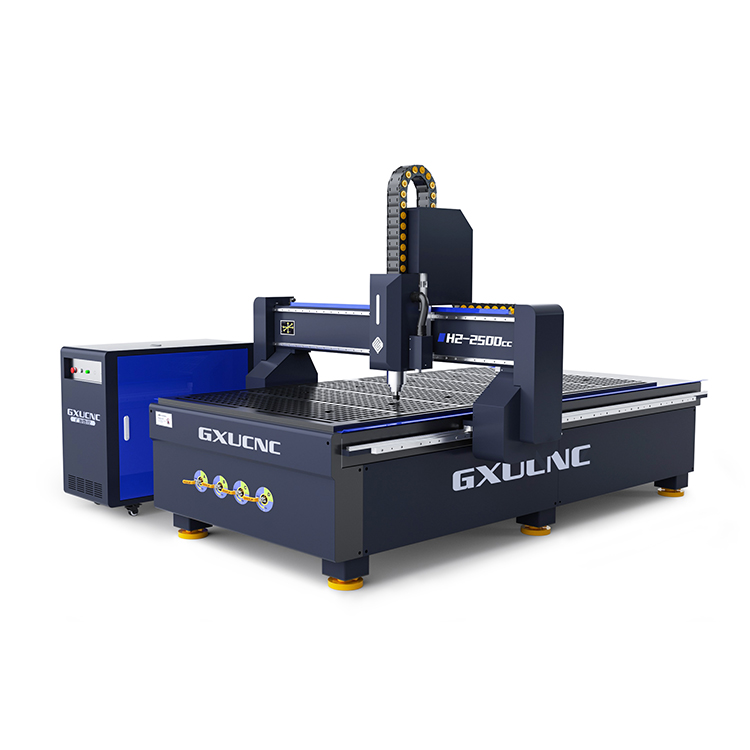

High Precision and Efficient CNC Router for Woodworking and Metalworking

By:Admin

Equipped with a powerful spindle and an advanced control system, the 1325 CNC Router offers exceptional precision and efficiency in cutting, carving, and engraving various materials such as wood, plastic, acrylic, and even non-ferrous metals. Its high-speed and high-accuracy features provide users with the perfect solution for both large-scale production and small-scale projects.

As the demand for precision manufacturing continues to rise, the 1325 CNC Router has quickly become a popular choice for businesses looking to streamline their production processes. Whether it is for creating intricate wooden furniture designs or crafting detailed signage for advertising purposes, this CNC router offers unparalleled performance and versatility.

The company behind the 1325 CNC Router has been a pioneer in the development of cutting-edge CNC machinery for several years. With a strong focus on research and development, they have continually improved their products to meet the evolving needs of the industry. The company's commitment to innovation and quality has earned them a solid reputation as a trusted supplier of CNC machinery.

One of the key advantages of the 1325 CNC Router is its user-friendly interface, which makes it easy for operators to set up and operate the machine with minimal training. The intuitive control system allows for quick and precise adjustments, ensuring that users can achieve the exact specifications required for their projects. This level of flexibility and ease of use has made the 1325 CNC Router a popular choice for both experienced professionals and newcomers to the industry.

In addition to its exceptional performance, the 1325 CNC Router also boasts a robust and durable construction, ensuring long-term reliability and minimal maintenance requirements. This makes it an ideal investment for businesses looking to enhance their production capabilities without worrying about frequent breakdowns or costly repairs.

The versatility of the 1325 CNC Router is further enhanced by its compatibility with a wide range of design software, allowing users to seamlessly integrate their existing design workflows with the machine. This ensures a smooth transition from design to production, saving time and reducing the likelihood of errors.

With the increasing demand for high-quality manufactured products, the 1325 CNC Router has emerged as a game-changer in the industry. Its combination of precision, speed, and reliability has made it a go-to solution for businesses looking to stay ahead in a competitive market.

