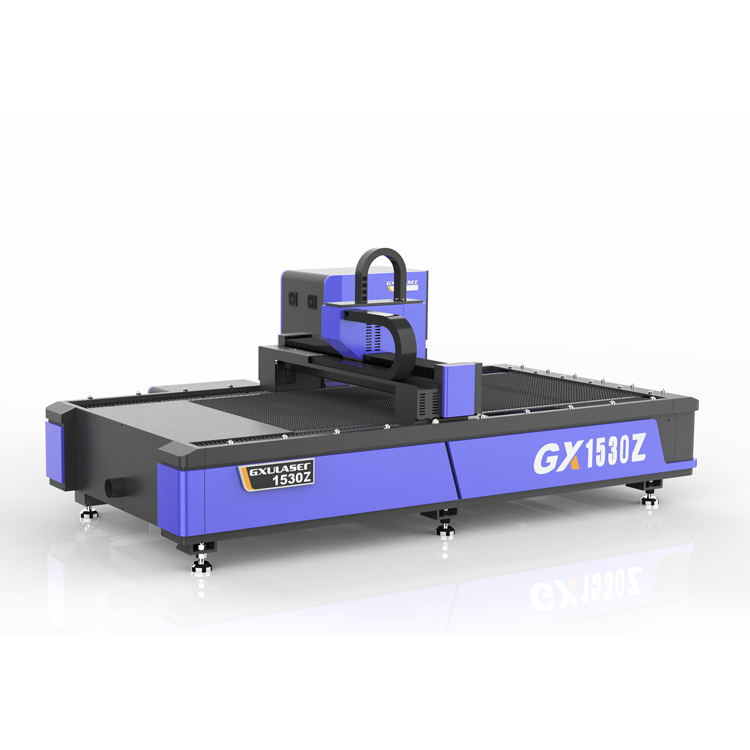

Advanced CNC Machine for Laser Cutting and Routing Operations

By:Admin

With the ability to switch between a laser and router tool head, this versatile machine offers businesses the flexibility to take on a variety of projects without the need for multiple machines. Whether it's creating intricate designs on wood or cutting through thick sheets of metal, the Laser and Router CNC Machine from [Company Name] is up to the task.

The precision and accuracy of this machine make it ideal for industries such as woodworking, signage manufacturing, and metal fabrication. The laser head can produce incredibly detailed designs with clean edges, while the router head can cut through materials with speed and efficiency.

In addition to its cutting and engraving capabilities, the CNC machine is equipped with a user-friendly control system that allows for easy programming and operation. This makes it suitable for businesses of all sizes, from small workshops to large-scale production facilities.

Furthermore, [Company Name] has incorporated the latest technology into this machine to ensure optimal performance and reliability. With features such as automatic tool calibration and advanced motion control, businesses can rest assured that they will achieve consistent and high-quality results with every use.

"We are thrilled to introduce our new Laser and Router CNC Machine to the market," said [Spokesperson Name], the CEO of [Company Name]. "We believe that this machine will help businesses increase their production efficiency and expand their capabilities, ultimately leading to greater success in their respective industries."

With a commitment to providing top-of-the-line machinery and excellent customer service, [Company Name] has established itself as a trusted provider in the manufacturing sector. The introduction of the Laser and Router CNC Machine further underscores the company's dedication to innovation and meeting the evolving needs of its customers.

Businesses that are interested in learning more about the Laser and Router CNC Machine from [Company Name] can visit their website or contact their sales team for more information. With customizable options available, businesses can tailor the machine to their specific needs and requirements.

As the manufacturing industry continues to evolve, having access to advanced machinery such as the Laser and Router CNC Machine can give businesses a competitive edge. With its precision, versatility, and cutting-edge technology, this machine is poised to become an essential tool for businesses looking to elevate their production capabilities and deliver exceptional results to their customers.

