Advanced Laser Technology for Rust Cleaning and Removal

By:Admin

In today's fast-paced industrial world, maintaining equipment and machinery is essential for ensuring smooth and efficient operations. Rust and corrosion are common enemies of industrial equipment, leading to costly repairs and downtimes. However, a revolutionary solution has emerged in the form of the Rust Cleaning Laser, a cutting-edge technology that is changing the way industrial maintenance is conducted.

The Rust Cleaning Laser, developed by a leading technology company, utilizes the power of laser technology to effectively remove rust and corrosion from a variety of surfaces. Unlike traditional methods such as sandblasting or chemical treatment, the Rust Cleaning Laser offers a non-abrasive and environmentally friendly solution that is highly efficient and precise.

The technology works by delivering a high-energy laser beam to the affected area, which rapidly heats and vaporizes the rust, leaving behind a clean and smooth surface. This innovative process not only removes rust but also prepares the surface for coating and painting, ensuring long-term protection against corrosion.

One of the key advantages of the Rust Cleaning Laser is its versatility. The technology can be applied to a wide range of materials, including metal, concrete, and even delicate surfaces such as historical artifacts and monuments. This makes it an ideal solution for diverse industries such as manufacturing, construction, maritime, and cultural heritage preservation.

In addition to its efficiency and versatility, the Rust Cleaning Laser also offers significant cost savings. By eliminating the need for chemicals, abrasive materials, and manual labor, companies can reduce maintenance costs and achieve greater operational efficiency. Furthermore, the technology helps to extend the lifespan of equipment and machinery, ultimately leading to a higher return on investment.

The company behind the Rust Cleaning Laser has established itself as a leader in the field of industrial laser technology. With a strong commitment to innovation and quality, the company has developed a range of cutting-edge solutions that address the evolving needs of the industry. Their team of experienced engineers and technicians continues to push the boundaries of what is possible with laser technology, driving the development of new applications and capabilities.

Furthermore, the company is dedicated to providing exceptional customer service and support. They work closely with their clients to understand their specific requirements and tailor solutions that meet or exceed their expectations. With a global presence and a proven track record of success, the company has earned the trust and loyalty of a diverse customer base across the industrial sector.

As the demand for efficient and sustainable industrial maintenance solutions continues to grow, the Rust Cleaning Laser is poised to make a significant impact on the industry. By offering a reliable, cost-effective, and environmentally friendly alternative to traditional rust removal methods, the technology is helping companies to optimize their maintenance processes and achieve greater operational resilience.

In conclusion, the Rust Cleaning Laser represents a paradigm shift in industrial maintenance, providing a powerful solution for rust and corrosion removal. With its advanced technology, versatility, cost savings, and exceptional performance, the Rust Cleaning Laser is set to transform the way companies approach maintenance and upkeep of their equipment and assets. As industries continue to evolve and adapt to new challenges, the Rust Cleaning Laser stands out as a game-changing innovation that is driving progress and sustainability.

