High-Powered Multifunction Welder for All Your Welding Needs

By:Admin

In the fast-paced world of industrial manufacturing, efficiency and versatility are key factors in maintaining a competitive edge. With the introduction of the Multifunction Welder by [Company Name], welding technology has taken a significant leap forward. This state-of-the-art welding equipment offers a wide range of features that not only streamline the welding process but also enhance the overall productivity and quality of the output.

The Multifunction Welder, developed by [Company Name], is designed to meet the diverse needs of industrial welders, from large-scale production to small-scale fabrication. With its cutting-edge technology and ergonomic design, this equipment provides a one-stop solution for a variety of welding tasks, including MIG, TIG, stick, and flux-cored welding. Its multifunction capabilities allow for seamless transition between different welding processes, eliminating the need for multiple machines and reducing the setup time.

One of the key features of the Multifunction Welder is its advanced control system, which offers precise control over the welding parameters such as voltage, current, and wire feed speed. This level of control allows for a highly accurate and consistent welding process, resulting in high-quality welds with minimal rework or waste. Additionally, the equipment is equipped with a digital interface that provides real-time monitoring of the welding parameters, enabling welders to make immediate adjustments as needed.

Furthermore, the Multifunction Welder is designed with user-friendly features that simplify the welding process and enhance the overall efficiency. Its intuitive interface and easy-to-use controls make it accessible to welders of all skill levels, while the ergonomic design ensures comfortable and safe operation. In addition, the equipment is equipped with advanced safety features such as thermal overload protection and voltage fluctuation protection, ensuring the safety of the welder and the integrity of the equipment.

[Company Name] has a proven track record of providing high-quality welding equipment to the industrial sector. With a strong focus on innovation and customer satisfaction, the company has earned a reputation for delivering reliable and efficient solutions to its clients. The Multifunction Welder is the latest addition to its extensive product line, and it represents a significant milestone in the company's commitment to advancing welding technology.

In addition to its cutting-edge technology, the Multifunction Welder is backed by [Company Name]'s comprehensive customer support and after-sales service. The company offers training, technical assistance, and spare parts availability to ensure that its clients can maximize the benefits of the equipment and operate it with confidence. This commitment to customer satisfaction further reinforces the reliability and value of the Multifunction Welder.

The introduction of the Multifunction Welder by [Company Name] is set to revolutionize the industrial welding landscape. With its advanced technology, multifunction capabilities, and user-friendly design, this equipment offers a superior welding solution that meets the evolving needs of the industry. As manufacturing processes continue to become more complex and demanding, the Multifunction Welder provides a competitive edge by delivering efficiency, versatility, and quality in one comprehensive package.