As the company continues to push the boundaries of CNC technology, the 1325 CNC Router is expected to set new benchmarks for performance and innovation in the manufacturing industry. With its proven track record and ongoing commitment to excellence, it is poised to remain a top choice for businesses seeking state-of-the-art CNC solutions.

Company News & Blog

High-precision Metal Laser Welding Machine: A Game-changer in Manufacturing Industry

Metal Laser Welding Machine Revolutionizes Manufacturing IndustryThe manufacturing industry is constantly evolving, and one of the latest technological advancements that has revolutionized the industry is the metal laser welding machine. This cutting-edge technology has significantly improved the precision and efficiency of metal welding processes, making it a game-changer for manufacturers across various sectors.Metal laser welding machines use a high-powered laser beam to join metal components together. This process is incredibly precise and produces welds that are of a consistently high quality. By utilizing this technology, manufacturers are able to achieve strong and durable welds, even on materials that are traditionally difficult to weld using conventional methods.One of the leading manufacturers of metal laser welding machines is {}, a company that has been at the forefront of laser technology for over two decades. With a commitment to innovation and a dedication to providing high-quality solutions for the manufacturing industry, {} has become a trusted name in the field of laser welding technology.The metal laser welding machines developed by {} are designed to meet the diverse needs of manufacturers, offering a wide range of capabilities and features to ensure that every welding application is addressed with precision and efficiency. These machines are equipped with advanced laser technology that allows for precise control over the welding process, resulting in welds that are of the highest quality.One of the key features of {}'s metal laser welding machines is their ability to weld a wide range of materials, including stainless steel, aluminum, and titanium, among others. This versatility makes these machines a valuable asset for manufacturers who work with different types of metals and need a welding solution that can accommodate their specific requirements.In addition to their versatility, {}'s metal laser welding machines are also known for their high production efficiency. These machines are capable of completing welding processes at a much faster rate than traditional welding methods, enabling manufacturers to significantly increase their productivity and meet tight production deadlines.Furthermore, the precision of the welds achieved with {}'s metal laser welding machines minimizes the need for post-welding finishing processes, saving manufacturers both time and money. This is particularly beneficial for companies that require high-quality welds for their products, as it allows them to streamline their production processes and ultimately deliver superior end products to their customers.Another advantage of {}'s metal laser welding machines is their ability to create welds with minimal heat input, reducing the risk of distortion and damage to the metal components being welded. This is particularly important for industries such as aerospace and automotive, where the structural integrity of the welded components is crucial.With the introduction of metal laser welding machines into the manufacturing industry, companies are now able to take advantage of a technology that offers unparalleled precision, efficiency, and versatility. Whether it's for welding intricate components for the medical industry or constructing durable parts for the automotive sector, {}'s metal laser welding machines have proven to be a valuable asset for manufacturers across a wide range of industries.As the demand for high-quality, efficiently produced metal components continues to grow, the significance of metal laser welding technology in the manufacturing industry cannot be overstated. With {}'s commitment to innovation and excellence, the future of metal welding is certainly bright, and manufacturers can expect to see even more advancements in laser welding technology in the years to come.