Company News & Blog

Advanced CNC Machine for Metal and Wood: A Game-Changer in Precision Fabrication

A leading CNC machinery company is revolutionizing the manufacturing industry with its innovative CNC machine for metal and wood. This cutting-edge technology has the capability to greatly enhance productivity and precision in a wide range of manufacturing processes.The CNC machine is equipped with state-of-the-art technology that allows for the precise cutting, shaping, and carving of both metal and wood materials. This advanced machinery is ideal for a variety of industries, including aerospace, automotive, furniture, and more. With its ability to work with both metal and wood, this CNC machine offers unmatched versatility for manufacturers looking to streamline their production processes.One of the key features of this new CNC machine is its high level of automation, which allows for seamless operation and minimal human intervention. This not only improves efficiency but also reduces the risk of errors, resulting in higher quality products. Additionally, the machine is designed to be user-friendly, with intuitive controls and software that make it easy for operators to program and operate.In addition to its impressive performance capabilities, this CNC machine is also designed with durability and reliability in mind. The company has a reputation for producing high-quality machinery that is built to withstand the demands of industrial settings. This means that manufacturers can rely on this CNC machine to deliver consistent, precise results day in and day out.Furthermore, the company offers comprehensive technical support and training to ensure that customers can make the most of their investment in this CNC machine. This includes on-site assistance with installation and setup, as well as ongoing support to address any technical issues or questions that may arise.The introduction of this advanced CNC machine is expected to have a significant impact on the manufacturing industry. With its ability to handle both metal and wood materials with precision and efficiency, this machinery has the potential to revolutionize production processes across a wide range of industries.In addition to the tangible benefits of improved productivity and quality, this CNC machine also offers manufacturers the opportunity to explore new design possibilities and expand their capabilities. The ability to work with both metal and wood opens up new opportunities for innovation and creativity, allowing manufacturers to explore new product designs and production techniques.Overall, this CNC machine is poised to make a significant impact on the manufacturing industry. Its advanced technology, combined with the company's commitment to quality and support, sets a new standard for CNC machinery. With its potential to improve efficiency, precision, and versatility, this CNC machine is a game-changer for manufacturers looking to stay ahead in a competitive marketplace.

How to Choose a High-Quality CNC Wood Router for Optimal Results

Title: Revolutionary CNC Wood Router Poised to Transform the Woodworking IndustryIntroduction:As the demand for intricate and high-quality woodwork continues to rise, companies are constantly seeking innovative tools and machinery to meet these requirements. In keeping with this trend, X Manufacturing has recently unveiled its state-of-the-art 1325 CNC Wood Router, a game-changing solution guaranteeing precision, efficiency, and unparalleled craftsmanship. With its advanced features and cutting-edge technology, this revolutionary woodwork equipment is set to transform the woodworking industry.I. Overview of the 1325 CNC Wood Router:The 1325 CNC Wood Router is a machining tool meticulously designed for woodworking applications. Equipped with a sturdy frame and heavy-duty components, this router delivers exceptional stability, ensuring the utmost accuracy throughout the machining process. Its user-friendly interface and intuitive controls make it accessible for both seasoned professionals and beginners, enabling them to bring their creative ideas to life.II. Advanced Features: 1. High Precision and Versatility:The 1325 CNC Wood Router boasts a high-precision spindle that can operate at varying speeds, allowing craftsmen to achieve intricate details and smooth finishes on a wide range of wood materials. Its versatility extends to its compatibility with various file formats, making it a perfect fit for woodworking projects of any scale.2. Efficient Workflow:With its cutting-edge software and advanced automation, this wood router optimizes production processes, reducing wastage of materials, time, and effort. The tool's ability to perform multiple tasks simultaneously saves valuable production time, enhancing overall efficiency and productivity levels.3. Safety and Dust Control:Prioritizing user safety, the 1325 CNC Wood Router is equipped with built-in safety mechanisms, ensuring operators can work with peace of mind. Additionally, its integrated dust collection system effectively manages wood dust, creating a clean and safe environment, while minimizing potential health hazards.III. Market Impact and Industry Advancement:1. Enhanced Precision and Quality:The introduction of the 1325 CNC Wood Router marks a significant advancement in the woodworking industry, promising unparalleled precision, consistent quality, and intricate detailing. This revolutionary equipment unlocks endless possibilities, enabling craftsmen to create exquisite furniture, intricate carvings, and unique wooden products with exceptional accuracy.2. Cost Efficiency:By significantly reducing material waste and optimizing the production process, the 1325 CNC Wood Router contributes to cost savings, enabling woodworking businesses to enhance profitability. The efficient workflow of the router allows for increased output and shortened project completion times, resulting in improved resource allocation and reduced production costs.3. Accessibility and Skill Development:Thanks to its user-friendly interface and intuitive controls, the 1325 CNC Wood Router minimizes the learning curve, making it accessible to a broader ambit of woodworkers. Moreover, the machine's compatibility with various file formats encourages woodworkers to explore their creativity, fostering skill development and innovation within the industry.IV. Company Background:With a rich heritage spanning over two decades, X Manufacturing has established itself as a leading provider of cutting-edge woodworking machinery. The company prides itself on its commitment to innovation and the highest quality standards. Their portfolio encompasses a wide range of CNC routers, laser engravers, and other industry-leading machines, meeting the diverse needs of woodworking professionals worldwide.Conclusion:The introduction of the 1325 CNC Wood Router by X Manufacturing heralds a new era for the woodworking industry. This powerhouse device combines precision, versatility, and ease of use, significantly elevating craftsmanship standards. Woodworkers at all skill levels can now experience enhanced creativity and improved productivity. As this remarkable machine gains traction, it is set to revolutionize woodworking practices, contributing to the overall growth and advancement of the industry.