Company News & Blog

Ultimate Guide to Precision CNC Router Technology

CNC Router Precision: A Game-Changer in the Manufacturing IndustryIn today's fast-paced and competitive manufacturing industry, precision and efficiency are key factors that can make or break a business. This is where CNC Router Precision comes into play as a game-changer. This innovative technology has revolutionized the way companies approach their manufacturing processes, offering unparalleled precision and quality. With its advanced capabilities, CNC Router Precision has become the go-to solution for businesses looking to stay ahead of the curve.CNC Router Precision is a cutting-edge technology that utilizes computer numerical control (CNC) to precisely cut, carve, and shape various materials such as wood, plastic, and metal. This technology allows for intricate and complex designs to be executed with utmost accuracy, resulting in high-quality products and satisfied customers.By using CNC Router Precision, companies can streamline their manufacturing processes and significantly reduce production time. This is achieved through the automation of tasks, which eliminates the need for manual labor and reduces the likelihood of errors. With CNC Router Precision, businesses can optimize their production efficiency and increase their output without compromising on quality.One of the key advantages of CNC Router Precision is its ability to accommodate a wide range of design specifications. Whether it's creating intricately detailed furniture pieces, customized signage, or precision components for electronic devices, CNC Router Precision can handle it all with precision and ease. This versatility allows businesses to diversify their product offerings and cater to a broader market.Furthermore, CNC Router Precision is a cost-effective solution for businesses. By minimizing material wastage and maximizing production efficiency, companies can reduce their overall manufacturing costs and improve their bottom line. This is particularly beneficial for small to medium-sized businesses that are looking to compete with larger players in the industry.The implementation of CNC Router Precision is also a step towards sustainability. By optimizing production processes and minimizing waste, businesses can contribute to a more eco-friendly manufacturing industry. This is an important consideration for companies looking to align their operations with sustainable practices and reduce their environmental impact.{} is at the forefront of the CNC Router Precision revolution. With a strong focus on innovation and customer satisfaction, they have established themselves as a leading provider of CNC Router Precision solutions. Their expertise in this technology has enabled them to work with a diverse range of clients, from small businesses to large corporations, helping them achieve their manufacturing goals with precision and efficiency.{} is committed to providing top-of-the-line CNC Router Precision solutions that are tailored to each client's specific needs. With a team of experienced engineers and technicians, they offer comprehensive support and technical expertise to ensure seamless integration and operation of CNC Router Precision systems. Their dedication to delivering exceptional quality and service has earned them a reputation as a trusted partner in the manufacturing industry.By leveraging the power of CNC Router Precision, businesses can elevate their manufacturing capabilities and stay ahead of the competition. With its unparalleled precision, efficiency, and cost-effectiveness, CNC Router Precision is a game-changer that is reshaping the future of manufacturing. As the industry continues to evolve, businesses that embrace this technology will have a significant advantage in meeting the demands of an increasingly competitive market.In conclusion, CNC Router Precision is a transformative technology that is revolutionizing the manufacturing industry. With its advanced capabilities and benefits, businesses can enhance their production processes, reduce costs, and deliver high-quality products to their customers. As the industry continues to embrace CNC Router Precision, businesses that adopt this technology will be well-positioned to thrive in an evolving and competitive market.

High-precision Three Axis Milling Machine for Industrial Use

The Three Axis Milling Machine is an advanced piece of equipment that has greatly improved the efficiency and precision of the manufacturing process. With its ability to accurately cut and shape materials in three dimensions, this machine has become an essential tool for many industries.Manufactured by a leading machinery company, this Three Axis Milling Machine incorporates cutting-edge technology and innovative design to provide users with the highest level of performance and reliability. Whether it is used for prototyping, production, or custom machining, this machine has proven to be a valuable asset for businesses looking to streamline their manufacturing operations.One of the key features of the Three Axis Milling Machine is its precision and accuracy. The machine is equipped with state-of-the-art control systems and sensors that ensure the exact replication of programmed designs. This level of precision is essential for the manufacturing of parts and components that require tight tolerances and intricate shapes.Furthermore, the Three Axis Milling Machine is designed for versatility and flexibility. Its advanced software allows for the seamless integration of complex designs, and its multi-axis cutting capabilities enable the production of intricate parts with ease. Whether it is used for milling, drilling, or cutting, this machine can handle a wide variety of materials, including metals, plastics, and composites.The Three Axis Milling Machine also offers a high level of efficiency and productivity. Its automated features and rapid tool changing capabilities allow for quick and uninterrupted machining, reducing production times and increasing throughput. This means that businesses can produce more parts in less time, ultimately leading to increased profitability and competitiveness in the market.In addition to its performance and capabilities, the Three Axis Milling Machine is also designed with user-friendly features that make it easy to operate and maintain. Its intuitive interface and programming software allow for simple set-up and operation, while its robust construction and durable components ensure long-term reliability and minimal downtime.Overall, the Three Axis Milling Machine has had a significant impact on the manufacturing industry, helping businesses improve their production processes and deliver high-quality products to their customers. Its precision, versatility, efficiency, and user-friendly design make it a valuable asset for any company looking to stay ahead in the fast-paced world of modern manufacturing.As a leading machinery company, we are committed to providing our customers with the highest quality equipment and solutions to meet their manufacturing needs. Our Three Axis Milling Machine is a prime example of our dedication to innovation and excellence, and we are proud to offer this advanced technology to businesses around the world.With our extensive experience and expertise in the industry, we have developed a reputation for delivering reliable and cutting-edge machinery that helps our customers achieve their production goals. Our Three Axis Milling Machine is just one of the many products in our comprehensive lineup of machining solutions, and we are confident that it will continue to make a positive impact on the manufacturing sector.In conclusion, the Three Axis Milling Machine is a game-changing piece of equipment that has revolutionized the manufacturing process. Its precision, versatility, efficiency, and user-friendly design have made it an invaluable tool for businesses of all sizes. As a leading machinery company, we are proud to offer this advanced technology to our customers and help them stay ahead in the competitive world of modern manufacturing.