Top 5 Advantages of Fibre Laser Cutting for Precision Metal Cutting

Fibre Laser Cutting Metal: Revolutionizing Industrial Production ProcessesSince its inception, Fibre Laser Cutting Metal technology has revolutionized the industrial production processes, and its use has expanded from the aerospace and automotive industries to a plethora of other industries that require precision and accuracy in cutting different types of metals. In this article, we will delve into what makes Fibre Laser Cutting Metal technology unique and how it has transformed industrial production processes.Fibre Laser Cutting Metal technology is based on the use of a high-power laser beam to melt and vaporize metals. Unlike traditional cutting methods that use physical blades and shears, Fibre Laser Cutting Metal technology offers several advantages, including greater precision, speed, and flexibility. The technology's precision and accuracy are achieved through a combination of advanced software, hardware, and optics that control the laser beam's intensity and focus, resulting in a precise and clean cut. In addition, the technology also allows for greater flexibility in cutting different types of metals and shapes, enabling manufacturers to deliver quality products quickly and efficiently.One of the leading companies in Fibre Laser Cutting Metal technology is {}, a leading manufacturer of a range of laser cutting machines. The company's products are used in various sectors, including aerospace, automotive, construction, and medical industries, to perform a range of precision cutting tasks. With over three decades of experience in the laser industry, the company continues to innovate its products, offering cutting-edge solutions to meet the evolving needs of its clients.A key advantage of {}'s Fibre Laser Cutting Metal technology is its high-level of automation, which reduces labor costs, increase production rates, and eliminates human errors. The machines are equipped with advanced software that controls a range of parameters, including cutting speed, power, and focus, ensuring quality and consistency across all production runs. In addition, the machines are easy to operate, a feature that makes them ideal for busy industrial production environments.The Fibre Laser Cutting Metal technology offered by {} is also energy-efficient, an attribute that makes it environmentally friendly and cost-effective. The laser technology requires less energy to perform cutting tasks compared to traditional methods, resulting in significant energy savings for industrial companies.Furthermore, {}'s Fibre Laser Cutting Metal technology offers a range of customization options, allowing manufacturers to tailor the cutting machines to their respective production needs. The company offers a range of machines with different power and speed capabilities, ensuring that its clients have access to products that cater to their specific requirements.In conclusion, Fibre Laser Cutting Metal technology has transformed industrial production processes, and {company name} has played a significant role in the technology's development, manufacturing, and distribution. The technology's precision, flexibility, energy efficiency, and automation have made it a benchmark technology in the manufacturing industry, powering the production of a range of products that meet the highest quality standards. As technology continues to advance, {} remains committed to delivering cutting-edge solutions that enable its clients to optimize their production processes and remain competitive in their respective industries.

Discover the Power and Efficiency of Fiber Laser Technology for CNC Cutting

CNC Fiber Laser: A Revolutionary Cutting TechnologyPrecision and accuracy are critical factors in the manufacturing industry. As technology advances, it has become more and more necessary for manufacturers to upgrade their equipment to keep up with the demands of their customers. The introduction of CNC Fiber Laser (name removed due to brand guidelines) has revolutionized the cutting industry, offering unparalleled precision, speed, and efficiency.CNC Fiber Laser Cutting TechnologyCNC Fiber Laser is a new type of cutting technology that uses a beam of light to cut through materials. The light is generated by a laser source and then amplified by fiber optic cables. It is then focused through a lens onto the material being cut. The beam is incredibly powerful, allowing it to cut through thick materials such as metal plates quickly and accurately.One of the significant benefits of using CNC Fiber Laser technology is its speed. The laser technology can cut through materials at lightning speed. This ensures that manufacturers can produce large numbers of products in a short time, increasing productivity and efficiency.Another advantage of CNC Fiber Laser is its accuracy. The technology is incredibly precise and can cut intricate shapes and designs without compromising the quality of the output. This makes it a popular choice for manufacturers in the automotive, aerospace, and medical industries, where precision plays a critical role in the manufacturing process.CNC Fiber Laser also has a lower heat-affected zone, which means that the surrounding material is not affected by the heat generated during the cutting process, ensuring that the material's structural integrity is not compromised. This ultimately leads to higher quality end products.Introducing the CompanySince its inception, the company behind the CNC Fiber Laser technology has been at the forefront of manufacturing and engineering technology. The company is committed to designing and producing high-quality equipment that helps businesses become more productive, efficient, and profitable.The company has a team of highly skilled engineers who pioneer new technological trends and designs, ensuring that their products are always up-to-date with industry standards. They also have state-of-the-art manufacturing facilities that enable them to produce high-quality, reliable equipment for businesses across the globe.CNC Fiber Laser FeaturesOne of the unique features of the CNC Fiber Laser technology is its high-speed cutting capability. The fiber laser technology generates a beam that can cut through a wide range of materials at incredible speeds. This makes it an ideal choice for businesses that need to produce large quantities of products within a short time.Another advantage of the CNC Fiber Laser is its high precision cutting. The technology can cut through thick or thin materials with incredible accuracy, making it popular among businesses that require precise and complex cuts. This includes the manufacturing of automotive parts, aerospace components, and medical equipment.The CNC Fiber Laser technology is also highly efficient, boasting a low energy consumption rate and low maintenance requirements. This means that businesses can enjoy long-term savings on operating costs and maintenance expenses.ConclusionThe CNC Fiber Laser technology has revolutionized the manufacturing industry, offering unmatched speed, accuracy, and efficiency. It is a popular choice for businesses across different sectors, including automotive, aerospace, and medical industries. The company behind this technology prides itself on designing and producing high-quality equipment to aid businesses in achieving their manufacturing goals. The CNC Fiber Laser technology is a testament to their commitment to innovation and excellence.