Key Maintenance Tips for Industrial CNC Routers in Woodworking

Investing in an industrial grade CNC router machine is a significant decision for any woodworking business. To ensure the longevity, performance, and dependability of the machine, it is crucial to maintain it correctly and efficiently. Daily, weekly, monthly, and quarterly maintenance measures help protect your CNC router and ensure maximum uptime. In this blog post, we will cover daily maintenance procedures that woodworkers can carry out to keep their router machines in excellent working condition.Daily Maintenance:Daily maintenance measures are quick and easy, often taking less than ten minutes. The following are some of the daily tasks that woodworkers can perform to ensure the optimal performance of their CNC router machines:1. Clean the machine: Use a soft and dry cloth to wipe down the machine's exterior and remove any dust, debris, or dirt that may accumulate on the surface. This not only keeps the machine looking clean and maintained, but it also prevents the debris from entering the internal components.2. Check the coolant level: Ensure that the coolant is at the right level for the machine's spindle and refill it if needed. Low coolant levels may cause the machine to overheat, resulting in damage to the spindle or other integral components.3. Check the air filter: Check the air filter if the router machine has one and make sure it is clean. A dirty air filter can reduce airflow to the machine's spindle or motor, causing it to overheat or malfunction.4. Check the lubrication system: Check the machine's lubrication system to ensure that it is working correctly. Make sure there is enough lubrication for the spindle and other moving parts. Running the machine without adequate lubrication can cause premature wear and tear, leading to additional maintenance costs in the long run.5. Inspect the tooling: Inspect the tooling before use. Ensure that the cutters, bits, and other tools are sharp and in good condition. Dull or damaged tools can cause the machine to work harder and produce a low-quality output.In conclusion, by carrying out these daily maintenance procedures, woodworkers can keep their CNC router machines in excellent working order and avoid unwanted downtime. It is essential to invest time and effort in maintaining the machine and follow the manufacturer's guidelines to ensure the machine's optimal performance and longevity.

Discover the Ultimate 3-Axis Router for Enhanced Efficiency and Precision

The three-axis router has been revolutionizing precision cutting and milling in various industries. Its ability to work on three different axes opens up a world of possibilities for manufacturers, designers, and engineers looking to create complex and intricate designs in a fast and efficient manner. With its easy-to-use software and versatile capabilities, it's no surprise that more and more businesses are looking to invest in this technology.One company that has been at the forefront of this industry is {Company Name}, a leading supplier of this cutting-edge technology. With a range of high-quality, reliable, and user-friendly three-axis routers in their inventory, the company has been making waves in the market by providing cutting-edge solutions to its clients.One of the standout features of {Company Name}'s three-axis routers is its modular construction, which allows for easy customization and upgrades. This means that businesses can easily tailor the machines to suit their specific needs and adapt as their operation evolves. Additionally, {Company Name}'s routers can be used on a wide range of materials, including wood, plastic, metal, and composites, making it a truly versatile tool.But it's not just the hardware that is a draw for customers, as {Company Name} goes above and beyond to provide exceptional customer service. The company's team of experienced technicians is always on hand to provide support and advice to customers on machine operation and maintenance. They're even available for onsite installations and training to help customers make the most of their investment.One of the key benefits of investing in {Company Name}'s three-axis routers is that it can significantly improve productivity and efficiency in manufacturing processes. By eliminating many of the manual processes traditionally required, the routers can quickly perform repetitive tasks with great accuracy. This not only speeds up production times but also reduces the risk of human error, improving the overall quality of the finished product.Moreover, the software used with {Company Name}'s routers is intuitive and user-friendly, allowing operators to create intricate designs without the need for specialized training. This ease of use, combined with the accuracy of the routers, allows businesses to develop complex designs in a fraction of the time it would traditionally take.In addition, with an increasing emphasis on sustainability and reducing waste in manufacturing, {Company Name}'s three-axis routers offer a greener solution. The routers can be programmed to minimize material waste, further reducing costs for businesses and contributing towards greener manufacturing practices.Overall, {Company Name}'s three-axis routers provide a smart and efficient solution for those looking to revolutionize their manufacturing processes. With its versatility, reliability, and exceptional customer service, the company has quickly become a go-to for businesses looking to take their operations to the next level.

