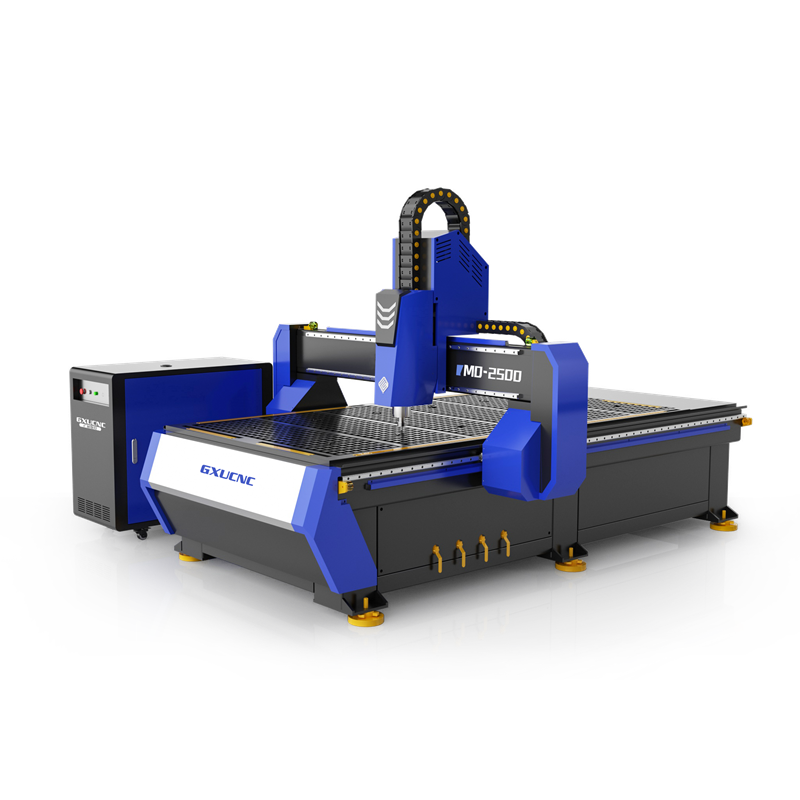

High Precision Cnc Router Machine for Woodworking and Metal Fabrication

By:Admin

The 6090 CNC router machine, manufactured by {}, is known for its superior quality and performance. Equipped with a high-speed spindle and a rigid frame, this machine is capable of handling a wide range of materials with ease. Its precision and accuracy make it ideal for intricate designs and complex patterns, making it a valuable asset for companies in the furniture, sign-making, and prototype industries.

One of the key features of the 6090 CNC router machine is its user-friendly interface, which allows operators to easily program and control the machine for various cutting and carving tasks. Whether it's a small-scale production or a large-scale manufacturing project, this machine can be customized to meet the specific needs of the business, offering flexibility and versatility.

In addition, the 6090 CNC router machine is equipped with advanced software that enables 3D modeling and simulation, allowing users to visualize the end product before the actual production process. This not only reduces the risk of errors but also enhances the overall efficiency of the manufacturing process.

With its cutting-edge technology and reliable performance, the 6090 CNC router machine has garnered praise and recognition from professionals in the industry. Many companies have reported significant improvements in their production processes, thanks to the precision and speed offered by this machine. As a result, it has become a popular choice for businesses looking to enhance their manufacturing capabilities and stay ahead of the competition.

Furthermore, the 6090 CNC router machine is backed by exceptional customer support and service from {}. Their team of experts is dedicated to providing assistance with installation, training, and ongoing maintenance, ensuring that businesses can maximize the benefits of this machine for years to come.

In conclusion, the 6090 CNC router machine has set a new standard in the manufacturing industry with its advanced technology and exceptional performance. As businesses strive to improve their production processes and deliver high-quality products, this machine has become an essential tool for achieving success. With its precision, efficiency, and versatility, it has become a game-changer for many companies, paving the way for innovation and growth in the manufacturing sector.

