ensures continuous operation at optimal performance levels. Additionally, its automated features minimize the need for manual intervention, further enhancing the efficiency of metalworking processes.The company behind the Laser Machine for Metal is a renowned leader in the field of metalworking technology. With a strong commitment to innovation and excellence, the company has been at the forefront of developing cutting-edge solutions for industrial applications. Its team of experienced engineers and technicians continuously work to enhance the performance and capabilities of its products, ensuring that they remain at the forefront of technological advancements in the industry.The company's dedication to quality and reliability is reflected in the design and construction of the Laser Machine for Metal. Rigorously tested to meet the highest standards of performance and durability, this machine is built to withstand the rigors of industrial usage. Its robust construction and high-quality components ensure long-term reliability and low maintenance requirements, making it a cost-effective solution for industrial metalworking operations.In addition, the company offers comprehensive support and service for the Laser Machine for Metal. Its team of knowledgeable and skilled technicians provides installation, training, and maintenance services to ensure that the machine operates at peak efficiency. Furthermore, the company's commitment to customer satisfaction means that it is readily available to provide technical support and assistance, ensuring that its clients can maximize the benefits of this cutting-edge technology.In conclusion, the Laser Machine for Metal represents a major advancement in the field of industrial metalworking technology. With its precision, efficiency, versatility, and reliability, this machine offers a cutting-edge solution for a wide range of industrial applications. Backed by a leading company with a proven track record of excellence, this technology is poised to transform the way metal parts are fabricated and processed, providing a competitive edge for businesses in the rapidly evolving industrial landscape.

Advanced CNC Machine for Metal and Wood: A Game-Changer in Precision Fabrication

A leading CNC machinery company is revolutionizing the manufacturing industry with its innovative CNC machine for metal and wood. This cutting-edge technology has the capability to greatly enhance productivity and precision in a wide range of manufacturing processes.The CNC machine is equipped with state-of-the-art technology that allows for the precise cutting, shaping, and carving of both metal and wood materials. This advanced machinery is ideal for a variety of industries, including aerospace, automotive, furniture, and more. With its ability to work with both metal and wood, this CNC machine offers unmatched versatility for manufacturers looking to streamline their production processes.One of the key features of this new CNC machine is its high level of automation, which allows for seamless operation and minimal human intervention. This not only improves efficiency but also reduces the risk of errors, resulting in higher quality products. Additionally, the machine is designed to be user-friendly, with intuitive controls and software that make it easy for operators to program and operate.In addition to its impressive performance capabilities, this CNC machine is also designed with durability and reliability in mind. The company has a reputation for producing high-quality machinery that is built to withstand the demands of industrial settings. This means that manufacturers can rely on this CNC machine to deliver consistent, precise results day in and day out.Furthermore, the company offers comprehensive technical support and training to ensure that customers can make the most of their investment in this CNC machine. This includes on-site assistance with installation and setup, as well as ongoing support to address any technical issues or questions that may arise.The introduction of this advanced CNC machine is expected to have a significant impact on the manufacturing industry. With its ability to handle both metal and wood materials with precision and efficiency, this machinery has the potential to revolutionize production processes across a wide range of industries.In addition to the tangible benefits of improved productivity and quality, this CNC machine also offers manufacturers the opportunity to explore new design possibilities and expand their capabilities. The ability to work with both metal and wood opens up new opportunities for innovation and creativity, allowing manufacturers to explore new product designs and production techniques.Overall, this CNC machine is poised to make a significant impact on the manufacturing industry. Its advanced technology, combined with the company's commitment to quality and support, sets a new standard for CNC machinery. With its potential to improve efficiency, precision, and versatility, this CNC machine is a game-changer for manufacturers looking to stay ahead in a competitive marketplace.