High Precision Laser Cutting Machines for 4060 Materials

Laser cutting technology has revolutionized the manufacturing industry, offering precision, speed, and efficiency in the cutting of various materials. One company that has been at the forefront of the development and implementation of laser cutting machines is {Company Name}. Their latest innovation, the Laser Cutting Machine 4060, is set to further enhance the capabilities of manufacturers in various fields.{Company Name} is a leading manufacturer of laser cutting machines, with a strong focus on innovation and technological advancements. Their commitment to quality and reliability has earned them a stellar reputation in the industry, and their machines are used by businesses around the world for a wide range of applications.The Laser Cutting Machine 4060 is the latest addition to {Company Name}'s line of cutting-edge equipment. With a cutting area of 400mm x 600mm, this machine is designed to handle a variety of materials, including wood, acrylic, fabric, leather, and more. Equipped with a high-powered laser, the 4060 is capable of delivering precise and clean cuts, making it ideal for intricate designs and complex patterns.One of the standout features of the Laser Cutting Machine 4060 is its user-friendly interface. The machine is equipped with intuitive software that allows for easy programming and control, making it accessible to both experienced professionals and newcomers to the world of laser cutting. This ease of use is further enhanced by the machine's speed and efficiency, allowing businesses to increase their productivity and meet tight deadlines without sacrificing quality.In addition to its cutting capabilities, the Laser Cutting Machine 4060 is also equipped with a range of safety features to ensure the well-being of operators. These include a fully enclosed design to prevent exposure to the laser beam, as well as emergency stop buttons and safety interlocks. As a result, businesses can have peace of mind knowing that their employees are protected while working with the machine.{Company Name} has a long history of providing exceptional customer support, and the launch of the Laser Cutting Machine 4060 is no exception. The company offers comprehensive training and technical assistance to help businesses integrate the machine into their operations seamlessly. Furthermore, they provide ongoing maintenance and support to ensure that the machine continues to perform at its best for years to come.The introduction of the Laser Cutting Machine 4060 represents {Company Name}'s commitment to pushing the boundaries of laser cutting technology. With its precision, efficiency, and user-friendly design, this machine is poised to become a valuable asset for businesses across various industries. Whether it's creating custom signage, intricate decorative pieces, or precision parts, the 4060 is capable of delivering exceptional results.In conclusion, {Company Name}'s Laser Cutting Machine 4060 is a testament to their dedication to innovation and excellence in the manufacturing industry. With its advanced features, user-friendly interface, and comprehensive support, this machine is set to empower businesses to unlock new possibilities in the world of laser cutting. As the demand for high-quality, precision-cut products continues to grow, {Company Name} remains at the forefront of providing cutting-edge solutions to meet these evolving needs.