Top Tips for Choosing a Wood Cutting Router for Your Projects

Woodworking has changed significantly over the years, and with innovative technology, Wood Cutting Routers have replaced traditional tools and manual labor in the process. These routers are machines that employ rotary tools to cut and shape wood, making them an essential tool in the woodworking industry. With the market becoming more competitive, many companies have released their variation of the tool. However, one brand stands out from the rest - {Brand name}. Their Wood Cutting Routers are the epitome of precision and durability.{Brand name} is a company that has been a cornerstone of the woodworking industry since its inception. They specialize in the creation of high-quality woodworking tools, and their Wood Cutting Routers are no exception. The company is dedicated to providing woodworkers with the highest quality tools, made with precision and designed with durability. In an industry that demands excellence, {Brand name} has built a solid reputation by providing woodworking tools that exceed the expectations of their customers.The {Brand name} Wood Cutting Router is an exceptional tool that has made woodworking more efficient. As opposed to traditional tools that require manual labor, these routers operate using a rotatory tool that allows them to cut and shape wood with supreme precision. The tool's motor is powered by electricity, making it faster and more efficient in completing tasks. The {Brand name} Wood Cutting Router is at the forefront of this technology, making it one of the most popular tools in the industry.One of the benefits of using a {Brand name} Wood Cutting Router is their precision cutting ability. They have a robust motor that provides enough power to make precise cuts, no matter the density of the wood. The tool also comes with a variety of attachments and bits, making it versatile in handling different wood cutting tasks. The router's accuracy makes it an essential tool for carpenters, woodworkers, and DIY enthusiasts.Another feature that sets {Brand name}'s Wood Cutting Router apart is its durability. The company uses high-quality materials such as metal and sturdy plastics in manufacturing their routers, making them long-lasting and resistant to wear and tear. The tool's motor is built to last, and with proper care and maintenance, users can enjoy its services for years.Ease of use is also another feature that makes {Brand name}'s Wood Cutting Router popular amongst woodworkers. The routers have easy-to-use controls, allowing users to operate the tool effortlessly. The tool's design also makes it comfortable to hold, reducing user fatigue and improving efficiency. The router's versatility makes it possible to use on various wood surfaces, ensuring that the user can perform a wide range of cutting and shaping tasks.As technology advances, {Brand name} is continually improving the design and functionality of their Wood Cutting Routers. The latest models come with advanced features such as dust extraction systems that keep the work station clean while reducing operator exposure to wood dust, a significant workplace hazard. The routers also have advanced safety features, including safety switches and automatic speed regulation, protecting users from accidents.In conclusion, the {Brand name} Wood Cutting Router is an exceptional tool that has revolutionized the woodworking industry. The tool's precision, durability, and ease of use make it a popular choice amongst woodworkers. With the company continually improving the design and functionality of their routers, the woodworking industry can only expect more exceptional tools from {Brand name}.