In conclusion, the Laser and Router CNC Machine from [Company Name] represents a significant advancement in the manufacturing industry. With its ability to perform precise cutting and engraving on various materials, along with its user-friendly control system and cutting-edge technology, this machine is set to make a lasting impact on businesses across a wide range of industries. [Company Name] continues to demonstrate its commitment to innovation and excellence, providing businesses with the tools they need to thrive in a competitive market.

Company News & Blog

Fiber Laser CNC Machine Revolutionizes Manufacturing Processes

Title: Cutting-Edge Fiber Laser CNC Machine Revolutionizes Manufacturing IndustryIntroduction:In a groundbreaking development within the manufacturing industry, a leading company has recently launched an innovative Fiber Laser CNC Machine that is set to transform the way businesses operate. With its cutting-edge technology and state-of-the-art features, this revolutionary machine is poised to pave the way for increased efficiency, precision, and productivity in metal fabrication processes.[Company Name], a renowned player in the industrial equipment sector, has successfully created a game-changer with its latest Fiber Laser CNC Machine. Investing heavily in research and development, the company has taken a significant stride towards meeting the evolving needs of the industrial sector, resulting in a product that promises to revolutionize manufacturing processes across various industries.I. Unparalleled Precision and Efficiency:The Fiber Laser CNC Machine boasts a high-powered fiber laser source, which offers exceptional precision and accuracy in cutting metal materials. Equipped with advanced computer numerical control (CNC) capabilities, this machine provides an unprecedented level of control and repeatability, ensuring consistent and precise cuts, even on intricate designs. The highly focused laser beam generated by the machine allows for minimal wastage and optimal utilization of materials, resulting in cost savings and enhanced productivity.II. Versatile Applications:The new Fiber Laser CNC Machine has a broad range of applications across several industries, including automotive, aerospace, electronics, and more. From cutting and engraving metal sheets to manufacturing complex parts, this machine can handle a wide variety of materials, including stainless steel, aluminum, brass, and copper. Its versatility and adaptability make it an ideal choice for businesses of all sizes seeking to streamline their manufacturing processes.III. Enhanced Speed and Productivity:The Fiber Laser CNC Machine is built with speed in mind. Thanks to its advanced technology, it can significantly reduce production time while maintaining optimum quality. With its fast cutting speeds, this machine guarantees high productivity levels and quick turnaround times for manufacturing projects. This increased efficiency translates into a competitive edge for businesses, allowing them to meet market demands without compromising on quality.IV. Intuitive Interface and User-Friendly Features:[Company Name] has focused on creating a user-friendly interface, ensuring that even operators with minimal technical expertise can operate the Fiber Laser CNC Machine with ease. The machine features an intuitive control panel, allowing operators to command complex cutting patterns effortlessly. Additionally, the interface provides real-time information, remote monitoring, and troubleshooting support, facilitating seamless operation and minimizing downtime.V. Commitment to Sustainability:As environmental concerns continue to shape industries worldwide, [Company Name]'s Fiber Laser CNC Machine takes sustainability into account. With its precision cutting capabilities, this machine minimizes unnecessary waste of raw materials, reducing environmental impact. Moreover, the machine's energy-efficient design optimizes power consumption, leading to significant energy savings and a more sustainable manufacturing process.Conclusion:The launch of the Fiber Laser CNC Machine by [Company Name] represents a pivotal moment in the manufacturing industry. With its unparalleled precision, versatility, and speed, this game-changing machine is set to reshape metal fabrication processes across multiple sectors. By investing in cutting-edge technology and putting a strong emphasis on sustainability, [Company Name] continues to lead the way in providing innovative solutions that enhance productivity and minimize environmental impact.As businesses strive to remain competitive in an evolving market, the Fiber Laser CNC Machine offers an indispensable tool to revolutionize manufacturing operations. Its user-friendly features, combined with remarkable precision and efficiency, make it a must-have for companies aiming to optimize their manufacturing processes and gain a competitive edge.