Top 5 Benefits of Using a CNC Router 2030 for Your Woodworking Projects

In today's fast-paced manufacturing industry, the demand for precision and efficiency has never been higher. With the advancement of technology, CNC routers have become an indispensable tool for creating intricate and detailed designs with speed and accuracy. Among the numerous options available in the market, the CNC Router 2030 has emerged as a top choice for manufacturers worldwide.The CNC Router 2030, manufactured by a leading company in the industry, is a state-of-the-art machine designed to meet the diverse needs of modern manufacturing processes. With a large working area of 2000mm x 3000mm, this CNC router offers ample space to handle a wide range of materials, from wood and plastic to non-ferrous metals. This versatility makes it an ideal choice for industries such as woodworking, signage, and metal fabrication.One of the key features that set the CNC Router 2030 apart is its high-speed spindle, capable of reaching speeds of up to 24000 RPM. This allows for precise and detailed cutting, carving, and milling, ensuring superior finished products. Additionally, the CNC Router 2030 is equipped with a high-precision rack and pinion drive system, which guarantees smooth and accurate movement along the X, Y, and Z axes.In terms of control and operation, the CNC Router 2030 is powered by an advanced CNC control system, offering user-friendly interface and intuitive programming. This allows operators to easily program complex designs and execute them with minimal effort. Furthermore, the machine is compatible with a wide range of design software, offering seamless integration into existing manufacturing processes.The company behind the CNC Router 2030 takes pride in its commitment to quality and customer satisfaction. With decades of experience in the industry, they have earned a reputation for delivering reliable and high-performance CNC machines that meet the evolving needs of modern manufacturing. The CNC Router 2030 is a testament to their dedication to innovation and excellence, providing manufacturers with a competitive edge in the market.The CNC Router 2030 has already garnered accolades from industry professionals for its exceptional performance and reliability. It has been praised for its ability to handle complex designs with precision and speed, making it a valuable asset for manufacturers looking to streamline their production processes. Furthermore, the machine's robust construction and durable components ensure long-term reliability and minimal maintenance requirements.As the manufacturing industry continues to evolve, the demand for advanced CNC routers like the CNC Router 2030 is expected to rise. With its superior capabilities and proven track record, this machine is well-positioned to meet the needs of manufacturers across various sectors. Whether it's creating intricate wooden furniture, eye-catching signage, or precision-cut metal components, the CNC Router 2030 offers the versatility and performance needed to bring designs to life.In conclusion, the CNC Router 2030 stands as a testament to the advancements in CNC technology, offering manufacturers a powerful and reliable solution for their production needs. With its advanced features, precision capabilities, and industry-leading performance, this machine is set to redefine the standards of CNC routing in the manufacturing industry. As the demand for high-quality and efficient production equipment continues to grow, the CNC Router 2030 is poised to make a lasting impact on the industry, empowering manufacturers to achieve greater levels of productivity and quality in their operations.

Discover the Powerful Capabilities of a High-Power Laser Cutter!