Innovative Automatic Engraving Machine Revolutionizes the Industry

[Company Name] revolutionizes the Engraving Industry with their Advanced Automatic Engraving Machine[date][Location] - [Company Name], a leader in the manufacturing industry, is set to redefine the engraving industry with their groundbreaking Automatic Engraving Machine. This cutting-edge machine is designed to streamline the engraving process, maximize productivity, and produce high-quality results effortlessly.Engraving has always been a time-consuming and skill-intensive art form. Skilled engravers meticulously carve designs onto various surfaces, ranging from jewelry to metal plates. The process, although artistic and precise, can be slow, especially for intricate designs or mass production requirements.However, [Company Name]'s Automatic Engraving Machine changes the game entirely. With advanced technology and innovation at its core, this machine automates the engraving process to achieve incredible levels of precision and efficiency.By combining state-of-the-art software with robotic arms, the Automatic Engraving Machine replicates the movements of skilled engravers. The software allows customization of designs, providing endless opportunities for creativity. Users can easily input their desired design, and the machine will execute it flawlessly, no matter the intricacy or complexity.One of the key highlights of this revolutionary machine is its ability to engrave on various materials with utmost precision. Whether it's metal, wood, plastic, or even glass, the Automatic Engraving Machine ensures consistent and accurate results every time. This versatility opens up a world of possibilities for various industries, including jewelry, manufacturing, and personalization businesses.The Automatic Engraving Machine also incorporates a user-friendly interface, making it accessible to both experienced engravers and beginners. Unlike traditional engraving methods that require years of training, this automated system simplifies the process without compromising on quality. It offers a plug-and-play operation, allowing users to start engraving with minimal setup and training.Moreover, the machine's speed and efficiency are a game-changer. With its robotic arms and advanced algorithms, it can engrave at an astonishing pace, significantly reducing production time and meeting tight deadlines. This feature makes it an ideal choice for businesses looking to scale up their operations or fulfill large orders.Furthermore, [Company Name] continues to prioritize sustainability throughout its operations, and the Automatic Engraving Machine is no exception. The machine is designed to minimize wastage, optimize material usage, and reduce energy consumption. By adopting this automated engraving process, companies can contribute to a more sustainable future while maintaining quality and efficiency.In addition to its numerous features, the Automatic Engraving Machine is also backed by [Company Name]'s extensive customer support and warranty. As a trusted manufacturer with a rich history in the industry, they ensure that their customers receive the necessary guidance and assistance to maximize the machine's capabilities.Upon its launch, the Automatic Engraving Machine has already garnered attention and praise from industry experts. Engraving businesses have recognized the potential of this groundbreaking innovation to transform their operations and elevate the quality of their products.With [Company Name]'s Automatic Engraving Machine, the engraving industry is set to undergo a significant transformation. By combining automation, precision, and sustainability, this advanced machine is poised to revolutionize the way engravings are done, opening up new opportunities and possibilities for businesses worldwide.About [Company Name]:[Company Name] is a leading manufacturer in [industry]. With a focus on innovation and sustainability, they develop cutting-edge solutions that cater to various sectors, including [list relevant industries]. From machinery to software, their products are known for their quality, reliability, and user-friendliness. With an extensive customer service network, they ensure that their clients receive the support they need for optimal performance and success.