High-Quality CNC Wood Cutting Machine for Precision and Efficiency

In an era of technological advancement, the demand for precision and efficiency in woodworking has led to the development of innovative machinery. The introduction of Computer Numerical Control (CNC) wood cutting machines has revolutionized the woodworking industry, offering unmatched accuracy and speed in wood cutting and carving processes. One of the leading manufacturers in this industry, {} has continuously set new benchmarks with its cutting-edge CNC wood cutting machines.The company has been at the forefront of technological innovation with a strong focus on research and development. With a legacy of over 20 years, the company has consistently delivered high-quality, reliable, and efficient CNC wood cutting machines to its global customer base. Its commitment to excellence and customer satisfaction has made it a trusted name in the woodworking machinery industry.The CNC wood cutting machines offered by {} are equipped with advanced features that enable precise and intricate wood cutting, shaping, and carving. The machines are designed to meet the diverse needs of woodworking professionals, from small-scale artisans to large-scale production facilities. With high-performance spindles, robust frames, and state-of-the-art control systems, these machines offer unparalleled accuracy and efficiency in wood processing.One of the key advantages of {}'s CNC wood cutting machines is their ability to automate the woodworking process, reducing manual labor and improving productivity. The integration of computer control allows for the creation of intricate designs with utmost precision, ensuring the highest quality output. This level of automation not only saves time and labor costs but also minimizes material wastage, making it an environmentally sustainable option for wood processing.Moreover, {} provides comprehensive training and technical support to its customers, ensuring that they can maximize the potential of their CNC wood cutting machines. The company's team of skilled technicians and engineers are dedicated to offering prompt assistance and maintenance services, minimizing downtime and ensuring uninterrupted production.The application of CNC wood cutting machines extends beyond traditional woodworking, finding utility in diverse industries such as furniture manufacturing, cabinetry, and architectural millwork. The precision and versatility of these machines make them indispensable for creating custom designs and intricate patterns, meeting the ever-evolving demands of the market.As the global woodworking industry continues to evolve, {} remains committed to pushing the boundaries of innovation and technological advancement in CNC wood cutting machines. By leveraging its expertise and experience, the company strives to address the evolving needs of the woodworking industry by introducing new and advanced solutions that set new standards in precision, efficiency, and reliability.With a strong emphasis on quality, performance, and customer satisfaction, {} has established itself as a pioneer in the manufacturing of CNC wood cutting machines. The company's dedication to excellence and its relentless pursuit of innovation continue to drive the woodworking industry forward, setting new benchmarks and shaping the future of wood processing.In conclusion, the CNC wood cutting machines offered by {} represent a paradigm shift in woodworking technology, ushering in a new era of precision and efficiency. With their advanced features, unmatched accuracy, and versatile applications, these machines are poised to transform the woodworking industry, offering new possibilities for creativity and productivity. As the demand for high-quality, automated wood processing solutions continues to grow, {} remains at the forefront, leading the way with its cutting-edge CNC wood cutting machines.