Title: Cutting-Edge Laser Technology Revolutionizes Manufacturing ProcessesIntroduction: In a groundbreaking development, a prominent manufacturing company has introduced its latest innovation, a state-of-the-art 100W Laser Cutter. This cutting-edge technology is set to redefine traditional manufacturing processes, showcasing the company's commitment to innovation, precision, and efficiency in the ever-evolving industry.With its fine-tuned laser beam, this new machine has the potential to transform various industries, including automotive, aerospace, electronics, and textile. Offering a myriad of possibilities, this news article will explore the capabilities and impact of this 100W Laser Cutter, as well as highlight the key features and competitive advantage it brings to the market.1. Importance of Laser Cutters in Manufacturing:Laser cutting technology has long been recognized as vital for precision cutting, engraving, and etching in manufacturing. From intricate designs to mass production, laser cutters offer several advantages including accuracy, speed, flexibility, and cost-efficiency. The introduction of a 100W Laser Cutter takes these defining characteristics one step further.2. Key Features and Specifications:The company's 100W Laser Cutter boasts several innovative features that enhance its performance and versatility. Equipped with a highly powerful 100W laser beam, it can precisely cut through a wide range of materials, including metals and non-metals. The machine's advanced control system and cutting-edge software ensure precise cuts, reduced material wastage, and increased production efficiency.Additionally, the laser cutter offers a large working area, allowing for the processing of various-sized materials. With exceptional speed and accuracy, this cutter can produce complex, intricate designs with unparalleled finesse, revolutionizing the manufacturing process.3. Enhanced Efficiency and Precision:The 100W Laser Cutter has set new benchmarks in manufacturing by greatly improving efficiency and precision across various applications. Traditional cutting processes often require secondary operations, such as deburring or polishing, which increase both time and cost. However, this laser cutter significantly reduces the need for additional finishing, resulting in quicker turnaround times and increased productivity.Furthermore, its high precision eliminates human error, enabling the production of intricate designs and complex shapes with unparalleled accuracy. This advanced laser cutting technology ensures consistent quality and meets the most demanding manufacturing requirements.4. Diverse Applications:The versatility of the 100W Laser Cutter opens a multitude of possibilities across different industries. In the automotive sector, it can produce intricate components with precision, improving overall performance and safety. For the aerospace industry, this laser cutter helps create lightweight materials with complex geometries that enhance fuel efficiency and reduce emissions.In the electronics field, the laser cutter aids in manufacturing microcircuits, connectors, and precision components, ensuring reliability and longevity. Textile manufacturers can leverage this technology for intricate fabric designs, enabling customization and enhancing aesthetic appeal.5. Environmental Impact:Along with its revolutionary capabilities, the 100W Laser Cutter promotes sustainable manufacturing practices. By minimizing material wastage and reducing the need for secondary operations, it significantly contributes to a greener manufacturing process. Additionally, the laser cutting process produces minimal emissions, ensuring a cleaner and safer work environment.Conclusion:The introduction of the 100W Laser Cutter by the company marks a significant milestone in the manufacturing industry. With its powerful laser beam, advanced control system, and impeccable precision, this cutting-edge technology stands at the forefront of transforming traditional manufacturing processes. Its diverse applications, enhanced efficiency, and minimal environmental impact solidify its position as a game-changer in various industries.As the manufacturing sector continues to evolve, this innovation paves the way for increased productivity, improved product quality, and reduced costs. The 100W Laser Cutter truly embodies the company's dedication to innovative solutions, further cementing its position as an industry leader.

High-Precision Wood Engraving Machine for CNC Use

The wood engraving industry has seen a significant shift with the introduction of advanced CNC (Computer Numerical Control) machines. These machines have revolutionized the way intricate designs and patterns are etched onto wooden surfaces, making the process faster, more precise, and efficient. One company at the forefront of this innovation is {}, leading the way in providing high-quality wood engraving CNC machines to meet the ever-growing demands of the industry.With over a decade of experience in the manufacturing and distribution of CNC machinery, {} has established itself as a trusted name in the market. The company's commitment to excellence and continuous technological advancement has set them apart as a leader in the industry. {} offers a wide range of CNC wood engraving machines that cater to the diverse needs of woodworkers, craftsmen, and industrial manufacturers.The {} CNC wood engraving machines are equipped with the latest technology, ensuring exceptional precision and accuracy in the engraving process. These machines are capable of handling a variety of wood materials, including hardwoods, softwoods, MDF, and plywood, making them versatile and suitable for various applications. Whether it's intricate designs for furniture, custom signage, decorative panels, or cabinetry, {} CNC machines deliver superior results with efficiency and consistency.One of the standout features of {} CNC wood engraving machines is their user-friendly interface and intuitive controls. This allows for easy operation and programming, making it accessible to both experienced professionals and beginners in the woodworking industry. The machines are also equipped with advanced software that enables the importation of designs in various file formats, giving users the freedom to create unique and custom engravings with ease.In addition to their technical capabilities, {} is dedicated to providing exceptional customer support and after-sales services. The company's team of experts is available to offer guidance, training, and technical assistance to ensure that customers get the most out of their CNC wood engraving machines. This commitment to customer satisfaction has earned {} a reputation for reliability and trustworthiness in the industry.Moreover, {} places a strong emphasis on innovation and continuous improvement. The company invests in research and development to stay ahead of market trends and technological advancements, ensuring that their products remain cutting-edge and competitive. By staying abreast of the latest developments in CNC technology, {} is able to introduce new features and enhancements to their wood engraving machines, further solidifying their position as a leader in the industry.As the demand for customized and intricately engraved wood products continues to grow, {} remains dedicated to meeting the needs of their customers with state-of-the-art CNC wood engraving machines. Their commitment to quality, precision, and innovation has made them a trusted partner for woodworkers and craftsmen across the globe. With {} CNC machines, engraving intricate designs on wood has never been easier and more efficient, setting new standards for the industry.