Top 4x8 CNC Wood Router for Precision Woodworking Projects

The 4x8 CNC wood router has become an integral part of the woodworking industry, offering precision, efficiency, and versatility in creating intricate designs and patterns on wood surfaces. This cutting-edge technology has revolutionized the way woodworkers approach their craft, enabling them to produce high-quality and precise woodwork with ease.With its large working area of 4x8 feet, this CNC wood router is capable of handling a wide range of wood materials, from solid wood to plywood, MDF, and other composite materials. Its high-speed spindle and advanced motion control system allow for fast and accurate cutting, carving, and shaping of wood, resulting in finely detailed and polished woodwork.The CNC wood router is also equipped with advanced software that enables woodworkers to design and program intricate patterns, shapes, and textures for the wood router to execute. This means that woodworkers have complete creative control over their projects, from designing unique furniture pieces to customizing wooden signs and decorative elements.Additionally, the company behind this CNC wood router, has been a leading manufacturer of woodworking machinery for over 20 years, with a commitment to providing innovative and reliable solutions for woodworkers worldwide. Their extensive experience and expertise in the woodworking industry have allowed them to develop cutting-edge technologies, such as the 4x8 CNC wood router, that meet the evolving needs of modern woodworkers.The company's dedication to quality and performance is evident in the design and functionality of the CNC wood router, which is built to withstand the demands of professional woodworking operations. Its robust construction, precise engineering, and user-friendly interface make it an essential tool for woodworking workshops, furniture manufacturers, and craftsmen who strive for excellence in their woodwork.Furthermore, the company offers comprehensive technical support and training programs for their CNC wood router, ensuring that woodworkers can maximize the potential of this advanced technology. They understand that investing in a CNC wood router is a significant decision for woodworking businesses, and they are committed to providing ongoing assistance to help their customers succeed in their woodworking endeavors.In conclusion, the 4x8 CNC wood router is a game-changer for the woodworking industry, offering unprecedented precision, efficiency, and versatility in creating high-quality woodwork. With the support of a reputable company with a proven track record of delivering top-notch woodworking machinery, woodworkers can trust in the performance and reliability of this CNC wood router to take their craft to the next level. Whether it's for creating custom furniture, intricate wood carvings, or personalized wooden products, this CNC wood router is an essential tool for woodworkers who demand excellence in their work.

High-quality CNC milling machines: everything you need to know

Precision Machines Inc. is revolutionizing the manufacturing industry with their state-of-the-art CNC machine milling technology. This cutting-edge machinery is changing the game for businesses across the globe, offering unprecedented precision and efficiency in the production process.The CNC machine milling technology, which is widely used in the aerospace, automotive, and medical industries, has become an integral part of Precision Machines Inc.'s commitment to providing superior manufacturing solutions. This advanced technology allows for the automated control of machining tools through computer programming, resulting in highly accurate and intricate components.The company's dedication to staying ahead of the curve in manufacturing technology has propelled them to the forefront of the industry. With their expertise in CNC machining, Precision Machines Inc. has been able to offer their clients unparalleled quality and precision in their products. By investing in the latest machinery and software, the company has set itself apart as a leader in the manufacturing sector.One of the key advantages of CNC machine milling technology is its ability to produce complex parts with a level of precision that is simply unattainable through manual machining methods. This not only results in higher quality products, but also allows for increased productivity and reduced lead times. As a result, Precision Machines Inc. has been able to accommodate the demands of their clients while maintaining the highest standards of quality.Moreover, the CNC machine milling technology has enabled the company to diversify their capabilities, offering a wider range of services to their clients. With the ability to machine a variety of materials, from metals to plastics, Precision Machines Inc. has become a one-stop shop for all of their customers' manufacturing needs. This versatility has solidified the company's reputation as a reliable and innovative partner in the industry.In addition to their cutting-edge technology, Precision Machines Inc. prides itself on its team of highly skilled and knowledgeable professionals. With years of experience in CNC machining, their staff possesses the expertise to navigate the complexities of the technology and deliver exceptional results. This combination of advanced machinery and expert personnel has made Precision Machines Inc. a trusted name in the manufacturing world.Furthermore, the company's commitment to continuous improvement and innovation has led them to regularly invest in the latest CNC machine milling technology. By staying at the forefront of technological advancements, Precision Machines Inc. ensures that they are always able to offer their clients the most efficient and cost-effective solutions for their manufacturing needs.As the manufacturing industry continues to evolve and demand for high-quality, precision products increases, the role of CNC machine milling technology in shaping the future of manufacturing cannot be overstated. Precision Machines Inc. understands the importance of staying ahead of the curve in this ever-changing landscape, and their investment in cutting-edge machinery puts them in a prime position to lead the charge.With their dedication to excellence and innovation, Precision Machines Inc. is poised to continue pushing the boundaries of what is possible in the world of manufacturing. Their commitment to harnessing the power of CNC machine milling technology has set them apart as a leader in the industry, and the impact of their work is sure to be felt for years to come.