Company News & Blog

An Overview of Automatic Woodworking Machines and Their Benefits

[Company Name], a leading provider of automated manufacturing solutions, has recently unveiled their latest innovation in the woodworking industry - the Automatic Woodworking Machine. This state-of-the-art machine is designed to revolutionize the way wood products are manufactured, providing companies with increased efficiency and productivity.The Automatic Woodworking Machine is equipped with advanced technology and precision engineering to ensure high-quality and consistent output. It is capable of performing a wide range of woodworking tasks, including cutting, shaping, and carving, with unparalleled speed and accuracy. This innovative machine is set to streamline the manufacturing process for wood products, offering companies a competitive edge in the market.One of the key features of the Automatic Woodworking Machine is its fully automated operation. This means that the machine can run continuously without the need for constant human intervention, significantly reducing labor costs and increasing production capacity. In addition, the machine is equipped with smart sensors and monitoring systems to detect and adjust for any potential errors or malfunctions, ensuring a smooth and efficient operation.The Automatic Woodworking Machine is also designed for versatility, being able to adapt to different types of wood and varying specifications. This level of flexibility allows companies to easily switch between different production orders without the need for extensive retooling or adjustments. This is particularly valuable for companies that require quick turnaround times and frequent changes in production requirements.In addition to its advanced features, the Automatic Woodworking Machine is also designed with safety in mind. The machine is equipped with multiple safety mechanisms and protocols to protect operators and prevent accidents. This includes safety guards, emergency stop buttons, and automatic shutdown in the event of a malfunction. As a result, companies can have peace of mind knowing that their workers are protected while using the machine.“We are thrilled to introduce the Automatic Woodworking Machine to the market,” says [Company Name] CEO. “This innovative machine represents a significant leap forward in woodworking technology, offering companies a more efficient and cost-effective solution for their production needs. We are confident that this machine will help our customers enhance their manufacturing capabilities and achieve greater success in the industry.”As a leading provider of manufacturing solutions, [Company Name] has a long-standing reputation for delivering cutting-edge technology and exceptional customer service. With a team of experienced engineers and technicians, the company is dedicated to helping their clients achieve their production goals and stay ahead of the competition. The introduction of the Automatic Woodworking Machine further solidifies their commitment to innovation and excellence in the manufacturing industry.The Automatic Woodworking Machine is now available for purchase, with [Company Name] offering comprehensive training and support for their customers. With this groundbreaking new machine, companies can expect to optimize their production processes, reduce costs, and elevate the overall quality of their wood products. The future of woodworking manufacturing has arrived, and [Company Name] is leading the way with their cutting-edge solution.

Boost Your Metal Fabrication Process: Discover the Power of Stainless Steel CNC Cutting