Advanced CNC Machine for Laser Cutting and Routing Operations

[Company Name], a leading manufacturer of industrial machinery, has recently introduced an innovative Laser and Router CNC Machine that is set to revolutionize the manufacturing industry. This state-of-the-art machine is designed to provide businesses with the ability to perform precise cutting and engraving on a wide range of materials, including wood, plastic, metal, and more.With the ability to switch between a laser and router tool head, this versatile machine offers businesses the flexibility to take on a variety of projects without the need for multiple machines. Whether it's creating intricate designs on wood or cutting through thick sheets of metal, the Laser and Router CNC Machine from [Company Name] is up to the task.The precision and accuracy of this machine make it ideal for industries such as woodworking, signage manufacturing, and metal fabrication. The laser head can produce incredibly detailed designs with clean edges, while the router head can cut through materials with speed and efficiency.In addition to its cutting and engraving capabilities, the CNC machine is equipped with a user-friendly control system that allows for easy programming and operation. This makes it suitable for businesses of all sizes, from small workshops to large-scale production facilities.Furthermore, [Company Name] has incorporated the latest technology into this machine to ensure optimal performance and reliability. With features such as automatic tool calibration and advanced motion control, businesses can rest assured that they will achieve consistent and high-quality results with every use."We are thrilled to introduce our new Laser and Router CNC Machine to the market," said [Spokesperson Name], the CEO of [Company Name]. "We believe that this machine will help businesses increase their production efficiency and expand their capabilities, ultimately leading to greater success in their respective industries."With a commitment to providing top-of-the-line machinery and excellent customer service, [Company Name] has established itself as a trusted provider in the manufacturing sector. The introduction of the Laser and Router CNC Machine further underscores the company's dedication to innovation and meeting the evolving needs of its customers.Businesses that are interested in learning more about the Laser and Router CNC Machine from [Company Name] can visit their website or contact their sales team for more information. With customizable options available, businesses can tailor the machine to their specific needs and requirements.As the manufacturing industry continues to evolve, having access to advanced machinery such as the Laser and Router CNC Machine can give businesses a competitive edge. With its precision, versatility, and cutting-edge technology, this machine is poised to become an essential tool for businesses looking to elevate their production capabilities and deliver exceptional results to their customers.In conclusion, the Laser and Router CNC Machine from [Company Name] represents a significant advancement in the manufacturing industry. With its ability to perform precise cutting and engraving on various materials, along with its user-friendly control system and cutting-edge technology, this machine is set to make a lasting impact on businesses across a wide range of industries. [Company Name] continues to demonstrate its commitment to innovation and excellence, providing businesses with the tools they need to thrive in a competitive market.