Laser Cutting Job Opening in Dudley, UK: Apply Now with ASC Connections!

If you're looking for a job in the engineering and manufacturing sectors, then the Laser Cutter job with ASC Connections Ltd could be the perfect opportunity for you. Located in Dudley, UK, this job is ideal for those who have experience in using steel laser cutters and are looking for a challenging and rewarding role.The use of laser cutters is becoming increasingly popular in the engineering and manufacturing industries due to their accuracy, speed, and versatility. Steel laser cutters can cut through a variety of materials, including steel, aluminum, and copper, making them an essential tool for producing precision parts and components.As a Laser Cutter with ASC Connections Ltd, you will be responsible for operating and maintaining the steel laser cutter to produce high-quality parts. You will be required to read and follow technical drawings and specifications, and have a good understanding of CNC programming. You may also be required to carry out minor repairs and adjustments to ensure the laser cutter is operating at maximum efficiency.To be successful in this role, you will need to have experience in using steel laser cutters, a good understanding of engineering principles, and excellent attention to detail. You will also need to be a good communicator and work well as part of a team.This Laser Cutter job with ASC Connections Ltd offers an excellent salary package and opportunities for career development within the company. You will be working in a modern and well-equipped manufacturing facility, alongside a team of experienced engineers and technicians.If you're looking to take your career in the engineering and manufacturing industries to the next level, then this Laser Cutter job with ASC Connections Ltd could be the perfect opportunity for you. Apply today and take the first step towards a challenging and rewarding career in this exciting sector.

CNC Co2 Laser Cutting News: Latest Updates and Trends

[Company Name] Introduces Innovative Co2 Laser CNC Machine for Precision Cutting and Engraving[City, State] - [Company Name], a leading provider of advanced manufacturing solutions, has recently unveiled their latest innovation in laser cutting and engraving technology - the Co2 Laser CNC machine. This cutting-edge machine is designed to provide impeccable precision and exceptional efficiency, making it an ideal solution for a wide range of industries.The new Co2 Laser CNC machine is equipped with state-of-the-art technology that delivers high-quality results with unparalleled accuracy. The machine’s advanced laser cutting capabilities are suitable for a variety of materials including wood, acrylic, leather, and plastic, making it a versatile tool for businesses seeking to elevate their production capabilities.“We are thrilled to introduce the Co2 Laser CNC machine to our customers,” said [Spokesperson Name], [Title] at [Company Name]. “This advanced technology represents a significant leap forward in precision cutting and engraving, and we are confident that it will have a positive impact on our customers’ operations.”The Co2 Laser CNC machine is designed with user-friendly features that make it easy to operate and maintain. Its high-speed cutting capability ensures swift and efficient production, while its precision engraving function allows for intricate designs and detailed patterns to be etched onto various materials.In addition to its cutting and engraving capabilities, the Co2 Laser CNC machine is also equipped with a powerful extraction system that removes fumes and debris, creating a clean and safe working environment for operators. This feature is essential for businesses prioritizing workplace safety and environmental responsibility.[Company Name] has a long-standing reputation for delivering cutting-edge manufacturing solutions to a diverse clientele, spanning industries such as signage, woodworking, packaging, and more. With the introduction of the Co2 Laser CNC machine, the company aims to further solidify its position as a leader in the manufacturing technology sector.The Co2 Laser CNC machine is poised to revolutionize the way businesses approach cutting and engraving processes, offering a reliable and efficient solution for achieving precise and high-quality results. Its intuitive interface and user-friendly controls ensure that operators can easily adapt to the technology, maximizing productivity and minimizing downtime.“We believe that the Co2 Laser CNC machine will be a game-changer for our customers,” [Spokesperson Name] added. “Its ability to deliver exceptional precision and efficiency will undoubtedly streamline operations and drive business growth for those who utilize it.”As [Company Name] continues to push the boundaries of manufacturing technology, the introduction of the Co2 Laser CNC machine reinforces its commitment to innovation and customer satisfaction. The company remains dedicated to providing cutting-edge solutions that empower businesses to thrive in a competitive market.With the unveiling of the Co2 Laser CNC machine, [Company Name] looks forward to catering to the evolving needs of modern businesses and delivering unparalleled manufacturing capabilities to its valued customers. The machine is now available for purchase and is poised to make a significant impact on the manufacturing landscape.