Title: Revamping Precision in Metal Fabrication with Stainless Steel CNC CuttingIntroduction (100 words):In an era fueled by technological advancements, the manufacturing industry strives to enhance precision and efficiency to meet evolving demands. One such innovation revolutionizing metal fabrication is stainless steel CNC cutting. By harnessing the power of computer numerical control (CNC) technology, this cutting-edge process caters to a diverse range of industries. This article explores the capabilities of stainless steel CNC cutting and highlights how it contributes to the company's commitment to delivering high-quality and precise metal fabrication solutions.Body:1. The Advantages of Stainless Steel CNC Cutting (200 words):Stainless steel CNC cutting is rapidly gaining popularity due to its exceptional benefits. The process combines the advantages of stainless steel, renowned for its durability and corrosion resistance, with the precise cutting capabilities of CNC technology. The inclusion of this technique in the company's metal fabrication arsenal allows for the efficient production of intricate and complex designs without compromising on the material's integrity.The CNC cutting system boasts unmatched precision, repeatability, and speed, ensuring consistent and accurate results batch after batch. By utilizing cutting-edge computer programming, the company can accommodate various design specifications, creating customized solutions to meet specific client requirements. Moreover, stainless steel CNC cutting minimizes material wastage, ultimately leading to cost savings and environmental sustainability.2. Industry Application and Diverse Uses (250 words):Stainless steel CNC cutting has found widespread application across several industries due to its versatility. From automotive and aerospace to architecture and medical equipment, this technology imparts immense value by fabricating high-quality metal components. The company leads the way by leveraging stainless steel CNC cutting to cater to the unique demands of its clients.In the automotive sector, precision is paramount. Stainless steel CNC cutting ensures the production of accurate parts for critical systems, including suspension, exhaust, and engine components. By adhering to strict quality controls and flawlessly executing complex designs, the company aligns with industry standards to deliver superior products.Likewise, the aerospace industry relies heavily on stainless steel CNC cutting for aircraft parts such as turbine blades, airframes, and structural components. The precise and intricate nature of these components demands the employment of cutting-edge CNC technology, ensuring not only structural integrity, but also upholding safety standards.Architecture and interior design benefit from stainless steel CNC cutting as it provides the opportunity for innovative and visually stunning metalwork. From intricate metal furniture designs to striking building facades, the company's CNC cutting expertise offers architects and designers the freedom to explore their creative boundaries while maintaining structural integrity.Additionally, stainless steel CNC cutting serves the medical industry, crafting intricate surgical instruments, orthopedic implants, and medical devices with utmost precision and detail. The technology affords superior surface quality for biocompatible stainless steel, enhancing patient safety and medical professionals' peace of mind.3. Company Name: Pioneering Excellence and Innovation in Stainless Steel CNC Cutting (200 words):Company {} (please insert the company name) stands at the forefront of revolutionizing the metal fabrication landscape with its expertise in stainless steel CNC cutting. With a commitment to excellence and innovation, the company strives to deliver superior quality products by leveraging the potential of cutting-edge technologies.{} (Please include company introduction, such as history, values, certifications, and commitment to customer satisfaction). As an industry leader, the company's state-of-the-art facilities and highly trained technicians ensure precise execution of designs, delivering exceptional results to clients across diverse industries.Furthermore, the company's dedication to consistent improvement and investment in research and development enables them to stay ahead in a highly competitive market. By staying up-to-date with the latest advancements in stainless steel CNC cutting, they continually expand their capabilities, providing customers with cutting-edge metal fabrication solutions.Conclusion (150 words):Stainless steel CNC cutting has ignited a revolution in precision metal fabrication, enabling the manufacturing industry to achieve unparalleled accuracy and efficiency. The company's expertise in this field has facilitated the delivery of robust and intricate metal components across diverse sectors, including automotive, aerospace, architecture, and healthcare.Through adopting this cutting-edge technology, the company remains committed to providing clients with superior quality, customizable metal fabrication solutions that adhere to the highest industry standards. The fusion of stainless steel's remarkable properties with CNC cutting's exemplary precision ensures that the company remains at the forefront of manufacturing excellence, meeting the evolving needs of their valued customers efficiently and sustainably.

Advanced 5-Axis CNC Router for Precise Woodworking and Carving Applications

Are you looking for a 4-axis CNC router machine that can provide exceptional precision, speed, and reliability while working on various materials? Look no further than the RCF 2560 CNC router from China. This top-of-the-line machine is designed to meet the highest standards of the industry and can deliver unparalleled performance and quality.The RCF 2560 CNC router is a 5-axis machine that offers a massive working area of 2500mm x 6000mm (approximately 98.4in x 236.2in), allowing you to handle large-sized materials with ease. With its advanced 5-axis technology, the machine can move the cutting tool in multiple directions, which makes it perfect for complex and intricate designs. Whether you're working on wood, plastics, composites, or non-ferrous metals, this machine can deliver optimal results.One of the most significant advantages of the RCF 2560 CNC router is its unparalleled speed and precision. The machine is equipped with a powerful spindle and a high-speed servo motor that can deliver up to 24000 RPM, allowing you to work on multiple materials quickly and efficiently. Additionally, the machine's accuracy is ensured by its advanced control system that can adjust the cutting speed and depth according to the material being worked on.Another key feature of the RCF 2560 CNC router is its user-friendly interface. The machine's control system is straightforward to use and allows you to create and edit your designs easily. Additionally, the machine is compatible with various software, making it versatile and adaptable to your needs.In terms of versatility, the RCF 2560 CNC router can be used for a wide range of applications, from furniture making to sign-making to aerospace industry. The machine's ability to cut different materials with exceptional precision and speed makes it a perfect choice for businesses that require high-quality output in a short amount of time.In conclusion, the RCF 2560 CNC router machine is the ideal solution for anyone looking for a 4-axis machine that can handle large-sized materials with exceptional precision and speed. Its user-friendly interface, advanced control system, and versatile applications make it a valuable investment for businesses in various industries. Contact us today to learn more about the RCF 2560 CNC router and how it can benefit your business.