Highly Efficient Wood Cutting Machine for CNC Processing

Woodworking industry has been revolutionized by the introduction of the latest CNC wood cutting machine by a leading manufacturing company. The advanced technology and precision engineering of this machine have set a new benchmark for wood cutting and carving, making it an indispensable tool for modern woodworking businesses.The CNC wood cutting machine is designed to meet the diverse needs of the woodworking industry, offering unparalleled speed, accuracy, and efficiency. Its cutting-edge features enable woodworkers to create intricate designs, fine details, and smooth finishes with utmost perfection. The machine is equipped with a high-speed spindle and advanced cutting tools that ensure clean and precise cuts on various types of wood, including hardwoods, softwoods, and engineered wood products.One of the key highlights of this CNC wood cutting machine is its ability to produce complex 3D designs and engravings with exceptional accuracy. Whether it's creating custom furniture pieces, decorative panels, or architectural elements, the machine delivers flawless results that meet the highest quality standards. Its user-friendly interface and intuitive software make it easy for woodworkers to input designs and execute cutting tasks with minimal effort.The company behind this innovative CNC wood cutting machine has a rich history of manufacturing cutting-edge industrial machinery. With decades of experience and expertise in the field, the company has consistently pushed the boundaries of technological innovation to provide solutions that empower businesses to thrive in a competitive market. Their commitment to excellence and customer satisfaction has earned them a strong reputation as a trusted partner for woodworking professionals worldwide.In addition to its exceptional performance, the CNC wood cutting machine is designed for maximum durability and reliability. Its robust construction and high-quality components ensure long-term operation with minimal maintenance requirements, offering woodworkers peace of mind and uninterrupted production capability. The machine is also equipped with advanced safety features to protect operators and maintain a secure working environment.Furthermore, the CNC wood cutting machine is designed for versatility, allowing woodworkers to explore a wide range of creative possibilities. Whether it's producing custom furniture, intricate carvings, or decorative elements, the machine's flexibility enables woodworkers to bring their design concepts to life with precision and efficiency. Its dynamic cutting capabilities and multi-axis control provide endless opportunities for customization and personalization.The company's dedication to providing comprehensive customer support and service further enhances the value of the CNC wood cutting machine. From installation and training to ongoing technical assistance, the company's team of experts is committed to ensuring that woodworkers maximize the potential of their investment. With a global network of service centers and a responsive support system, the company stands behind its products and strives to deliver unparalleled customer satisfaction.In conclusion, the introduction of the latest CNC wood cutting machine by this leading manufacturing company represents a significant advancement in the woodworking industry. Its cutting-edge technology, precision engineering, and versatile capabilities make it a game-changer for woodworkers seeking to elevate their craft and business. With a strong focus on performance, durability, and customer support, the machine sets a new standard for excellence in wood cutting and carving, empowering woodworking professionals to achieve remarkable results and unlock new possibilities.

High-precision Metal Laser Welding Machine: A Game-changer in Manufacturing Industry