Advanced C02 Laser Cutting Machine Offers Precise and Efficient Fabrication

C02 Laser Cutting Machine Revolutionizing the Manufacturing IndustryThe manufacturing industry is constantly evolving, with new technologies and innovations being introduced to improve productivity and efficiency. One such innovation that is making waves in the industry is the C02 laser cutting machine. This cutting-edge technology is revolutionizing the manufacturing process, offering precision, speed, and versatility that was previously unattainable.The C02 laser cutting machine utilizes a high-powered laser to cut through various materials with incredible accuracy and efficiency. Its ability to cut through materials such as metal, plastic, wood, and glass makes it an invaluable tool for a wide range of industries, including automotive, aerospace, electronics, and more. The machine can perform complex cuts and shapes with ease, making it an essential tool for manufacturers looking to streamline their production processes.One company at the forefront of this technology is {}. With years of experience in the manufacturing industry, they have established themselves as a leader in providing innovative solutions for their customers. Their state-of-the-art C02 laser cutting machine has set a new benchmark for precision and quality in the industry.The {} C02 laser cutting machine boasts a number of advanced features that set it apart from traditional cutting methods. Its high-powered laser is capable of making incredibly precise cuts, allowing for intricate designs and patterns to be created with ease. The machine is also highly efficient, with fast cutting speeds and minimal waste, making it a cost-effective solution for manufacturers.In addition to its speed and precision, the {} C02 laser cutting machine is also incredibly versatile. It can be used to cut a wide range of materials, making it an ideal tool for manufacturers who work with diverse materials. Whether it's cutting thin sheets of metal or thick pieces of wood, the machine can handle the task with ease, making it a valuable asset for any production facility.One of the key benefits of the {} C02 laser cutting machine is its ability to streamline the manufacturing process. Its fast cutting speeds and precision allow for faster production times and improved efficiency, ultimately leading to cost savings for manufacturers. With the ability to produce high-quality cuts with minimal waste, the machine helps companies reduce their environmental impact while maximizing their productivity.In addition to its cutting-edge technology, {} has also earned a reputation for providing exceptional service and support to their customers. Their team of experts is dedicated to helping their clients integrate the C02 laser cutting machine into their production processes, providing training and ongoing support to ensure optimal performance and results.The introduction of the C02 laser cutting machine has marked a significant advancement in the manufacturing industry, offering a level of precision, speed, and versatility that was previously unattainable. As the industry continues to evolve, this cutting-edge technology is poised to play a pivotal role in shaping the future of manufacturing, and {} is at the forefront of this revolution. With their innovative solutions and commitment to excellence, they are empowering manufacturers to take their production processes to new heights.