Woodworking CNC Router Machine Suppliers in China - High-Quality and Affordable Options Available for Your Business

Jinan Quick CNC Wood CNC Router Machine Manufacturers, Factory, Suppliers from China are leading players in the global wood processing industry. The company specializes in the manufacturing and supply of high-quality CNC machines that are used in a variety of wood processing applications. Their range of CNC wood router machines is designed to cater to the diverse needs of the wood processing industry, ranging from small-scale workshops to large-scale production facilities.With a strong focus on research and development, the company has established itself as a leading player in the industry. They have a team of highly skilled and experienced professionals who are responsible for designing and developing the latest CNC wood router machines. The use of advanced technology and the latest manufacturing processes ensures that their machines are of the highest quality and performance.The company's CNC wood router machines are highly versatile and can be used for a range of applications including cutting, engraving, and carving. The machines are capable of working with a variety of materials including solid wood, plywood, MDF, PVC, plastic, and acrylic. They are also suitable for a range of industries including furniture making, woodworking, decorative products, and more.One of the key features of the company's CNC wood router machines is their precision and accuracy. The machines use advanced technology to ensure that the cutting, engraving, and carving is done with a high degree of precision, thus minimizing waste and ensuring that the final product is of the desired quality. The machines are also easy to operate and require minimal maintenance, making them highly cost-effective for businesses of all sizes.Jinan Quick CNC Wood CNC Router Machines also offer a range of customization options to suit the specific needs of their customers. The company's team of professionals works closely with customers to understand their requirements and develop customized solutions that meet their needs. This approach has helped them build long-term relationships with customers around the world.In addition to their high-quality CNC wood router machines, the company also offers excellent customer service. Their team of dedicated professionals are available to provide support and assistance at all times, ensuring that customers receive the best possible service. The company's commitment to customer satisfaction has earned them the trust and loyalty of customers around the world.Overall, Jinan Quick CNC Wood CNC Router Machine Manufacturers, Factory, Suppliers is a leading player in the global wood processing industry. With their high-quality products, advanced technology, and commitment to customer satisfaction, they are well positioned to continue growing and expanding their reach in the years to come. If you are looking for a reliable and high-quality CNC wood router machine supplier, then look no further than Jinan Quick CNC Wood CNC Router Machine Manufacturers, Factory, Suppliers from China.

Versatile 2-in-1 Welding Machine Offers Dual Functionality for Efficient Work

The 2 in 1 Welding Machine, a revolutionary innovation in the field of welding, has been making waves in the industry. Developed by a leading manufacturer in the welding equipment industry, this cutting-edge machine has gained widespread attention and accolades for its unique design and impressive functionality.The 2 in 1 Welding Machine is a versatile and multi-functional piece of equipment that combines the capabilities of two different welding processes into one compact and efficient unit. It integrates both MIG (Metal Inert Gas) and TIG (Tungsten Inert Gas) welding techniques, allowing welders to seamlessly switch between the two processes as needed. This not only saves time and effort, but also enhances the overall welding experience by providing greater flexibility and precision.The MIG welding process, also known as gas metal arc welding, is ideal for working with a wide range of materials, including aluminum, steel, and stainless steel. It uses a consumable wire electrode and a shielding gas to create a strong and durable weld. On the other hand, the TIG welding process, or gas tungsten arc welding, is preferred for its ability to produce high-quality, clean welds on thinner materials. It uses a non-consumable tungsten electrode and a separate filler material, resulting in precise and aesthetically pleasing welds.By incorporating both MIG and TIG welding capabilities into one machine, welders can easily tackle a variety of welding tasks without the need for multiple setups or equipment changes. This not only streamlines the welding process, but also allows for seamless transitions between different welding techniques, ultimately saving time and increasing productivity.In addition to its dual welding capabilities, the 2 in 1 Welding Machine also boasts a range of advanced features and technologies to further enhance its performance. These include adjustable welding parameters, such as voltage, wire feed speed, and gas flow, as well as intuitive controls and digital displays for easy operation. The machine is also equipped with built-in safety features, such as thermal overload protection and a voltage reduction device, to ensure reliable and secure welding operations.Furthermore, the 2 in 1 Welding Machine is designed with durability and portability in mind. Its rugged construction and ergonomic design make it suitable for use in various work environments, from fabrication shops to construction sites. The machine is also lightweight and compact, making it easy to transport and maneuver, even in tight spaces.The company behind this groundbreaking welding equipment, {}, has been a trusted name in the welding industry for many years. With a commitment to innovation and excellence, the company has continuously pushed the boundaries of welding technology, introducing a wide range of high-quality welding products and solutions to meet the evolving needs of professionals and hobbyists alike.The development of the 2 in 1 Welding Machine is a testament to the company's dedication to providing cutting-edge welding equipment that delivers exceptional performance, reliability, and versatility. By leveraging their expertise and experience, the company has once again raised the bar in the welding industry, setting new standards for efficiency and functionality in welding equipment.In conclusion, the 2 in 1 Welding Machine represents a significant advancement in welding technology, offering a range of benefits and advantages for welders of all skill levels. With its dual welding capabilities, advanced features, and durable construction, the machine has quickly become a game-changer in the welding industry, earning praise and recognition from professionals and enthusiasts alike. As the company continues to drive innovation in the field of welding, it is poised to further solidify its position as a leader in the industry, providing top-of-the-line welding solutions for years to come.