Ultimate Guide to Three Axis Milling Machine: Everything You Need to Know

In the world of manufacturing, precision and efficiency are key components to achieving success. One company that has been leading the way in the industry is {company name}. With a strong emphasis on innovation and technology, {company name} has recently introduced their latest cutting-edge product, the Three Axis Milling Machine.The Three Axis Milling Machine is a highly advanced piece of equipment that is designed to deliver precise and accurate machining for a wide range of materials. With its state-of-the-art technology and robust construction, this machine is capable of producing intricate and complex components with ease. The three-axis design allows for simultaneous movement along the X, Y, and Z axes, enabling the machine to achieve high levels of precision and efficiency.One of the key features of the Three Axis Milling Machine is its versatility. It is capable of handling a wide variety of materials, including metals, plastics, and composites. This makes it an ideal choice for manufacturers who need to produce a diverse range of components. Additionally, the machine is equipped with advanced automation features, which help to streamline the production process and reduce the need for manual intervention. This not only increases productivity but also ensures consistent quality across all manufactured parts.Another notable aspect of the Three Axis Milling Machine is its user-friendly interface. Despite its advanced capabilities, the machine is designed to be intuitive and easy to operate. This is thanks to the inclusion of modern control systems that allow operators to program and monitor the machining process with ease. Furthermore, the machine is equipped with advanced safety features to protect both the operator and the equipment, ensuring a secure working environment.{company name} has a long-standing reputation for delivering high-quality products and services to its customers. The introduction of the Three Axis Milling Machine is yet another example of the company's commitment to innovation and excellence. With its cutting-edge technology and unmatched performance, this machine is set to revolutionize the manufacturing industry and help businesses achieve new levels of success.In addition to its impressive product lineup, {company name} also offers comprehensive support services to its customers. This includes installation, training, and ongoing maintenance to ensure that the Three Axis Milling Machine operates at peak performance. Furthermore, the company's team of knowledgeable professionals are always on hand to provide expert advice and assistance to customers, helping them make the most of their investment in this advanced equipment.With the introduction of the Three Axis Milling Machine, {company name} has once again solidified its position as a leader in the manufacturing industry. This cutting-edge machine is set to empower businesses to achieve new levels of precision, efficiency, and quality in their production processes. As the industry continues to evolve, {company name} remains committed to pushing the boundaries of innovation and delivering solutions that meet the needs of modern manufacturing.In conclusion, the Three Axis Milling Machine is a testament to {company name}'s dedication to excellence and innovation. With its advanced technology, versatility, and user-friendly design, this machine is set to revolutionize the manufacturing industry. As businesses continue to seek ways to enhance their production processes, the Three Axis Milling Machine stands out as a game-changing solution that is set to drive success in the industry.

High Precision Laser Cutting Machine for Pipes: The Latest Technology in Industrial Cutting Solutions