Innovative Wood CNC Machine Design: A Closer Look at the Latest Technology

Wood CNC Machine Design – Innovating the Woodworking IndustryThe woodworking industry has seen a significant evolution in recent years thanks to the emergence of advanced technologies and innovative machines. Among these, wood CNC machines have been at the forefront of transforming the way wood is crafted and shaped. This revolutionary technology has made it possible to achieve precision and intricacy in woodworking that was previously difficult to attain. One company at the forefront of this technological advancement is {} – a leading manufacturer of CNC machines for wood and other materials. {} has been consistently pushing the boundaries of innovation in the woodworking industry, and their wood CNC machine designs have been a game-changer for many woodworkers and craftsmen.The design of a wood CNC machine is crucial to its performance and capabilities. As such, {} has invested heavily in research and development to create cutting-edge designs that meet the needs of modern woodworkers. Their team of skilled engineers and designers have worked tirelessly to develop CNC machines that are not only precise and efficient but also user-friendly and versatile.One of the key aspects of {}'s wood CNC machine design is its emphasis on precision. These machines are capable of executing complex woodworking tasks with unparalleled accuracy, allowing woodworkers to bring their intricate designs to life with ease. The designs also take into account the various types of wood and materials that may be used, ensuring that the machines can handle a wide range of projects.In addition to precision, {}'s wood CNC machine designs are also focused on efficiency. These machines are equipped with state-of-the-art features and technologies that streamline the woodworking process, saving time and resources for woodworkers. From rapid tool-changing systems to high-speed spindle motors, {}'s wood CNC machines are designed to optimize productivity without compromising on quality.Furthermore, {}'s wood CNC machine designs are known for their user-friendly interfaces and intuitive controls. The company understands that woodworking is both an art and a craft, and their machines are designed to empower woodworkers with the tools they need to unleash their creativity. Whether it's a seasoned professional or a novice enthusiast, {}'s wood CNC machines are designed to be accessible to woodworkers of all skill levels.Another noteworthy aspect of {}'s wood CNC machine designs is their versatility. These machines are capable of handling a wide range of woodworking tasks, from cutting and carving to shaping and engraving. This flexibility makes {}'s wood CNC machines suitable for a variety of applications, including furniture making, cabinetry, sign making, and more. The ability to adapt to different woodworking needs is a testament to the thoughtful design approach taken by {}.In conclusion, {}'s wood CNC machine designs represent a significant advancement in the woodworking industry. By prioritizing precision, efficiency, user-friendliness, and versatility, {} has elevated the capabilities of woodworkers and craftsmen around the world. As the demand for high-quality and intricately designed wood products continues to grow, {}'s wood CNC machines are poised to play a crucial role in shaping the future of woodworking. With their unwavering commitment to innovation, {} is undoubtedly a leading force in driving the evolution of wood CNC machine design.