Revolutionary Cutting Laser Machine Unveiled - A Game-Changer for Industries

Cutting-Edge Laser Machine Revolutionizes Precision CuttingIn the era of advanced technology, precision cutting plays a vital role in various industries ranging from manufacturing to healthcare. Companies are constantly seeking innovative tools and techniques to enhance their cutting processes and improve overall efficiency. In response to this demand, a renowned company has developed a groundbreaking solution — the Cutting Laser Machine (name removed), which is set to revolutionize precision cutting.The introduction of the Cutting Laser Machine marks a significant milestone in the field of cutting technology. It is a versatile and highly efficient machine that offers unparalleled precision and accuracy. This cutting-edge device is equipped with state-of-the-art laser technology, allowing it to perform intricate cuts on a wide range of materials, including metal, plastic, wood, and more.One of the key features of the Cutting Laser Machine is its exceptional speed and efficiency. The machine uses advanced laser technology that ensures rapid cutting while maintaining utmost precision. This allows companies to streamline their production processes, reducing time and costs associated with traditional cutting methods. With this cutting-edge machine, manufacturers can achieve more in less time, thereby increasing productivity and gaining a competitive edge in the market.Moreover, the Cutting Laser Machine ensures superior precision in every cut. Its laser technology provides an exceptional level of accuracy, guaranteeing clean and precise cuts without any deformation or damage to the material being cut. This accuracy is crucial, especially in industries such as aerospace and automotive, where even the smallest deviation can have significant consequences. With the Cutting Laser Machine, manufacturers can deliver flawless and high-quality products, meeting the strictest industry standards.Furthermore, the Cutting Laser Machine boasts an intuitive and user-friendly interface, making it accessible to both skilled operators and novices. The machine is equipped with advanced software that allows for easy programming and control of the cutting process. Operators can input their cutting specifications and the machine will execute the desired cuts with utmost precision. This user-friendly interface minimizes training requirements and allows for seamless integration into existing production lines.In addition to its remarkable cutting capabilities, the Cutting Laser Machine offers several safety features to ensure the well-being of operators and boost overall workplace safety. The machine is equipped with advanced sensors that detect any obstructions or anomalies, automatically stopping the cutting process to prevent accidents. Safety measures such as laser shields and emergency stop buttons provide an added layer of protection, making the machine compliant with the highest safety standards.The introduction of the Cutting Laser Machine has garnered significant attention from various industries. Manufacturers across sectors are eager to incorporate this cutting-edge technology into their operations, recognizing its potential to revolutionize precision cutting. The machine's versatility, exceptional precision, and user-friendly interface make it a game-changer in the world of cutting technology.Company XYZ, the developer of this groundbreaking technology, brings extensive experience and expertise to the world of precision cutting. With a track record of delivering innovative solutions, XYZ has established itself as a leading player in the industry. The Cutting Laser Machine is a testament to the company's commitment to pushing the boundaries of technology and delivering cutting-edge solutions to its clients.In conclusion, the introduction of the Cutting Laser Machine is set to reshape the landscape of precision cutting. With its exceptional speed, accuracy, and user-friendly interface, this revolutionary machine will undoubtedly transform manufacturing processes across various industries. Company XYZ's commitment to innovation and expertise has solidified its position as a leading provider of cutting-edge solutions. As technology continues to advance, the Cutting Laser Machine is poised to drive efficiency, productivity, and unmatched precision in the field of cutting.

Polyurethane Belt Welding Machine for Seamless Connectors - 220V, Temperature Range of 180-200 Degrees, Achieves Perfect Belt Forming

BAOSHISHAN PU Round Belt Welding Machine: The New Revolution in Polyurethane Belt Hot Melt TechnologyBAOSHISHAN, a leading technology company that specializes in the development of advanced welding machines, has recently released a new product on the market - the PU Round Belt Welding Machine. This machine is designed to weld polyurethane round belts using a hot melt process, thus providing a much stronger and more efficient connection between the belts.The machine is made from the highest quality materials and is available in several different models, each with its own unique features and capabilities. Regardless of which model you choose, you can be sure that your welding projects will be completed quickly and efficiently, with minimal downtime and high-quality results.One of the most significant advantages of the BAOSHISHAN PU Round Belt Welding Machine is its temperature range. The welding machine usually ranges from 180 to 200 degrees Celsius, which is perfect for welding polyurethane belts without damaging them. This ensures that your belts will remain strong and durable, even after years of continuous use.Another feature that sets the PU Round Belt Welding Machine apart from its competitors is its belt forming effect. With this machine, you can easily form belts into a perfect circle, which gives them a cleaner and more professional look. Plus, this feature guarantees a much tighter connection between the belts, ensuring that they stay in place even under heavy loads.The machine is also very versatile, making it suitable for use in a wide range of industries, including automotive, packaging, construction, and many more. Whether you need to weld belts for conveyor systems, packaging machines, or industrial equipment, the BAOSHISHAN PU Round Belt Welding Machine can handle it all.Furthermore, the machine is incredibly easy to use, thanks to its simple design and intuitive controls. Even if you're not familiar with welding machines, you'll be able to operate this machine with ease, thanks to its user-friendly interface and detailed instructions.In conclusion, the BAOSHISHAN PU Round Belt Welding Machine is an excellent choice for anyone looking to improve the quality and durability of their polyurethane belts. With its advanced features, high-quality materials, and ease of use, this machine is sure to exceed your expectations and provide you with the best possible results. So why wait? Order your BAOSHISHAN PU Round Belt Welding Machine today and experience the new revolution in polyurethane belt hot melt technology!