Pipe Laser Cutting Machine Revolutionizes Manufacturing IndustryIn recent years, the manufacturing industry has seen a significant shift towards automation and advanced technology. One of the latest advancements in this field is the introduction of the Pipe Laser Cutting Machine, a cutting-edge tool that has revolutionized the way pipes and tubes are manufactured.The Pipe Laser Cutting Machine is a state-of-the-art tool that uses laser technology to precisely cut, drill, and shape pipes and tubes. This innovative machine has set a new standard for accuracy and efficiency in the manufacturing industry, offering a range of benefits to companies that specialize in producing pipes and tubes for various applications.By integrating the latest laser technology with advanced automation features, the Pipe Laser Cutting Machine has significantly improved the speed and precision of pipe and tube manufacturing processes. The machine can accurately cut through a wide range of materials, including stainless steel, aluminum, and carbon steel, allowing manufacturers to create high-quality products with minimal waste and maximum efficiency.One of the key benefits of the Pipe Laser Cutting Machine is its ability to produce complex and intricate designs with unmatched precision. This level of accuracy is especially important in industries such as aerospace, automotive, and construction, where the quality of pipe and tube components directly impacts the performance and safety of the final product.Furthermore, the Pipe Laser Cutting Machine has also proven to be a cost-effective solution for manufacturers. By reducing material waste and minimizing the need for manual labor, the machine allows companies to optimize their production processes and increase their overall output without compromising on quality.The introduction of the Pipe Laser Cutting Machine has been met with enthusiasm by manufacturers worldwide, and many companies have already adopted this technology to enhance their production capabilities. One such company that has embraced this innovation is [], a leading manufacturer of pipes and tubes for the construction industry.With over 20 years of experience in the industry, [] has built a reputation for delivering high-quality products that meet the strictest performance and safety standards. By investing in the latest technology, including the Pipe Laser Cutting Machine, the company has further strengthened its position as a leading provider of pipes and tubes for construction projects of all sizes.The implementation of the Pipe Laser Cutting Machine has allowed [] to streamline its manufacturing processes and offer a wider range of customization options to its customers. By leveraging the machine's advanced capabilities, the company is now able to produce complex designs and shapes with unmatched precision, catering to the diverse needs of its clients in the construction industry.In addition to improving its production capabilities, the Pipe Laser Cutting Machine has also enabled [] to enhance the overall quality and durability of its products. The machine's precise cutting and shaping capabilities have resulted in pipes and tubes that exhibit superior strength and resilience, making them ideal for use in demanding construction applications.Moreover, the adoption of the Pipe Laser Cutting Machine has positioned [] as a more sustainable and environmentally conscious manufacturer. By minimizing material waste and optimizing its production processes, the company has reduced its environmental impact while maintaining its commitment to delivering high-quality products to its customers.Looking ahead, the future looks promising for companies that have embraced the Pipe Laser Cutting Machine as part of their manufacturing processes. As the technology continues to evolve and become more accessible, we can expect to see even greater advancements in the manufacturing industry, further solidifying the position of laser cutting as a game-changing innovation.

Ultimate Guide to Precision CNC Router Technology

CNC Router Precision: A Game-Changer in the Manufacturing IndustryIn today's fast-paced and competitive manufacturing industry, precision and efficiency are key factors that can make or break a business. This is where CNC Router Precision comes into play as a game-changer. This innovative technology has revolutionized the way companies approach their manufacturing processes, offering unparalleled precision and quality. With its advanced capabilities, CNC Router Precision has become the go-to solution for businesses looking to stay ahead of the curve.CNC Router Precision is a cutting-edge technology that utilizes computer numerical control (CNC) to precisely cut, carve, and shape various materials such as wood, plastic, and metal. This technology allows for intricate and complex designs to be executed with utmost accuracy, resulting in high-quality products and satisfied customers.By using CNC Router Precision, companies can streamline their manufacturing processes and significantly reduce production time. This is achieved through the automation of tasks, which eliminates the need for manual labor and reduces the likelihood of errors. With CNC Router Precision, businesses can optimize their production efficiency and increase their output without compromising on quality.One of the key advantages of CNC Router Precision is its ability to accommodate a wide range of design specifications. Whether it's creating intricately detailed furniture pieces, customized signage, or precision components for electronic devices, CNC Router Precision can handle it all with precision and ease. This versatility allows businesses to diversify their product offerings and cater to a broader market.Furthermore, CNC Router Precision is a cost-effective solution for businesses. By minimizing material wastage and maximizing production efficiency, companies can reduce their overall manufacturing costs and improve their bottom line. This is particularly beneficial for small to medium-sized businesses that are looking to compete with larger players in the industry.The implementation of CNC Router Precision is also a step towards sustainability. By optimizing production processes and minimizing waste, businesses can contribute to a more eco-friendly manufacturing industry. This is an important consideration for companies looking to align their operations with sustainable practices and reduce their environmental impact.{} is at the forefront of the CNC Router Precision revolution. With a strong focus on innovation and customer satisfaction, they have established themselves as a leading provider of CNC Router Precision solutions. Their expertise in this technology has enabled them to work with a diverse range of clients, from small businesses to large corporations, helping them achieve their manufacturing goals with precision and efficiency.{} is committed to providing top-of-the-line CNC Router Precision solutions that are tailored to each client's specific needs. With a team of experienced engineers and technicians, they offer comprehensive support and technical expertise to ensure seamless integration and operation of CNC Router Precision systems. Their dedication to delivering exceptional quality and service has earned them a reputation as a trusted partner in the manufacturing industry.By leveraging the power of CNC Router Precision, businesses can elevate their manufacturing capabilities and stay ahead of the competition. With its unparalleled precision, efficiency, and cost-effectiveness, CNC Router Precision is a game-changer that is reshaping the future of manufacturing. As the industry continues to evolve, businesses that embrace this technology will have a significant advantage in meeting the demands of an increasingly competitive market.In conclusion, CNC Router Precision is a transformative technology that is revolutionizing the manufacturing industry. With its advanced capabilities and benefits, businesses can enhance their production processes, reduce costs, and deliver high-quality products to their customers. As the industry continues to embrace CNC Router Precision, businesses that adopt this technology will be well-positioned to thrive in an evolving and competitive market.