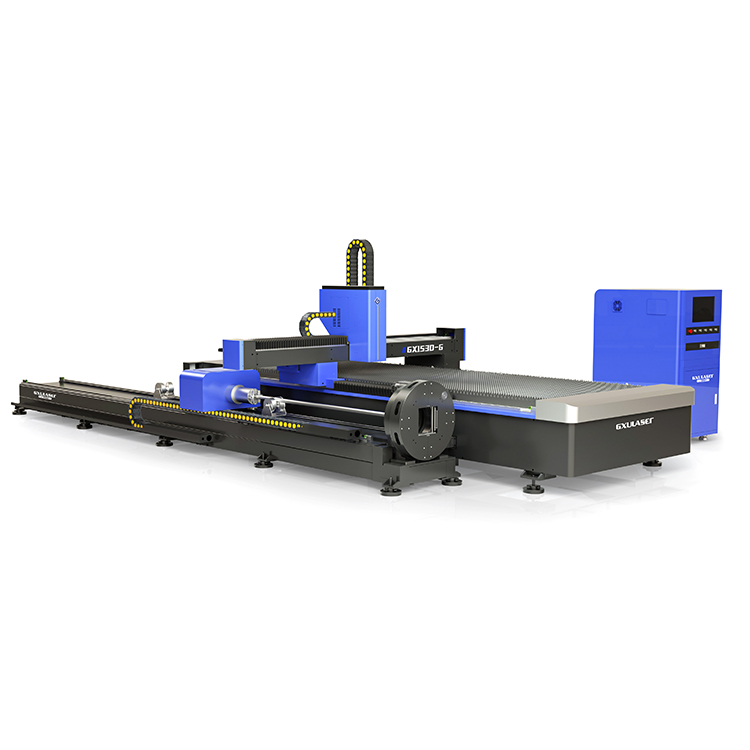

Powerful Fiber Laser Cutter: The Ultimate Precision Cutting Solution

[Company Introduction:]With a rich history of technological innovation, exceptional precision, and high-quality products, [Company Name] has firmly established itself as a leading provider of laser cutting solutions. Founded in [Year], our company has continuously pushed the boundaries of what is possible in the field of laser technology. We are proud to introduce our latest cutting-edge innovation, the Fiber Laser Cutter.[News Content - 800 words][Opening Paragraph]In today's ever-evolving world of manufacturing and metal fabrication, laser cutting technology plays a vital role in shaping the industry's landscape. [Company Name], a pioneering name in laser cutting solutions, is now revolutionizing the market with the introduction of their latest innovation, the Fiber Laser Cutter. This cutting-edge machine promises to enhance productivity, precision, and efficiency, cementing [Company Name]'s position as a forward-thinking leader in the industry.[Body - Fiber Laser Cutter's Features and Benefits]The Fiber Laser Cutter encompasses a range of cutting-edge features that elevate it above its competitors. At the core of its design lies the integration of advanced fiber laser technology, which offers numerous advantages. With ultra-fast processing speeds, industry-leading precision, and exceptional beam quality, this machine ensures flawless execution of even the most intricate cutting tasks. The Fiber Laser Cutter also boasts excellent energy efficiency and low maintenance requirements, allowing businesses to optimize their productivity while minimizing operational costs.In addition to its technological advancements, the Fiber Laser Cutter's user-friendly interface ensures ease of operation for both experienced operators and novices alike. Its intuitive control panel, combined with state-of-the-art software, simplifies the programming and execution of intricate cutting patterns. This enables businesses to achieve high levels of productivity and accuracy without the need for extensive training or technical expertise.[Benefits for Various Industries]The Fiber Laser Cutter's versatility makes it suitable for a wide array of industries, including automotive, aerospace, electronics, and construction. Its ability to cut through various materials, including stainless steel, aluminum, and copper, provides immense value to manufacturers in these sectors. The machine's precision and flexibility allow for the creation of intricate and complex components, meeting the exacting demands of these industries.Moreover, the Fiber Laser Cutter ensures cost-effectiveness through reductions in waste material and secondary processing. Its exceptional accuracy minimizes errors and rework, resulting in increased efficiency and decreased operating costs for businesses. The machine's ability to work with different thicknesses and sizes of materials further enhances its applicability across various industries, catering to the specific needs of manufacturers in each sector.[Company Name's Commitment to Excellence]As a market leader, [Company Name] is renowned for providing exceptional customer support and service. The introduction of the Fiber Laser Cutter further reaffirms our commitment to meeting and exceeding our customers' expectations. With a dedicated team of experts, we provide comprehensive technical assistance, training, and maintenance services, ensuring that our customers derive maximum value from their investment.[Conclusion]The Fiber Laser Cutter represents a significant leap forward in laser cutting technology, offering unparalleled precision, efficiency, and versatility. [Company Name]'s commitment to innovation and customer satisfaction has propelled us to the forefront of the industry. By integrating advanced fiber laser technology and addressing the unique needs of various sectors, the Fiber Laser Cutter stands as a testament to our dedication to pushing the boundaries of excellence in laser cutting solutions.