Advanced CNC Machine for Metal and Wood: A Game-Changer in Precision Fabrication

A leading CNC machinery company is revolutionizing the manufacturing industry with its innovative CNC machine for metal and wood. This cutting-edge technology has the capability to greatly enhance productivity and precision in a wide range of manufacturing processes.The CNC machine is equipped with state-of-the-art technology that allows for the precise cutting, shaping, and carving of both metal and wood materials. This advanced machinery is ideal for a variety of industries, including aerospace, automotive, furniture, and more. With its ability to work with both metal and wood, this CNC machine offers unmatched versatility for manufacturers looking to streamline their production processes.One of the key features of this new CNC machine is its high level of automation, which allows for seamless operation and minimal human intervention. This not only improves efficiency but also reduces the risk of errors, resulting in higher quality products. Additionally, the machine is designed to be user-friendly, with intuitive controls and software that make it easy for operators to program and operate.In addition to its impressive performance capabilities, this CNC machine is also designed with durability and reliability in mind. The company has a reputation for producing high-quality machinery that is built to withstand the demands of industrial settings. This means that manufacturers can rely on this CNC machine to deliver consistent, precise results day in and day out.Furthermore, the company offers comprehensive technical support and training to ensure that customers can make the most of their investment in this CNC machine. This includes on-site assistance with installation and setup, as well as ongoing support to address any technical issues or questions that may arise.The introduction of this advanced CNC machine is expected to have a significant impact on the manufacturing industry. With its ability to handle both metal and wood materials with precision and efficiency, this machinery has the potential to revolutionize production processes across a wide range of industries.In addition to the tangible benefits of improved productivity and quality, this CNC machine also offers manufacturers the opportunity to explore new design possibilities and expand their capabilities. The ability to work with both metal and wood opens up new opportunities for innovation and creativity, allowing manufacturers to explore new product designs and production techniques.Overall, this CNC machine is poised to make a significant impact on the manufacturing industry. Its advanced technology, combined with the company's commitment to quality and support, sets a new standard for CNC machinery. With its potential to improve efficiency, precision, and versatility, this CNC machine is a game-changer for manufacturers looking to stay ahead in a competitive marketplace.

Top CNC Wood Router Machine Manufacturers and Suppliers in China - Visit Our Factory for Long-Term Cooperation Opportunities

CNC Wood Router Machines: The Next Leap in Woodwork ManufacturingIn the world of woodworking, there's a constant need for innovation that can streamline production processes, enhance productivity, and ultimately improve the quality of the final product. The advent of Computer Numerical Control (CNC) technology has proven to be a game-changer in this industry, revolutionizing how woodworking is done.CNC wood router machines have become increasingly popular in recent years, as they offer unparalleled precision, speed, and consistency. If you're not familiar with this technology, let's take a closer look at what it is, how it works, and why it's quickly becoming a must-have tool for woodworkers.What is a CNC Wood Router Machine?At its core, a CNC wood router machine is a computer-controlled cutting tool that's primarily used for shaping wood. The technology involves the use of sophisticated software that converts a 2D or 3D design into machine-readable code, which is then fed into the router's computer. This allows the machine to make highly accurate cuts, curves, and patterns that would be virtually impossible to achieve by hand.CNC Router Machine Design: How It WorksCNC router machines are designed to cut wood, plastic, or metal using a cutting tool that's mounted onto a spindle. The spindle rotates the cutting tool at high speeds, while the machine's computer-controlled X, Y, and Z-axis motors determine the cutting path. In other words, the machine moves the cutting tool along the pre-determined path, according to the design specifications.One key advantage of CNC router machines is that they can be programmed to make highly precise cuts, regardless of the complexity of the design. This means that the same design can be replicated on different pieces of wood with extraordinary accuracy and consistency.Benefits of Using CNC Wood Router MachinesSo, why are more and more woodworkers turning to CNC routers? Here are some of the key benefits.1. Precision - CNC wood router machines can make precise cuts and shapes, which results in high-quality products.2. Ease of use - The software used to program the machine is user-friendly and intuitive, which means that even beginners can use the machine safely and effectively.3. Efficiency - CNC router machines can work for extended periods without interruption, which means that large batches of woodwork can be produced quickly and efficiently.4. Versatility - CNC router machines can work on a variety of wood types, including hard and softwood, MDF, and plywood.5. Cost-Effective - The use of CNC wood router machines can reduce labor costs, and they can produce the same quality of work as manual labor would.ConclusionCNC wood router machines represent the next step in woodworking technology. They offer unmatched precision, speed, and efficiency, making them an excellent investment for woodworkers and manufacturers alike. If you're looking to improve your woodworking processes and enhance the quality of your final products, then it's time to consider investing in a CNC wood router machine. The market offers various options with different features, so it's best to research before making a final decision.