Compact Laser Marking Machine for Increased Productivity and Efficiency

Title: Innovative Portable Laser Marking Machine Revolutionizes Industrial EfficiencyIntroduction:In an ever-evolving technological landscape, the introduction of the state-of-the-art Portable Laser Marking Machine promises to revolutionize the industrial sector. Developed by a leading company in laser technology, this cutting-edge machine is set to transform manufacturing processes, boasting unparalleled precision, flexibility, and efficiency. With its innovative features and extensive capabilities, this ground-breaking device is set to become an integral asset for industries worldwide.I. Overview of Portable Laser Marking MachineThe Portable Laser Marking Machine is a game-changer for manufacturers seeking to improve their productivity and staying ahead of the competition. With its compact and lightweight design, this machine offers an unprecedented level of mobility, making it easily maneuverable on the factory floor. Its versatility enables it to mark an array of materials, including metal, plastic, and even glass, with utmost precision and accuracy.II. Unmatched Precision and EfficiencyThis advanced laser marking machine utilizes state-of-the-art technology to achieve unparalleled precision and efficiency. Equipped with a high-powered laser beam, it provides a wide range of marking options, from intricate designs to clear and readable text. The machine's exceptional speed ensures fast and efficient production, reducing downtime and increasing overall productivity.III. Cutting-Edge Features and VersatilityThe Portable Laser Marking Machine incorporates a range of innovative features that set it apart from traditional marking techniques. With advanced software integration, operators can easily design and customize markings, logos, serial numbers, and barcodes, promoting effortless personalization. The machine's intuitive interface and user-friendly controls allow for seamless operation, minimizing the need for extensive training.Adaptable to diverse manufacturing environments, this portable machine supports both static and dynamic marking, accommodating a wide variety of product shapes and sizes. Furthermore, it facilitates the marking of both flat and curved surfaces, ensuring optimal versatility across different industries.IV. Enhanced Safety MeasuresSafety is a key concern in industrial settings, and the Portable Laser Marking Machine addresses this by implementing stringent safety features. It incorporates a fully enclosed housing that effectively contains stray laser beams, preventing potential hazards. Integrated cooling systems ensure temperature regulation, preventing overheating and ensuring long-term functionality.V. Industry Applications and Market ProspectsThe Portable Laser Marking Machine has significant implications across a wide range of industries. In the automotive sector, it enables permanent marking of critical components, enhancing traceability and improving quality control. In the medical field, this machine offers precise engraving on surgical instruments and medical devices, facilitating easy identification and minimizing errors.The electronics industry can benefit from the Portable Laser Marking Machine for marking small components or circuit boards, aiding in product authentication and reducing counterfeiting risks. Other applications include aerospace, jewelry, and packaging industries, all of which can capitalize on the machine's high accuracy and rapid marking capabilities.Market projections for the Portable Laser Marking Machine are highly favorable, given its unmatched precision and efficiency. With its ability to streamline manufacturing processes, this machine is poised to become an indispensable tool for industries worldwide. Experts predict a significant growth in demand, as businesses aim to optimize production, ensure product authenticity, and comply with stringent quality standards.Conclusion:The introduction of the Portable Laser Marking Machine represents a significant leap forward in industrial efficiency and productivity. With its precision, adaptability, and safety features, this game-changing device is primed to revolutionize the way industries operate. As manufacturers seek innovative solutions to remain competitive, this portable machine offers an unprecedented level of customization and efficiency, propelling businesses to new heights.