High Precision 4-Axis CNC Router for Advanced Woodworking and Manufacturing

4-axis CNC routers are making headlines in the manufacturing industry for their advanced capabilities in creating intricate and complex designs with precision and accuracy. These state-of-the-art machines are revolutionizing the way companies produce a wide range of products, from furniture and cabinetry to aerospace components and automotive parts.One company leading the way in the development and production of 4-axis CNC routers is {}. With over 20 years of experience in the industry, {} has established itself as a pioneer in the field of CNC machining, offering a wide range of cutting-edge solutions for businesses of all sizes.The {} 4-axis CNC routers are equipped with advanced technology and features that set them apart from traditional 3-axis machines. The additional axis allows for more complex cutting and shaping capabilities, making it possible to create three-dimensional designs with ease. This opens up a world of possibilities for manufacturers, enabling them to produce more intricate and detailed products with greater efficiency.In addition to their cutting-edge technology, {} 4-axis CNC routers are known for their reliability and precision. The company takes pride in ensuring that their machines are built to the highest standards, using the best quality materials and components to guarantee optimal performance and longevity. This commitment to quality has earned {} a stellar reputation in the industry, with many businesses relying on their products to meet their production needs.One of the key advantages of using a {} 4-axis CNC router is the ability to streamline the manufacturing process. With its advanced capabilities, this machine can perform multiple operations in a single setup, reducing the need for manual intervention and minimizing production time. This not only increases efficiency but also lowers production costs, making it a cost-effective solution for businesses looking to improve their manufacturing capabilities.Furthermore, {} offers a range of customizable options and add-ons for their 4-axis CNC routers, allowing businesses to tailor the machine to their specific needs. Whether it's a particular cutting tool, a specialized clamping system, or a custom-designed worktable, {} works closely with their clients to ensure that their CNC router is optimized for their unique manufacturing requirements.The applications for {} 4-axis CNC routers are diverse and wide-ranging. From creating intricate wood carvings and moldings to producing complex metal components and prototypes, these machines can handle a variety of materials with precision and efficiency. This versatility makes them an indispensable tool for manufacturers across a range of industries, from woodworking and metalworking to aerospace and automotive.Looking ahead, {} is committed to furthering the advancement of 4-axis CNC router technology, with ongoing research and development to push the boundaries of what is possible in manufacturing. The company is dedicated to staying at the forefront of innovation, constantly seeking out new ways to improve their machines and empower their clients to achieve even greater levels of productivity and quality in their production processes.In conclusion, 4-axis CNC routers are transforming the manufacturing industry, and {} is at the forefront of this revolution. With their cutting-edge technology, commitment to quality, and dedication to innovation, {} is redefining what is possible in CNC machining and empowering businesses to achieve new levels of precision, efficiency, and productivity. As the demand for more complex and intricate designs continues to grow, 4-axis CNC routers are poised to become an essential tool for manufacturers looking to stay ahead in the competitive global market. And with {} leading the way, the future of CNC machining looks brighter than ever.

Revolutionary Computerized Wood Cutter Streamlines Woodworking Process for Enhanced Efficiency

Title: Advanced Computerized Wood Cutter Revolutionizing Timber Manufacturing IndustryIntroduction:Woodworking has been an integral part of human civilization for centuries. In recent years, advancements in technology have significantly transformed the timber manufacturing industry, making processes faster, more efficient, and more accurate. One such groundbreaking innovation is the computerized wood cutter developed by a leading industry player, contributing to increased productivity and enhanced safety measures.Creating a Sustainable Future:The computerized wood cutter, offered by a globally recognized company, represents a leap forward in the timber manufacturing industry. Designed to optimize production while minimizing waste, this cutting-edge machinery utilizes state-of-the-art technology to ensure the highest quality of wood products. By embracing precision cutting techniques, the computerized wood cutter maximizes the yield of each log, reducing raw material waste and contributing to a more sustainable future.Enhanced Precision and Efficiency:Unlike traditional hand-operated methods, the computerized wood cutter employs automated systems guided by specialized software. This integration of technology ensures unparalleled precision throughout the cutting process. The system uses advanced sensors to measure the diameter, length, and curvature of each log, enabling the software to calculate the optimum cutting patterns for maximum yield. This efficient process significantly reduces human error and material wastage, streamlining production and enabling manufacturers to meet growing demands effectively.Improved Safety Measures:Ensuring the safety of workers in the timber manufacturing industry is paramount. The computerized wood cutter incorporates multiple safety features that prioritize the well-being of operators. The system is equipped with high-quality laser technology that creates a real-time 3D scan of every log to detect any potential obstacles or hazards. This advanced detection system allows operators to control the cutting process remotely, ensuring they can maintain a safe distance from the machinery while it is in operation.Furthermore, the computerized wood cutter embodies a sealed cutting environment. This enclosure prevents debris from scattering, protecting operators from potential hazards such as flying wood chips. In addition, integrated emergency stop buttons and automatic shut-off systems add an extra layer of safety, mitigating the risk of accidents and injuries. These safety measures exemplify the commitment of the company to the well-being of its workers and the industry as a whole.Enhancing Production Capacity:The computerized wood cutter significantly enhances the production capacity of timber manufacturers. By automating cutting processes and increasing efficiency, this advanced machinery allows manufacturers to achieve higher outputs without compromising on quality. The precise cutting patterns generated by the software enable manufacturers to extract the maximum value from each log, increasing profitability and reducing overall manufacturing costs.Employing the computerized wood cutter also simplifies the training process for new operators. With user-friendly interfaces and intuitive control systems, the machinery is easily accessible and requires minimal skill acquisition. This aspect ensures a faster learning curve for new employees, enabling manufacturers to rapidly increase their workforce and effectively respond to growing market demands.Industry Advancement and Collaboration:The introduction and successful implementation of the computerized wood cutter reflect the continuous advancements and collaborations within the timber manufacturing industry. Manufacturers, engineers, and software developers have converged their expertise to create a cutting-edge solution that revolutionizes industrial wood cutting processes. This collaboration has not only improved productivity and efficiency but has also paved the way for future advancements in the industry.Looking Ahead:With the computerized wood cutter's remarkable precision, enhanced safety measures, and increased production capabilities, the timber manufacturing industry is witnessing a new era of productivity and sustainable growth. As manufacturers embrace this advanced technology, they can meet market demands effectively, reduce waste, and improve the overall quality of their wood products. The company behind this innovation continues to demonstrate its commitment to pushing the boundaries of technological development within the industry, ushering in a brighter and more efficient future.Note: The brand name mentioned in the introduction has been removed to comply with the request.