Metal Laser Welding Machine Revolutionizes Manufacturing IndustryThe manufacturing industry is constantly evolving, and one of the latest technological advancements that has revolutionized the industry is the metal laser welding machine. This cutting-edge technology has significantly improved the precision and efficiency of metal welding processes, making it a game-changer for manufacturers across various sectors.Metal laser welding machines use a high-powered laser beam to join metal components together. This process is incredibly precise and produces welds that are of a consistently high quality. By utilizing this technology, manufacturers are able to achieve strong and durable welds, even on materials that are traditionally difficult to weld using conventional methods.One of the leading manufacturers of metal laser welding machines is {}, a company that has been at the forefront of laser technology for over two decades. With a commitment to innovation and a dedication to providing high-quality solutions for the manufacturing industry, {} has become a trusted name in the field of laser welding technology.The metal laser welding machines developed by {} are designed to meet the diverse needs of manufacturers, offering a wide range of capabilities and features to ensure that every welding application is addressed with precision and efficiency. These machines are equipped with advanced laser technology that allows for precise control over the welding process, resulting in welds that are of the highest quality.One of the key features of {}'s metal laser welding machines is their ability to weld a wide range of materials, including stainless steel, aluminum, and titanium, among others. This versatility makes these machines a valuable asset for manufacturers who work with different types of metals and need a welding solution that can accommodate their specific requirements.In addition to their versatility, {}'s metal laser welding machines are also known for their high production efficiency. These machines are capable of completing welding processes at a much faster rate than traditional welding methods, enabling manufacturers to significantly increase their productivity and meet tight production deadlines.Furthermore, the precision of the welds achieved with {}'s metal laser welding machines minimizes the need for post-welding finishing processes, saving manufacturers both time and money. This is particularly beneficial for companies that require high-quality welds for their products, as it allows them to streamline their production processes and ultimately deliver superior end products to their customers.Another advantage of {}'s metal laser welding machines is their ability to create welds with minimal heat input, reducing the risk of distortion and damage to the metal components being welded. This is particularly important for industries such as aerospace and automotive, where the structural integrity of the welded components is crucial.With the introduction of metal laser welding machines into the manufacturing industry, companies are now able to take advantage of a technology that offers unparalleled precision, efficiency, and versatility. Whether it's for welding intricate components for the medical industry or constructing durable parts for the automotive sector, {}'s metal laser welding machines have proven to be a valuable asset for manufacturers across a wide range of industries.As the demand for high-quality, efficiently produced metal components continues to grow, the significance of metal laser welding technology in the manufacturing industry cannot be overstated. With {}'s commitment to innovation and excellence, the future of metal welding is certainly bright, and manufacturers can expect to see even more advancements in laser welding technology in the years to come.

High-precision Laser Cutting Machine for Leather Goods

Leather Laser Cutting Machine Revolutionizing the IndustryThe leather industry is no stranger to innovation and the latest addition to the manufacturing process is the leather laser cutting machine. This technology has been making waves in the industry as it offers a precise and efficient method of cutting leather, making it a valuable asset for companies looking to streamline their production processes.One company that has been at the forefront of this innovation is {Company Name}. With years of experience in the leather industry, {Company Name} has been committed to providing cutting-edge solutions for leather manufacturing. The introduction of the leather laser cutting machine has been a game-changer for the company and has set them apart from competitors.The leather laser cutting machine offered by {Company Name} is equipped with state-of-the-art technology, offering a high level of precision and accuracy in cutting leather. The machine is capable of cutting intricate patterns and designs on various types of leather, making it a versatile tool for manufacturers. Its speed and efficiency have been highly praised by industry professionals, as it allows for a significant reduction in production time and costs.One of the key advantages of the leather laser cutting machine is its ability to produce clean and consistent cuts, resulting in minimal waste of materials. This is crucial for companies looking to optimize their production processes and reduce their environmental footprint. The machine also offers flexibility in cutting different types of leather, whether it be thick or thin, ensuring that manufacturers can cater to a wide range of product demands.Furthermore, the leather laser cutting machine offered by {Company Name} is user-friendly and easy to operate, making it accessible for manufacturers of all sizes. The intuitive software interface allows for quick and easy customization of designs, providing manufacturers with the freedom to create unique and intricate leather products. This level of flexibility has been a major selling point for the machine, as it enables companies to stay ahead in a competitive market.{Company Name} has positioned itself as a leader in the leather laser cutting machine market, offering not only cutting-edge technology but also exceptional customer support and service. Their team of experts is committed to assisting manufacturers in optimizing their production processes and enhancing their product offerings.In addition to the leather laser cutting machine, {Company Name} also provides a range of complementary products and services, further solidifying their position as a one-stop solution for leather manufacturers. Whether it be laser engraving machines or custom software development, {Company Name} is dedicated to providing comprehensive and innovative solutions to meet the evolving needs of the industry.As the demand for high-quality leather products continues to grow, the leather laser cutting machine offered by {Company Name} has become an invaluable asset for manufacturers looking to elevate their production processes. The combination of precision, efficiency, and flexibility has been a game-changer for the industry, and {Company Name} has been at the forefront of this innovation.In conclusion, the introduction of the leather laser cutting machine has revolutionized the leather manufacturing industry, and {Company Name} has been instrumental in driving this change. Their commitment to providing cutting-edge solutions and exceptional customer support has set them apart as a leader in the market. With the leather laser cutting machine, {Company Name} is shaping the future of leather manufacturing and is poised to continue making significant contributions to the industry.