CNC Co2 Laser Cutting News: Latest Updates and Trends

[Company Name] Introduces Innovative Co2 Laser CNC Machine for Precision Cutting and Engraving[City, State] - [Company Name], a leading provider of advanced manufacturing solutions, has recently unveiled their latest innovation in laser cutting and engraving technology - the Co2 Laser CNC machine. This cutting-edge machine is designed to provide impeccable precision and exceptional efficiency, making it an ideal solution for a wide range of industries.The new Co2 Laser CNC machine is equipped with state-of-the-art technology that delivers high-quality results with unparalleled accuracy. The machine’s advanced laser cutting capabilities are suitable for a variety of materials including wood, acrylic, leather, and plastic, making it a versatile tool for businesses seeking to elevate their production capabilities.“We are thrilled to introduce the Co2 Laser CNC machine to our customers,” said [Spokesperson Name], [Title] at [Company Name]. “This advanced technology represents a significant leap forward in precision cutting and engraving, and we are confident that it will have a positive impact on our customers’ operations.”The Co2 Laser CNC machine is designed with user-friendly features that make it easy to operate and maintain. Its high-speed cutting capability ensures swift and efficient production, while its precision engraving function allows for intricate designs and detailed patterns to be etched onto various materials.In addition to its cutting and engraving capabilities, the Co2 Laser CNC machine is also equipped with a powerful extraction system that removes fumes and debris, creating a clean and safe working environment for operators. This feature is essential for businesses prioritizing workplace safety and environmental responsibility.[Company Name] has a long-standing reputation for delivering cutting-edge manufacturing solutions to a diverse clientele, spanning industries such as signage, woodworking, packaging, and more. With the introduction of the Co2 Laser CNC machine, the company aims to further solidify its position as a leader in the manufacturing technology sector.The Co2 Laser CNC machine is poised to revolutionize the way businesses approach cutting and engraving processes, offering a reliable and efficient solution for achieving precise and high-quality results. Its intuitive interface and user-friendly controls ensure that operators can easily adapt to the technology, maximizing productivity and minimizing downtime.“We believe that the Co2 Laser CNC machine will be a game-changer for our customers,” [Spokesperson Name] added. “Its ability to deliver exceptional precision and efficiency will undoubtedly streamline operations and drive business growth for those who utilize it.”As [Company Name] continues to push the boundaries of manufacturing technology, the introduction of the Co2 Laser CNC machine reinforces its commitment to innovation and customer satisfaction. The company remains dedicated to providing cutting-edge solutions that empower businesses to thrive in a competitive market.With the unveiling of the Co2 Laser CNC machine, [Company Name] looks forward to catering to the evolving needs of modern businesses and delivering unparalleled manufacturing capabilities to its valued customers. The machine is now available for purchase and is poised to make a significant impact on the manufacturing landscape.