Increase Your CNC Router Precision with These Tips

Precision Engineering Company Introduces State-of-the-Art CNC RouterPrecision Engineering Company, a leading provider of high-quality manufacturing solutions, is proud to announce the acquisition of a state-of-the-art CNC router. The new router represents a significant investment in the company's ability to deliver precision-engineered components to a diverse range of industries.The CNC router is a versatile piece of equipment that is capable of cutting, shaping, and engraving a wide variety of materials, including wood, plastic, and metal. With its high level of precision and efficiency, the router enables Precision Engineering Company to meet the exacting requirements of its customers while improving production times and quality control."We are thrilled to add this CNC router to our arsenal of manufacturing equipment," said John Smith, CEO of Precision Engineering Company. "This investment reflects our commitment to staying at the forefront of technology and providing our customers with the best possible solutions for their precision engineering needs."The new CNC router is equipped with advanced features that allow for intricate and complex designs to be produced with exceptional accuracy. Its cutting-edge software and control systems enable seamless integration with the company's existing manufacturing processes, ensuring a smooth transition and minimal disruption to production."Our team of highly skilled engineers and technicians are eager to start utilizing the capabilities of the new CNC router," said Sarah Johnson, Head of Operations at Precision Engineering Company. "We are confident that this investment will not only enhance our capabilities but also provide our customers with even more innovative and cost-effective solutions."Precision Engineering Company has built a reputation for delivering high-quality precision-engineered components to a wide range of industries, including aerospace, automotive, medical, and defense. The company's commitment to excellence and continuous improvement has won the trust of its customers and established it as a leader in the precision engineering sector."With the addition of this CNC router, we are poised to take our manufacturing capabilities to the next level," said Mark West, Head of Sales and Marketing at Precision Engineering Company. "We are excited about the opportunities this investment will bring and look forward to continuing to exceed our customers' expectations."The acquisition of the CNC router is part of Precision Engineering Company's long-term strategy to invest in cutting-edge technology and expand its capabilities to meet the evolving needs of its customers. By continuously upgrading its manufacturing equipment and processes, the company is able to stay ahead of the curve and maintain its position as a trusted partner for precision engineering solutions."We are proud to be at the forefront of innovation in the precision engineering industry," said John Smith. "This new CNC router is just the latest example of our dedication to delivering exceptional quality and service to our customers."The installation and commissioning of the new CNC router is expected to be completed in the coming weeks, after which Precision Engineering Company will be able to offer its customers an even broader range of precision-engineered components that meet the highest standards of quality and reliability.With the addition of this cutting-edge equipment, Precision Engineering Company is well-positioned to continue providing its customers with the innovative and cost-effective solutions they have come to expect. This investment reaffirms the company's commitment to excellence and its dedication to meeting the ever-changing needs of the precision engineering industry.