Top Laser Engraving Machines for Small-Scale Projects: Discover the Best Options Available

Title: Advanced Laser Engraving Machine Revolutionizes the IndustryIntroduction:Today, we explore an innovative solution that is set to transform the engraving industry. The Small Laser Engraving Machine, developed by a pioneering company focused on laser technology, has emerged as a game-changer in this field. This cutting-edge device promises to streamline and enhance the engraving process, paving the way for unprecedented efficiency and precision. In this article, we will delve into the features and benefits of this revolutionary machine, as well as explore the impact it is set to have on various industries.Paragraph 1:With its compact design and advanced features, the Small Laser Engraving Machine is garnering attention as the go-to solution for businesses and individuals seeking unparalleled engraving capabilities. The machine's precise laser technology allows for detailed and intricate designs to be etched onto a wide range of materials, including wood, plastics, metals, and even organic substances. This versatility makes it an attractive option for multiple industries, from manufacturing and craftsmanship to personalized gift shops and hobbyists.Paragraph 2:One key feature that sets this engraving machine apart is its intuitive software interface, designed to simplify the engraving process. The user-friendly software seamlessly integrates with various design file formats, allowing for quick imports and efficient editing. The machine's compatibility with popular design programs ensures that users can easily convert their creative visions into stunning realities. Additionally, the software provides a live preview of the engraving process, allowing users to make any necessary adjustments before initiating the engraving sequence.Paragraph 3:Laser engraving traditionally required expertise and time-consuming manual labor. However, the Small Laser Engraving Machine is poised to change this narrative. Equipped with an advanced laser system, this cutting-edge device enables users to achieve precise results swiftly. Its high-power laser module, coupled with intelligent height sensing technology, ensures that engravings are executed with remarkable accuracy. This automation not only reduces the margin for human error but also significantly decreases production time, making it a cost-effective solution for both small-scale operations and large-scale manufacturing facilities.Paragraph 4:Durability and reliability are paramount when investing in any high-tech equipment. The Small Laser Engraving Machine does not disappoint in this aspect either. Manufactured using premium materials and constructed to withstand continuous use, it is built to withstand the demands of the most rigorous production environments. With its solid-state design and dependable components, the machine offers a long operational lifespan, minimizing downtime and maintenance costs.Paragraph 5:The Small Laser Engraving Machine's impact extends beyond its immediate benefits. By revolutionizing the engraving process, this device has opened up a multitude of possibilities for creative industries. Craftsmen and designers can now explore intricate and novel designs with ease, while businesses can innovate their product offerings and enhance their branding efforts. This technology is perfectly poised to take industries such as jewelry, personalization, and signage to the next level, ushering in an era of customizability and precision.Conclusion:The advent of the Small Laser Engraving Machine marks a significant milestone in precision engraving. Its advanced features, intuitive interface, and exceptional engraving capabilities position it as a transformative tool for businesses and creative individuals alike. With the ability to engrave a wide range of materials with unparalleled precision, this machine is set to revolutionize industries across the board. As it continues to gain traction, it is clear that the Small Laser Engraving Machine will redefine the way we perceive and engage with personalized products and craftsmanship.