Powerful Benchtop Laser Welder - Revolutionizing Metal Joining Processes

In today's ever-changing and fast-paced world, technology is evolving faster than we could think possible. With each passing day, new innovations are being introduced to make our lives easier and more efficient. One such advancement in technology is the Benchtop Laser Welder from a leading manufacturer of high-quality industrial equipment for the automotive, aerospace, and medical industries.The Benchtop Laser Welder is an extremely versatile and reliable piece of equipment that is highly sought after by professionals in various industries. The device can perform a wide range of welding tasks like spot welding, seam welding, milling, and drilling. It offers great precision, accuracy, and consistency in every weld.The Benchtop Laser Welder is highly effective in welding various materials such as stainless steel, titanium, copper, brass, aluminum, and other metals. It is also equipped with advanced features that allow it to weld plastics, ceramics, and glass with equal efficiency. The machine offers different welding modes that provide flexibility in welding depending on the substrate thickness, geometry, and other factors.This cutting-edge technology from {} is built with the latest in laser technology, which ensures rapid and precise welding of materials without causing any damage to the weld area. The welding process is so precise that it can weld a tiny spot as small as 0.1mm in diameter, making it the perfect solution for those who need very precise and accurate welding without causing any damage to the product.The Benchtop Laser Welder is designed for easy operation, with a user-friendly interface and intuitive controls. The machine is equipped with a high-resolution touchscreen that displays all the essential parameters for the welding process. The device requires minimal setup time and is easy to use, even for those new to laser welding.The Benchtop Laser Welder is a cost-effective solution for businesses that need to weld products with precision and accuracy. The equipment's speed and efficiency offer significant time savings for manufacturers, thus increasing productivity and profitability. The device's versatility allows companies to weld a wide range of materials without the need for additional equipment, reducing overall costs.The safety features of this device are also top-notch. It comes with a built-in safety shutter that prevents any accidental exposure to the laser beam. The machine also has an emergency stop button that can be operated in case of any unforeseen incidents.{} is renowned for providing its customers with high-quality products that are built to last. The Benchtop Laser Welder is no exception. The machine is manufactured with high-quality components that perform consistently and have a long life span. The equipment is also designed to be low maintenance, reducing overall running costs.In conclusion, the Benchtop Laser Welder from {} is an absolute game-changer in the world of welding technology. Its accuracy, precision, speed, and versatility make it a must-have for businesses that require high-quality welding results with minimal setup time and low maintenance costs. The Benchtop Laser Welder is an excellent investment for businesses looking to increase productivity and profitability while maintaining the highest standards of quality in their products.

Fiber Laser Cutting Machines: Advanced Metal Cutting Solutions at Affordable Prices

The Industrial Revolution has brought about a major change in the way we manufacture things. With the advent of technology, there has been a paradigm shift in the way we fabricate metal and other materials. The emergence of new machines like the Fiber Laser Cutting Machine has revolutionized the way we cut, engrave, and mark metals.As one of the leading fiber laser cutting machine companies, Bodor Laser has been setting new standards in the industry. Known for its innovative and high-quality products, the company has established itself as a reliable supplier of high-end cutting and engraving machines.Fiber laser cutting machines are highly advanced machines that utilize fiber optics to cut metals with precision and speed. These machines are extremely versatile and can cut a variety of metals including aluminum, brass, copper, stainless steel, and more. The ability to cut through a wide range of materials has made these machines highly popular in the industrial world.Bodor Laser's range of fiber laser cutting machines includes high power laser cutting machines, fiber laser cutting machines for sheet, high-precision fiber laser cutting machines, fiber laser tube cutting machines, dual-use fiber laser cutting machines, coil laser cutting machines, CO2 laser engraving machines, and fiber laser marking machines. No matter what your requirement, Bodor Laser has a machine that matches your needs.If you're looking for a fiber laser cutting machine that can cut tubes efficiently, Bodor Laser's fiber laser cutting tube machine is ideal for you. Designed with precision engineering, this machine can cut through tubes with accuracy and speed. With Bodor's cutting-edge technology, you can expect smooth, precise cuts every time.The fiber laser cutting tube machine from Bodor Laser is equipped with a high-power fiber laser source that ensures excellent beam quality. With its advanced automatic focusing system, the machine can quickly and efficiently adjust the focus distance, thus ensuring accurate cutting.Bodor's laser cutting tube machine is also designed for safety. The machine is equipped with an advanced dust removal system that prevents dust from accumulating inside the machine. This improves the lifespan of the machine and ensures that it operates at optimum efficiency. Additionally, the machine is equipped with sensors that automatically shut off the machine in case of any malfunction, preventing accidents and ensuring safety in the workplace.In conclusion, Bodor Laser's range of fiber laser cutting machines is an excellent choice for industrial cutting, engraving, and marking needs. Whether you're looking for precision cutting of sheets, tubes, or coils, Bodor has a machine that meets your requirements. With their commitment to quality and innovation, Bodor Laser is sure to continue to set new standards in the industry for years to come.