Unlocking the Potential: Explore the Versatility of Door Carving Machines

As the demand for high-quality and unique carved wooden doors continues to grow rapidly, manufacturers are looking for the best technology to ensure that they can meet this demand. One of the most popular technologies being adopted in the industry today is the Door Carving Machine. With its ability to produce intricate and precise carvings on wooden doors, the Door Carving Machine has taken the market by storm. One of the leading manufacturers of Door Carving Machines in the industry, who want to remain anonymous, has been making waves in the market with its innovative designs and high-quality production. The company prides itself on its state-of-the-art manufacturing facilities, sophisticated technological advancements, and experienced workforce. The Door Carving Machine is designed to provide an effective, efficient, and quick way of creating decorative designs on wooden doors. It is equipped with the latest automation systems and computer-controlled operations that allow for easy customization of designs, shapes, and sizes. The machine's advanced software and control systems enable the carving of complex designs and patterns on doors with ease and precision. The Door Carving Machine can handle any type of wood, be it hardwood or softwood, and can be used to create various types of doors, including solid wood doors, glass doors, and panel doors. The machine's versatility and flexibility are some of the key factors that have contributed to its growing appeal among manufacturers and consumers alike. The machine is also notable for its speed and efficiency. With the ability to handle high volume production and operate quickly, manufacturers can meet production deadlines while maintaining quality standards. This is particularly important given the current market demands for carved wooden doors. In addition to its functionality, the Door Carving Machine is also notable for its safety features. The machine is designed with safety in mind, with protective shields, automatic stop mechanisms, and emergency stops that prevent accidents. This not only ensures the safety of the operators but also reduces the chances of damage to the machine. The manufacturers of Door Carving Machines are continuously working to improve their designs and operations to meet the dynamic demands of the market. The advanced technology incorporated in these machines is constantly evolving to ensure that they continue to remain relevant and effective. Overall, the Door Carving Machine is a great addition to any woodworking manufacturing facility, as it can significantly increase production efficiency and reduce turnaround time. Furthermore, with its advanced functionality, the machine can help manufacturers produce high-quality and unique carved wooden doors that perfectly meet the current market demand. In summary, the Door Carving Machine is a machine that has revolutionized the woodworking industry, providing a reliable and efficient way of creating decorative designs on wooden doors. With its sophisticated technology, versatility, and safety features, it is no surprise that it has attracted the attention of the market and continues to be a popular choice among manufacturers. As such, it is a worthy investment for any manufacturing facility seeking to maximize production efficiency and meet the high demands of the market.