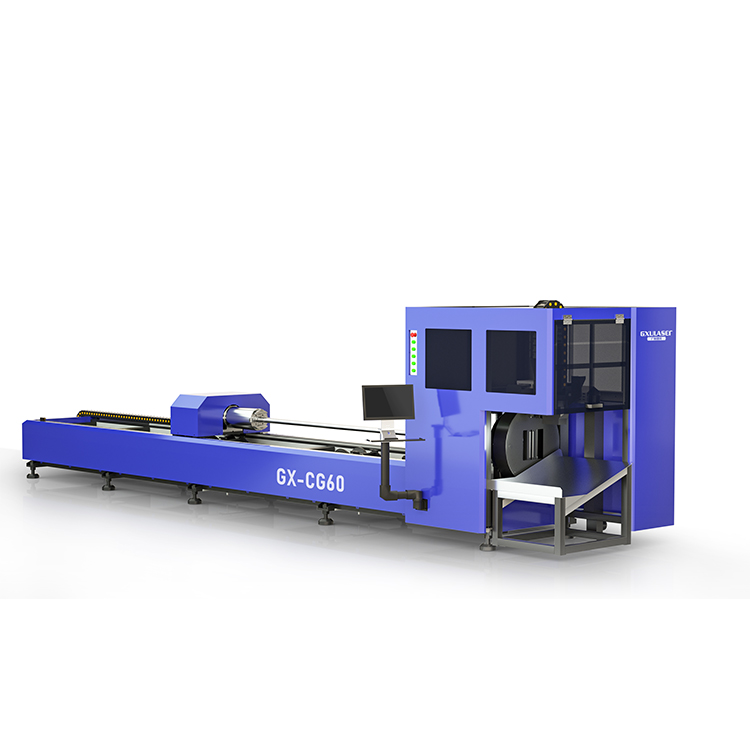

High Precision Laser Cutting Machine for Pipes: The Latest Technology in Industrial Cutting Solutions

Pipe Laser Cutting Machine Revolutionizes Manufacturing IndustryIn recent years, the manufacturing industry has seen a significant shift towards automation and advanced technology. One of the latest advancements in this field is the introduction of the Pipe Laser Cutting Machine, a cutting-edge tool that has revolutionized the way pipes and tubes are manufactured.The Pipe Laser Cutting Machine is a state-of-the-art tool that uses laser technology to precisely cut, drill, and shape pipes and tubes. This innovative machine has set a new standard for accuracy and efficiency in the manufacturing industry, offering a range of benefits to companies that specialize in producing pipes and tubes for various applications.By integrating the latest laser technology with advanced automation features, the Pipe Laser Cutting Machine has significantly improved the speed and precision of pipe and tube manufacturing processes. The machine can accurately cut through a wide range of materials, including stainless steel, aluminum, and carbon steel, allowing manufacturers to create high-quality products with minimal waste and maximum efficiency.One of the key benefits of the Pipe Laser Cutting Machine is its ability to produce complex and intricate designs with unmatched precision. This level of accuracy is especially important in industries such as aerospace, automotive, and construction, where the quality of pipe and tube components directly impacts the performance and safety of the final product.Furthermore, the Pipe Laser Cutting Machine has also proven to be a cost-effective solution for manufacturers. By reducing material waste and minimizing the need for manual labor, the machine allows companies to optimize their production processes and increase their overall output without compromising on quality.The introduction of the Pipe Laser Cutting Machine has been met with enthusiasm by manufacturers worldwide, and many companies have already adopted this technology to enhance their production capabilities. One such company that has embraced this innovation is [], a leading manufacturer of pipes and tubes for the construction industry.With over 20 years of experience in the industry, [] has built a reputation for delivering high-quality products that meet the strictest performance and safety standards. By investing in the latest technology, including the Pipe Laser Cutting Machine, the company has further strengthened its position as a leading provider of pipes and tubes for construction projects of all sizes.The implementation of the Pipe Laser Cutting Machine has allowed [] to streamline its manufacturing processes and offer a wider range of customization options to its customers. By leveraging the machine's advanced capabilities, the company is now able to produce complex designs and shapes with unmatched precision, catering to the diverse needs of its clients in the construction industry.In addition to improving its production capabilities, the Pipe Laser Cutting Machine has also enabled [] to enhance the overall quality and durability of its products. The machine's precise cutting and shaping capabilities have resulted in pipes and tubes that exhibit superior strength and resilience, making them ideal for use in demanding construction applications.Moreover, the adoption of the Pipe Laser Cutting Machine has positioned [] as a more sustainable and environmentally conscious manufacturer. By minimizing material waste and optimizing its production processes, the company has reduced its environmental impact while maintaining its commitment to delivering high-quality products to its customers.Looking ahead, the future looks promising for companies that have embraced the Pipe Laser Cutting Machine as part of their manufacturing processes. As the technology continues to evolve and become more accessible, we can expect to see even greater advancements in the manufacturing industry, further solidifying the position of laser cutting as a game-changing innovation.