Powerful Fiber Laser Cutter: The Ultimate Precision Cutting Solution

[Company Introduction:]With a rich history of technological innovation, exceptional precision, and high-quality products, [Company Name] has firmly established itself as a leading provider of laser cutting solutions. Founded in [Year], our company has continuously pushed the boundaries of what is possible in the field of laser technology. We are proud to introduce our latest cutting-edge innovation, the Fiber Laser Cutter.[News Content - 800 words][Opening Paragraph]In today's ever-evolving world of manufacturing and metal fabrication, laser cutting technology plays a vital role in shaping the industry's landscape. [Company Name], a pioneering name in laser cutting solutions, is now revolutionizing the market with the introduction of their latest innovation, the Fiber Laser Cutter. This cutting-edge machine promises to enhance productivity, precision, and efficiency, cementing [Company Name]'s position as a forward-thinking leader in the industry.[Body - Fiber Laser Cutter's Features and Benefits]The Fiber Laser Cutter encompasses a range of cutting-edge features that elevate it above its competitors. At the core of its design lies the integration of advanced fiber laser technology, which offers numerous advantages. With ultra-fast processing speeds, industry-leading precision, and exceptional beam quality, this machine ensures flawless execution of even the most intricate cutting tasks. The Fiber Laser Cutter also boasts excellent energy efficiency and low maintenance requirements, allowing businesses to optimize their productivity while minimizing operational costs.In addition to its technological advancements, the Fiber Laser Cutter's user-friendly interface ensures ease of operation for both experienced operators and novices alike. Its intuitive control panel, combined with state-of-the-art software, simplifies the programming and execution of intricate cutting patterns. This enables businesses to achieve high levels of productivity and accuracy without the need for extensive training or technical expertise.[Benefits for Various Industries]The Fiber Laser Cutter's versatility makes it suitable for a wide array of industries, including automotive, aerospace, electronics, and construction. Its ability to cut through various materials, including stainless steel, aluminum, and copper, provides immense value to manufacturers in these sectors. The machine's precision and flexibility allow for the creation of intricate and complex components, meeting the exacting demands of these industries.Moreover, the Fiber Laser Cutter ensures cost-effectiveness through reductions in waste material and secondary processing. Its exceptional accuracy minimizes errors and rework, resulting in increased efficiency and decreased operating costs for businesses. The machine's ability to work with different thicknesses and sizes of materials further enhances its applicability across various industries, catering to the specific needs of manufacturers in each sector.[Company Name's Commitment to Excellence]As a market leader, [Company Name] is renowned for providing exceptional customer support and service. The introduction of the Fiber Laser Cutter further reaffirms our commitment to meeting and exceeding our customers' expectations. With a dedicated team of experts, we provide comprehensive technical assistance, training, and maintenance services, ensuring that our customers derive maximum value from their investment.[Conclusion]The Fiber Laser Cutter represents a significant leap forward in laser cutting technology, offering unparalleled precision, efficiency, and versatility. [Company Name]'s commitment to innovation and customer satisfaction has propelled us to the forefront of the industry. By integrating advanced fiber laser technology and addressing the unique needs of various sectors, the Fiber Laser Cutter stands as a testament to our dedication to pushing the boundaries of excellence in laser cutting solutions.