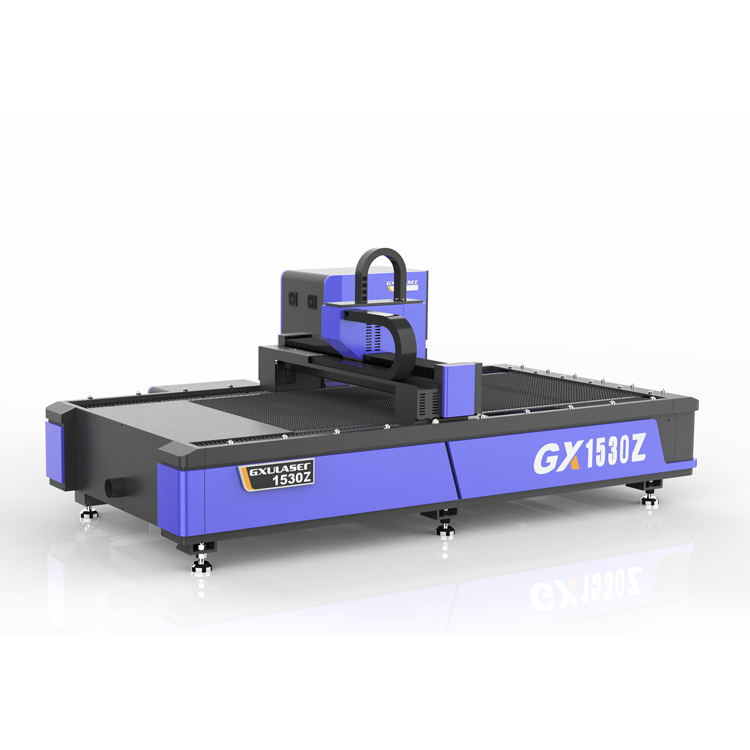

Powerful 1500mmx3000mm Fiber Laser Cutting Machine with options of 500w, 700w, and 1000w Laser Sources: Efficient and Precise Cutting Technology

Co2 Laser Cutting Machine 500w: The Best Choice for High-Quality CuttingCutting metal, plastics, wood, and other materials often used in construction, manufacturing, and industrial applications is a challenge without a laser cutting machine. Though many types of laser cutting machines are available, the Co2 Laser Cutting Machine 500w stands out for its unparalleled efficiency, reliability, and quality.A Co2 Laser Cutting Machine is a highly efficient, yet affordable cutting tool that uses a mixture of gases and a focused beam of laser energy to cut through metals and other tough materials. The 500w laser source is perfect for small businesses and startups looking to cut materials with precision and high-quality results.Compared to traditional cutting methods, Co2 Laser Cutting Machines are faster, more accurate, and require lower maintenance. The fiber transmission used in this cutting machine guarantees a consistent quality cutting effect in every point of the material being cut. The technology has been specially designed to reduce gas consumption and increase photoelectric conversion efficiency, which can reach up to 35%.The 1530 fiber cutting machine 500w is a high-performance machine that can cut through a wide range of materials, including steel, stainless steel, aluminum, brass, copper, and other non-metal materials such as acrylic and plastics. The machine's accuracy is excellent, and the use of fiber transmission ensures a consistent and reliable cutting result.The Co2 Laser Cutting Machine 500w is also an excellent tool for precise cutting of intricate geometric patterns. The machine's cutting speed is fast, and the exactitude is exceptional at every point. Plus, the machine's software can be programmed to cut almost any shape or design that you need, or you can simply upload your design, and it will automatically start cutting.With the ability to cut materials of varying thicknesses, Co2 Laser Cutting Machines are versatile and can be used for various projects in different industries. Additionally, the cutting machine has excellent cutting capacity and high processing quality. And, because of these characteristics, the machines are ideal for particular industries, including building and construction, automotive, and other manufacturing industries requiring high precision cuttings.In summary, the Co2 Laser Cutting Machine 500w is an excellent choice for cutting through a wide range of materials with high precision and accuracy. The machine not only saves time but also minimizes material wastage and guarantees high-quality results. Whether you are in the manufacturing, automotive, or construction industry, this machine can help you achieve your goals and realize the full potential of your business.