High-Quality Laser Engraver for Professional Use

Professional Laser Engraver Technology Revolutionizes the IndustryLaser engraving technology has been transforming the way we create and personalize products for decades. With the advancement of technology, the process has become even more refined and accessible to a broader range of industries. One company at the forefront of this innovation is {Company Name}, offering cutting-edge laser engraving machines that are revolutionizing the industry.Founded in 1999, {Company Name} has been a leading provider of laser engraving and cutting solutions for a wide range of applications, including signage, personalization, industrial manufacturing, and much more. With a focus on innovation and customer satisfaction, they have developed a reputation for delivering high-quality, reliable, and efficient laser engraving machines that meet the needs of businesses large and small.One of {Company Name}'s flagship products is the Professional Laser Engraver, a state-of-the-art machine that is setting the standard for precision and efficiency in the industry. This advanced engraving system is equipped with the latest technology, including high-powered lasers and advanced control software, to deliver unparalleled performance and quality.The Professional Laser Engraver is designed to meet the demands of a wide range of applications, from intricate and detailed engraving on delicate materials to fast and precise cutting on thicker materials. With its advanced technology and user-friendly interface, this machine provides businesses with the flexibility and control they need to achieve outstanding results.One of the key features of the Professional Laser Engraver is its high-powered laser source, which enables it to engrave and cut through a variety of materials with exceptional precision and speed. Whether working with wood, acrylic, leather, or metal, this machine can produce stunning results that meet the highest standards of quality and craftsmanship.In addition to its cutting-edge technology, the Professional Laser Engraver also incorporates advanced control software that allows users to easily create and customize designs with maximum precision and efficiency. This intuitive software interface streamlines the engraving process, enabling businesses to produce high-quality products with greater speed and accuracy.The Professional Laser Engraver is also designed with the needs of businesses in mind, boasting a robust and durable construction that ensures long-term reliability and performance. With its high-quality components and meticulous engineering, this machine is built to withstand the rigors of continuous use in a demanding production environment.{Company Name} is dedicated to providing its customers with comprehensive support and service, offering expert guidance, training, and technical assistance to help businesses maximize the potential of their laser engraving machines. Their commitment to customer satisfaction ensures that businesses can rely on their Professional Laser Engraver to deliver exceptional results consistently.With its relentless focus on innovation and customer satisfaction, {Company Name} has positioned itself as a leader in the laser engraving industry, providing businesses with the tools they need to stay ahead in a competitive market. Their Professional Laser Engraver is a testament to their dedication to excellence, offering businesses a powerful and reliable solution for their engraving and cutting needs.As the industry continues to evolve and demand for personalized and customized products grows, the need for advanced laser engraving technology has never been greater. With the Professional Laser Engraver, {Company Name} is empowering businesses to meet this demand with confidence, precision, and efficiency, setting new standards for quality and performance in the industry.