Automatic Door Carving Machine: The Latest Innovation in Woodworking Technology

Door Carving Machine Revolutionizes Woodworking IndustryWoodworking industry has seen a significant revolution with the introduction of the latest Door Carving Machine by a leading machinery manufacturing company. This innovative machine has taken the woodworking industry by storm, offering unparalleled precision and efficiency in carving and shaping wooden doors.The Door Carving Machine is equipped with the latest technology and advanced features to cater to the growing demands of the woodworking industry. Its high-speed cutting and carving capabilities have made it a popular choice among woodworking professionals, enabling them to produce intricate and detailed designs with ease.With its user-friendly interface and automated functions, the Door Carving Machine has significantly reduced the production time and labor costs for woodworking businesses. This has resulted in higher productivity and profitability for companies using this cutting-edge machine.The company behind this revolutionary Door Carving Machine has been a pioneer in the manufacturing of woodworking machinery for over two decades. With a strong focus on innovation and quality, the company has built a reputation for delivering reliable and high-performance machinery to its customers.The Door Carving Machine is the latest addition to the company's diverse range of woodworking equipment, further solidifying its position as a leader in the industry. The machine has been designed and developed by a team of skilled engineers and technicians who have extensive experience in woodworking machinery.One of the standout features of the Door Carving Machine is its ability to work with various types of wood, including hardwoods, softwoods, and engineered wood. This versatility has made it an essential tool for woodworking businesses that deal with a wide range of wooden doors and furniture products.Moreover, the machine's precise cutting and carving capabilities have enabled woodworking professionals to bring their creative designs to life with exceptional accuracy and detail. This has opened up new opportunities for custom door designs and intricate patterns that were previously challenging to achieve.The company's commitment to customer satisfaction is evident in the Door Carving Machine, as it comes with comprehensive technical support and after-sales service. This ensures that woodworking businesses can get the most out of the machine while having peace of mind in its reliability and performance.In addition to its technological advancements, the Door Carving Machine also prioritizes safety and efficiency in its operations. With built-in safety features and ergonomic design, the machine provides a secure and comfortable working environment for woodworking professionals.As the woodworking industry continues to evolve, the Door Carving Machine has emerged as a game-changer for businesses looking to stay ahead of the competition. Its ability to streamline production processes and deliver superior results has made it a valuable investment for woodworking companies of all sizes.With its successful launch and positive reception in the market, the Door Carving Machine is expected to set new industry standards and inspire further innovations in woodworking machinery. It is a testament to the company's dedication to pushing the boundaries of technology and delivering cutting-edge solutions to its customers.In conclusion, the Door Carving Machine has undoubtedly made a significant impact on the woodworking industry, redefining the way wooden doors are crafted and designed. With its advanced capabilities, versatility, and user-friendly features, it has become a must-have tool for woodworking professionals who strive for precision and excellence in their craft. As the company continues to lead the way in woodworking machinery, the future looks promising for further advancements and groundbreaking solutions in the industry.