Affordable Metal Engraving Machine for Small Projects

Mini Metal Engraving Machine Revolutionizing the IndustryThe metal engraving industry has seen a significant transformation with the introduction of the Mini Metal Engraving Machine by a leading company in the field. This innovative machine has revolutionized the way metal engraving is done, making the process faster, more precise, and efficient.The Mini Metal Engraving Machine is a compact and versatile tool that is designed to meet the growing demand for high-quality metal engraving in various industries such as jewelry making, metalworking, and signage production. This machine offers a range of features that make it an ideal choice for both small-scale businesses and large industrial operations.One of the standout features of the Mini Metal Engraving Machine is its precision and accuracy. Equipped with advanced technology and high-quality components, the machine is capable of engraving intricate designs and patterns with remarkable detail. This level of precision is essential for industries where the quality of the engraving is paramount, such as jewelry making where every detail matters.In addition to its precision, the Mini Metal Engraving Machine also offers speed and efficiency. With its fast engraving speed and automated functions, the machine can significantly reduce production time and increase output. This is particularly beneficial for businesses looking to streamline their operations and meet tight deadlines without compromising on quality.Furthermore, the Mini Metal Engraving Machine is user-friendly and easy to operate. Its intuitive interface and simple controls make it accessible to both experienced engravers and those new to the industry. This ensures that businesses can quickly integrate the machine into their production processes without the need for extensive training or specialized skills.The versatility of the Mini Metal Engraving Machine is another key advantage. It is capable of engraving a wide range of metals including stainless steel, aluminum, brass, and copper, as well as other materials such as plastics and acrylics. This flexibility allows businesses to expand their offerings and cater to a diverse range of customer needs.The company behind the Mini Metal Engraving Machine has a strong reputation in the industry for delivering high-quality and reliable engraving solutions. With years of experience and a commitment to innovation, they have continually pushed the boundaries of what is possible in metal engraving technology. Their dedication to excellence is evident in the performance and capabilities of the Mini Metal Engraving Machine.In addition to the machine itself, the company also provides comprehensive customer support and service. From installation and training to ongoing maintenance and technical assistance, they ensure that their clients are fully supported in maximizing the potential of the Mini Metal Engraving Machine. This level of dedication to customer satisfaction sets them apart as a trusted partner in the industry.Overall, the Mini Metal Engraving Machine is a game-changer for the metal engraving industry. Its combination of precision, speed, efficiency, and versatility has raised the bar for what is possible in metal engraving technology. With the backing of a reputable company and a strong emphasis on customer support, the machine is set to become a must-have tool for businesses looking to elevate their metal engraving capabilities.

Revolutionary CNC Machines Transforming Industrial Manufacturing Processes

CNC routers have been very popular in the manufacturing industry for many years. These computer-controlled machines are used for a wide variety of purposes, ranging from woodworking to metal cutting. With the advancement of technology, CNC routers have improved significantly and are now capable of producing highly precise cuts, reducing waste, and increasing efficiency in the production process. In this blog, we will explore the various applications of CNC routers in metal cutting.One of the most significant advantages of CNC routers is their precision. They are capable of creating highly accurate cuts, which is essential for metal cutting. This precision is a result of the computerized control, which allows for the machine to follow a set program that is designed to achieve the desired result. This is especially important when working with materials such as sheet metal or aluminum, where even the tiniest of errors can lead to costly mistakes.CNC routers also offer a high degree of versatility, allowing for a variety of materials to be cut, including steel, brass, and copper. The machines can cut through these materials with precision, making them ideal for applications such as the creation of intricate metal parts, components, and prototypes.Another advantage of CNC routers is their ability to produce multiple identical pieces with consistent quality. This is achieved by programming the machine to follow a set of instructions that ensures the same cut is replicated each time. This is particularly useful in mass production processes where identical pieces are required. The machine can produce these parts quickly and efficiently, which is vital when working to meet tight production deadlines.CNC routers are also an excellent option when it comes to creating complex shapes and designs. The machine can cut intricate patterns, curves and shapes with precision, allowing for the creation of detailed metal components. This is especially important in the creation of specialized equipment, where every component needs to be perfectly aligned for optimal functionality.In addition to these benefits, CNC routers are also highly automated, reducing the need for manual labor. This automation not only speeds up the production process but also reduces the likelihood of human error and increases efficiency. Operators can focus on other important tasks, such as designing and programming the machine, ensuring that the production process is streamlined and cost-effective.In conclusion, CNC routers are an invaluable tool when it comes to metal cutting. Their precision, versatility, and efficiency make them a popular choice in the manufacturing industry. From mass production of intricate metal components to the creation of complex designs and patterns, CNC routers provide a range of benefits that make them an ideal option for businesses looking to increase their productivity. If you're looking to incorporate metal cutting into your manufacturing process, a CNC router is an essential investment that can help your business thrive.Keywords: CNC router, metal cutting, precision, versatility, automation, efficiency, mass production, complex shapes.