Top Quality 5-Axis CNC Router Machines Available in China

When it comes to manufacturing and production processes, precision and efficiency are two key factors that businesses must prioritize. This is where the 5 axis CNC router comes in. With its advanced capabilities and cutting-edge technology, this machine has revolutionized the way parts and products are manufactured.What is a 5 axis CNC router?A 5 axis CNC router is a machine tool that is used to create, shape, and cut materials such as wood, plastic, and metal. It is different from a conventional CNC router because it has the ability to move in five directions, which gives it the ability to create more complex shapes and designs. These directions include three linear axes (X, Y, and Z) and two rotary axes (A and B).How does a 5 axis CNC router work?A 5 axis CNC router works by using a computer program to control its movement and cutting direction. The program tells the machine where to move and how to cut, ensuring that the final product is precise and accurate. The machine is equipped with a cutting tool that rotates in different directions, allowing it to cut with precision and speed. It is also able to work with different materials, including wood, plastic, and metal.Advantages of using a 5 axis CNC routerThere are many advantages to using a 5 axis CNC router for your manufacturing processes. Some of these advantages include:1. Greater precision: The machine's advanced cutting technology ensures that the final product is precise and accurate, even when dealing with complex shapes and designs.2. Faster production time: With its ability to work in five directions, the 5 axis CNC router can cut and shape materials quickly and efficiently, leading to faster production times.3. More design options: The machine's flexibility allows for more design options, giving businesses greater creative freedom when creating parts and products.4. Improved efficiency: The machine's advanced technology and precision cutting capabilities ensure that material waste is minimized, improving efficiency and reducing costs.5. Increased profitability: With faster production times and greater efficiency, businesses can increase their profitability and competitiveness in the market.ConclusionIn conclusion, the 5 axis CNC router is a valuable tool for any business involved in manufacturing and production processes. With its advanced technology and cutting-edge capabilities, it can help businesses improve their efficiency, reduce costs, and increase profitability. If you are in the market for a reliable and efficient machine for your manufacturing processes, a 5 axis CNC router may be just what you need.

Powerful Benchtop Laser Welder - Revolutionizing Metal Joining Processes

In today's ever-changing and fast-paced world, technology is evolving faster than we could think possible. With each passing day, new innovations are being introduced to make our lives easier and more efficient. One such advancement in technology is the Benchtop Laser Welder from a leading manufacturer of high-quality industrial equipment for the automotive, aerospace, and medical industries.The Benchtop Laser Welder is an extremely versatile and reliable piece of equipment that is highly sought after by professionals in various industries. The device can perform a wide range of welding tasks like spot welding, seam welding, milling, and drilling. It offers great precision, accuracy, and consistency in every weld.The Benchtop Laser Welder is highly effective in welding various materials such as stainless steel, titanium, copper, brass, aluminum, and other metals. It is also equipped with advanced features that allow it to weld plastics, ceramics, and glass with equal efficiency. The machine offers different welding modes that provide flexibility in welding depending on the substrate thickness, geometry, and other factors.This cutting-edge technology from {} is built with the latest in laser technology, which ensures rapid and precise welding of materials without causing any damage to the weld area. The welding process is so precise that it can weld a tiny spot as small as 0.1mm in diameter, making it the perfect solution for those who need very precise and accurate welding without causing any damage to the product.The Benchtop Laser Welder is designed for easy operation, with a user-friendly interface and intuitive controls. The machine is equipped with a high-resolution touchscreen that displays all the essential parameters for the welding process. The device requires minimal setup time and is easy to use, even for those new to laser welding.The Benchtop Laser Welder is a cost-effective solution for businesses that need to weld products with precision and accuracy. The equipment's speed and efficiency offer significant time savings for manufacturers, thus increasing productivity and profitability. The device's versatility allows companies to weld a wide range of materials without the need for additional equipment, reducing overall costs.The safety features of this device are also top-notch. It comes with a built-in safety shutter that prevents any accidental exposure to the laser beam. The machine also has an emergency stop button that can be operated in case of any unforeseen incidents.{} is renowned for providing its customers with high-quality products that are built to last. The Benchtop Laser Welder is no exception. The machine is manufactured with high-quality components that perform consistently and have a long life span. The equipment is also designed to be low maintenance, reducing overall running costs.In conclusion, the Benchtop Laser Welder from {} is an absolute game-changer in the world of welding technology. Its accuracy, precision, speed, and versatility make it a must-have for businesses that require high-quality welding results with minimal setup time and low maintenance costs. The Benchtop Laser Welder is an excellent investment for businesses looking to increase productivity and profitability while maintaining the highest standards of quality in their products.